Professional Documents

Culture Documents

Kiln-Operation KURT PERAY

Uploaded by

Ali Hüthüt0 ratings0% found this document useful (0 votes)

233 views99 pages1) The document provides an overview of key parameters, priorities, and operational considerations for rotary kiln systems used in cement production.

2) Maintaining stability, protecting equipment, ensuring quality production, and optimizing operations are the top priorities for kiln operation.

3) Key parameters that must be monitored and controlled include back end temperature, feed rate, dust return, water injection, chain system, hood pressure, and secondary air temperature to maintain a stable operating environment.

Original Description:

Operation KURT PERAY

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document provides an overview of key parameters, priorities, and operational considerations for rotary kiln systems used in cement production.

2) Maintaining stability, protecting equipment, ensuring quality production, and optimizing operations are the top priorities for kiln operation.

3) Key parameters that must be monitored and controlled include back end temperature, feed rate, dust return, water injection, chain system, hood pressure, and secondary air temperature to maintain a stable operating environment.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

233 views99 pagesKiln-Operation KURT PERAY

Uploaded by

Ali Hüthüt1) The document provides an overview of key parameters, priorities, and operational considerations for rotary kiln systems used in cement production.

2) Maintaining stability, protecting equipment, ensuring quality production, and optimizing operations are the top priorities for kiln operation.

3) Key parameters that must be monitored and controlled include back end temperature, feed rate, dust return, water injection, chain system, hood pressure, and secondary air temperature to maintain a stable operating environment.

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 99

TABLE OF CONTENTS PAGE GENERAL KILN SECTION 1 Description of Main Kiln System 04

2 Kiln Operation Priorities 05 3 Kiln System Stability 06 4 Main Parameters, Trends

and Absolute Values 08 5 Main Parameters to Control and Evaluate Kiln 13 6

Variables which the Operator Cannot Control 15 7 Variables which the Operator Can

Control 15 8 Kiln Limitation Factor 16 9 Kiln Operation Target 17 10 Optimization

of Kiln System 18 11 List of Most Frequent Factors when Kiln Operation Is not

Satisfactory 19 12 List of Typical Kiln Operation Problems 20 13 What to Look for

When Looking Inside a Kiln 21 14 Kiln Upsets 27 15 Kiln Cycling 28 16 How to Break

a Cycle in a Kiln 29 KILN EMERGENCY CONDITIONS SECTION 17 Red Spot on Kiln Shell

30 18 Raw Unburned Feed in Clinker Cooler 31 19 Large Ring Broken Loose in Kiln 32

20 Burning Zone Dangerously Hot 33 21 Sudden Sharp Raise in Back End Temperature

(B.E.T.) 34 22 Black Smoke Emission from Kiln Stack 35 23 Distorted Flame Shape 36

24 Loss of Section of Refractory Lining 37 25 Cooler Drive or Clinker Conveyor

Stopped 37 26 Red Clinker at Cooler Discharge 38 27 Rapid Rise of Temperature in

Coal System 39 28 Power Failure 40 29 A Chain Fire 42 30 Heavy Rain or Thunder

Storm 43 31 Sudden High Positive Pressure 43 32 Overheated Kiln Bearing 44 33

Kiln Hazardous Conditions 44 KILN OPERATION SECTION 34 Kiln Operation Techniques

47 35 Burning Zone Evaluation 48 36 Kiln Stable Temperature Profile 49 37 Target

Set Point and Operation References 50 38 Back End Temperature Control 51 39 The

Three Basic Variables 51 40 Target Range for the Three Variables 51 41 The Three

Basic Conditions 52 42 The 27 Conditions (Kurt Peray) 53 43 Kiln Slow Down 56 44

Normal Operation Procedures on Shift 59 45 Plan of Action 59 46 Oxygen Level in

Automatic Mode 60 KILN START-UP AND SHUTDOWN PROCEDURES 47 Light-up Flame Example

(Gas) 61 48 Preheat or Drying of Refractory Lining 62 49 Heating to Reach

Temperature Ready to put Feed On. 63 50 Feed On 64

51 Kiln Start-up Procedures after a Brick Job 64 52 Example of How to Re-start if

Preheat is Required 68 53 Example of How to Re-start if No Preheat is Required 69

54 Kiln Shutdown General Information 70 55 Cooling Procedures 70 56 Kiln Rotation

Schedule 71 57 Burner Pipe and Hood Protection 72 58 Emptying the Feed from the

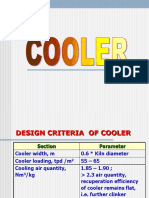

Kiln 73 59 Kiln Shutdown Procedures for Brick Job and Red Spot 73 COOLER SECTION

60 Cooler Function 76 61 Cooler Operation 77 62 Cooler Controllers 77 63 Rule on

Cooler Operation 78 64 Main Sensors to Control the Cooler Operation 79 65

Particle Size of Clinker 80 66 Operation of Cooler Fans 80 67 Clinker and Air

Distribution 81 COMBUSTION SECTION 68 Flame 82 69 Rules on Flame 85 70

Combustion 86 71 Heat Transfer in Rotary Kiln 89 72 Burner Pipes and Nozzles 89

73 Fuels in Cement Industry 92 74 Solid Fuels 94 75 Drying, Grinding and Firing

Solid Fuels 96 76 Comparison of the Three Major Fuels 97 77 Combustion Reaction

97

78 Non-Combustibles (Ash) 98 BASIC PRINCIPLES SECTION 79 Basic Principles,

System of Units 98 80 Temperature Scale n/a 81 Some Useful Conversion Factors n/a

82 Basic Principles, Pressure and Flows n/a 83 Basic Principles, Heat and

Temperature n/a 84 Basic Principles, Heat Exchange or Transfer n/a GENERAL KILN

SECTION DESCRIPTION OF MAIN KILN SYSTEMS Wet Process Better homogeneity of raw

feed Dust produced is approximately 15 to 20% of clinker production Dust return to

kiln by means of Vortex at feed location (mixing problem) Scoop near kiln

discharge Dust insulation in burning zone Back end temperature is the main

parameter to control and react on behavior of slurry through chain system. (ring

formation in chain, spillage near feed end) High heat consumption (near 1300

kilocalories or 4676 MBtu/st), therefore there is a lower secondary air

temperature. All other parameters are the same as a dry process kiln. Long Dry

Feed is dry dust.

Long residence time (up to 2 hours), so we have to take this into account when

stabilizing the kiln. Heat consumption is approximately 920 kilocalories (3309

MBtu/st). Natural load movement often unstable and creates pushes. Pre-calciner

and Pre-heater Residence time in tower is from 2 to 5 seconds. Residence time in

kiln is approximately 30 minutes. Fast reaction time, requires fast action to

control the kiln. About 50 to 90% calcinations is done in tower. More stable than

long dry, because calcinations is taking place in tower. Heat consumption nears 800

kilocalories (2878 MBtu/st). Very high secondary air temperature especially with

pre-calciner need tertiary air duct. Fuel ratio split: kiln = +/- 40%, pre-calciner

= +/- 60% KILN OPERATION PRIORITIES 1. Protection of the personnel working in and

around the kiln system is a basic safety rule that must be strictly followed at all

times. 2. Protection of the equipment. Around the kiln, the safety of the

equipment is mainly related to overheating problems and could be: a) Back-end of

kiln Do not exceed 840oF (450oC) at precipitator inlet b) Feed Do not exceed 10

minutes without feed as the feed end temperature would go high. c) Chain inlet

temperature Do not exceed metallurgical maximum temperature of chain system.

(usually approximately 1900oF or 1038oC)

d) Burning zone Do not over-heat; keep the raw load near end of flame. Set a

maximum amps level on kiln motor. e) Cooler Avoid overloaded cooler grates, cut

kiln speed down to protect the cooler grates. Avoid high exhaust gas temperature;

could damage dust filter system. Avoid high clinker temperature; could damage the

clinker evacuation circuit. 3. Quality. To produce a well-burned clinker with good

free-lime at the desired liter-weight 4. Stability. Continuous operation should

always have priority over maximum production. Stable kiln operation is the key to

long refractory life, high fuel efficiency and uniform quality clinker. 5.

Optimization. Strive for optimum production level at the lowest possible cost.

KILN SYSTEM STABILITY 1. Stable Feed a) Chemical Feed quality range should be:

+/- 0.4% in CaO +/- 0.4% in SiO2 +/- 0.2% in Al2O3 C3S variations in clinker not

to exceed +/- 3%

Approximately 25% relative potential liquid phase in the clinker is good for kiln

burning and fuel saving. b) Physical Good and accurate feed rate indication. Weigh-

feeder should be linear at low, medium and high feed rate. Good calibration by

physical weight of the material should be done at every major kiln shutdown. Good

feed and speed ratio. 2. Stable Dust Re-introduction to Kiln Dust collector

cleaning cycle sequencing. Dust circuit configuration should provide stable re-

introduction. Monitoring of the dust return flow is an added advantage. If dust

wasting is required, wasting should be done in such a way not to upset the dust

return to the kiln. 3. Stable Water Spray Injection in Kiln or in Conditioning

Tower Good spray injects into gas stream, not in material load. Good regulation of

water injection with respect to ESP inlet temperature control. (will cause changes

in kiln oxygen level if water flow is not changing smoothly). 4. Good Chain System

Design (Wet and Long Dry) Act as a good dust curtain (dust trap). Wet kiln design

needs to favor a good plastic zone in order to prevent ring formation. Chain

tonnage should be between 12 to 14% of clinker production for large kiln and 10 to

12% for small kiln. Good chains should stand high temperature so that in return

enable high production rates. 5. Good Control of Hood Pressure

Hood pressure control is critical because it prevents the cooler variations to

upset the burning zone conditions. Hood pressure set point should be set as close

as possible to zero, while remaining negative. 6. Stable Secondary Air Temperature

The temperature variations during normal operation should not exceed +/- 85oF

(29oC) Good regulation of the cooler under-grate pressure is then required with a

thick clinker bed depth. The secondary air temperature should be as hot as

possible, without damaging the nose ring or the refractory at the kiln discharge

section. 7. Good Production Level Lower limit: Under-60% capacity kiln tends to

become unstable Upper limit: Production restriction due to: Kiln diameter; (maximum

flame size, flame erosion on kiln walls). ID fan capacity; (no leeway on oxygen

level) Precipitator capacity (cooler grates overloaded and high clinker temperature

at cooler outlet) 8. Constant Fuel Quality and Quantity Constant fuel quality and

quantity to allow constant heat input inside the kiln. MAIN PARAMETERS, TRENDS

AND ABSOLUTE VALUES Back End Temperature Set point varies with the kiln production

level. Set point varies with the condition of the chain system.

Absolute value allows one to draw conclusions about efficiency of the kiln system

and the kiln operation. BET trend is important for the kiln operation. With the use

of water spray in the back end, the water volume will show the reactions of the

back end temperature. Material Temperature Slow reaction compared to gas

temperature. In wet process kiln, material temperature is a good indication of the

behavior of the material in the chain system. Chain Gas Temperature This

temperature is generally a limiting parameter for the kiln operation. The chain gas

temperature set point is generally fixed by the metallurgy of the chain system and

its design. Absolute value is very important and must be held below the allowed T

for the chain system. The trend is representative but has slow reactions with

respect to the back end temperature. Very important to the kiln operation in order

to make a good material preparation before it reached the burning zone. Burning

Zone Temperature Importance of this instrument is often overestimated. Precise only

when kiln conditions are clear. The secondary air dust influence in the indication

of the instrument and readings are in error when kiln gets hot and dusty. It must

be correlated with the kiln amps indication and the secondary air temperature to

ensure the validity of the reading. Shell Temperature (Scanner) Importance of this

instrument is underestimated.

It is often used only to detect hot spots on the kiln shell, an estimation of brick

thickness, and coating in the kiln. On bigger charts, it gives a good indication of

the burning zone temperature profile. It is one of the fastest indications of a

slowly moving ignition point in burning zone. It is a very good indication of flame

variations due to the burner pipe position, flame shape and direction. (Good

indication when adjusting flame in kiln). Absolute value is important to detect hot

spots and rings. Trend indicates changes in the burner system, kiln speed, ignition

point movement and operating conditions which are affecting the temperature profile

of the burning zone. Kiln Drive Amps It is the most important sensor used to

evaluate the burning zone state. The running set point will change according to the

raw material composition. Amperage value changes with ring formation. Amperage

value changes with the size of the clinker. The absolute value is important only

when amperage is high (fuse protection limitations). The trend is a very good

indication of burning zone length and temperature; therefore the amps should be

recorded in such a way to give a good indication in its variations. A drastic

increase of the amps trend, followed by a fast decrease is an indication of loss of

coating or a broken ring inside the kiln. A target amps range should be established

(depending on raw mix and other factors) through which this variable can fluctuate

safely. A drastic increase in amps could indicate a possible mechanical condition

problem. NOx Analyzer Essentially it is an indication of the flame temperature.

Higher is the flame temperature, the higher will be the NOx concentration. NOx

content in the flue gases in the smoke stack originate partly from high temperature

synthesis in flame from oxygen and nitrogen. NOx level has been measured in the

range between 500 and 2000 ppm in the Lafarge group. NOx increase with excess air

and is strongly correlated to low excess air levels.

At higher levels, i.e. 3% and greater, NOx is weakly dependent on excess air.

Correlation between burning zone temperature and NOx level is good. NOx is

generally, but not systematically correlated with the kiln drive amps. NOx gives a

truer picture of burning conditions. Kiln drive amps will change due to ring

formation and degradation, whereas NOx signal will not. NOx correlates better with

clinker liter weight than free lime. NOx is affected by fuel changes. Natural gas

flames yield the highest NOx level. All the factors having an impact on the flame

temperature will affect the NOx signal like the following: The secondary air

temperature, The primary air temperature, The burning zone temperature, Chemical

composition and fineness of the fuel, The air and fuel ratio and The flame

environment (reduced or oxidized atmosphere). A quick decrease in the NOx signal is

an indication of the burning zone temperature dropping. A slow and even decrease on

the NOx signal is an indication of a slow cooling of the burning zone and is

related to a bad material preparation from the kiln back end. On the automatic kiln

control system developed by Lafarge, the program is giving 30% of it as evaluation

of the burning zone state to the NOx signal, 55% to the kiln amps, and 15% to the

clinker temperature at the kiln outlet. Secondary Air Temperature It should be

kept as stable as possible by the automatic cooler control system (+/- 85oF or

39oC). Absolute value is not important because most indications are incorrect due

to instrument inaccuracy. Trend is very important as it shows variations of

material from the kiln and the gas temperature variations to the kiln. The

secondary air temperature should be as high as possible in respect of the various

refractory temperatures in front of the kiln.

Hood Draft Absolute value is important and is automatically controlled at a

constant value (usually looped to cooler exhaust fan damper / fan). It should be

low as possible (to reduce in-leakage). It is the separation between cooler and

kiln and it should be always constant to avoid influences of changes in the cooler

gas flow to the kiln operation. A poor regulation of this signal will induce

variations in the kiln gas flow and could bring the kiln into cycling. Feed End

Draft and ID Fan Draft Trend and absolute value help to detect build-up in the

kiln. This is a very important sensor if many ring problems occur in a plant.

Cooler Exhaust Gas Temperature Trend will give you information about the

temperature profile in cooler gas flow variations and clinker temperature. Absolute

value is an important limitation for protection of the dust collection system. The

cooler exhaust temperature is a more reliable clinker discharge indication than the

clinker temperature. Clinker Discharge Temperature Trend has no importance for

cooler operation. Absolute value is an important limitation for safety of the

clinker transport system. Clinker temperature measurements are generally not very

accurate. Under Grate Pressure The absolute value should be maintained constant

with automatic control. The value varies with the cooler bed depth and with clinker

size. It must be held constant in order to achieve a constant secondary air

temperature. Also, only a constant air flow can allow the relationship between

under grate pressure, bed depth and secondary air temperature to be valid.

Variations of the under grate pressures trend are reflected by variations in the

cooler grate speed. Under grate pressures together with cooler drive amps, should

give an indication of the clinker size. Under grate pressure set point should be at

least 5 inches (H2O) in order to get good heat recuperation from the clinker bed in

the cooler. Oxygen Analyzer Trend and set point value are very important. It

should be maintained as constant as possible. It can supply indications about

general kiln conditions, burning zone and back end temperature. One of the best

indications when the kiln is pushing to indicate if the push is still on or over

(related with the amount of CaO in the kiln gases). It should be kept as low as

possible when the kiln is stable, without going into CO range. However, when using

coal or coke, set point should be increased to overcome the fuel quality

variations. MAIN PARAMETERS USED TO CONTROL AND EVALUATE KILN Kiln Amps It is

a very good indication of the burning zone state, accurate at 80% of the time. NOx

Analyzer Nitrogen Oxide level is related to the flame temperature than the burning

zone temperature. NOx vary all the factors that has an effect on the flame. It is a

very good indication of the burning zone state. Fuel Flow

It should be related to the kiln feed rate. It should be used as the main

controller for the burning zone and the kiln back end temperature. Kiln Speed It

should be related to feed rate. It should be set with a constant feed ratio. Small

variations of the kiln speed (1 to 3 revs) could be used to control the burning

zone state. However, kiln speed variations should be used only after the fuel flow

rate has been used as the primary controller on long wet and dry kiln. Often if

over used, speed variations in the material loading of the kiln and will lead the

kiln into a cycle. On large temperature variations in burning zone like raw

material pushes, the kiln speed must be used with wide variations (as example 30

revs or even a complete stop) to avoid raw materials to go in the cooler and to re-

heat the burning zone. Fan Draft It should be related to the oxygen level, fuel

flow rate and feed rate. It is the main controller to keep the temperature profile

along the kiln. The rpm variations should be small during kiln normal operation +/-

15 rph. During kiln pushes and kiln slow speed, large speed variations will be

required to maintain the chain gas temperature under safe limit of the chain

system. Back End Temperature It should be kept at constant level according to feed

rate. It should be kept stable in auto by the water spray system. Good indication

of the feed end T. Indicate variations in the feed and dust variations to the

kiln. When in auto, use water flow variations for indication. Gas Temperature It

is the main variable to control the kiln.

It should be kept inside a certain T range. It is controlled by the ID fan speed

variations and the fuel rate. Oxygen level It is related to the ID fan speed and

fuel rate. Minimum and maximum level limits need to be established, to control

combustion efficiency. When kiln stability has been reached the O2 level should be

set in auto with the ID fan speed to lock the temperature profile of the kiln.

Hood Pressure Control of excess air by cooler exhaust fan Open during kiln pushes

Need to be kept stable to avoid variations in cooler to upset the burning zone

Secondary Air Temperature Temperature of combustion carried back to kiln from the

cooler Large variations during kiln pushes Should be controlled in a very small

range in auto during normal kiln operation with a good regulation of the clinker

cooler (+/- 85oF or 39oC) Cooler Exhaust Temperature Varies with clinker input to

cooler Will indicate variations during a push Under Grate Pressure Related to

cooler grate speed Set point controlled by the under grate pressure of second

compartment to keep a constant clinker bed depth in order to get stable and high

secondary air temperature VARIABLES WHICH THE OPERATOR CANNOT CONTROL

Quality and characteristics of the raw materials Quality of the fuel used as a

example: heat value, ash content, volatile matter and moisture level Dust quality

and quantity returned to the kiln Accuracy of the feeders Chain system design

Accuracy and good response of all control loops and sensors of the kiln system For

these variables that he cannot control, the operator should be kept informed of any

changes done and should make sure that those variables are kept inside an

acceptable range to maintain a good kiln stabilization. VARIABLES WHICH THE

OPERATOR CAN CONTROL Material feed to the kiln Fuel feed to the kiln Speed

rotation of the kiln Temperature profile along the kiln Draft at the feed end of

the kiln Supply of combustion air Retention time of the material in the kiln

Temperature of the combustion air Flame shape Observation of instruments, and

correct reaction to their readings Observation of the kiln burning zone, and

correct reaction to this evaluation However, some restrictions are sometimes given

on the utilization of those variables and may vary from plant to plant due to local

conditions and are usually the following: Set point on the maximum speed of the

kiln Set point on the maximum feed rate to the kiln Automatic loop set point for

oxygen level and ID fan speed

Settings on the burner pipe and its position Primary air settings and fuel tip

velocity Set point on cooler fans flow Set point for the under grate pressure and

the clinker bed depth in the cooler KILN LIMITATION FACTORS Dust Emission at

Precipitator Stack (Local emission regulations) Gas Chain Temperature Maximum

value depend on chain quality and position Diameter of Kiln Gas velocity in kiln

(70 ft/sec in free section of kiln and 30 ft/sec in chain section maximum) Heat

load in front of kiln, flame erosion on kiln walls ID Fan Capacity Maximum fan

speed and low oxygen level Cooler Capacity No red clinker should be present after

third compartment of cooler in normal operation Clinker discharge temperature not

to exceed 170oF (80oC) Cooler exit gas should be about 370oF (190oC) Bed depth to

allow good under grate pressure (15) with sufficient fan capacity KILN OPERATION

TARGET Highest clinker production with Good quality clinker

Stable kiln operation Oxygen level as low as possible Gas and fuel oil 1.0 to

1.5% Coal and coke around 2.0% (depending on the variations in fuel mixture)

Kiln exit temperature as low as possible Flame as short as possible (with respect

of the burning zone refractory) Keep burning zone short in front of the kiln

Secondary air temperature as high as possible but stable Temperature not above

liquid phase temperature in front of kiln to protect refractory and coating Run

with an under grate pressure as high as possible Compatible with the cooler fans

static pressure capacity Primary air as low as possible As combustion air to

replace by hot air from cooler as much as possible Clinker Temperature Not to

exceed 230oF (110oC) as it could promote quality problems (false set) during the

grinding process Gravel bed filter Normal operation temperature is 350oF (180oC)

Maximum temperature for normal operation is 660oF (350oC) For 2 hours, up to 750oF

(400oC) For 20 minutes, up to 840oF (450oC) OPTIMAZATION OF THE KILN SYSTEM

Operate the kiln: With higher free lime Reduce air leakages: Around and near the

nose ring area and seal Air in-leakage on kiln hood Around blast pipe port holes

and doors Hood pressure set point as close as possible to zero Primary air should

be kept as low as possible Reduce length of pre-cooling zone by: Adjusting the

burner position Proper material load (kiln speed/feed ratio) Increase clinker bed

depth in cooler (near 15 inches) Oxygen to be maintained at minimum level Good

flame shape and temperature Good chemical composition Good burnability factors

Constant raw mix TYPICAL KILN PROBLEMS List of most frequent factors at work

when kiln operation is unsatisfactory 1) High leakage, pre-heater only into feed

end seal (more than 5%)

2) Faulty suspension results in high pre-heater outlet temperatures, thus reduces

capacity (bleed air) 3) Poor operating practices (burning techniques) 4) Reducing

conditions in kiln 5) Reducing conditions in burning zone due to flame impingement

with load 6) Lack of momentum at burner tip leads to long, lazy flame 7) High

primary air, (30%+) due to direct firing of coal, (critical in dry process kiln) 8)

High level of volatile elements in raw feed particularly chlorine 9) Systematically

hot burning 10) Inadequate chain system 11) Poor cooler heat recovery due to cooler

fan design 12) Poor cooler heat recovery due to excessive air flows, insufficient

pressure in under grate compartments 13) Chemically variable raw mix C3S, more than

10 points over a shift 14) Variable slurry moisture (more than 3 points) 15)

Variable addition of hi-alkali or hi-volatile dust from precipitator (over a period

of more than one-half hour) 16) Erratic feed rate 17) Erratic fuel rate (wet coal)

18) High leakage into hood seal (more than 10% of combustion air) 19) Inadequate or

obsolete design of equipment or facilities 20) High leakage into pre-heater and

down-comer duct 21) Flame erosion on lining could create premature brick failure

22) Kiln misalignment, excessive tire clearances and other factors of shell

deflection 23) Bricking techniques lead to rings not tight enough 24) Low slurry

moisture 25) High slurry moisture List of Typical Kiln Operating Problems

1) Heat consumption higher than normal Long dry: Higher than 3.4 MBtu/ton Long wet:

Higher than 5.2 MBtu/ton Four stage Pre-heater: Higher than 3.1 MBtu/ton 2) Output

lower than nominal and / or standard 3) Kiln is unstable and requires frequent

massive shutdowns 4) Kiln is cycling spontaneously without any action of operator

5) Kiln is out of draft with output below nominal 6) Stack stinks SO2 emissions

are high 7) Mud ring in chain section on wet kiln 8) Back-spills on wet kiln 9)

Burning zone rings 10) Discharge end rings 11) Snowmen in cooler 12) Frequent

burning zone burnouts (brick life is less than 3 months) 13) High dust return

(above 20% of clinker) causes handling problems 14) Cyclones plug-ups (four stage

pre-heater) 15) Build-ups in pre-heater feed box (four stage pre-heater) 16) Cooler

exhaust system seems undersized/under-designed - Hood frequently under pressure

(during pushes) - Exhaust temperature is higher than normal - Bleed in damper is

open very often - Frequent bag burnouts in cooler bag house 17) Red grates in the

cooler all the time. Frequent grates burnouts 18) Red rivers on side of cooler 19)

Under pushes, cooler speed up to maximum, yet some fans stop blowing any air

(pressure overload) 20) Kiln drive seems undersized, kicks out upon start-up after

a short shutdown WHAT TO LOOK FOR WHEN LOOKING INSIDE A KILN

Viewing the kiln interior This may sound somewhat elementary, but we should never

forget that we are looking into an extremely luminous source. Although filtering

glasses are used, the light source is so strong that focusing the eyes into it for

too long a time could cause partial blindness. One should look no longer than one

minute at a time into the fire. If longer viewing is required, look a side for few

seconds occasionally to rest the eyes. Looking steadily too long at the flame

results in the eye losing its ability to see details, hence the need for a short

rest every minute or so. The question of what type of colored filter glass to use

must be left to the operators. Burning with a natural gas flame usually makes

necessary a darker colored than oil fire would require, because of the greater

luminosity of the flame. As a rule, one should always use a glass that enables him

to see under and behind the flame. Once a certain glass has been chosen, the

operators should stay with this glass at all times in order to properly judge the

burning zone conditions. How frequently should one look into the burning zone?

There is no set answer to this question. Experienced operators sometimes become

over-confident and think that it would be perfectly safe to leave the kiln alone

for periods in excess of 30 minutes. This action however, is against good burning

practice. The secret of every good operator is his ability to recognize a change in

kiln condition at the time a change takes place and not later. For this reason, a

good operator will never leave a kiln too long a time unchecked. When things are

going smoothly, the kiln should be checked every half hour, with more frequent

checks if adjustments are being made. There is no such thing as operating a kiln by

the instrument alone, as the instruments do not show, for example heavier and

lighter loads entering the burning zone until it is almost too late to make the

necessary adjustment. The kiln condition can be estimated from the color observed

in the hottest part of the flame. Dark red cherry red orange-yellow white Cold -

- normal hot Any deviations from the orange-yellow range should be investigated to

determine the cause and when adjustments need to be made to the kiln operation to

get back to normal kiln condition.

Appearance of burning zone Good or bad visibility Bright white or dark red color

Good appearance is an orange-yellow color The gas stream should be calm without

great turbulence Appearance of coating Coating should begin approximately .

diameter of kiln size from the nose ring Color of coating tells a great deal about

the condition in burning zone as coating acts as heat storage in burning zone

Overall thickness of coating should be between 9 and 12 inches and is dependent of

the type of raw mix Check for ring formation near lower or upper section of the

kiln If the surface of the coating appears smooth, then the burning zone in this

area is hot If the coating appears lumpy then the burning zone is okay A bare

spot without coating could be due to flame erosion, thick brick or high flame

temperature in this location Appearance of the coating falling off from the top of

the kiln shell: Large pieces: normal Fine noodles dripping: too hot The location

where the coating pieces are falling from the top of the kiln wall, above the end

of the flame is generally where the raw load is. So whenever the raw load cannot be

seen in the bottom and behind the flame of the kiln, try to look at the top.

Appearance of material load

Is clinker balling or fine? Is material sticky? Is material heavy or light? Is

material movement fast or slow? Is material climbing low or high in the wall?

(material should climb up +/- to the 10 oclock position in normal operation)

Appearance of material before falling in the cooler, fine or nodular Upper burning

zone section Are rings building up or not? Is coating formation seem normal? Try

to evaluate the length of the coating (50 to 100 feet from burning zone to far up)

Raw feed location Look behind the flame at the bottom of the kiln Normal position

is approximately . diameter distance under the flame Never allow raw feed to come .

way under the flame as kiln speed will have to be reduced to control it (kiln low

speed) An advancing or receding dark feed is the earliest indication of a burning

zone that is warming up or cooling down. So that is why it is important for the

kiln operation to be able to see this load. Every effort should be done during

normal operation to keep this load in sight. Flame appearance Should always be

evaluated during stable kiln condition Long (100 ft) or short (30 ft) Hard or lazy

Bushy or narrow

Bright or dark White or orange yellow Eroding the coating or the brick wall Aiming

high, low or in the center Eroding the material load If fuel is burning in

suspension or in the material load Position of the ignition point when coal or coke

is used The flame temperature should be as hot as possible as long as it does not

create problems with the coating and the kiln refractory. Whenever a change is made

on the flame shape, a close monitoring of the shell temperature should be done.

Coal flames Coal normally burns with longer flame than oil A coal flame normally

starts at 3 to 5 feet from the burner tip Coal fineness to be about 85% passing 200

mesh Keep the coal system air flow at about 70 ft/sec to avoid coal deposit inside

pipe, while keeping primary air to minimum (direct system and burner design) On

direct firing system, coal fan damper setting should be set at minimum value and

the fuel rate changes made only by making changes with the coal feeder system in

order to keep the flame shape short and as constant as possible. Burner pipe

appearance Is the tip of the blast pipe in good condition? Is the burner cast-able

in good condition? Is the burner pipe aimed correctly? How is the pipe location

relative to the nose ring? Are snowmen building up on top of burner pipe? Whenever

a bad condition deflecting the flame is observe, a quick evaluation should be done

to evaluate if the kiln can continue its operation or if it needs to be shut down

to fix the burner pipe.

Nose ring appearance . Check the condition of the cast-able or the refractory on

the top of the nose ring if okay . Check the temperature aspect and the wear of the

nose ring castings . Check if the nose ring seal is in good condition Secondary

air . Calm or upset . Dusty if the clinker is fine . Clear if clinker is balling .

Foggy and white if temperature is hot The secondary air temperature has a major

influence on the flame and its shape. Primary air . Should be as low as possible

to obtain satisfactory heat recuperation from cooler . Has an important influence

on the shape of the flame (bushy or narrow) . Pressure should be as constant as

possible When good settings of the flame have been found, the primary air settings

should not be changed in normal operation unless a high temperature condition in

the kiln refractory has raised and required to change the flame. When the kiln is

down . Look for ball or ring formation at upper section of burning zone . Evaluate

length of coating if okay, too long means we burned the kiln too far up . Load

level inside kiln if even and normal

. Appearance on load during kiln jacking (sticky or normal) Look at the sealing

efficiency of the kiln back end (no suction or gases movement inside of kiln should

be observed). When kiln is shutdown, the gases should be bottled inside of the kiln

as fast as possible by closing the kiln back end damper or its equivalent and by

adjusting the hood pressure set point, slightly positive. The procedure need to be

done to avoid heat loss from the kiln to insure a slow cooling of the refractory

and avoid thermal shocks on the bricks. KILN UPSETS Burning zone too hot Too

much liquid is formed and all temperatures are above the solid state temperature

therefore no coating is formed. Coating will be lost and this could damage the

refractory. A) Appearance the kiln could be white and hazy in front end and the

clinker will be balling. B) Appearance of the kiln could appear cold if burning is

too far. The clinker could be fine (very long burning zone). A) Hot burning zone

with high secondary air temperature . The front of kiln is very hot and white,

often hazy . The secondary air temperature is high . The clinker is balling and

getting bigger . Often the dark load is visible behind the flame These conditions

occurs when the burning zone length is moving down and concentrating the heat on a

shorter burning zone length in front of kiln. This situation can be overcome quite

easily by reducing the fuel rate and the ID fan slowly step by step until the

burning zone gets back to its normal condition. B) Hot burning zone with dusty

secondary air

. Can be caused by burning too far back into the kiln . Flame too long and ignite

too far . Pre-cooling zone is too long in front of the kiln . Long burning zone

promotes very fine clinker formation which is sent back as dust into the kiln with

the secondary air gas stream Whenever dusty conditions prevail in front, corrective

measures should be based on the clinkering conditions behind the flame rather than

on the color of the front of the kiln. Aspect of the clinker falling in cooler is

very important at that time to evaluate the kiln condition. Kiln amps, fuel flow

rate, shell temperature and back-end temperature are usually above the normal

operation settings during these conditions. Get free lime done from clinker coming

out of the kiln to see if OK If operator is in doubt about the kiln being cold or

hot, the kiln rotation could be stopped (out of the interlock for a few seconds) to

allow condition of the burning zone to clear and to view inside the kiln If doubt

still persists, the kiln should be assumed to be hot and it should be cooled down

by reducing the fuel and the ID fan speed until the burning zone get back normal or

end up to be completely cold. Except for very hot and emergency conditions, such as

cooling should take as long as a full shift to be done, to avoid high heat

concentration in front and quick losses of coating from the upper section of the

burning zone which could upset the burning zone temperature. KILN CYCLING This

is an unstable condition when the load in the kiln decreases, causing the

temperature of the burning zone to rise and forcing the operator to reduce the fuel

rate. Then, the burning zone starts to cool off in turn forcing the operator to

increase the fuel rate. In severe cases, the temperature continue

to drop, even though the fuel rate is at maximum and it become necessary to reduce

the kiln speed to slow down the entry of the feed into the burning zone. Once a

kiln gets into an upset such as this, the cycle will repeat. Kiln cycling could be

related to the following reasons; . Variations in kiln feed: physical or chemical,

. Variations in dust re-introduction to kiln, . Variations in the water spray

control system in kiln inlet (if any), . Materials hold up in the chain system (for

wet process kilns), . Poor chain system design (for wet process kilns), .

Variations in hood pressure control . Poor cooler settings and control which

promote secondary air temperature variations, . Operating the kiln above its

production capacity, . Variations in the quality and the quantity of the fuel

supply to the kiln, . Bad operating practices, especially over reacting with the

kiln speed and . Volatile recirculation inside the kiln system especially chlorine

So all the above reasons should be investigated in order to find the cause of the

cycling problem and corrected. HOW TO BREAK A CYCLE IN A KILN . Reduce

feed/speed ratio by approximately 10% in order to change the material load in the

kiln (also mainly to change the material load in the chain system). . Increase the

fuel flow rate by 5% above the normal setting of the current production level. .

Keep the oxygen level above 2% and try to control the back end temperature

variations as much as possible by using fuel rate and ID fan variations.

. Let the kiln amps vary and do not attempt to chase them by varying the kiln

speed. Just try to control them if they get above or below the critical range by

varying the fuel flow rate. . If the kiln speed need to be varied than it should

be done with very small variations, in order to avoid upsetting the material in the

kiln. . If the kiln speed needs to be increased to go back to normal production

level, then it should be carried out more slowly than normal. As you get to normal

production level, fuel settings should be held above normal before returning to

normal operation settings. KILN EMERGENCY CONDITIONS SECTION RED SPOT ON KILN

SHELL Indicators: . By visual observations . Shell scanner sharp and rapid shell

temperature increase to level above 850oF (450oC) . Visual observations of loose

refractory bricks in the material load of the kiln or in the clinker at the cooler

discharge Possible Effects and Danger . Severe warping and damage to kiln shell .

Shell temperature between 900 and 1100oF (480 and 590oC), deep red color on shell .

Shell temperature over 1200oF (650oC), very bright red and shell bulges and warps

Recommended Actions to Take A) For small red spot located in the upper transition

or center of burning zone Continue normal operation of kiln but:

. Place shell cooling fans in the area of red spot . Shorten flame to bring black

feed over area of red spot in attempt to form new coating . Keep watching the shell

temperature trend . Maintain normal burning zone temperature . Change kiln feed

chemistry to obtain an easier burning mix B) For large red spot located under or

near a kiln tire or in areas were no coating is formed SHUT DOWN KILN IMMEDIATELY

Warning: Under no circumstances should a water spray be used on the red spot, as

this could result in severe kiln shell damage. Possible Measures to Prevent Re-

occurrence . Make sure flame configuration and characteristics are not causing

localized coating erosion or continuous and excessive overheating . Employ proper

refractory installation methods . Minimize frequency of kiln shutdowns and upsets .

Minimize frequency of clinker type changes over . Avoid hard burning mixes (i.e.

ensure sufficient percentage of liquid content in mix to promote coating formation)

RAW, UNBURNED FEED IN CLINKER COOLER Indicators: . On rush of raw feed into and

beyond burning zone . Black feed position advanced more than . way under the

flame . Black-out in burning zone . Red grates in cooler . Rapid rise in cooler

grate and clinker discharge temperatures . Cooler drag-chain amperage increases

rapidly Possible Effects and Danger

. Thermal damage to cooler grates and grate drive mechanism . Fire on clinker

conveyor belts . Excessive high temperatures in coal mill air circuit Warning:

Watch for incomplete combustion when visibility in burning zone is severely

restricted. Actions to Take First and foremost, do not wait until raw feed is in

the cooler; act when the first signs of impending problems are visible in the

burning zone. . Immediately reduce kiln speed to minimum (or turn on auxiliary

drive) . Reduce fuel and ID fan speed in accordance with standard slowdown

procedures to protect the kiln back end temperature . Reduce cooler grate drive

speed (switch to manual control) to allow material in cooler more time for cooling

. Adjust cooler air flow rates to obtain maximum cooling without the hood pressure

going positive . Advise all unauthorized personnel to stay clear of the firing

floor, cooler and coal mill area Preventive Measures to Avoid Re-occurrence .

Accelerate frequency of visual observations of burning zone for early detection of

impending cooler upsets . Evaluate kiln output rates vs. capabilities and kiln

operating stability LARGE RING BROKEN LOOSE IN KILN Indicators . Visual

observations of large junks in burning zone . Sudden drop in kiln back end draft .

Large drop in oxygen content of kiln exit gases . Hood pressure tending towards

positive side . Sudden change in kiln drive amperage

Possible Effects and Dangers . Overloading cooler with unburned feed . On rush of

excessive amounts of feed into the burning zone . Damage to cooler drives and

grates . Large pieces jamming cooler hammer crusher . Red hot clinker leaving

cooler Actions to Take . When amount of feed and ring fragments in burning zone are

extremely large: . Immediately reduce kiln speed to minimum . Reduce fuel and ID

fan speed to keep back end temperature under control . Switch cooler grate control

to manual and reduce grate speed . Adjust cooler air flows to maximum flow

possible, without the hood pressure going positive . Have personnel on standby to

watch the cooler and the hammer crusher for possible overloading, overheating and

jamming Possible Preventive Measures to Avoid Re-occurrence . Laboratory to

reevaluate chemistry of kiln feed (including dust return rates) for possible

elimination of ring formation if no solution in this area possible, then . Initiate

regular schedule to remove rings and heavy build-up by means of special devices

design for this purpose . Initiate regular procedures to displace the burning zone

location on a daily basis BURNING ZONE DANGEROUSLY HOT Indicators . Clinker

balling in burning zone . Material load sausage-like . Coating dripping off the

wall . Sliding molten clinker bed in burning zone . Burning zone recording

temperature too high

. Cooler under grate pressure too high . Material load turning to liquid in burning

zone . Very brilliant and white burning zone Possible Effects and Dangers . Loss

of coating and thermal damage to refractory . Red spot in the kiln shell . Thermal

damage to cooler and kiln hood components Possible Actions . Reduce fuel flow rate

to minimum until sausaging stops . Increase kiln speed approximately 10 rph until

sausage is broken . Provide maximum air in cooler (without hood pressure going

positive) . The kiln rotation to be adapted is the aspect of the material near to

fall into the cooler. No liquid material in the cooler, stop kiln rotation if

needed. . Reduced primary air flow, then as soon as the objective of breaking the

agglomeration is accomplished, . Reduced the kiln and ID fan speed then increase

fuel flow rate to normal operating conditions Preventive Measures . If sausaging

is frequent and result of easy-burning mix, have laboratory evaluate possibility of

providing a mix with less percentage of liquid content . Make more frequent,

vigilant observation of the burning zone conditions . Evaluate flame position and

shape to determine if thinner, longer flame is possible SUDDEN, SHARP RAISE IN

BACK-END TEMPERATURE Possible Reasons . Feed shortage . Combustion in exit gas

. ID fan speed too high . Kiln speed too low . Chain fire Possible Effects and

Dangers . Chain fire on wet and dry kilns . Thermal damage to back end, dust

collector and pre-heater tower equipment . Delayed ignition of fuel in back end of

kiln Possible Actions . Immediately de-energize electrostatic precipitator .

Immediately reduce fuel flow rate and ID fan speed to obtain less than 0.3% oxygen

in exit gas Warning: Do not cut off fuel flow rate completely as this could trigger

an explosion. . Increase kiln speed and feed rate . Warn personnel to stay clear of

kiln back-end . Do not open any doors in kiln back-end Then as soon as the primary

objective of bringing the kiln back-end temperature under control is accomplished:

. Return kiln control variables to normal to restore operating conditions . Check

out back-end to determine if thermal damage had occurred Preventive Measures . Do

not operate kiln without feed for more than 10 minutes . Provide alarms and

properly maintain kiln instrumentation to obtain warnings before the back-end

temperature gets out of maximum range . Maintain close vigilance over combustion,

back-end and flow conditions during kiln starts, shutdowns and upsets BLACK SMOKE

EMMISION FROM KILN STACK

Indicators . Combustibles in exit gases . Oxygen in exit gas too low . Flame

extinguished for poor ignition conditions . Burning zone temperature too low .

Excessive fuel rates and/or insufficient kiln draft Possible Actions . Immediately

de-energize electrostatic precipitator . Immediately reduce fuel flow rate (do not

shut off) . Increase ID fan speed to obtain: a) Zero combustible in exit gas b)

Oxygen between 0.2 and a maximum of 0.5% in exit gas . After black smoke has

cleared, maintain the low oxygen/zero combustibles for at least 10 minutes before

restoring kiln variables to normal Preventive Measures . Improve control over

flame and firing conditions . Make frequent, vigilant observation of fuel flow

rates, gas analysis, flame and kiln draft conditions during kiln starts and upsets

DISTORTED FLAME SHAPE Indicators . Irregular and unusual flame shape . Fragmented

flame where part of flame impinges on lining near kiln discharge area Possible

Effects and Dangers . Inspect burner pipe for damage or plugged circuit . If flame

is erratic and severely impinges upon lining near the kiln discharge area: Shutdown

kiln immediately!

. If flame is only slightly distorted; adjust burner position and primary air flow

. Check shell temperature on kiln scanner . Schedule a burner pipe repairs for next

kiln shutdown Preventive Measures . Frequent visual inspection when looking inside

the kiln . Regular inspection and maintenance of burner pipe during each prolonged

kiln shutdown . Improve protection (castables, air cooling) for burner pipe .

Maintain primary air flow for at least 2 hours after a kiln has been shutdown or

pull back the burner pipe immediately when kiln is being shutdown LOSS OF SECTION

OF REFRACTORY LINING Indicators . Loose bricks in clinker bed of burning zone .

Delineated (linear instead of round) red spot on kiln shell . Rapid rise in kiln

shell temperature Possible Effects and Dangers . Thermal damage and distortion of

kiln shell and tire . Further collapse of large sections of linings (especially in

alumina brick sections) Possible Actions . Immediately shutdown the kiln

Preventive Measures . Employ proper refractory installation methods and procedures

. Make annual checks of kiln alignment and shell ovality . Have refractory

manufacturer provide uniform shapes and proper expansion allowance for each type of

brick

. Avoid excessive turning when kiln is cold during shutdowns COOLER DRIVES OR

CLINKER BELT STOPPED Indicators . Cooler overloaded . Large chunks of coating in

cooler . High under grate pressure . High cooler drive amps prior to drive stop .

Clinker transfer chutes plugged Possible Effects and Dangers . Thermal damage to

cooler components Possible Actions . Immediately reduce kiln speed to minimum and

attempt to restart clinker belt and/or cooler drive . If drives cannot be restarted

within 5 minutes, shutdown the kiln Note: After kiln has been shutdown, consider

possibility of turning the kiln in less frequent intervals to prevent further

overloading of cooler. (Kiln still had to be rotated periodically nevertheless)

Preventive Measures . Know at what amperage the cooler drive is likely to fail and

provide alarm for overload . Adjust kiln parameters (namely kiln speed) before

cooler can become overloaded at the times when heavier feed load is observed in the

burning zone RED CLINKER AT COOLER DISCHARGE Indicators

. High drag chain amps . Sudden drop in under grate pressure (grate out) .

Excessively high under grate pressure (cooler overloaded) . Cooler drive amps and

clinker bed depth too high . Cooler loaded with coating and ring fragments .

Snowman formation at cooler inlet Possible Effects and Dangers . Thermal damage to

cooler components . Thermal damage to clinker transport equipment Possible Actions

. Immediately make a visual check of the cooler to determine reason for red-clinker

discharge If cooler grate out, shutdown kiln If cooler overloaded, reduce kiln

speed to minimum and reduce cooler grate drive speed to allow more time for cooling

. Increase air flow into cooler . Activate water spray at cooler discharge and

reroute clinker to prevent damage to conveyor belts Preventive Measures a) On

frequent grate failures . Investigate for possible faulty grate installation

methods by maintenance department . Investigate quality of grates and bolts used b)

On frequent one-sided loading of cooler bed . Investigate possible cooler design

changes . Investigate possibilities for elimination of stalagmite (snowmen)

formation at cooler inlet c) On frequent overloading of cooler due to upsets . Slow

down kiln speed before raw feed enters cooler or cooler can become overloaded (make

your corrective moves before things get out of control)

RAPID RAISE OF TEMPERATURE IN COAL SYSTEM Possible Effects and Dangers .

Explosion . Thermal damage to coal system Possible Actions Warning: Do not open

any door in the system that could provide the oxygen for an explosion or a more

serious fire. . Inject inert gas (CO2) into coal mill inlet . Flood coal mill with

kiln feed or excessive coal . Warn all personnel to stay clear of system . Stop or

reduce air flow to coal mill to minimum Preventive Measures for Re-occurrence .

Provide coal mill inlet with magnetic device to extract metal fragments from coal

feeder belt . Keep paper, rags, etc. out of coal storage pile . Do not feed coal

mill with coal that has undergone spontaneous ignition (smothering) while in

storage . Keep coal mill de-tramp chute clear . Provide coal mill system with

automatic fire-extinguishing devices . Do not operate coal mill above predetermined

safe temperature for any given type of coal POWER FAILURE Possible Effects and

Dangers . Warping of kiln shell . Thermal damage to burner pipe, instrumentation

and equipment at kiln discharge area

. On coal-fired kilns, settlement of ground coal in coal system that could lead to

a fire and/or explosion Possible Actions . Immediately start auxiliary power

generator and primary air fan (coal mill fan on direct fired kilns) . Retract

burner pipe and protect TV monitor in kiln hood . Start . turn on kiln not later

than 10 minutes after the power failure . If available, close feed-end damper

manually to prevent hot gases from escaping from kiln by natural draft Power

Failure Main Procedures . Start generator or auxiliary drive . If it is raining,

carry out . turn as described previously . Close kiln back-end, ID fan damper, or

precipitator inlet damper if power failure is of long duration . Keep primary air

fan running to cool down the burner pipe (and pre-calciner burners) or pull the

burners out of the kiln . Try to restore power as soon as possible The following

should be connected on the auxiliary power system: . Emergency light in control

room . Emergency light in kiln platform . Telephone system for outside calls .

Radio system inside the plant . ID fan louvers and precipitator inlet damper . Kiln

auxiliary drive . Primary air fan . Recirculation pump for the industrial water

system (water cooling system)

Instructions should be given to all members of the shift for specific

responsibilities during a power failure as example: Operator A: . Carry out safety

procedures on kiln system . Start the auxiliary power system . Close kiln back end

(if on auxiliary system) . Rotate the kiln . If it is raining continuously, rotate

kiln as soon as possible . Protection of burner pipe (pull out of kiln . Call the

power company Operator B: . Get to main power breaker and try to reset it . Go to

kiln back-end and close ID fan louvers (if they are not connected on the auxiliary

drive) . If the auxiliary drive control is not remote, make kiln rotation in local

A CHAIN FIRE Indicators . Rapid, sudden rise in intermediate and exit gas

temperatures . By visual observation Possible Effects and Dangers . Melt-down and

loss of chains . Damage to kiln shell in chain system area . On wet process kilns;

steam explosion . Thermal damage to kiln back-end equipment Possible Actions

Warning: Under no circumstances should water be added at the feed end.

. Immediately reduce fuel rate to minimum (but dont shut fuel off completely) . At

the same time, reduce ID fan speed to obtain zero combustibles and less than 0.3%

oxygen . Increase kiln speed and feed rate to maximum until the back end

temperature is under control . On wet process kilns, clear all personnel from

firing floor Preventive Measures . Avoid operating the kiln for more than 10

minutes when there is feed shortage . Establish and enforce maximum permissible

operating limits for intermediate and/or exit gas temperatures HEAVY RAIN OR

THUNDERSTORMS Possible Effects and Dangers . On kilns that are exposed to

elements; . Loss of coating and collapse of refractory lining . Thermal damage and

warping of kiln shell . Possibility of power failure Possible Actions If storm

occurs shortly after a kiln shutdown; . Jack (turn) kiln more frequently or

continuously on auxiliary drive . Start auxiliary power generator in preparation

for a possible power failure SUDDEN, HIGH POSITIVE HOOD PRESSURE Possible

Reasons . ID fan failure . Large ring or build-up broken loose inside kiln .

Instrumentation failure of cooler air flow, cooler stack damper, or ID fan control

. Steam explosion on wet-process kilns Possible Effects and Dangers . All

personnel on firing floor is in danger . Thermal damage to equipment on firing

floor and hood . Danger of backfire in coal system Possible Actions . Immediately

clear all personnel from firing floor . Immediately reduce fuel rate to minimum and

increase ID fan speed . Reduce cooler air flow rates into under grate compartments

. Open cooler excess air damper manually OVERHEATED KILN BEARINGS (Procedure

needs to be approved by your Maintenance Department) Slow down kiln speed near

minimum 20 rph. Do not stop the kiln (bearing will seize) Open reset door on top of

bearing and pour in sulfur until noise stops You can add also powdered graphite

to the bearing lubricating oil The sulfur must be poured on the shaft and not on

the bearing casing Keep a bag of sulfur near the control room location Call the

Maintenance Supervisor Check if the oil heating is on or not, and stop it if it is

in operation (breaker location must be known to all) Check if the water or glycol

circulation is okay. If there is no circulation, open the water valve very slowly

If you cannot reach the Maintenance Supervisor, call for an Oiler and a Maintenance

man Install a water hose to get cold water in the bearing (not a close circuit

loop) Drain the oil and add new oil until the new oil has reached its normal

temperature (below 120oF/50oC you should have a temperature gauge showing the oil

temperature on each bearing) Temperature sometimes requires from 6 to 12 hours to

reach 120oF/50oC

Type of oil to use for the bearings to be confirmed by your maintenance department

KILN HAZARDOUS CONDITIONS Shooting Rings with Gun . Do not allow any employees

other than the gun crew on the firing hood during ring shooting . Do not tamper

with the ammunition . Keep all live ammunition locked up and away from the firing

floor when not in use . Permit only experienced and trained persons to operate the

kiln gun . Use ear muffs when firing gun . Cotton stuffed in the ear is not

adequate . Clean gun at frequent intervals and do not attempt to fire an apparent

defective gun . If kiln has no chain section, keep all persons away from the kiln

back end and rope this area off before shooting Clinker, Fuel Oil and Coal Dust

Spills . Clean up spills immediately . Provide adequate clean-up cans and

facilities for easy removal of spills . Initiate repair action when spills are

caused by leaks that can be repaired Gas, Fuel Oil, Coal and Steam Leaks in Fuel

System . Report any gas odor on the firing floor immediately to the shift

supervisor . Provide for periodic inspection of fuel and steam lines and system to

detect leaks and other defects as a preventive measure against major breaks in the

system Burner Hood, Porthole and Cooler Doors . Do not allow anyone to look into

the burning zone while the kiln is on operation unless approved safety equipment

for viewing is used . Use proper protective clothing when working near open burner

hood and cooler doors while the kiln is in operation

. Instruct all persons to stay clear of the portholes whenever the hood pressure is

temporarily on the positive side Relining the Kiln with Refractory Bricks and

Materials . Use protective screen when working under loose refractory and coating,

if no alternate procedure is possible . Any employee working inside the kiln should

have positive means, such as locking out the kiln drive with his own lock, to

assure that the kiln cannot be started while he is inside . Have proper posture and

steady footing when lifting bricks or scaling coating . Do not work underneath the

burner hood bridge while material is being hauled in and out of the kiln . Do not

test run cooler fans when workmen are inside the kiln . Do not run ID fan when

workmen are at kiln rear or in chain section Working Near or on Dust Collecting

Equipment . Wear extra protective clothing to guard against burns from hot dust .

Wash skin thoroughly with clear water after contact with alkaline dust . Have a

second workman as safety man standing by whenever working under or in bins or

hoppers containing material . Do not allow workmen to work inside hopper without

being properly secured on safety lines and belts . When working on plugged flue

hangers, be constantly on guard against potential dust flushes and cave in of

overhanging materials Backfire and explosion During Kiln Light-up . Open either

one cooler or burner hood door before lighting fire in kiln . Secure proper draft

in kiln before fire is lighted (very important) . Do not allow unauthorized person

to stand near the burner hood during light-up . Stay clear of burner hood ports

when igniting the fuel . Avoid excessive fuel flow on initial light-up of flame .

Start the primary air fan before opening the fuel valve

. When firing coal, make sure that no coal dust spills are present on firing floor,

around coal feeder, or in the primary air pipe Setting any Kiln Machinery into

Motion During Start-up . Make sure all persons are clear of kiln equipment before

each unit started . Sound horn to signal startup . Inspect all circuit breakers

before the startup to make sure that all safety tags and locks have been removed .

Make sure all machine guards are in place before any equipment is started Relining

the Kiln with Refractory Bricks Construct a proper bridge across the burner hood

from firing floor to kiln nose Inspect coating and remove loose overhangs before

passing underneath Keep all unauthorized personnel out of kiln interior KILN

OPERATION SECTION KILN OPERATION TECHNIQUES There are Three Common Techniques for

Burning Clinker in a Rotary Kiln . Maintain a constant kiln speed, and vary the

fuel rate to counteract the temperature changes in the burning zone . Maintain a

constant fuel rate, and vary the kiln speed to hold the burning zone temperature at

the desired label . Vary the kiln speed, the fuel rate or both to maintain the

desired burning zone temperature These techniques have one error in common. They

show concern only for the burning zone temperature.

Unfortunately, many kiln operators think that this is good enough, reasoning that,

as long as good-clinkers are produced, what more is necessary? The fallacy of this

reasoning lie in the fact that ideal stable kiln conditions can be obtain faster

and more economically when equal consideration is given to all zones in the kiln

and not the burning zone alone. The process of clinker burning, therefore the

process of rotary kiln control starts not at the place where the feed enters the

burning zone but at the point where feed enters the kiln. The Proper Operation

Technique is: Vary the kiln speed, the fuel rate and the induced draft fan in any

combination to maintain the proper burning zone temperature and maintain a constant

back-end temperature for a given rate of feed. This technique is called; Burning a

kiln from the rear. By doing so, you prevent the variations instead of reacting to

them when they reached the burning zone. If you stabilize the kiln back-end

temperature you will be able most of the time to overcome the burning zone

temperature variations mainly by using the fuel input to the kiln and the ID fan

speed. In long wet and dry kilns, kiln speed variations should be avoided as much

as possible in normal operation as it create variations in the material loading of

the kiln and eventually could lead to the kiln into an upset. If kiln speed

variations is to be used, then they should be small (1 to 3 rph) keeping in mind

that the material load of the kiln will be more or less +/- 2 hours later as it

will reach the burning zone, (kiln retention time). However, speed variations must

be used on pre-calciner kilns to control the burning zone temperature as the

calcinations rate or the feed preparation is done by the fuel input on the pre-

calciner burners. The feed/speed ratio must remain constant all the time once the

perfect loading of the kiln has been found. Speed/feed ratio should not be changed

to control the kiln.

BURNING ZONE EVALUATION The burning zone condition can be estimated from the

colors observed in the hottest part of the flame. An orange-yellow color is normal.

When looking into burning zone, one will observe a sharp color change of the lowest

part of the feed bed under the flame from dark to bright. This point in burning

zone is of great importance to the operator as it is the earliest indication when

the burning zone tends to warm up or to cool down. In normal operation, the

position of the dark feed remains stationary approximately one quarter of the

distance into the flame. This point should be used at the main indicator for

evaluation of the burning zone. If the dark feed move further under the flame

(towards the front of the kiln) the burning zone is cooling down. If the dark feed

shifts in the direction of the kiln rear the burning zone is warming up. The

position of the dark feed can feed can move because of changes in the flame shape,

the feed loading of the kiln or if the feed to kiln is harder to burn. Any change

in the position of the dark feed must be viewed in the light of all of these

influences. The operator must be able to see the dark feed whenever he looks

inside the kiln and he must regulate the operation of the kiln so as to achieve

this; A slow shifting of the dark feed in either direction can usually be

counteracted by a small change in the fuel input rate in order to keep the feed in

its proper place.

If it become necessary to counteract the condition in which the feed has slipped

too far under the flame than the kiln speed should be varied to restore the dark

feed position to the proper location. STABLE KILN TEMPERATURE PROFILE When there

is no movement (up or down) of the dark feed, and no changes were made on the kiln

speed, the fuel rate and the ID fan speed for the last 2 hours, and the back-end

temperature has remained stable than; The kiln temperature profile should be

considerately satisfactory and the kiln system stable, Then the burning zone should

be considered as set point for this kiln feed; When the burning zone as reached

this condition than the related back-end temperature, and gas chain temperature

should be considered as set point also for this kiln feed. TARGET SET POINT AND

OPERATION REFERENCES Whenever the operator has achieved a perfect and stable

temperature profile on the kiln system, the value of the following sensors should

be taken as references set point for future operation and are: . Back-end

temperature . Gas chain temperature . Material chain temperature . Kiln amps .

Burning zone temperature . NOx value And these values need to be correlated to the

main controllers on the kiln which are: . The feed rate to the kiln (and the type

of clinker produced) . The kiln speed . The ID fan speed . The fuel rate to kiln

. The oxygen level References and set point for operation need to be established on

each type of clinker produced and this, at the maximum feed rate on each kiln

system. Also a copy page of the kiln operation should be taken. With all these

references, the operator has all the tools to make an optimized kiln operation.

BACK END TEMPERATURE CONTROL Back End Temperature is controlled principally by 3

factors; . ID fan speed - Change in kiln exit draft (oxygen level) . Fuel rate -

Causing changes in heat input in kiln . Feed rate - From feed variations in feed

ratio, kiln speed, or dust return rate to kiln Back End Temperature control goes

hand in hand with oxygen, fuel rate and burning zone control. As a matter of fact,

whenever the operator makes an adjustment in any one of the main control variables,

he has to consider the reaction that will take place in all regions of the kiln. Of

these, the ID fan speed and the fuel rate are the usual causes for changes in back-

end temperature, as the feed rate should remain constant. THE THREE BASIC

VARIABLES Variable Conditions in the kiln are indicated by: . The Burning Zone

Temperature or dark load position, NOx signal, and kiln amps level which has the

dominant influence on the clinker quality . The Back-End Temperature or the gas

chain temperature which are the principal controls on the operation stability . The

Percentage of Oxygen in the exit gas, which governs the combustion and the fuel

efficiency

In most conditions, except for the emergencies or upset conditions, the operator

will find that these three variables can be maintained within reasonable limits by

means of adjustments of one or more of the 3 basic controls. TARGET RANGES FOR

THE THREE VARIABLES Ranges for the Three Variables For the kiln operation, it is

necessary to establish target ranges for the three variables. This information will

be supplied by the past experience and depend on the raw mix composition, clinker

type and other factors. These ranges has to be established where these variables

can safely be permitted to fluctuate without upsetting the kiln operation.

Examples of Values which have been established: target range limits Burning Zone

Temperature 2800oF (1550oC) +/- 50oF (+/- 50oC) 2750oF to 2850oF (1500oC to 1600oC)

Back-End Temperature 1450oF (800oC) +/- 20oF (+/- 20oC) 1430oF to 1470oF (780oC to

820oC) Oxygen Percentage 1.2% +/- 0.8% 0.4% to 2.0% THE THREE BASIC CONTROLS .

Fuel flow to the burner . Change in the kiln speed . Change in the speed of the ID

fan The operator needs to use one or all of its three controllers to keep these

variables inside their limits. The operator must be alert and correct any out of

range conditions as soon as it reaches the limits of tolerance.

Correction should be made promptly, but care must be exercised to avoid

overreacting as this could lead the kiln to an upset. THE 27 CONDITIONS (KURT E.

PERAY) Because any of these variables can be within, below or above the allowable

range, there are 27 possible conditions that will be encountered by the operator.

These are shown graphically in the following figure. Note that a case number has

been assigned to each condition as an aid to identification. This chart should be

used by the operators to understand the logic of good kiln operation procedures

where the Back-End Temperature, the Burning Zone Temperature and Oxygen level were

all taken in consideration in order to make a logic correction to an out of range

variable. Case Condition Action to be taken Reasons 1 BZT low Ox low BET low When

BZT is drastically low, a) reduce kiln speed b) reduce fuel rate When BZT is

slightly low, c) increase ID fan speed d) increase fuel rate a) to increase BZT

and BET b) to move Ox percentage into range c) to raise BET and Ox d) to raise BZT

and Ox into range 2 BZT low Ox low BET OK a) reduce kiln speed b) reduce fuel rate

c) reduce ID fan speed a) to raise BZT b) to raise Ox percentage into range c) to

maintain BET 3 BZT low Ox low BET high a) reduce kiln speed b) reduce fuel rate c)

reduce ID fan speed a) to raise BZT b) to increase Ox c) to reduce BET 4 BZT low Ox

OK BET low When BZT is drastically low, a) reduce kiln speed When BZT is slightly

low, b) increase ID fan speed c) increase fuel rate a) to raise both BZT and BET

b) to raise BET and Ox c) to raise BZT 5 BZT low Ox OK BET OK When BZT is

drastically low and Ox is in lower part of range, a) reduce kiln speed b) reduce

fuel rate c) reduce ID fan speed a) to raise BZT b) to raise Ox c) to maintain

BET

When BZT is slightly low and Ox is in higher part of range, d) increase fuel rate

d) to raise BZT 6 BZT low Ox OK BET high When BZT is drastically low, a) reduce

kiln speed b) reduce fuel rate c) reduce ID fan speed When BZT is slightly low and

Ox in higher part of range, d) reduce ID fan speed a) to raise BZT b) to raise Ox

c) to lower BET d) to reduce BET and raise BZT 7 BZT low Ox high BET low When BZT

is drastically low, a) reduce kiln speed b) reduce ID fan speed When BZT is

slightly low, c) increase fuel rate a) to raise both BZT and BET b) to maintain BET

c) to raise BZT and lower Ox & BET. BET should be rising also, if not keep

increasing fuel rate and ID fan speed 8 BZT low Ox high BET OK When BZT is

drastically low, a) reduce kiln speed b) reduce ID fan speed When BZT is slightly

low, c) increase fuel rate a) to raise BZT b) to maintain BET. If Ox is still

available after this move, increase fuel also c) to raise BZT and lower Ox 9 BZT