Professional Documents

Culture Documents

Iscc Texas 2017 Poster

Iscc Texas 2017 Poster

Uploaded by

Ademario JuniorOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iscc Texas 2017 Poster

Iscc Texas 2017 Poster

Uploaded by

Ademario JuniorCopyright:

Available Formats

Online direct sampling system coupled to gas chromatography

for chemical profiling of coffee roasting volatiles

Ademrio Iris da Silva 1

Junior ; Fbio Junior Moreira 2

Novaes ; Chadin 3

Kulsing ; Yada 3

Nolvachai ; Philip John Marriott 3

(1) Instituto Federal do Rio de Janeiro; (2) Universidade Federal do Rio de Janeiro; (3) Monash University;

ademario.junior@ifrj.edu.br

INTRODUCTION

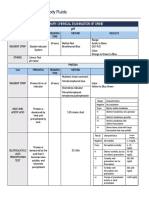

SOLID PHASE EXTRACTION APPROACH

Coffee is the 2nd commodity in the world, but coffee without roasting is 42.5

not the coffee as we know it. The best produced coffee is levelled and 50 More volatile

falls flat with bad roasting and consistent roasting is important for coffee release around 3-

Normalized Values

40 6 min ??

cupping or tasting consistency. 14.5

21.4 21.6

Coffee roasting entails an endothermic phase at first and an exothermic 30

step later. Chemical reactions inside the beans are extremely complex. 20

Routinely used indicators of roasting evolution Temperature and Color Total Semi-VOC

Heavy & Polar (HP)

are only indirectly related to this evolution. On the other hand, the 10

Heavy & Nonpolar (HN)

evolution of organic volatiles are directly related to process evolution. 0 Light & Polar (LP)

Organic volatiles can be measured with trapping systems, but usual 0-3 min

3-6 min

Light & Nonpolar (LN)

trapping devices using solid phase extraction, for example, can show bias 6-9 min

9-12 min

related to more affinity to certain classes of compounds. Direct Roasting Sampling to Gas Chromatography

There were several attempts to monitor coffee roasting directly, for

example: Near infrared of the bean wall (Santos et al., 2016), Acoustic of

the cracking system (Wilson, 2014), Electronic nose (Radi et al., 2016),

and Direct Mass Spectrometry the most successful (Dorfner et al., 2004

and Hertz-Schnemann et al., 2013).

Direct mass spectrometry objectively measures organic volatiles and

helped develop an online control of the roasting process. However, this

strategy entailed high costs and a lack of separation and identification

power the soft ionization was restricted to low-mass substances.

The direct measurement of organic volatiles developed in this work

aimed at avoid the bias (e.g. in solid phase extraction) of trapping

systems, lower the cost of studying roasting processes, improve the

separation and identification power of the whole set of volatiles and

improve the knowledge on roasting process.

METODOLOGY

100 g of green coffee beans (Coffea arabica L). 12 min of roasting at 230

C to develop the characteristic conditions associated with light roast.

Commercial benchtop air stream coffee bean roaster from Gene Caf

(model CBR-101, Gyeonggi - Do, Korea). Vacuum pump drew the

exhaust roasting gases at 5 L min-1 through the sampling system. 10-way

valve at 250 C and inlet at 300 C in splitless mode.

The chromatographic run starts with the roasting. Valve acquisition starts

at each pre-determined time. 3 s for each loop sampling, 10 loop

injections (total of 30 s for each roasting injection). GC oven at 30 C until

2.5 min after pre-determined roasting injection time, then at 10 C min-1

until 300 C that stays for 10 min. Column DB-17ht (10 m x 0.25 mm I.D.

x 0.1 m film thickness; SGE) coupled to FID at 300 C, H2 at 30 mL

min-1 and air at 300 mL min-1. Coffee bean mass loss was 13.8% w/w.

CONCLUSION

The coupling of direct roasting gas extraction to gas chromatrography is a

promising and low cost technique to monitor coffee roasting evolution

without the bias of other extraction systems, achieve higher separation

power and improve the understanding of this complex chemical process.

ACKNOWLEDGMENTS

Monash Workshop facility, Bennetts Coffees, Anne Cooper (Equilibrium

Master Roasters), Bruno de Sousa (Academia do Caf).

REFERENCES

Hertz-Schnemann, R., Dorfner, R., Yeretzian, C., Streibel, T., & Zimmermann, R. (2013). On-line

process monitoring of coffee roasting by resonant laser ionisation time-of-flight mass spectrometry:

bridging the gap from industrial batch roasting to flavour formation inside an individual coffee bean.

Journal of Mass Spectrometry, 48(12), 1253-1265. doi:10.1002/jms.3299

Radi, Rivai, M., & Purnomo, M. H. (2016). Study on Electronic-Nose-Based Quality Monitoring

System for Coffee Under Roasting. Journal of Circuits, Systems and Computers, 25(10), 1650116.

doi:10.1142/S0218126616501164

Santos, J. R., Viegas, O., Pscoa, R. N. M. J., Ferreira, I. M. P. L. V. O., Rangel, A. O. S. S., &

Lopes, J. A. (2016). In-line monitoring of the coffee roasting process with near infrared spectroscopy:

Measurement of sucrose and colour. Food Chemistry, 208, 103-110.

doi:http://dx.doi.org/10.1016/j.foodchem.2016.03.114

Wilson, P. S. (2014). Coffee roasting acoustics. The Journal of the Acoustical Society of America,

135(6), EL265-269. doi:10.1121/1.4874355.

You might also like

- 223A Master Packet 2020F 7-29Document36 pages223A Master Packet 2020F 7-29Ashara DemarestNo ratings yet

- Rate Equations MCQ QP PDFDocument5 pagesRate Equations MCQ QP PDFdovidNo ratings yet

- Caffeine in Coffee HPLC PDFDocument6 pagesCaffeine in Coffee HPLC PDFDewi WulandhariNo ratings yet

- Du 2013 Nanotechnology 24 365101Document10 pagesDu 2013 Nanotechnology 24 365101hardevNo ratings yet

- Tài liệu báo thuyết trình AVCN4Document6 pagesTài liệu báo thuyết trình AVCN4Huy Đức NguyễnNo ratings yet

- Journal Tea EngDocument7 pagesJournal Tea EngI'isyul Laili FithrohNo ratings yet

- Talanta: Nádia Reis, Adriana S. Franca, Leandro S. OliveiraDocument6 pagesTalanta: Nádia Reis, Adriana S. Franca, Leandro S. OliveiraAlex AndruNo ratings yet

- Extraction Wang - 2014 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 62 - 012035Document7 pagesExtraction Wang - 2014 - IOP - Conf. - Ser. - Mater. - Sci. - Eng. - 62 - 012035Mokr Guerrero EsperanzaNo ratings yet

- Review of Quality Coffee Degree: Roasting EvaluationDocument48 pagesReview of Quality Coffee Degree: Roasting EvaluationSadam Abagojam AbananoNo ratings yet

- From The Green Bean To The Cup of Coffee: Investigating Coffee Roasting by On-Line Monitoring of VolatilesDocument13 pagesFrom The Green Bean To The Cup of Coffee: Investigating Coffee Roasting by On-Line Monitoring of VolatilesStanley RusliNo ratings yet

- Molecules: Dissipation of Emamectin Benzoate Residues in Rice and Rice-Growing EnvironmentsDocument9 pagesMolecules: Dissipation of Emamectin Benzoate Residues in Rice and Rice-Growing EnvironmentsDiarrassoubaNo ratings yet

- Aantekeningen Molecuul Tot MedicijnDocument84 pagesAantekeningen Molecuul Tot Medicijnaliasgharkoohbori1350No ratings yet

- 2018-10 MT-KR Part 2 v02Document64 pages2018-10 MT-KR Part 2 v02davide grioniNo ratings yet

- Textbook Nanoparticles in Humans Experiments Methods and Strategies 1St Edition Ruzer Ebook All Chapter PDFDocument53 pagesTextbook Nanoparticles in Humans Experiments Methods and Strategies 1St Edition Ruzer Ebook All Chapter PDFdavid.teich900100% (9)

- Analysis of The Headspace Volatiles of Freshly Brewed Arabica Coffee Using Solid-Phase MicroextractionDocument9 pagesAnalysis of The Headspace Volatiles of Freshly Brewed Arabica Coffee Using Solid-Phase MicroextractionJosé CâmaraNo ratings yet

- Per Many Er 1989Document2 pagesPer Many Er 1989Vito AdrianNo ratings yet

- Analysis of ParaphenylenediamineDocument6 pagesAnalysis of Paraphenylenediaminetraining mandomNo ratings yet

- Poster Presentation Template 36x48Document1 pagePoster Presentation Template 36x48api-433006160No ratings yet

- 2009 - Reinvestigation of The Caffeine-Chlorogenate ComplexDocument10 pages2009 - Reinvestigation of The Caffeine-Chlorogenate ComplexnataliaNo ratings yet

- The Analytical Method Development and VaDocument25 pagesThe Analytical Method Development and VacapvirgenmonserratNo ratings yet

- Ingestion of Arti Ficial Sweeteners Leads To Caloric Frustration Memory in DrosophilaDocument10 pagesIngestion of Arti Ficial Sweeteners Leads To Caloric Frustration Memory in DrosophilawielbladNo ratings yet

- Determination of The Hydrogen Mod04 PreparationDocument3 pagesDetermination of The Hydrogen Mod04 Preparationj.s.hooglandNo ratings yet

- Gravimetric Determination of Tannins and Their Correlations With Chemical and Protein Precipitation MethodsDocument5 pagesGravimetric Determination of Tannins and Their Correlations With Chemical and Protein Precipitation MethodsErika Nafa SalsabilaNo ratings yet

- Applied and Environmental Microbiology-1958-Borzani-225.fullDocument4 pagesApplied and Environmental Microbiology-1958-Borzani-225.fullAli HusnainNo ratings yet

- 5 Extraction of Caffeine v2Document10 pages5 Extraction of Caffeine v2skyeandoNo ratings yet

- ML For Scent: Alex Wiltschko, Benjamin Sanchez-Lengeling, Brian Lee, Carey Radebaugh, Emily Reif, Jennifer WeiDocument46 pagesML For Scent: Alex Wiltschko, Benjamin Sanchez-Lengeling, Brian Lee, Carey Radebaugh, Emily Reif, Jennifer WeiInes ZBhNo ratings yet

- Coffee Taste Analysis of An EspressoDocument45 pagesCoffee Taste Analysis of An EspressoGiorgos AlaniadisNo ratings yet

- UNIDAD 1. PRACTICA. BANANA A Ripening Index For Banana Fruit Based On Starch ContentDocument2 pagesUNIDAD 1. PRACTICA. BANANA A Ripening Index For Banana Fruit Based On Starch ContentSara Jacqueline RonNo ratings yet

- Food Chemistry: M.S. Altaki, F.J. Santos, M.T. GalceranDocument6 pagesFood Chemistry: M.S. Altaki, F.J. Santos, M.T. GalceranAberuNo ratings yet

- Et ST 9 Mod-2Document14 pagesEt ST 9 Mod-2pdchemigcse1786No ratings yet

- Caffeine Extraction andDocument5 pagesCaffeine Extraction andAlam HdzNo ratings yet

- Iron and Manganese Removal From Groundwater by Chemical and A Natural Coagulant (Moringa Oleifera Seed) Aided Coagulation-Flocculation ProcessesDocument29 pagesIron and Manganese Removal From Groundwater by Chemical and A Natural Coagulant (Moringa Oleifera Seed) Aided Coagulation-Flocculation ProcessesTanusree RayNo ratings yet

- Vapor Pressure: 1.25 Mpa (9.4×10 Melting Point: 104.5-105.5 Density: 1.18 Solubility: in Water 0.9mg/l at 25Document5 pagesVapor Pressure: 1.25 Mpa (9.4×10 Melting Point: 104.5-105.5 Density: 1.18 Solubility: in Water 0.9mg/l at 25Diệu Trần QuangNo ratings yet

- Journal of Food Science - March 1971 - PANGBORN - ANALYSIS OF COFFEE TEA AND ARTIFICIALLY FLAVORED DRINKS PREPARED FROMDocument8 pagesJournal of Food Science - March 1971 - PANGBORN - ANALYSIS OF COFFEE TEA AND ARTIFICIALLY FLAVORED DRINKS PREPARED FROMhamxarehman999No ratings yet

- Design Problem Hche513 October 2022Document5 pagesDesign Problem Hche513 October 2022Takunda MsagombaNo ratings yet

- Phoshorus Xsys0015 CDocument4 pagesPhoshorus Xsys0015 CAniket DubeyNo ratings yet

- Topic 6.1 Expected Results, Limitation of Study240621Document19 pagesTopic 6.1 Expected Results, Limitation of Study240621RABI'ATUL NABILAH MOHAMAD RADZINo ratings yet

- C1 Lugtu Expt1Document5 pagesC1 Lugtu Expt1Richard EnriquezNo ratings yet

- Fluorescence of Vegetable Oils Olive Oils - 2005 - Journal of Agricultural and Food ChemistryDocument9 pagesFluorescence of Vegetable Oils Olive Oils - 2005 - Journal of Agricultural and Food Chemistrypurin phokhunNo ratings yet

- Flow Injection Spectro Photo Metric Determination ofDocument7 pagesFlow Injection Spectro Photo Metric Determination ofvjimeneztrigoNo ratings yet

- Fenvs 10 825112Document13 pagesFenvs 10 825112Luz Stella Márquez TorresNo ratings yet

- EPRW2014 Steffens Analysis of Fumigants in Cereals and Dried Fruits 93Document1 pageEPRW2014 Steffens Analysis of Fumigants in Cereals and Dried Fruits 93hüseyinNo ratings yet

- Determination of Soyabean ProteinDocument63 pagesDetermination of Soyabean Proteinghcfg7tkxkNo ratings yet

- 1 PBDocument6 pages1 PBKucing UnpadNo ratings yet

- Activated Sludge ProcessDocument3 pagesActivated Sludge ProcessYakshagna DivveNo ratings yet

- Determination of Caffeine Theobromine and Theophylline in Standard Reference Material 2384 Baking Chocolate Using Reversed Phase Liquid ChromatographyDocument5 pagesDetermination of Caffeine Theobromine and Theophylline in Standard Reference Material 2384 Baking Chocolate Using Reversed Phase Liquid ChromatographyAdab GlezNo ratings yet

- Nakai1980 ProteinDocument5 pagesNakai1980 ProteinPedro Andrés R. SánchezNo ratings yet

- tn đo tỷ trọng trích ly cà phêDocument6 pagestn đo tỷ trọng trích ly cà phêDuy PhamNo ratings yet

- CHM 260 Experiment 6 As120 5C Group 3 PDFDocument7 pagesCHM 260 Experiment 6 As120 5C Group 3 PDFnabilaNo ratings yet

- Marquez AM and Pascual MG - BSC 2B - Virtual Laboratory Report 2Document9 pagesMarquez AM and Pascual MG - BSC 2B - Virtual Laboratory Report 2John Mar OrnaNo ratings yet

- Exp 2 Protein DeterminationDocument5 pagesExp 2 Protein DeterminationNur Fadhilah100% (1)

- Trugo 1984Document4 pagesTrugo 1984Mujahid AmeenNo ratings yet

- Biosensors and Sensors For Dopamine DetectionDocument16 pagesBiosensors and Sensors For Dopamine DetectionArjun BalaramanNo ratings yet

- Foods 13 00389Document16 pagesFoods 13 00389jimmyq2006No ratings yet

- Analytical ProceduresDocument20 pagesAnalytical ProceduresAnh VõNo ratings yet

- Hamza 2018 J. Phys. Conf. Ser. 1123 012063Document10 pagesHamza 2018 J. Phys. Conf. Ser. 1123 012063Sanjay singhNo ratings yet

- Partial Purification of Anthocyanins From Brassica Oleracea (Red Cabbage)Document15 pagesPartial Purification of Anthocyanins From Brassica Oleracea (Red Cabbage)Nicol Mejías RojasNo ratings yet

- Aubf ChemsummaryDocument4 pagesAubf ChemsummaryApril Lady Faith P. PaundogNo ratings yet

- Anal Methods 2011Document9 pagesAnal Methods 2011artemNo ratings yet

- Natural Product Research: Formerly Natural Product Letters: Click For UpdatesDocument7 pagesNatural Product Research: Formerly Natural Product Letters: Click For UpdatesGustavo RuizNo ratings yet

- Fluorescence and Phosphorescence Spectroscopy: Physicochemical Principles and PracticeFrom EverandFluorescence and Phosphorescence Spectroscopy: Physicochemical Principles and PracticeNo ratings yet

- James Sebastian Utomo - The Particulate Nature of MatterDocument2 pagesJames Sebastian Utomo - The Particulate Nature of MatterIgnasia Gabriella PNo ratings yet

- Salt) Base) : Kantipur Engineering College Dhapakhel, LalitpurDocument3 pagesSalt) Base) : Kantipur Engineering College Dhapakhel, Lalitpursachin50% (2)

- Detailed TuesdayDocument32 pagesDetailed Tuesdaymscott6086No ratings yet

- Dyeing of Polyester Fabric With Disperse DyesDocument4 pagesDyeing of Polyester Fabric With Disperse DyesKushagradhi Debnath100% (2)

- Diffusion and Osmosis ChallengeDocument2 pagesDiffusion and Osmosis Challengeharasika0% (1)

- What Is A Heat Sink and Its ImportanceDocument8 pagesWhat Is A Heat Sink and Its ImportancezulNo ratings yet

- AHRI Low-GWP AREP-Literature Review PDFDocument30 pagesAHRI Low-GWP AREP-Literature Review PDFAnonymous ffje1rpa100% (2)

- Lab 7 - Phase DiagramsDocument7 pagesLab 7 - Phase Diagramsabd333No ratings yet

- Atomic Absorption Spectroscopy (Ac Slide)Document31 pagesAtomic Absorption Spectroscopy (Ac Slide)Ashraff Zaki100% (1)

- LAB 3 SHEET - MECHANICAL HEAT PUMP 2020 - Group 1Document15 pagesLAB 3 SHEET - MECHANICAL HEAT PUMP 2020 - Group 1Thaneswaran BaluNo ratings yet

- Electron Configurations and Orbital NotationsDocument2 pagesElectron Configurations and Orbital NotationsJessa BrackettNo ratings yet

- The Electrochemical CellDocument41 pagesThe Electrochemical CellRaveendra GundlapalliNo ratings yet

- CHEM333 Syllabus 2020 2021Document4 pagesCHEM333 Syllabus 2020 2021lina kwikNo ratings yet

- PRINCIPLES OF MASS TRANSFER OPERATIONS - I Volume I - Nodrm PDFDocument616 pagesPRINCIPLES OF MASS TRANSFER OPERATIONS - I Volume I - Nodrm PDFknowledge is power0% (1)

- Fentroliona NiquelDocument6 pagesFentroliona NiquelCARLOS FELIPE MEJIA GOMEZNo ratings yet

- XIIth STD CHEMISTRY (EM) LAB MANUAL PDFDocument48 pagesXIIth STD CHEMISTRY (EM) LAB MANUAL PDFVishnu PrashanthNo ratings yet

- Justice Design ProjectDocument67 pagesJustice Design ProjectEmmanuelNo ratings yet

- Problems 42Document12 pagesProblems 42mail2sgarg_841221144No ratings yet

- Lab 1 Determination of Acetic Acid in VinegarDocument20 pagesLab 1 Determination of Acetic Acid in Vinegaramiraaikharah100% (1)

- Chemistry Question PaperDocument7 pagesChemistry Question PaperVishwas Jadav50% (2)

- Corrosion Prevention 2Document329 pagesCorrosion Prevention 2Manuel GomesNo ratings yet

- Junctions ExplainedDocument4 pagesJunctions ExplainedJulio SaldanhaNo ratings yet

- Oxidation-Dominated Wear Behaviors of Carbide-Based Cermets A Comparison Between WC-WB-Co and Cr3C2-NiCr CoatingsDocument15 pagesOxidation-Dominated Wear Behaviors of Carbide-Based Cermets A Comparison Between WC-WB-Co and Cr3C2-NiCr CoatingsAbhinandan KabburNo ratings yet

- Incropera Ex 2.2 7 Ed.Document2 pagesIncropera Ex 2.2 7 Ed.luanremNo ratings yet

- SolutionDocument22 pagesSolutionDien AuliaNo ratings yet

- ExperimentDocument9 pagesExperimentsatyakrishna1234No ratings yet

- Doubble Effect Evaporator - Lab470sDocument30 pagesDoubble Effect Evaporator - Lab470swas mkNo ratings yet

- Process in Colloid and Polymer Science PDFDocument317 pagesProcess in Colloid and Polymer Science PDFMaria ClaraNo ratings yet