Professional Documents

Culture Documents

Tool Reconditioning: Normal Wear Heavy Wear Excessive Wear

Uploaded by

almedin0 ratings0% found this document useful (0 votes)

7 views1 pagedsadsadsa

Original Title

Tool Reconditioning

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdsadsadsa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageTool Reconditioning: Normal Wear Heavy Wear Excessive Wear

Uploaded by

almedindsadsadsa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Tool Reconditioning

We design and manufacture our tools to provide maximum performance and tool life. We also pro-

vide factory reconditioning services. Using our reconditioning services guarantees performance you

can depend on and can drive your return on investment.

Our Process

Tools are reground on the same state-of-the-art CNC equipment as originally manufactured. Tools

are sent through a rigorous before and after coating inspection process.

Special Request Capabilities

In addition to reconditioning, tool modifications are also available:

End work only

Cutting diameter only

Recoating

Monitoring your specified minimum length of cut requirements

Current resharpening count marked on the shank

Additional modifications during reconditioning

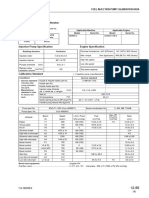

Total Cost of Tooling Over 400 Parts

(based on HEV-R-50500-R.030)

Savings

[Figure 1.0]

Normal Wear 150.26 99.14

Heavy Wear 163.36 86.04

Excessive Wear 176.45 72.95

No Resharps 249.00

0 50 100 150 200 250

Dollar Amount

Reconditioning Terms & Conditions

Minimum 3/8 tools and larger

Helical Solutions tools only

Minimum order quantities may apply

Reconditioning form can be downloaded from our website

You might also like

- 6CTA8 3-GcatalogDocument2 pages6CTA8 3-Gcatalogmardalan nabisukNo ratings yet

- Cylindrical Roller Bearing Technical CharacteristicsDocument12 pagesCylindrical Roller Bearing Technical CharacteristicsFrancisNo ratings yet

- CAT ELECTRONIC TECHNICIAN REPORTDocument17 pagesCAT ELECTRONIC TECHNICIAN REPORTJalel SaidiNo ratings yet

- 6CTA8 3-G2 (ZIt)Document10 pages6CTA8 3-G2 (ZIt)nam phạmNo ratings yet

- Amico As Scroll Air Systems Sell SheetDocument4 pagesAmico As Scroll Air Systems Sell SheetCAROLINA MONGUINo ratings yet

- HP600Document2 pagesHP600xinpu shanNo ratings yet

- DFM 2021Document42 pagesDFM 2021Damian DariusNo ratings yet

- DFM 2021Document42 pagesDFM 2021Damian DariusNo ratings yet

- Series: Hydraulic MotorsDocument11 pagesSeries: Hydraulic MotorsSchweisteger 14No ratings yet

- Motor Maintenance: General InspectionDocument3 pagesMotor Maintenance: General InspectionWaskito AjiNo ratings yet

- Service Guide: Valvoline Professional SeriesDocument13 pagesService Guide: Valvoline Professional SeriesBenNo ratings yet

- Bearingcalculation 1596707809178Document1 pageBearingcalculation 1596707809178spannerradyperkasaNo ratings yet

- Activity Centre Pool Rate ($/driver) Zodiac NovelleDocument5 pagesActivity Centre Pool Rate ($/driver) Zodiac NovelleShewanti ShendeNo ratings yet

- MM1500i UK 1.4 DS 014 0218Document3 pagesMM1500i UK 1.4 DS 014 0218budi handoyo100% (1)

- Group 00 General Manual PrecautionsDocument28 pagesGroup 00 General Manual PrecautionsGPRNo ratings yet

- Profit (Sales-Cost of Sales) 110,000.00Document4 pagesProfit (Sales-Cost of Sales) 110,000.00Rajshri SaranNo ratings yet

- Cat Electronic Technician 2019C v1.0 Product Status ReportDocument5 pagesCat Electronic Technician 2019C v1.0 Product Status ReportLimosh BsNo ratings yet

- Spec Check - AMMANN ASC 170 DDocument3 pagesSpec Check - AMMANN ASC 170 DOli MijanaNo ratings yet

- D31!37!39ShopM T&a BeforeProof 1Document74 pagesD31!37!39ShopM T&a BeforeProof 1data9999No ratings yet

- Cameron CCDocument6 pagesCameron CCYogesh Badhe100% (1)

- Appoint Graisse Pour RoulementDocument1 pageAppoint Graisse Pour RoulementLassaad GoubantiniNo ratings yet

- qsk23 Data SheetDocument2 pagesqsk23 Data SheetMuhammad IshfaqNo ratings yet

- Maintenance Methodology: By, Tanweer Saiyad Assistant Manager Mechanical PI IndustriesDocument72 pagesMaintenance Methodology: By, Tanweer Saiyad Assistant Manager Mechanical PI IndustriesTanweer SaiyadNo ratings yet

- Mechanical Drying Equipment FinalDocument8 pagesMechanical Drying Equipment Finalvijaypal2000100% (1)

- Cost Theory & Analysis (CH 5)Document20 pagesCost Theory & Analysis (CH 5)sandeepanNo ratings yet

- John Deere Lubrication and Maintenance Service Interval Chart - Omrg39578 - Servic...Document4 pagesJohn Deere Lubrication and Maintenance Service Interval Chart - Omrg39578 - Servic...Rick Van den BosNo ratings yet

- Testing and adjusting standard value table for Komatsu WB146-5 backhoe loaderDocument39 pagesTesting and adjusting standard value table for Komatsu WB146-5 backhoe loaderLuis Gustavo Escobar MachadoNo ratings yet

- The Basics of Lubricants For KunriDocument60 pagesThe Basics of Lubricants For KunriwaleedtanvirNo ratings yet

- Komatsu PC400LC-7L A86001 TESTDocument408 pagesKomatsu PC400LC-7L A86001 TESTHai Van100% (2)

- Cost of Production: BS-BA (2 Years) Microeconomics Dr. Ayaz Ahmed Date: 01/12/2020Document13 pagesCost of Production: BS-BA (2 Years) Microeconomics Dr. Ayaz Ahmed Date: 01/12/2020Muhammad HassanNo ratings yet

- 107E-1 Engine Standard Value TableDocument41 pages107E-1 Engine Standard Value TableWr Sb100% (1)

- Daewoo l136 Operationing ManualDocument10 pagesDaewoo l136 Operationing Manualchelsea100% (50)

- General Discussions On Lubricating OilsDocument59 pagesGeneral Discussions On Lubricating OilsHari PurwadiNo ratings yet

- Equipment Economics: Dr. Mallikarjun Pillalamarry Department of Mining and Process Engineering Polytechnic of NamibiaDocument50 pagesEquipment Economics: Dr. Mallikarjun Pillalamarry Department of Mining and Process Engineering Polytechnic of Namibiaanon_622910368No ratings yet

- The Basics of Lubricants For WaterpumpDocument59 pagesThe Basics of Lubricants For WaterpumpwaleedtanvirNo ratings yet

- MANN+HUMMEL Oil-Wetted Air Cleaners GuideDocument4 pagesMANN+HUMMEL Oil-Wetted Air Cleaners GuideZubin PatelNo ratings yet

- Reciprocating Air Compressors AmicoDocument4 pagesReciprocating Air Compressors AmicoONURNo ratings yet

- OverheadsDocument25 pagesOverheadsankit_katarya100% (6)

- 13-2103471 Engine Friction and LubricationDocument25 pages13-2103471 Engine Friction and LubricationDime Sac100% (1)

- Re 530 CatalogDocument12 pagesRe 530 CatalogCarlos Antonio Gonzalez MendozaNo ratings yet

- 0 402 066 733ab Fuel Injection Pump Calibration DataDocument1 page0 402 066 733ab Fuel Injection Pump Calibration Datahichkiim KukuNo ratings yet

- Overheads: Faculty: Zaira AneesDocument59 pagesOverheads: Faculty: Zaira AneesVishal MalhiNo ratings yet

- A Holistic Approach to Cost Control and ReductionDocument79 pagesA Holistic Approach to Cost Control and ReductionIshrat BanuNo ratings yet

- Service Manual Ve d12Document32 pagesService Manual Ve d12ramsi17100% (1)

- Low Load and Low Sulphur Fuel Operation On Two Stroke Diesel EnginesDocument51 pagesLow Load and Low Sulphur Fuel Operation On Two Stroke Diesel EnginesTziouris Vasileios100% (1)

- Cat Electronic Technician 2019C v1.0 Product Status ReportDocument5 pagesCat Electronic Technician 2019C v1.0 Product Status ReportLIMOSHNo ratings yet

- Bearing selection and lubrication settingsDocument1 pageBearing selection and lubrication settingsLassaad GoubantiniNo ratings yet

- The Aquatarder SWR For Mercedes-Benz TrucksDocument6 pagesThe Aquatarder SWR For Mercedes-Benz TrucksArtemio QCNo ratings yet

- Adh2 14 SEER - High Efficiency - R410aDocument6 pagesAdh2 14 SEER - High Efficiency - R410atitomottaNo ratings yet

- Detroit S60 SpecsDocument2 pagesDetroit S60 Specsgrgramm50% (2)

- Faizan Bhai Overhead WorkingDocument3 pagesFaizan Bhai Overhead WorkingSalman SajidNo ratings yet

- ASYS-OA-008992-R1Baker HughesDocument2 pagesASYS-OA-008992-R1Baker HughesateeqrahNo ratings yet

- 小松再制造产品型号简介Document8 pages小松再制造产品型号简介Yan Zhao100% (1)

- FA 13 DepreciationDocument53 pagesFA 13 DepreciationStuti GargNo ratings yet

- Bill - Hyundai - Santro Xing - MH12DE4121Document7 pagesBill - Hyundai - Santro Xing - MH12DE4121Neeraj CharateNo ratings yet

- 8 Costs Production 2022Document40 pages8 Costs Production 2022Pletea GeorgeNo ratings yet

- Overheads Allocation and ApportionmentDocument60 pagesOverheads Allocation and ApportionmentNesto Yohana SadukaNo ratings yet

- Cat Electronic Technician 2020C v1.0 Product Status ReportDocument5 pagesCat Electronic Technician 2020C v1.0 Product Status ReportLimosh BsNo ratings yet

- CHM 100 001 01Document1 pageCHM 100 001 01almedinNo ratings yet

- 55 MMMMMMDocument10 pages55 MMMMMMalmedinNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1Document9 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1almedinNo ratings yet

- My WorkpieceDocument1 pageMy WorkpiecealmedinNo ratings yet

- ReadmeDocument4 pagesReadmeexcArnesNo ratings yet

- Read MeDocument1 pageRead MealmedinNo ratings yet

- My ToolDocument1 pageMy ToolalmedinNo ratings yet

- ReadmeDocument4 pagesReadmeexcArnesNo ratings yet

- Machining Tolerance For 303SSTDocument11 pagesMachining Tolerance For 303SSTnick10686No ratings yet

- Read MeDocument1 pageRead MealmedinNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1Document9 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1almedinNo ratings yet

- Maga For TextDocument48 pagesMaga For TextalmedinNo ratings yet

- Cat Bowl SummaryDocument1 pageCat Bowl SummaryalmedinNo ratings yet

- Software License AgreementDocument7 pagesSoftware License Agreementalmedin100% (1)

- In Class & HW - 2/22/2017 (001) - 2/23/2017 (002) : Create The Isometric View of The Following ObjectsDocument4 pagesIn Class & HW - 2/22/2017 (001) - 2/23/2017 (002) : Create The Isometric View of The Following ObjectsalmedinNo ratings yet

- CHM 100 001 01Document1 pageCHM 100 001 01almedinNo ratings yet

- Gasket Drawing PDFDocument1 pageGasket Drawing PDFalmedinNo ratings yet

- ThreadDocument4 pagesThreadalmedinNo ratings yet

- Cat Bowl SummaryDocument1 pageCat Bowl SummaryalmedinNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1Document9 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1almedinNo ratings yet

- Mounting details for wall-mounted cooling unitsDocument4 pagesMounting details for wall-mounted cooling unitsalmedinNo ratings yet

- Gasket DrawingDocument1 pageGasket DrawingalmedinNo ratings yet

- 11.845.000 (A) Fluted Axle 50mmDocument1 page11.845.000 (A) Fluted Axle 50mmalmedinNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1Document9 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1almedinNo ratings yet

- Balinit DLC Pin On DiscDocument2 pagesBalinit DLC Pin On DiscalmedinNo ratings yet