Professional Documents

Culture Documents

Chapt03 Cause Effect

Uploaded by

TinnysumardiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapt03 Cause Effect

Uploaded by

TinnysumardiCopyright:

Available Formats

Introduction Main steps Benefits

Chapter 3

Cause-Effect Diagrams

Marvin Rausand

marvin.rausand@ntnu.no

RAMS Group

Department of Production and Quality Engineering

NTNU

(Version 0.1)

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 1 / 14

Introduction Main steps Benefits

Slides related to the book

System Reliability Theory

Models, Statistical Methods,

and Applications

Wiley, 2004

Homepage of the book:

http://www.ntnu.edu/ross/

books/srt

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 2 / 14

Introduction Main steps Benefits

What is a cause-effect diagram?

I A tool to identify, explore, and graphically display in increasing detail

all the possible causes related to a specified problem

I The cause-effect diagram is established by a team of analysts

I The analysis is based on brainstorming

I Created by Professor Kaoru Ishikawa, Tokyo University in 1943

I Adopted by W. Edwards Deming

I Also known as Ishikawa or Fishbone diagrams

I A cause-effect diagram is not a quantitative tool

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 3 / 14

Introduction Main steps Benefits

Why use cause-effect diagrams?

In the context of this book, a cause-effect diagram may be used:

I To identify all the possible causes of a (system or subsystem) fault

I To display the relationship between the causes and the fault

I To suggest solutions to the problems

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 4 / 14

Introduction Main steps Benefits

Step 1

Identify, describe, and delimit the main problem (e.g., a system fault).

Briefly describe the problem in a box at the right-hand side of a page, draw

a long arrow across the page pointing at the box. The arrow is sometimes

referred to as the spine of the (fishbone) diagram

System fault

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 5 / 14

Introduction Main steps Benefits

Step 2

Agree on 4-7 main categories of causes (e.g., manpower, methods, materials,

machinery, milieu). Draw arrows pointing at the main arrow (spine), and

write a category of causes in a box at the end of each arrow.

Materials Methods Manpower

System fault

Milieu Machines

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 6 / 14

Introduction Main steps Benefits

Step 3

For each category (e.g., Materials), identify factors that may contribute to

the main problem.

I Factors are identified by repeatedly asking: Which factors may

contribute within this category?

I Carefully define and delimit each factor.

I Draw arrows pointing at the categorys arrow and enter the factors

identified

Materials Methods Manpower

Inadequate

material

System fault

Too high

humidity

Milieu Machines

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 7 / 14

Introduction Main steps Benefits

Step 4

For each factor (e.g., Too high humidity), identify sub-factors (i.e., causes)

that may contribute to the factor. Define and delimit the sub-factors and

draw arrows pointing to the arrow from the factor.

Materials Methods Manpower

Inadequate

material

System fault

Too high

humidity

Milieu Machines

Continue the identification of sub-factors and sub-sub-factors until the

desired level of resolution is reached.

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 8 / 14

Introduction Main steps Benefits

Step 4 Example

Assume that we are analyzing an automobile that has crashed and

identified the factor Brake failure. This factor may be further analyzed by

asking the following questions:

Question Possible answer

Why did the brakes fail? Brake pads were worn

Why were the brake pads worn? They were not checked

Why were they not checked? The automobile was not properly ser-

viced

Why was the automobile not properly The importance of regular servicing

serviced? was not realized

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 9 / 14

Introduction Main steps Benefits

Step 5

Analyze the obtained cause-effect diagram.

I Check the logic and the completeness of the diagram

I Look for causes that appear repeatedly

I Look for what you can measure in each cause so you can quantify the

effects of the changes you make

I Identify and circle the causes you can take action on

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 10 / 14

Introduction Main steps Benefits

Step 6

Prioritize and plan actions.

I Decide which of the cause-effect chains that are the most likely causes

of the problem (e.g., system fault)

I Identify actions needed to remove the causes or reduce the likelihood

of the problem

I Decide on

What to do?

Who is going to do it or be responsible?

When should it be done?

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 11 / 14

Introduction Main steps Benefits

Categories of causes - 1

Categories for Step 2 used in the manufacturing industry are:

I Machine (technology)

I Method (process)

I Material (incl. raw materials, consumables, information)

I Manpower (physical work) and Mindpower (brainwork)

I Measurement (inspection)

I Milieu (the environment)

Two additional categories are sometimes added:

I Management / Money power

I Maintenance

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 12 / 14

Introduction Main steps Benefits

Categories of causes - 2

Categories for Step 2 used in the service industry are:

I Surroundings

I Suppliers

I Systems

I Skills

I Safety

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 13 / 14

Introduction Main steps Benefits

Benefits

I It generates a structured list of possible causes of the specified problem

(e.g., a system fault)

I The graphical form of the diagram helps to present the results to others

I The causes can be prioritized

I It encourages group participation and makes use of group knowledge

I It uses an orderly, easy-to-read format to show the cause-effect

relationships

I It increases the system knowledge and helps the participants learn

more about factors influencing the system performance

I It identifies areas where data should be collected for further study

Marvin Rausand (RAMS Group) System Reliability Theory (Version 0.1) 14 / 14

You might also like

- Chapt03 Fta PDFDocument29 pagesChapt03 Fta PDFrodrigo_domNo ratings yet

- 083 Moan Structural ReliabilityDocument22 pages083 Moan Structural ReliabilitypachernyangyuenNo ratings yet

- Wamit Theory ManualDocument66 pagesWamit Theory Manualspsingh72No ratings yet

- TMR4225 Marine Operations - 7b - Offshore Loading Operations - 2020Document37 pagesTMR4225 Marine Operations - 7b - Offshore Loading Operations - 2020Manoj GuptaNo ratings yet

- Chap4 - 1 Time To FailureDocument36 pagesChap4 - 1 Time To FailureKhushboo BansalNo ratings yet

- SeafemDocument87 pagesSeafemPriscila KImNo ratings yet

- Application of Lifetime Models in Maintenance (Case Study: Thermal Electricity Generation in Sudan)Document14 pagesApplication of Lifetime Models in Maintenance (Case Study: Thermal Electricity Generation in Sudan)IOSRjournalNo ratings yet

- Supply Chain Hurricane Tabletop Exercise: Situation ManualDocument24 pagesSupply Chain Hurricane Tabletop Exercise: Situation ManualKarthik PrasadNo ratings yet

- 11 ReliabilityDocument21 pages11 ReliabilityAnkit NayakNo ratings yet

- Event Tree Analysis: SverdrupDocument13 pagesEvent Tree Analysis: SverdrupRachmah RizkyNo ratings yet

- 0132554909Document22 pages0132554909vil66No ratings yet

- MARIN Seminar 04oct2016 v2Document59 pagesMARIN Seminar 04oct2016 v2anon_723643771No ratings yet

- 10 - Chapter 4 PDFDocument30 pages10 - Chapter 4 PDFOscar Kelvin NsituNo ratings yet

- 03 Failure Distribution r1Document8 pages03 Failure Distribution r1Jie Lucas TzaiNo ratings yet

- Lac-Mégantic Runaway Train and Derailment Investigation SummaryDocument13 pagesLac-Mégantic Runaway Train and Derailment Investigation SummaryJustin MassieNo ratings yet

- Reliability-Based Bridge Assessment Using Risk-Ranking Decision AnalysisDocument9 pagesReliability-Based Bridge Assessment Using Risk-Ranking Decision AnalysissalmanNo ratings yet

- Introduction To PHM - AC3EDocument95 pagesIntroduction To PHM - AC3EJorgeNo ratings yet

- Fault TreeDocument30 pagesFault TreeMTECH IPSNo ratings yet

- AHP With Different Scoring MethodDocument23 pagesAHP With Different Scoring MethodTeny SylviaNo ratings yet

- Reliability Engineering Lec Notes #3Document4 pagesReliability Engineering Lec Notes #3peach5No ratings yet

- Contoh Tugas Fatigue-Fracture Mech 2017Document2 pagesContoh Tugas Fatigue-Fracture Mech 2017Raymond DanielleNo ratings yet

- Miem M.ADocument33 pagesMiem M.AMuhamad sairul azhar bin yaNo ratings yet

- Markov Chains: Mathematics Applications & Interpretation HLDocument26 pagesMarkov Chains: Mathematics Applications & Interpretation HLBennaya KendranaNo ratings yet

- ME 5702 Module 3 System ReliabilityDocument75 pagesME 5702 Module 3 System ReliabilityIgnacio Ceballos100% (1)

- Assignment/ Tugasan - Emergency Response ManagementDocument9 pagesAssignment/ Tugasan - Emergency Response Managementsya assignment0% (1)

- Learning To See - From End To EndDocument47 pagesLearning To See - From End To EndGabriel TortoleroNo ratings yet

- Balancing Uncertainty in Structural DecisionDocument10 pagesBalancing Uncertainty in Structural DecisionAfifi MohammadNo ratings yet

- Environmental Stress Screening TutorialDocument30 pagesEnvironmental Stress Screening TutorialMariut Elena LarisaNo ratings yet

- NASA Reliability PracticesDocument28 pagesNASA Reliability PracticesvicenteqNo ratings yet

- Stochastic Fatigue, Fracture and Damage AnalysisDocument37 pagesStochastic Fatigue, Fracture and Damage AnalysisVinayaga Murthy GNo ratings yet

- Dynamic Response of Fixed Offshore Structures Under Environmental LoadsDocument16 pagesDynamic Response of Fixed Offshore Structures Under Environmental LoadsxautraixxxxxxNo ratings yet

- 1 Free Trial: STAAD - Pro Structural Engineers 2 Handbook of Titration 3 Download This To PDF Start DownloadDocument9 pages1 Free Trial: STAAD - Pro Structural Engineers 2 Handbook of Titration 3 Download This To PDF Start DownloadAbsec PandaNo ratings yet

- Failure Modes & Effects Analysis: Project Activities in Which The FMEA Is UsefulDocument10 pagesFailure Modes & Effects Analysis: Project Activities in Which The FMEA Is Usefulpajaro1111111No ratings yet

- Mass and Energy Analysis of Control VolumesDocument22 pagesMass and Energy Analysis of Control VolumesYeiLan StasiaNo ratings yet

- Abaqus Interaction ModuleDocument10 pagesAbaqus Interaction Modulephineasferb02No ratings yet

- Repairable and Non-Repairable Items: When Only One Failure Can OccurDocument70 pagesRepairable and Non-Repairable Items: When Only One Failure Can OccurEdin100% (1)

- Matrix Approach To Perform Dependent Failure Analysis in Compliance With Functional Safety StandardsDocument6 pagesMatrix Approach To Perform Dependent Failure Analysis in Compliance With Functional Safety StandardsDuewee87No ratings yet

- Fault Tree AnalysisDocument6 pagesFault Tree AnalysisJon JimmyNo ratings yet

- Fracture MechanicsDocument174 pagesFracture Mechanicsroijen_pkNo ratings yet

- Root Cause Analysis: Marvin RausandDocument16 pagesRoot Cause Analysis: Marvin RausandSunil GurubaxaniNo ratings yet

- FmecaDocument43 pagesFmecaOsvaldo Jimenez100% (1)

- PhaDocument36 pagesPhaSathish KumarNo ratings yet

- EMT 480 Reliability & Failure AnalysisDocument38 pagesEMT 480 Reliability & Failure AnalysisK ULAGANATHANNo ratings yet

- FmecaDocument46 pagesFmecarobigedNo ratings yet

- Chapt 14Document19 pagesChapt 14fakhriNo ratings yet

- TRIZ and Root Cause Analysis Article by Karen GaddDocument15 pagesTRIZ and Root Cause Analysis Article by Karen GaddTameta DadaNo ratings yet

- Reliability Evaluation and Risk Based Maintenance in A Process PlantDocument8 pagesReliability Evaluation and Risk Based Maintenance in A Process PlantMectrosoft Creative technologyNo ratings yet

- A Dempster-Shafer Theory-Based Approach To The Failure Mode, Effects andDocument11 pagesA Dempster-Shafer Theory-Based Approach To The Failure Mode, Effects and弘瑞 蒋No ratings yet

- FMEA DeckDocument20 pagesFMEA Deckgogisetty100% (1)

- TRIZ Method by Genrich AltshullerDocument5 pagesTRIZ Method by Genrich AltshullerAnonymous JyrLl3RNo ratings yet

- Nasa FMEA Presentation PDFDocument28 pagesNasa FMEA Presentation PDFgowtham raju buttiNo ratings yet

- Week 9: Lecture Notes / SAFE DESIGN: Safety Is A Management DecisionDocument5 pagesWeek 9: Lecture Notes / SAFE DESIGN: Safety Is A Management DecisionJustinAddodNo ratings yet

- Part 2 Risk Management White Paper D02Document3 pagesPart 2 Risk Management White Paper D02crackatowa100% (1)

- MainFEMA SKH PDFDocument46 pagesMainFEMA SKH PDFswapan kumar hazraNo ratings yet

- Introduction To Failure ModeDocument10 pagesIntroduction To Failure ModeAMIT THAKKARNo ratings yet

- Hazard IdentificationDocument43 pagesHazard IdentificationMANISH BHADAURIANo ratings yet

- PE1 APP21 - What-If Checklist Procedure (Rev B, Nov 02)Document6 pagesPE1 APP21 - What-If Checklist Procedure (Rev B, Nov 02)Mohamed MostafaNo ratings yet

- Prem Kumar SDocument24 pagesPrem Kumar SPrem KumarNo ratings yet

- Chapter No. 1: 1.1 Problem Statement (FMEA) Failure Mode Effect Analysis of Welding Defects of Beam AssemblyDocument27 pagesChapter No. 1: 1.1 Problem Statement (FMEA) Failure Mode Effect Analysis of Welding Defects of Beam AssemblyharshalNo ratings yet

- Biodegradability of SurfactantsDocument1 pageBiodegradability of SurfactantsTinnysumardiNo ratings yet

- Federal Register / Vol. 60, No. 183 / Thursday, September 21, 1995 / Proposed RulesDocument2 pagesFederal Register / Vol. 60, No. 183 / Thursday, September 21, 1995 / Proposed RulesTinnysumardiNo ratings yet

- Calibration, Validation and Verification of Equipment, Instruments and Other DevicesDocument2 pagesCalibration, Validation and Verification of Equipment, Instruments and Other DevicesTinnysumardiNo ratings yet

- Minireview Escherichia Coli in The Environment: Implications For Water Quality and Human HealthDocument8 pagesMinireview Escherichia Coli in The Environment: Implications For Water Quality and Human HealthTinnysumardiNo ratings yet

- Zoning in Processing Facilities 375003 7Document2 pagesZoning in Processing Facilities 375003 7TinnysumardiNo ratings yet

- Rlu PDFDocument7 pagesRlu PDFTinnysumardiNo ratings yet

- Escherichia Coli O157:H7 Issues and Ramifications: Executive SummaryDocument12 pagesEscherichia Coli O157:H7 Issues and Ramifications: Executive SummaryTinnysumardiNo ratings yet

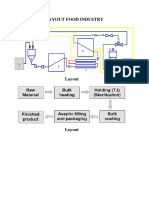

- Layout Food IndustryDocument2 pagesLayout Food IndustryTinnysumardiNo ratings yet

- Monitoring Suhu Dan RH WH Starch 2Document4 pagesMonitoring Suhu Dan RH WH Starch 2TinnysumardiNo ratings yet

- Escherichia Coli O157:H7 Strains Isolated From EnvironmentalDocument7 pagesEscherichia Coli O157:H7 Strains Isolated From EnvironmentalTinnysumardiNo ratings yet

- BookDocument155 pagesBookTinnysumardiNo ratings yet

- Infant Formula RecallDocument4 pagesInfant Formula RecallTinnysumardiNo ratings yet

- International Formula Council: Formerly The Enteral Nutrition Council and Infant Formula CouncilDocument6 pagesInternational Formula Council: Formerly The Enteral Nutrition Council and Infant Formula CouncilTinnysumardiNo ratings yet

- Broken Squares - Unfreezing Team Building ExerciseDocument4 pagesBroken Squares - Unfreezing Team Building Exerciselilywhite786No ratings yet

- Calcium Carbonate Lab ReportDocument2 pagesCalcium Carbonate Lab ReportAlexander Weber0% (1)

- Case Study1: Partnering For Success: Working Together: How Biotech Firms and Large Drug Companies Bring Pharmaceutical Products To MarketDocument2 pagesCase Study1: Partnering For Success: Working Together: How Biotech Firms and Large Drug Companies Bring Pharmaceutical Products To MarketLakhan SinghNo ratings yet

- CAPEX Acquisition ProcessDocument5 pagesCAPEX Acquisition ProcessRajaIshfaqHussainNo ratings yet

- Project Documentation - Sensorflex 30G Data SheetDocument15 pagesProject Documentation - Sensorflex 30G Data SheetOmar HectorNo ratings yet

- Homeless Class ActionDocument36 pagesHomeless Class ActionMichael_Lee_RobertsNo ratings yet

- Engineering Knowledge Syllabus PDFDocument3 pagesEngineering Knowledge Syllabus PDFsumitNo ratings yet

- Manusia LemahDocument8 pagesManusia LemahKhoirul MubinNo ratings yet

- C Programming Bit Bank U-1, U-2Document17 pagesC Programming Bit Bank U-1, U-2HariahNo ratings yet

- Policing System Indonesia PolicingDocument5 pagesPolicing System Indonesia Policingdanilo bituin jrNo ratings yet

- The Watchmen Novel AnalysisDocument10 pagesThe Watchmen Novel AnalysisFreddy GachecheNo ratings yet

- Guidelines On Setting Up A Newman Fellowship 2017-2018Document6 pagesGuidelines On Setting Up A Newman Fellowship 2017-2018Liz McFeelyNo ratings yet

- Law Sample QuestionDocument2 pagesLaw Sample QuestionknmodiNo ratings yet

- Dlis103 Library Classification and Cataloguing TheoryDocument110 pagesDlis103 Library Classification and Cataloguing Theoryabbasimuhammadwaqar74No ratings yet

- Karbohidrat: Gula, Pati & SeratDocument20 pagesKarbohidrat: Gula, Pati & SeratAlfi Syahrin SiregarNo ratings yet

- Pros and Cons of AbortionDocument14 pagesPros and Cons of AbortionSuman SarekukkaNo ratings yet

- ECB Priority III: Deutz - Starter MotorDocument7 pagesECB Priority III: Deutz - Starter MotorMarcelo OlivaresNo ratings yet

- Your Brain Is NOT A ComputerDocument10 pagesYour Brain Is NOT A ComputerAbhijeetNo ratings yet

- HOPE 2A MODULE 1 Introduction To SportsDocument11 pagesHOPE 2A MODULE 1 Introduction To SportsChristian Ray Lucnagan ReyesNo ratings yet

- DS ClozapineDocument3 pagesDS ClozapineMiggsNo ratings yet

- Sample Information For Attempted MurderDocument3 pagesSample Information For Attempted MurderIrin200No ratings yet

- Aditya Man BorborahDocument4 pagesAditya Man BorborahAditya BorborahNo ratings yet

- Math - Gr6 - Q2 - Week-08 - Comparing and Arranging Integers On The Number LineDocument37 pagesMath - Gr6 - Q2 - Week-08 - Comparing and Arranging Integers On The Number LineDiana TubigNo ratings yet

- Chapter 1Document25 pagesChapter 1Aditya PardasaneyNo ratings yet

- Au 170Document1 pageAu 170Ida Bagus Gede PalgunaNo ratings yet

- The Til Pat YearsDocument1 pageThe Til Pat Yearsrajkumarvpost6508No ratings yet

- Maths-Term End Examination-2020-2021 (2020-2021, MATHS)Document6 pagesMaths-Term End Examination-2020-2021 (2020-2021, MATHS)Venkat Balaji0% (1)

- Las Math 2 Q3 Week 1Document6 pagesLas Math 2 Q3 Week 1Honeyjo Nette100% (7)

- SLS Ginopol L24 151-21-3-MSDS US-GHSDocument8 pagesSLS Ginopol L24 151-21-3-MSDS US-GHSRG TNo ratings yet

- 12-List of U.C. Booked in NGZ Upto 31032017Document588 pages12-List of U.C. Booked in NGZ Upto 31032017avi67% (3)