Professional Documents

Culture Documents

Order Analysis PDF

Uploaded by

rizzo8Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Order Analysis PDF

Uploaded by

rizzo8Copyright:

Available Formats

Order Analysis

Analyzing the health and behavior of Synchronization usually starts with a you fill the block just as you get the

rotating machinery is a key applica- tachometer, which provides a pulse next tachometer pulse? Three

tion for dynamic signal analyzers or an integral number of pulses for techniques are commonly used.

(DSAs). Rotating machines produce each revolution. This signal indicates

repetitive vibrations and acoustic that the machine has finished one • Shaft encoders are electro-optical

signals related to rotational speed. cycle and is beginning the next. A devices that generate thousands of

These relationships are not always single tach pulse indicates when the digital pulses per revolution, gating

obvious with standard dynamic signal rotating machine has reached a time samples into the data block.

analysis, particularly with variations particular angular position. After

in the rotational speed. A measure- capturing two tach pulses, you can • A ratio synthesizer and tracking filter

ment technique called order analysis determine rotating speed by counting emulates a shaft encoder with alias

is the secret to sorting out all the clock cycles between the tach pulses. protection.

many signal components that a A third pulse will then tell you if the

rotating machine can generate. machine is changing speed. Using the • With the digital resampling technique,

tach pulse to trigger the DSA syn- the DSA digitizes data at a very high

Synchronizing the measurement chronizes the machine and the rate, collecting and storing tightly

With flexible settings for frequency measurement. spaced time samples. As tach pulses

span and resolution, a typical DSA arrive, the analyzer resamples the time

can do a great job of isolating noise DSAs use an analog-to-digital con- points into correctly spaced data.

and vibration components, as long as verter to collect a block of data. In

the machine is operating at a fixed regular spectrum analysis, this block With each of these three techniques

speed. As the speed changes, how- of data consists of voltage values the goal is a set of points evenly

ever, the signals of interest shift up or spaced at regular time intervals. spaced by shaft position, not by time

down in frequency, making analysis When you start gathering a block of (Figure 1). This yields data in the

difficult if not impossible. Synchroniz- such points, you also determine the revolution domain, rather than in the

ing the DSA’s data collection with the finish time. This is one of the difficul- time domain. Again, the key benefit

machine’s rotational speed is there- ties with order analysis. If the here is that the measurement rate

fore a key step in order analysis. machine is changing speed, how do tracks the rotational speed of the

machine.

Frequency spectrum vs.

order spectrum

Figure 1: The FFT process transforms time

Time Domain Shaft Position domain data to the frequency

Samples Samples domain, creating a spectrum. Signals

If samples are Synchronizing

gathered at equal

that are periodic (repetitive) in the

samples to shaft

time intervals, the position gives a time domain appear as peaks in the

number of samples constant number of frequency domain. In order analysis

per cycle will vary. points per cycle. the FFT transforms the revolution

Vibration Transducer Vibration Transducer domain data into an order spectrum.

Signals that are periodic in the

revolution domain appear as peaks in

Tachometer the order domain. For example, if a

vibration peak occurs twice every

revolution at the same shaft position,

a peak appears at the second order in

the order spectrum.

35670A 35670A

DYNAMIC SIGNAL ANALYZER DYNAMIC SIGNAL ANALYZER

MARKER D I S P L AY MARKER D I S P L AY

What do order spectra look like?

MEASUREMENT MEASUREMENT

Figure 2 is an FFT spectrum map of

an automobile engine run-up test

SYSTEM SYSTEM

from 665 to 3995 RPM. Figure 3 is an

order spectrum map of the same

measurement. The Y-axis in both

maps is amplitude. The X-axis is

frequency for the spectrum map and

orders of rotation for the order map.

Equal Time Spacing Equal Position Spacing

Realtime Update / Fall 1996 - Winter 1997 / Hewlett-Packard 1

Frequency spectrum map of 6 cylinder engine run-up

One obvious difference between the

two maps is how the peaks line up.

Each line of peaks on the order map

clearly indicates a relationship

between vibration and shaft position; Figure 2:

the peaks in the spectrum map are A frequency map

reveals peaks but it

difficult to relate to shaft speed. The is difficult to relate

maximum amplitude in the order map them to shaft

is at the 12th order and at 3815 RPM. speed.

This identifies the vibration in terms

of engine speed, indicating a compo-

nent is being excited 12 times per

each engine revolution.

Order tracking

In Figure 3, the 12th order appears to

be the most interesting, so you want

to examine that order and to ignore

the other orders. When you measure Order spectrum map of 6 cylinder engine run-up

one order and exclude the others, the

measurement is called an order track.

Figure 4 shows this 12th order

amplitude versus RPM for the engine

run-up.

In the order track measurement, the

relationship between the measured

order vibration and the engine speed

is clear. Order tracking helps you

focus on exact components and to Figure 3:

An order map

measure their contribution to the clarifies the

overall performance of a rotating relationships

machine. between shaft

speed and vibration

Orders are essentially harmonics. But amplitude.

unlike harmonics, many interesting

orders are noninteger multiples of

the 1st order. A speed reducer has an

output shaft order vibration at less

than the first order. An automobile

engine has order components that

are higher ordered noninteger Order track of 12th order, 6 cylinder engine run-up

multiples. These may be gear mesh

rates, timing chain engagement or

valve action, for instance.

Applications

Order tracking and order analysis

have become widely accepted

rotating machinery measurements.

Devices ranging from gear motors to

gas turbines are tested this way. Even

dental tools have been designed using

order analysis. Some of the more Figure 4:

unusual applications involve using Order tracking

order analysis to measure power line clarifies the

quality and for loudspeaker testing. relationship of a

These applications take advantage of particular shaft

speed to amplitude

the harmonic nature of the integer vs. rpm.

orders.

2 Realtime Update / Fall 1996 - Winter 1997 / Hewlett-Packard

You might also like

- Cummins Service Tool Bench Calibration 3377791 PDFDocument8 pagesCummins Service Tool Bench Calibration 3377791 PDFDuy Kha100% (4)

- GMW3172 GM Worldwide Engineering StandardsDocument97 pagesGMW3172 GM Worldwide Engineering Standardsrizzo8100% (2)

- Vibration Signal Analysis PDFDocument11 pagesVibration Signal Analysis PDFmicky1389No ratings yet

- Chapter-6 Seismic Data ProcessingDocument19 pagesChapter-6 Seismic Data Processingtarunag72801No ratings yet

- Vibration AnalysisDocument31 pagesVibration AnalysisDinesh Mohitkar50% (2)

- An Introduction To Time Waveform AnalysisDocument21 pagesAn Introduction To Time Waveform AnalysisMohd Asiren Mohd Sharif100% (3)

- Spectrum Analyzer PDFDocument18 pagesSpectrum Analyzer PDFAgus SantosaNo ratings yet

- Vibration Signature Plots PDFDocument18 pagesVibration Signature Plots PDFMohammedBujairNo ratings yet

- Digital Signal ProcessingDocument271 pagesDigital Signal ProcessingPECMURUGAN100% (3)

- Vibration AnalyzersDocument16 pagesVibration Analyzersyogacruise100% (1)

- An Introduction To Time Waveform AnalysisDocument17 pagesAn Introduction To Time Waveform AnalysisBassemNo ratings yet

- Order Tracking AnalysisDocument51 pagesOrder Tracking AnalysisWon-young SeoNo ratings yet

- 6c06dataacq OrderDocument2 pages6c06dataacq OrderUmer MukhtarNo ratings yet

- En 15085-1 2007Document10 pagesEn 15085-1 2007rizzo8No ratings yet

- Understanding Spectrum AnalyzerDocument32 pagesUnderstanding Spectrum AnalyzerRonNo ratings yet

- Vibration Analysis and Signal Processing in LabVIEWDocument12 pagesVibration Analysis and Signal Processing in LabVIEWJam Bab100% (1)

- Bently Book Chapter 4 Timebase Plots1Document18 pagesBently Book Chapter 4 Timebase Plots1Manuel L LombarderoNo ratings yet

- Draft Format - Method Statement of Commissioning NURSE CALLDocument12 pagesDraft Format - Method Statement of Commissioning NURSE CALLmohammed naseer uddinNo ratings yet

- EN12299-Evaluation of Ride Comfort For Rail Passengers (Alternative To ISO2631)Document24 pagesEN12299-Evaluation of Ride Comfort For Rail Passengers (Alternative To ISO2631)rizzo8100% (1)

- Ultrasonic TestingDocument36 pagesUltrasonic TestingRaj Kumar100% (4)

- l9000 Led Light Source User Guide (English Only Version)Document37 pagesl9000 Led Light Source User Guide (English Only Version)ismael0% (2)

- Chapter 4 Timebase PlotsDocument18 pagesChapter 4 Timebase PlotsNavid DavaniNo ratings yet

- Orbitas y Medición de Fases - Analisis VibraciónDocument2 pagesOrbitas y Medición de Fases - Analisis VibraciónRamon A. Ruiz O.No ratings yet

- 0rderanalys1s eDocument12 pages0rderanalys1s eLittle RascalNo ratings yet

- Vibration Engineering Reviewer FNDocument12 pagesVibration Engineering Reviewer FNBea Daniella CuaresmaNo ratings yet

- Angle Domain Processing BBMDocument4 pagesAngle Domain Processing BBMAlvaro CotaquispeNo ratings yet

- Modal Analysis and Condition Monitoring PDFDocument5 pagesModal Analysis and Condition Monitoring PDFJolito RamosNo ratings yet

- Research PaperDocument6 pagesResearch PaperKassaye GizawNo ratings yet

- Glosario Términos de Análisis de VibracionesDocument34 pagesGlosario Términos de Análisis de VibracionesgabrielNo ratings yet

- Basic Processing - Definitions - Presentation - From - Xsgeo-Dot-Com - 1999Document9 pagesBasic Processing - Definitions - Presentation - From - Xsgeo-Dot-Com - 1999Muhammad BilalNo ratings yet

- Time Domain Analysis With Copper Mountain Technologies PDFDocument19 pagesTime Domain Analysis With Copper Mountain Technologies PDFDaniel RomeroNo ratings yet

- Programing: Vehicle TestingDocument7 pagesPrograming: Vehicle TestingwerNo ratings yet

- 6c06dataacq Order VxiDocument2 pages6c06dataacq Order VxipcgibsonNo ratings yet

- Processing For Improved Spectral AnalysisDocument5 pagesProcessing For Improved Spectral AnalysisEric BechhoeferNo ratings yet

- A New Approach To Transient Processing in The Phase Vocoder: IRCAM, Analysis-Synthesis Team, FranceDocument6 pagesA New Approach To Transient Processing in The Phase Vocoder: IRCAM, Analysis-Synthesis Team, FranceJamesNo ratings yet

- The Relation Between Range Sampling Rate, System Bandwidth, and Variance Reduction in Spectral Averaging For Meteorological RadarDocument7 pagesThe Relation Between Range Sampling Rate, System Bandwidth, and Variance Reduction in Spectral Averaging For Meteorological Radarlpgx1962No ratings yet

- Module 3Document36 pagesModule 3ARJUN BEDI204005No ratings yet

- Fundamentals Os Signal ProcessingDocument16 pagesFundamentals Os Signal ProcessingSergio OrtegaNo ratings yet

- Capgo - Vibration MonitoringDocument3 pagesCapgo - Vibration MonitoringSufean SakinNo ratings yet

- Time To Frequency: The Transformation From DomainDocument20 pagesTime To Frequency: The Transformation From DomainCharmi PanchalNo ratings yet

- An 756Document12 pagesAn 756steviej85No ratings yet

- Data Acquisition Definitions: A. M. GanoDocument59 pagesData Acquisition Definitions: A. M. GanoaymanganoNo ratings yet

- Operating Deflection Shapes From Time Versus Frequency Domain MeasurementsDocument8 pagesOperating Deflection Shapes From Time Versus Frequency Domain MeasurementsOscar Daga CaravantesNo ratings yet

- Week 3 Chapter 2Document35 pagesWeek 3 Chapter 2Nouran YNo ratings yet

- Reviewer Vibration FinalsDocument6 pagesReviewer Vibration FinalsBea Daniella CuaresmaNo ratings yet

- Time Series Well LoggingDocument8 pagesTime Series Well LoggingAryan KhanNo ratings yet

- TimeFrequencyFiltering Brandenb99Document8 pagesTimeFrequencyFiltering Brandenb99Anonymous FGY7goNo ratings yet

- Ultrasound Analog Electronics Primer: by Bill OdomDocument3 pagesUltrasound Analog Electronics Primer: by Bill OdomMaha SoeNo ratings yet

- Vibration Analysis4Document37 pagesVibration Analysis4nagarajangopiNo ratings yet

- Toautocj 6 913Document6 pagesToautocj 6 913Nemer RaslenNo ratings yet

- Inertia Identification For The Speed Observer of The Low Speed Control of Induction MachinesDocument9 pagesInertia Identification For The Speed Observer of The Low Speed Control of Induction MachinesBorislav BrnjadaNo ratings yet

- Digital CommunicationDocument2 pagesDigital CommunicationHarshal SonarNo ratings yet

- Lecture38-Vibration Measurement Techniques - Data Acquisition and AnalysisDocument11 pagesLecture38-Vibration Measurement Techniques - Data Acquisition and Analysiskaran5singh-12No ratings yet

- AF1 Cesar Betancourt 1884251Document4 pagesAF1 Cesar Betancourt 1884251Cesar Eduardo Perez BetancourtNo ratings yet

- Mode ShapesDocument11 pagesMode ShapesCheenu SharmaNo ratings yet

- Rise Time 3dB Bandwidth Relationship Lab FactDocument26 pagesRise Time 3dB Bandwidth Relationship Lab Factvotasugs756No ratings yet

- Vibration Analysis Dictionary: AccelerationDocument36 pagesVibration Analysis Dictionary: Accelerationkamal arabNo ratings yet

- Source Coding Pulse Code Modulation (PCM)Document35 pagesSource Coding Pulse Code Modulation (PCM)nabeel hasanNo ratings yet

- 5989-8794EN - What Is The Difference Between An Equivalent Time Sampling Oscilloscope and A Real-Time Oscilloscope PDFDocument8 pages5989-8794EN - What Is The Difference Between An Equivalent Time Sampling Oscilloscope and A Real-Time Oscilloscope PDFskyhorseNo ratings yet

- Application of Wavelet Synchrosqueezing TransformDocument4 pagesApplication of Wavelet Synchrosqueezing TransformUma TamilNo ratings yet

- Digital Signal ProcessingDocument6 pagesDigital Signal ProcessingNemanja StevanovićNo ratings yet

- Running Modes AnalysisDocument15 pagesRunning Modes AnalysisVili KamenovaNo ratings yet

- Basic DefinitionsDocument23 pagesBasic DefinitionsVivek MarwadeNo ratings yet

- Do You Know How To Analyse Radio Signals 1700044979Document1 pageDo You Know How To Analyse Radio Signals 1700044979yahyacomm1No ratings yet

- Glossary of Commonly Used Vibration and Vibration Control TermsDocument5 pagesGlossary of Commonly Used Vibration and Vibration Control Termshasen kushlafNo ratings yet

- An Improved Analog Waveforms Generation Technique Using Direct Digital SynthesizerDocument4 pagesAn Improved Analog Waveforms Generation Technique Using Direct Digital SynthesizergezahegnNo ratings yet

- Preliminary Hazard AnalysisDocument40 pagesPreliminary Hazard Analysisrizzo8No ratings yet

- CV Joints and DriveshaftsDocument14 pagesCV Joints and Driveshaftsrizzo8No ratings yet

- GB 4208 Chinese StandardDocument32 pagesGB 4208 Chinese Standardrizzo8No ratings yet

- Iso GD&TDocument39 pagesIso GD&TSanjay Kumar SinghNo ratings yet

- Beaufort Wind ScaleDocument2 pagesBeaufort Wind Scalerizzo8No ratings yet

- MIL Standard For Tyre TestDocument1 pageMIL Standard For Tyre Testrizzo8No ratings yet

- F1971-05 Test Method For Tire Electrical ResistanceDocument4 pagesF1971-05 Test Method For Tire Electrical Resistancerizzo8No ratings yet

- BRT Standard 20141 PDFDocument60 pagesBRT Standard 20141 PDFrizzo8No ratings yet

- Falancs User en PDFDocument784 pagesFalancs User en PDFrizzo8No ratings yet

- BRT Standard 20141 PDFDocument60 pagesBRT Standard 20141 PDFrizzo8No ratings yet

- Beaufort Wind ScaleDocument2 pagesBeaufort Wind Scalerizzo8No ratings yet

- Iso GD&TDocument39 pagesIso GD&TSanjay Kumar SinghNo ratings yet

- Falancs User enDocument784 pagesFalancs User enrizzo8No ratings yet

- ECE R54 RegulationDocument72 pagesECE R54 Regulationrizzo8No ratings yet

- BRT Standard 20141 PDFDocument60 pagesBRT Standard 20141 PDFrizzo8No ratings yet

- Fatigue Under Mean ConditionsDocument6 pagesFatigue Under Mean Conditionsrizzo8No ratings yet

- Beaufort Wind Scale: Developed in 1805 by Sir Francis Beaufort of EnglandDocument2 pagesBeaufort Wind Scale: Developed in 1805 by Sir Francis Beaufort of Englandrizzo8No ratings yet

- BSEN 1370 - 2000. Examination of Surface ConditionDocument15 pagesBSEN 1370 - 2000. Examination of Surface Conditionrizzo8100% (1)

- Surge Protection Domestic and International StdsDocument28 pagesSurge Protection Domestic and International Stdsrizzo8No ratings yet

- BG 15 Error Code Lisit and State Signaling-1-1-1-1Document29 pagesBG 15 Error Code Lisit and State Signaling-1-1-1-1FuadNo ratings yet

- About AT&T Internet Service Provider - TechfreetricksDocument4 pagesAbout AT&T Internet Service Provider - TechfreetricksIqra SameerNo ratings yet

- Catalog - Broadcast and Entertainment Connector ProductsDocument32 pagesCatalog - Broadcast and Entertainment Connector ProductsОльга КолчинNo ratings yet

- Manual de Cámara Domo PTZ (Inglés - Francés - Alemán - Italiano - Español) para (WP-245W - WP-25505W - WP-244W)Document119 pagesManual de Cámara Domo PTZ (Inglés - Francés - Alemán - Italiano - Español) para (WP-245W - WP-25505W - WP-244W)yogyamadNo ratings yet

- K16A Training ManualDocument59 pagesK16A Training ManualAndrewWerdnaNo ratings yet

- Synchronous Optical Networking (Sonet)Document6 pagesSynchronous Optical Networking (Sonet)vickyNo ratings yet

- Goodwe Smart MeterDocument2 pagesGoodwe Smart MeterZakiNo ratings yet

- Unit 1 MOS Fabrication TechnologyDocument86 pagesUnit 1 MOS Fabrication TechnologyChinna ChowdaryNo ratings yet

- Vibracord: Digital Vibration MeterDocument5 pagesVibracord: Digital Vibration MeterAbdiyasa Dharma InovasiNo ratings yet

- Experiment 3: Channel Effects Elazegui, Diann Claire L.: Equation 1Document5 pagesExperiment 3: Channel Effects Elazegui, Diann Claire L.: Equation 1Diann ElazeguiNo ratings yet

- Dielectric Device KHB0914A01: Technical DataDocument2 pagesDielectric Device KHB0914A01: Technical DataJim LiebNo ratings yet

- E2209wf - Monitor - 44 - 51Document51 pagesE2209wf - Monitor - 44 - 51Davi TavaresNo ratings yet

- Chap3 Ftrans PDFDocument4 pagesChap3 Ftrans PDFRanz KopaczNo ratings yet

- MCP130 300 PDFDocument16 pagesMCP130 300 PDFdenisandreiNo ratings yet

- T14 PDFDocument99 pagesT14 PDFSSENo ratings yet

- Watkins Johnson ReceiversDocument42 pagesWatkins Johnson Receiversemulador05No ratings yet

- Implementation of Standalone PV Micro Grid With Multi-Level Converters For Rural ElectrificationDocument6 pagesImplementation of Standalone PV Micro Grid With Multi-Level Converters For Rural ElectrificationSakshiDawarNo ratings yet

- DC Characteristics of A CMOS Inverter: Out inDocument31 pagesDC Characteristics of A CMOS Inverter: Out insai jagadeeshNo ratings yet

- 9781107059320-SOLUTIONS Essential Digital SolutionsDocument47 pages9781107059320-SOLUTIONS Essential Digital SolutionsGulrez MNo ratings yet

- Hipath 1100 Hipath 1120 Hipath 1150 Hipath 1190: Service ManualDocument389 pagesHipath 1100 Hipath 1120 Hipath 1150 Hipath 1190: Service ManualLuis Suarez100% (1)

- Loop AntennaDocument12 pagesLoop Antennaalkesh.eng100% (1)

- Presentation List Int 2023Document16 pagesPresentation List Int 2023125Jonwin Fidelis FamNo ratings yet

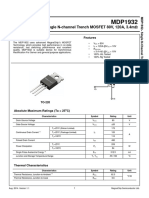

- MDP1932 MagnaChipDocument6 pagesMDP1932 MagnaChipVanderMucioNo ratings yet

- ANSI C82.3-2002 For Lamp Ballasts - Reference Ballasts For Fluorescent LampsDocument20 pagesANSI C82.3-2002 For Lamp Ballasts - Reference Ballasts For Fluorescent LampsJose Luis Perez RodriguezNo ratings yet

- EE 201 - HW 1 Solutions W2007Document11 pagesEE 201 - HW 1 Solutions W2007mrm3zaNo ratings yet

- Learning Activity 3 / Actividad de Aprendizaje 3 Evidence: Cell Phones For Sale / Evidencia: Celulares A La VentaDocument3 pagesLearning Activity 3 / Actividad de Aprendizaje 3 Evidence: Cell Phones For Sale / Evidencia: Celulares A La VentaKaventinas SASNo ratings yet

- Wechip w1 Wireless Fly Air Mouse Rechargeable 2 4ghz Wireless Gyro Sensor Keyboard Remote ControllerDocument2 pagesWechip w1 Wireless Fly Air Mouse Rechargeable 2 4ghz Wireless Gyro Sensor Keyboard Remote ControllerMach MachhiNo ratings yet