Professional Documents

Culture Documents

Chiller Design PDF

Uploaded by

Chahbi Ramzi0 ratings0% found this document useful (0 votes)

20 views16 pagesOriginal Title

chiller design.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views16 pagesChiller Design PDF

Uploaded by

Chahbi RamziCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

Pa APPLICATION

WATER PIPING

Form 1505, 25-AD

TABLE OF CONTENTS

GENERAL, Se

DEFINITIONS

ABBREVIATIONS .

CONVERSION VALUES

WATER PIPING CLASSIFICATION

PIPE SIZING

DESIGN LIMITATIONS

STANDARD SCHEDULE 40 PIPE. 2. 1.

SEAMLESS COPPER TUBING -

VELOCITY & PRESSURE DROP OF PIPE

VELOCITY & PRESSURE DROP OF COPPER TUBING

RESISTANCE OF VALVES AND FITTINGS

RESISTANCE OF SMOOTH COPPER TUBING

RESISTANCE OF FAIRLY SMOOTH PIPE.

RESISTANCE OF FAIRLY ROUGH PIPE .

RESISTANCE OF ROUGH PIPE

WATER PIPING FOR COOLING TOWER SYSTEM

WATER PIPING FOR CLOSED RE-CIRCULATION SYSTEM

20

10

R

GENERAL

Water lines should be selected for optimum size

with respect to)

Initial Cost

Operaticn and Maintenance Cost

Water Velocity

Pressure Drop

It is desirable to have line sizes as small as possi

ble from the standpoint of low initial cost.

How-

ever, small pipe sizes produce high water velocity

and pressure drop,

High water velocity may re-

sult in noise problems as well as rapid erosion and

early failure of the pips

High pressure drop will

increase pump operating cost and may require a

larger size pump.

DEFINITIONS

1

APPROACH ~ Is the difference in degrees

F. between the temperature of the water

Ieaving the tower basin and the wet bulb

temperature of the air entering the cooling

BLEED-OFF ~ Is the wasting to the drain

of @ small part of the circulating water to

control the buildup and concentration of

scale forming chemicals in the water.

COOLING RANGE ~ Is the number of

Segrees F. which the water is cooled while

passing through the cooling tower, It is

the difference in temperature of the water

entezing the cooling tower and the water

leaving the tower basin.

DRIFT ~ Is the amount of water lost in the

form of droplets which ig carried awey by

the circulating air. Drift is completely

independent of evaporation loss

EQUIVALENT FEET - Any component in

a water piping system creates friction

loss (Pressure Drop). Tests have estab-

Lshed the rate of friction loss in terms of

length of straight pipe. For example, an

elbow with @ rating of 5 equivalent fect has

the same friction loss as 5 feet of straight

pipe.

MAKE-UP ~ Is the water required to be

added to the eysiem to replace that which

has been lost due to evaporation, drift,

bleed-off oF leakage

ABBREVIATIONS

FPS = Feet Per Second, Velocity

GPM — = Gallons Per Minute, Flow Rate

PSI = Pounds Per Square Inch, Pressure

EO.FT. Equivalent Feet

CONVERSION VALUES

Pressure érop may be given in ject of

water or pounds per equare inch. To

2,

3.

(a) Pounds per square inch to feet of

water multiply by 2.31.

(o) Feet of water to pounds per square

inch multiply by / 434.

1 cubic foot of water

7.48 Gallons

= 62.4 Pounds

I gallon of water = 8.34 Pounds

= 0,133 Cubie Feet

WATER PIPING CLASSIFICATION

There are two primazy clatsifications of water

piping systems

A

Systems

An Open,

Open eve

Once through type where water flows

from a reservoir through piping to the

equipment and is relieved to a different

Re-circulation type where water flows

from a reservoir through piping to the

equipment and is returned to the original

reservoir for reveircalation,

are further classified as

Open ~ when water ie brought in close

contact with air in the reservoir

Closed ~ when water does not come in

close contact with air in the reservoir.

Expansion Tank does net constitute an

ie a6 the water contact with the air is

very limited.

EXAMPLES:

1

All pipin,

atmospheric pressure is exe

the water.

Open once through type:

(a) City water system.

(b) Water cooled condenser of air con-

ditioner with regulating value is.

charging water fo drain,

Open re-cizeulation type:

(a) Water cooled condenser of air con=

ditioner operated with cooling tower.

Closed re-circulation type:

(a) Water chiller with coil heat exchanger

for cooling and de-humifying the aff

(0) Hot water boiler with coil heat ex-

changer for heating the air.

1B systems have at least one point where

fod on the surface of

‘This is the reference point for deter

mination of hydrostatic lift imposed on the pump.

‘The hydrostatic lift is the vertical distance in fest

between

the water level on the suction side of the

pomp and the highest water level on the discharge

Bide of the pump.

In an open system, the suction reservoir may be

ata different elevation than the discharge reser~

voir. The pump must overcome the frictional

losses of the system, plus the hydrostatic Lit,

or the difference in elevation between the two

reservoirs. Refer to FIG. 1.

Ina closed system a pamp must overcome only

the frictional resistance of the system. The dis-

charge reservoir is also the suction reservoir so

there is no difference in elevation and consequently

no hydrostatic lift for the pump to overcome. See

FIG. 2.

PIPE SIZING

‘The design of a piping system is limited by:

Maximum velocity permissible which is

‘established by:

(a) Noise generated by water flowing

through piping.

(0) Erosion of piping by water and en-

treined sand, air and other foreign

particles

2. Friction loss:

(a) Once through systems must be sized

te provide the required flow at =

ssure loss within the pressure

Available after all other losses (Con-

Genser Pressure Drop, Hydrostatic

and Line, Valve and Fitting Losses)

have been deducted,

piscHarGe

RESERVOIR

JAtMosPHenic|

ATMOSPHERIC] yyoROSTATIC

urr

_

COOLING TOWER,

FIG. 1— Hydrostatic Litt

(b) Re-circulating pump systems are

sized to provide a reasonable balance

between increased pumping horse=

power due to high friction loss and

increased piping first cost due t

larger pipe tizes.

DESIGN LIMITATIONS:

Velocity — between 3 and 10 feet per

second.

2. Friction Loss = maximum 20 feet per

100 feet equivalent length.

‘The eystem ghould be laid out with valves, fittings,

Jength of runs and water quantities shown for all

mains and branches. The size of the mains should

be determined first and tabulated as shown in

Table 6. The pressure chould be indicated at the

points in the system where branch runouts are

taken. It will then be possible to determine the

available pressure drop across each unit being fed

from the main system so that pipe, valves and

fitting sizes may be determined. In this way, it

may be possible to use smaller eizes of branch

Funouts than would nozmally be considered good

practice. All available pressure érop should be

used in the branch to require a minimum of adjust-

ment to equalize pressures and volume of flew.

Each pipe size selection should inelude a compari-

son between the initial installation cost and the

operation and maintenance cost. Good engineering

practice may permit the selection of more than one

size for a given rate of flow.

a

ae

PLATE TYPE HEAT

—sTI

FIG, 2— Closed water System

TABLE 1— STANDARD SCHEDULE 40 PIPE

Grose-Sectionat =

Nominal External Internal Internal Area Volume

Size Diameter Diameter

Inches Toehes aches Sq. ta, Sa, Fhe Gallon Per

j nt) Fe) Foot Length

Ve 0.840 0.622 0.304 9.00211 10158

aa 1050 oles 01533 9,00370 0277

? usis 1049 01864 0, 0060 Jaa

1/4 1.660 11380 1150 00205 o777

nie 100 tee zoe olo1s2 f0s8

2 2375 21067 3136 010233 hita

nin 2875 21469 a9 010333 ‘aa9

3 31500 31088 73 0.0513 aes

e1/2 +5000 31548 989 0.0606 isla

4 4.500 4.026 12:7 0.0883 261%

5 51563 5.047 2010 01139 108

‘ 6625 6.065. 2819 012005 1150

TABLE 2— SEAMLESS COPPER TUBING

Cross-Sectional

Volume

Size Nominal External Internal ‘Thickness Earmal dies.

inches | Pipe Size | Diameter | Type | Diameter | of Metal en

OD. | ‘inches | “inches inches | “Inches | sq. an. | Sq. pe. | OMSR?

Ge | ea | LES

38 ve 1395 « 3.308 0, 035 0.073 | ,000507 |. 00379

L 0.518 0030 1078 | !o00ss0 | ‘ooaoa

we 3/8 500 x | oaoe 0. 089 0.127 | -co0se2 |. 00860

z | oato 0.035 orgs | Loo10r 0753

5/8 We 1625 K 0.527 0.049 0.218 | .0011 | .o1s

S E | oss 0.040 0.233 | loose | fo121

aa 3/8 750 K 0.652 0, 049 0.333 | , 00232 oir

L__|_ ose 0,042 o3e8 | looese ota

ve 3/4 875 x | ors 0, 065 0.436 | . 00302 0227

a 0.085 ol4es | ‘00336 0280

rie 1 1s «| 0.995 0. 065 0.778 | 00580 |. 040s

L 1,025 0.050 01825 | ‘oos73 O42

rave | va Tavs x 1285 0. 088 Laz | 0087 634

L 1.263 0.058 136 | loos7s 0655

rae | inive 165 © 1481 0.072 Li | 019 0894

> L 1505 0.060, Ure | Sone 0925

ze 2 215 ® 959 0.083) 301 | .0209 157

L 2985 0! 070 sito | Sean aie

25/6 | ease 2.625 « 2.435 0. 095 4.66 242

Ez a6s 0.080 ant 2

18 3 31s K 2.907 0. 109 6.64 av

c | Faas 0.090 a 354

x58 | sue 3.625 K 3.385 0. 120 300 | 0624 488

L 33s 0: 100, si2t | Losao ras

ze z eas * 3857 aise fina cele 7607

3 31908 oie fate O34 623

5-1/8 3 5.15 «| aos o10 [isa 126 -940

2 E | tes ois | 18:7 Go ion

1/8 ¢ 6.185 E Sal 0.192 ‘25.9 179 13s

c | sas oo fee 188 139

TABLE 3— VELOCITY (FPS) & PRESSURE DROP (Ft, of Water Per 100 Ft.) OF FAIRLY ROUGH PIPE

Nominal Pipe Diameter, Inches

eva 1 asa 3/2

Pres. v

Drop Drop Drop Drop | Y* | prop

Fi, Fe Fe Fr

Fe Fe s

Water water | FPS | water] FPS | water | FPS [water || FPS | worse

Pres,

Drop

ope | ver. Vel.

FPS

15,

sale | 2.

sre | 2

go | 3,

7

1

Bal

nis | 2.

ass | 4.

46.2 5!

6

8

1

B

100

+—— Nominal Pi

opm | ver.

ipe Diameter, Inches

72 2

Pres, Pres, Pres,

el vel. el.

Drop "| prep |e! | peop’ |] ¥ | drop Yee | os

Fe Fe Fe Fh

Water water | FPS | waver | FPS | water Water || FPS

9

Vel.

FPS

wpe

so | 3.

60 | 4

70 | 4,

go | 5.

90 | 6.

o.

3

100

150 |i

200 |1

250

300

400

300

600

700

800

900

2000

1500

TABLE 4— VELOCITY (FPS) & PRESSURE DROP (Ft, of Water per 100 Ft.) OF TYPE L SMOOTH

COPPER TUBING

‘Seamless Tubing O,D, Inches

5/8 7/8 11/8 1-3/8 15/8 21/8

Press Pres, Pres, Pres.

Drop | Yel | Drop| Ye | beset] ve | Bre ven.

Fi Ft Ft Fi || Ft Fie

Water || FPS | water] FPS | wares || PPS | water | FPS | water | FPS | woese

2.8

83

164 fz.

az] 2,

3e2 ff 3.

é

3.

Pres.[ ya) | Bree

cpm } vel,

Drop] rep

4

5

3.9] 67

5.9 | 134

20 78 | 2107

97

ur

3

sza |} 6 i

44.0 |] 717] tee

2 | 2708

2,

30 1

100 1

Seamless Tubing 0, D. Inches

is sie 51/8 E

Pres, Pres,

prop | ¥** | prop

178

y, Pres va, | Prem Pres,

cpm [ver ver. | Bree as

FE, Fi Fe Fi

Water Water || F?5 | water | FPS | water

vel.

FPS

30

60

70

80

90

100

150

200 %.

20 1

300

400

500,

600 1

700 1

00 1

900

1000

1500

TABLE 5— RESISTANCE OF VALVES AND FITTINGS, EQUIVALENT LENGTH STRAIGHT PIPE IN FEET

Tray sweep

case | ciove stencera steneara [SEES | stanaare

wominat vake | Waive | fale | Stve [Saat] Sabre | 9 eibow” | siandace

sn Full Open [rul'Open | rutf'Ozen [all pen | slow | eitow [mittee | stat Gu

aes

ee A a & O)ele lal &

Teas 7 a [ee i ae

va | oon | | a fon ss pe [20 he 43

1 pea [oe re [a3 [es ze Bs

rie [io ops va | ne | 3s Be zs

CC TC ee xe ne

[ee ie a as [ee

2.1/2 2.469 Lt 65 a 17.0 3.0 6.5 4.0 14.0 3

3 [ee [oar CC TC 30 | ane

ie | ae0 [0 |] sae Pa 0 | a0

[ems es ae Pe Pa a a

EC xo | 20

aces Tas se ea oe ae jae) 33.8

Leow ee. ter TOTSL stim (eden + 25%

easy AMF +9 OU for City

THe

QO

S Wht 1s Tyvek LHe ones

E See whe ew sven 12

~ HOS ts Uelocry anf

FLOW GALLOWS PER MINUTE

Kssue 2

PRESSURE onOF (psi PER 100 LIN. FT.)

NOTE: DIAMETERS AME EXPRESSED AS NOMINAL’ pipe size

REPRODUCED By PERMISSION OF HEATING AND VENTILATING FROM SATA OF THE

NATIONAL BUREAU OF STANDARDS, COPYRIGHT 1965 BY THE INDUSTAIAL oReES

FIG. 3— Resistance to Flow of Water Through Smooth Copper Tubing

FLOW GALLONS PER MINUTE

| j

PRESSURE DROP (PS! FER 100 LIN, FT.) .

REPRODUCED SY PERMISSION OF HEATING AND VENTILATING FROM DATA OF THE

NATIONAL BUREAU UF STANDARDS, COPYRIGHT 1965 BY THE INDUSTRIAL PRESS

FIG. 4— Resistance to Flow of Water Through Fairly Smooth Pipe

FLOW GALLONS PER MINUTE

100

SURE DROP (PSI PER 100 LIN, FT.)

a REPRODUCED BY PERMISSION OF HEATING AND VENTILATING FROM DATA OF THE

NATIONAL BUREAU OF STANDARDS, COPYRIGHT 1965 BY THE INOUSTRIAL PRESS

FIG. 5— Resistance to Flow of Water Through Fairly Rough Pipe

9

FLOW GALLONS PER MINUTE

PRESSURE DROP (PSI PER 100 LIN, FT.)

REPRODUCED BY PERMISSION OF HEATING AND VEKTILATING FROM DATA OF THE

NATIONAL BUREAU OF STANDARDS, COPYRIGHT 1965 BY THE INDUSTRIAL PRESS.

NIG. 6— Resistance to Flow of Water Through Rough Pipe

r else Pere 100! tht

FTE ther IS Coe Eirrine'a

WATER PIPING FOR COOLING TOWER SYSTEM 4. 5 Fe, hydrostatic lift of tower.

‘To solect the proper water piping for « cooling 5. 6 standare 90° elbows

tower ayster, the following information suet be 3 fate valves

svallable 1 Eandnrd tee thru side outlet

1 Stancard tec straight tira

1. Gallons of water per minute to be eir=

Slate 8. Schedule 40 Pipe (Assume to have

“Fairly Rough" interior surface)

2. Total length of piping.

3. Presoure drop across condenser (this

varies widely and must be obtained from Solutio:

equipment manufacturer).

Make preliminary selection of 1-1/2" standard

4, Hydrostatic lift of tower. schedule 40 pipe ac Table 3 gives 5.6 feet per

second velocity at flow rate of 30 GPM.

5. Number of valves, fittings and any other

resistances in piping system. 80 feet of 1-1/2" standard pipe = 80.0

6 standard 90° elbows @4.5 Ft. (Table 5) = 27.0

6. Type of pipe used (Copper Tubing or Iron 2 gate valves @.9 Ft. (Table 5) Le

Pipe). 1 standard teo side outlet @ 7.5 (Table 5) = 7.5

1 standard tee straight thru @ 3. 0(Table 5) =_3.0

Sample Selection: (Refer to Fig. 7) TOTAL EQUIVALENT FEET TI3.3

1, 30 GPM of water to be circulated, From Table 3 the pressure drop for 30 GPM of

water flowing thru l-1/2" standard pipe is 13.4

2. 80 Ft, of total piping. feet per 100 fect of pipe.

5ah.ce, isa

3. 11.4 PSI pressure drop across condenser 13.4 Ft. of water x 119.3 EO.FT. | 16.0 Ft.

at 30GPM. STOO Linear Ft. of water

Rp kt acer *

i oe

10 eau

(

oO

J

spaine eLeep-orr

Loaney Pressure Sona

meueeer So

PASS VALVE,

ume

concironer:

COBEN ER alveswan

FIG. 7— Typical Water Cooling Tower Arrangement

WATER

cooLine

TOWER

overrLow

TO ORAIN

ves

Total length of piping ~ 80 Ft,

Design water flow ~ 30 GPM

Pressure drop across condenser @ 30 GPM

= ila Pst

Hydrostatic lift across tower = 5 FL

6 standard 90° elbows

2 Gates valves

1 standard tee thru side outlet

1 standard tee straight thru

Pressure érop due to pipe and fittings = 16.0 Fe

Prescure érop due to cond. (11.4 pet x

2.31 Fe. /psi = 26.3 Fr,

Pressure drop due to hydrostatic list

TOTAL Head for selection of pump

5.0 Fe

War

Select « pump to circulate 30 GPM of water oper-

ating against a total head of 48 fect,

‘The 1-1/2" pipe is satisfactory since the velocity

and friction loss are within recommended limits

Ifa 2" pipe had been selected, the water velocity

and friction loss would be less with corresponding

lower pump horsepower requirement but with

greater initial cost due to the larger size pipes,

valves and fittings. (Would require « pump capa

ble of circulating 30 GPM of water operating

against a total head of 36 feet]

Ifa 1-1/4" pipe had been selected, the water

velocity and friction loss would be greater with

corresponding higher pump horsepawer require-

ment but with lower initial cost due to the smaller

size pipes, valves and fittings. (Would require a

pump capable of cizculating 30 GPM of water

Operating against a total head of 69 feet) Ie is

quite probable that the total operating head pres-

sure difference between 48 feet with 1-1/2" pipe

and 69 feet with 1-1/4" pipe would require a

lerger pump motor.

Refer to Table 7 which is a typical pump selection

table. Using the above figures, 30 GPM of water

with a 48 foot head would require @ model 1/2P100

pump but with a 69 foot head, a model 1P100 pump

ie required, ‘This indicates the seme size pump

would be used but mated with a larger motor.

ory

PREVAILING WINDS

Locate tower so prevailing winds are in same

direction as tower dlacharge air. A strong wind

blowing into the tower discharge can greatly re-

duce air flow theu the tower.

COOLING TOWER PUMP

Locate pump go that it discharges to the condenser,

To assure pump priming, the suction level to the

pump must be lower than the water level in the

tower basin,

VALVES

Install service or shutoff valves where needed to

perform maintenance or service, Should be gete

type to minimize pressure drop penalty on system.

Balancing valves should be installed to regulate the

flow of water in the system, Required where the

pressure from pump or main is sufficient to cause

excessive flow. Recommend globe valve or square-

head plug cock which provides pressure loss in

proportion to valve opening.

Gheck valves are used to prevent reversal of flow

during the off cycle. Swing check valves recom

mended,

WATER REGULATING VALVE

A water regulating valve normally is not needed

with a cooling tower but may be used when it is

Gesivable to maintain close control of the con=

densing pressure. When used, the pressure drop

across the valve must be included when calculating

the system pressure drop.

hen a water regulating valve is included, a

spring loaded pressure relief bypars valve must

be inctalled between the pamp discharge tnd the

inlet to the tower (See Fig. 7). This maintains a

constant head on the pump as the water regulating

valve opens and closes,

BLEED-OFF

Bleed-off is absolutely necessary to control the

concentration of seale forming minerals in the

water system unless make-up water treatment is

able to eliminate the need. The bleed-off line

should be installed in the hot water line near the

top of the tower, This will permit bleed-off only

when the pump is operating.

A valve or controller should be installed in the

bieed-otf line to regulate the amount of flow. The

Line should be routed to a drain or to tower over

flow pipe.

‘The amount of bleed-off required depends upon the

cooling range, rate of water clrevlation and the

local water conditions. It is imposeible to pro-

vide a specific bleed-off rate due to the variables

involved. A suggested bleed-of! rate for 10" to 15:

cooling range is 1/2 percent of circulation rate

(005 x GPM circulated)

WATER PIPING FOR CLOSED RE-CIRCULATION

“STEM

4 select the proper water piping for a closed re-

circulation eystem, the following information

must be available

1, Total gallone per minute of water to be

cireulsted ax well as gallone per minute

te be cireulated in each branch rune

2. Layout of system showing lengths of all

runs with location of units, valves and

fictings.

3. Pressure drop across condensers and

hheat exchanger (this varies widely ane

must be obtained from equipment manu

facturer).

4. Type of pipe to be used,

Sample Selection: (Refer to Fig. 8)

1. 60 GPM total water to be circulated.

2, Length of rune with unite, valves and

fitting as shown in Fig. &

3. Pressure Drop.

(a) 11,3 feet of water each unit con-

denser at 10. GPM flow zate.

(b) 15.0 feet of water for plate type heat

exchange? at 60 GPM flow rate

4. Schedule 40 pipe (assume to have "fairly

rough" interior surface).

12

Solution: (Refer to Fig. 8)

1

Select pipe sizes for most remote run

which will determine pressure drop of

system. In this example, circuit

aeeegehekeL

For fairly rough pipe, the velocity and

Pressure drop may be obtained from.

Table 3. For copper tubing or other

roughness of pipe, refer to Fig. 3 thru 6,

{e) Run (a-b) 60 GPM: try 2" pipe as this

gives a velocity of 6.2 FPS which te

SAthin recommended limits.

Length of pipe 3.0

T gate valve (Table 5) 2p 29-FT.

TOTAL EQUIVALENT FT = 3-2

From Table 3, at 60 GPM with 2" pipe,

the pressure drop is 12, 0 feet of water

per 100 feet of length,

5 Ft

of water

12.0 Ft. of water x 4.2 EQ. FT,

100 Linear FY

Record this and following calculations in

tabulation form as Ulustrated in Table 6.

(b) Run (b-c)at 60 GPM flow rate, pres-

Sure drop is 15.0 feet of water for

plate type heat exchanger av given as

Gata in ample selection sectio:

(c) Run (c-€)60 GPM: use 2” pipe as

selected for run (ab).

= 15.0

Lang fn 2S}eor

1 gate valve (Table 5)

TOTAL EQUIVALENT FT

12.0 Ft. of water x 16.2 EQ. FT

100 Linear Fr

(a) Run (d-e) 30 GPM; Try 1-1/2" pipe

as this gives a velocity of 5,6 FPS

which is within recommended limits.

Length of pipe

28.0

Std. tee thre run (Table 5)= 3,0 b EO. FT.

Std. 90° elbow (Table 8) = _4.5

TOTAL EQUIVALENT FT = 35-3

Lo FL

ofwater

From Table 3, at 30 GPM with 1-1/2"

pipe, the pressure crop is 13.4 feet of

water per 100 feet of length.

13.4 Ft. of water x 35.5 EO. FT.

Linear Fr

4a Ft

ofwater

fe) Run (e-f) 20 GPM; try 1-1/4" pipe as

this gives a velocity of 5.4 FES which

is within recommended limits

Length of pipe = 8.0

Sta, tee thru sun (Table 5) >_21 } EO-FT.

TOTAL EQUIVALENT FT = 10-5

From Table 3, at 20 GPM with 1-1/4"

pipe, the pressure drop is 15.5 feet of

Water per 100 feet of length.

%y

waren

SARE ue EXPAN

Sion

fanwe | overruow

\ocem oorm

ae <7] _»

mm] ol eS oor] el ge

iT | ae te | ee

ofa

vo crm oem

fuer Ke

8 ae bf

ocnm rosem

rr ee eee i ae

ES a + |S

. .

PLATE TYPE HEAT EXCHANGER

OR c 20" ”

Hm

T

I

2a x a

ae |e Pani

FIG. 8— ‘Typical Closed Water Recirculation System

15.5 Ft. of water x 10,5 EQ.FT. _ 1.6 Ft.

oor

1

From Table 3, at 10 GPM with 1" pipe

the pressure drop is 11.8 fect of water

per 100 feet of length.

Length of pipe

Lgate valve (Table 5)

5.

1 td, 90° elbow (Table 5) = 2

2

°

6

5

6.

T

13

11.8 Ft, ofwater x20. 1EQ.ET. _ 2.4 Ft

STOO Linear FETC of water

(g) Run (g-b) at 10 GPM flow rate, pres-

Sure drop is 11.3 feet of water for

unit condenser ae given as data in

sample selection section,

(h) Rum (b-i) 10 GPM; use 1” pipe ae

selected for run (fg)

Length of pipe

EO. FT.

Ygate valve (Table 5)

1 std. 90" elbow (Table 5)

TOTAL EQUIVALENT FT = T

11.8 Ft. of water x 18,1 BO.ET. | 2.1 Fr,

T00 Linear Ft ofwater

(i) Run (4-))20 GPM; use 1-1/4" pipe as

selected for run (ef)

Length of pipe = 8.0)

Tstd. tee thru run (Table 5) =_ 2.5

TOTAL EQUIVALENT FT. = 10-5"

EQ.FT.

15.5 Fi

of water x 10.5 EQ.FT. _2.15t,

100 Linear Fe * ofwate:

G) Run (-3) 30 GPM; use 1-1/2" pipe as

Selected for (ene).

Length of pipe = 28.0

Ystd. tee thra run (Table 5) = 3.0PEQ.FT.

L std. 90° elbow (Table 5) = _4.5,

TOTAL EQUIVALENT Fr, = 35-5

FT, _4.0F

of water

(k) Run (&-1)60 GPM; use 2" pipe as

selected for run (c=d),

Length of pipe

Vsta. tee thre (Table 5)

1 gate valve (Table 5)

TOTAL EQUIVALENT FT,

12.0 Ft, of water x 16.7

100 Linear Fr

FQ, .2.0Fn

of water

Determine total pressure drop of system

by adding the pressure crop of the sec-

tions making up the longest rin, Total

pressure drop ie 48,0 fect of water.

Select a pump which will produce a Slow

of 60 GPM against a total pressure ézop

of 48.0 feet of water.

The pressure at various points in the sys-

tem can now be computed by assuming the

total pressure drop of 48.0 ft. of wate:

is available at the pump discharge. Start-

ing at the pump discharge, subtract the

pressure drop for oach run of pipe to ob-

tain the pressure at the other ports.

(Refer to last column in Table 6).

Determine pipe sizes for second circuit

(Run d-o-p-k)-

(a) Pressure at d= 30.6 Ft. of water

Pressure atk=_2.0 Ft. of water

TED Feet of water

available for pressure drop in circuit.

Piping shoald be selected to use all avail-

able pressure drop. ‘This will minimice

the adjustment of valves for equalization

of pressure drop and volume of flow.

(b) Run (dm) 30 GPM; try 1-1/2" pipe

which gives a velocity of 5.6 FPS

which ts within recommended limits

Length of pipe

8.0

Ips tee Bs branch (ratte 5)2_ $a }EO. FT.

TOTAL EQUIVALENT FT. =

14

From Table 3 at 30 GPM flow rate, pres-

Sure drop is 13.4 feet of water per 100

feet of length,

13.4 Ft, of water x 17.0 20.FT, _ 2.3 Fe.

TOO Linear Fr. * ofwater

(e) Run (m-n) 20 GPM; try 1-1/4" pipe

which givas a velocity of 5.4 FPS

which is within recommended limits

Length of pipe 8.0

Tater tee ft sun (nabie 9) 2_2.S}EO. Fr.

TOTAL EQUIVALENT FT. = 0-3

From Table 3, at 20 GPM with 1-1/4"

Pipe, the pressure drop is 15.5 feet of

water per’ 100 foe: of length.

15.5 Fr. of water x10.5EO.FT. 1.6 Ft

100 Linear Fe. ofwater

(2) Run (n-0) 10 GPM; try 1" pipe whieh

gives a velocity of 4.2 FPS which is

within recommended Limits.

Length of pipe 13.07

Vgate valve (Table 5) 6b eg ye

L std. 90" elbow (Table 5) = 215 ¢2O-FT.

1 std. tee thru run (Table 5) = _ 21,

TOTAL EQUIVALENT Fr. = TET

From Table 3 at 10 GPM with 1” pipe,

the pressure drop ie 11.8 feet of water

per 100 feet of length,

11.8 Ft, of water x ILEOFT, 2.1 Ft

TOO Linear FF oiwater

(e) Run (0-p)10 GPM flow rate, pre

drop is 11.3 feet of water far unit

condenser as given as data in sample

selection section,

(2) Run (peq) 10 GPM; use 1" pipe as

selected for run (n-0}.

Length of pips

Ygate valve (Table 5)

1 ste. toe thru branch (Table 5)

TOTAL EQUIVALENT FT.

From Table 3 at 10 GPM with 1" pipe,

the pressure drop is 11.8 fect of water

per 100 feet of length.

11.8 Ft of water x 19.1 EO.FT, _ 2.3 Ft,

100 Linear Ft.

(@) Ran (g-7}20 GPM; use 1-1/4" pipe as

selected for run fm=n).

Length of pipe = 8.0

Tye ice BPS mun rane 5)2_E:8}e0. re

TOTAL EQUIVALENT FT. = TOS"

From Table 3 at 20 GPM with 1-1/4" pipe

the pressure drop is 15,5 feet of water

per 100 feet of length,

45.5 Ft. of water x 10.5 EQ.FT, 1.6 Fi

100 Linear Fe ofwater

(bh) Run (r-k) 30 GPM; try 1-1/4" pipe to 6, Determine total pressure érop of run

use the available pressure drop. (g-0-p-k) by adding the pressure drop of

the individual runs, Total pressure Soop

is 27.2 feet of water, From paragraph

5a, there was 28.6 fect of water pressure

drop available. Therefore, 28.6 minus

27.2 equals I. feot of water which is the

available pressure drop which was not

used. This 1.4 feet of water pressure

Grop must be taken up by valve adjusts

ment to obtain a balanced system at cal

culated flow rate.

Length of pipe

V'std. tee thru run (Table 5)

1 std. tee thru branch (Table 5)

TOTAL EQUIVALENT FT.

50. FT.

From Table 3 at 30 GPM with 1-1/4" pipe

the pressure atop te 33°5 feet of water

per 00 fect of east

Size branch lines from main supply to

nite fi #2, fa and 9S Use ee en

33.5 Fe of water x 18.0 FO.ET, 6.0 Ft of availble poteure drop oo potetncts

100 Linear Fe crwater rainiiiae valve aajesinche

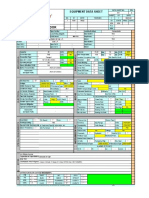

TABLE 6— TABULATION OF DATA FOR CLOSED WATER SYSTEM SAMPLE PROBLEM

—

Fittings, Equivalent Feet of Pipe Press. | Total | Actual

cations} Nomina | Length a total |Drop Ft. | Preer.| Pre:

Russ| “per | Pipe | of std. Tee| sta, Tee Equivalent] Water | ‘Drop at Varicus

Painute | eee | REE | Gate, | Bhra | “thea” | Sea. 90°] FSET Dertsog | Beep [at Various

Inches | Feet |valve | (Run | Branch | Elbow Lin. Ft. | Water [Feet Water

2 a0

60 2 3 | ue 42 | we as] as

60 Ble 325

eo w fone 1.2 | azo g}a soe

30 8 3.0 45 ass | 34 sfe ass

20 3 25 dos | ibs 6 | £ 24l

to 8 6] 20 25 zot | ant s]e aus

io Unie #6 23 |B lols

10 1 5 ‘ 1 25 wt] ne fi 'sa

zo | iiss | 8 25 ios | isis el; és

so | ice | 2s Xo 45 a5 | asia B]k 20

60 od ue | as asia | 20 ofr “o

‘Total Pressure Drop (Ft. of water) in Longest Run 7

2 30.6

a-m/ 30 | v2 | 6 9.0 wo | ans 2.3 | mae3

mal 20 | ie | 6s 2s ros | isis Le} 267

neo} to 1 8 6] Xo 28 tat | ane 21/0 ase

ep] i Unie #3 ana |p 183

pea] io 1 1 6 Ss i | ine 23} q ie

a-r] 20 | atys | 's zs jos | isis he] ‘os

eek] 30 | ie | zs | 73 yo | 335 | gol k dae

ack Total Pressure Drop (Ft. of water) in Shorter Run zz

i point i is 2.0 ft, of water as determined by the longest run and this {2 the system cone

ure drop. In order to have a balanced system with » minkinum adjustencet of veloc ae

branch runs should be sized so the available pressure drop between the supply pease wed sotcny reais

used in the branch run. “The 3.4 ft. of water 1s close ta the 2-0, re the difference of Tee eect eae!

‘must be taken up by valve adjustment,

15

TABLE 7— TYPICAL RATINGS FOR PUMP SELECTION

ee

PM

Lice

20 30 40 30 eo 70 80 90

10} 1/3 P1o0 | 1/3 Ptoo] 173 P100 [4/2 F100 | 172 Plo] ssa PI00| 1 Pleo] 1 P10 [isyapaeo

20_| 1/3 Pioa | 1/2 Pioo| 1/3 Pico | 1/2 P00 | 3/4 P100| 3/4 F100] 1 P100| 1 ~Pi00 | 1=1/eP OO

30_| 1/3 Pioo | 1/3 pio | 12 Pio0| 172 P100 | 3/4 P10] 1 P100| 1 Pioofi-wepaco| “2 Pee

40 | 1/3 Pio0 | 1/2 P100| 1/2 Pioo| 3/4 Pi00| 1 Pion] 1 Pico|i-1/2P200|1-1yep200| 2 F200

50 | 12 Pico | 2/4 Pico] 3/4 Pico] 1 F100] 1 Pi00|1-1/eP200|1-1/2P200| 2 paoo] 2 200

§0_[}-1/2P200 |1-1/2P200 |1-1/2P200 [1-1/2 200 [1-1/2 200 |1-1/2P200] 2 200] 2 Pe0o] 3 200

70_|1-1/2P200 [1-1/eP200 ft-ayePa00

asepz00 |1-1/2P200| 2 P2o0[ 2 P200| 3 poo] 3 R200

so | 2 peoo| 2 ra00] 2 p2oof 2 Peoo| 2 peco| 2 F200] 2 w200| 3 P200| 3 Pace

50 | 2 F300] 2 Poo} 2 Poo] 2 7300 2 300] 3 P300| 3 P00] 3 Ps0o] 5 P00

woo | 2 300] 2 Paco] 2 P300] 2 F300] 2 300| 3 P300| 3 ps00| s P30] 7s Paco

‘Motor Horsepower

‘Motor Pump Assembly

[Pump Size Designation

in

nae cng; aypical Pump Selection Table but should not be used for an actual pump selection, Refer toa

ap Manufacturers Ratings for a specific selection ag a number of pump size/moror comtinatinng ot

pursible,

sutacer cman rnnournoree YORK =

PPC SM 1173 40 Code: £16) Int

Form 1805 25-40. P.0, BOX 1802, YORK, PENNSYLVANIA 17405

i

\

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Unofficial MacGyver How-To Handbook Revised 2nd EditionDocument194 pagesThe Unofficial MacGyver How-To Handbook Revised 2nd Editionbret95% (75)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Decision Making Style InventoryDocument6 pagesDecision Making Style InventorySivakumar NadarajaNo ratings yet

- Celestial Sphere Star ChartsDocument3 pagesCelestial Sphere Star ChartsLonn ConleyNo ratings yet

- Pic Basic Pro ManualDocument220 pagesPic Basic Pro ManualSivakumar Nadaraja100% (3)

- Pic Basic Pro ManualDocument220 pagesPic Basic Pro ManualSivakumar Nadaraja100% (3)

- HVAC & Refrigeration SystemDocument22 pagesHVAC & Refrigeration SystemSivakumar NadarajaNo ratings yet

- !!!catia V5R12 Mechanical Design Solutions 1Document2,065 pages!!!catia V5R12 Mechanical Design Solutions 1api-26678597100% (2)

- Stefanescu - Science and Engineering of Casting SolidificationDocument354 pagesStefanescu - Science and Engineering of Casting SolidificationThais FernandesNo ratings yet

- Baldrige Award Benifits and CriteriaDocument9 pagesBaldrige Award Benifits and CriteriaSivakumar NadarajaNo ratings yet

- Basic Chiller System Design Part1Document55 pagesBasic Chiller System Design Part1Sivakumar Nadaraja100% (2)

- Chapter 6-Magnetic CeramicsDocument29 pagesChapter 6-Magnetic CeramicsVo Phong Phu0% (1)

- Why You Should Love Statistics by Alan Smith Parampara NeupaneDocument2 pagesWhy You Should Love Statistics by Alan Smith Parampara NeupaneParampara Neupane50% (2)

- NESTLE Financial Report (218KB)Document64 pagesNESTLE Financial Report (218KB)Sivakumar NadarajaNo ratings yet

- Motor Data SheetDocument3 pagesMotor Data SheetSivakumar NadarajaNo ratings yet

- Assignment 5 - Presentation To Class Rev1Document13 pagesAssignment 5 - Presentation To Class Rev1Sivakumar NadarajaNo ratings yet

- Magnehelic Differential Pressure Gage 2000.iDocument2 pagesMagnehelic Differential Pressure Gage 2000.iSivakumar NadarajaNo ratings yet

- Setting Work Standard For Clerical Service Orientated EnvironmentDocument11 pagesSetting Work Standard For Clerical Service Orientated EnvironmentSivakumar NadarajaNo ratings yet

- Basic Chiller System Design Part2Document48 pagesBasic Chiller System Design Part2Sivakumar NadarajaNo ratings yet

- Industrial Air HandlingDocument6 pagesIndustrial Air HandlingSivakumar NadarajaNo ratings yet

- PIC Micro Controllers For Beginners BookDocument205 pagesPIC Micro Controllers For Beginners BookAmit kumar100% (12)

- Catia V5 Mechanical Design Solutions 2Document709 pagesCatia V5 Mechanical Design Solutions 2Sivakumar Nadaraja100% (2)

- Industrial Automation PLC Communications in A Process Control SystemDocument9 pagesIndustrial Automation PLC Communications in A Process Control SystemMohammad HannanNo ratings yet

- Assignment 4 Area Under The Stanard Normal CurveDocument7 pagesAssignment 4 Area Under The Stanard Normal CurveAkamonwa KalengaNo ratings yet

- Theory of Architecture 1 - ANTHROPOMETRY AND ERGONOMICSDocument1 pageTheory of Architecture 1 - ANTHROPOMETRY AND ERGONOMICSJHON MICCO ERGINANo ratings yet

- At The Completion of The CourseDocument2 pagesAt The Completion of The Courseoday albuthbahakNo ratings yet

- PHD Thesis. Cyclic Behavior of Steel Fiber Reinforced Concrete: From Material To Seismic ColumnsDocument24 pagesPHD Thesis. Cyclic Behavior of Steel Fiber Reinforced Concrete: From Material To Seismic ColumnsZarr AkshNo ratings yet

- D 3014 - 04 - RDMWMTQ - PDFDocument4 pagesD 3014 - 04 - RDMWMTQ - PDFsusanaNo ratings yet

- Measurement of Light Intensity On Working Surfaces. A Case Study of Building Department in The University of Jos NigeriaDocument66 pagesMeasurement of Light Intensity On Working Surfaces. A Case Study of Building Department in The University of Jos Nigeriasuyidam johnNo ratings yet

- ExamView - A2 Sem1 ReviewDocument18 pagesExamView - A2 Sem1 ReviewMitchell, Brady M StudentNo ratings yet

- Ecs556 Structural Analysis Assignement Question FinalDocument9 pagesEcs556 Structural Analysis Assignement Question FinalMuhammad IqbalNo ratings yet

- Vaporizador: Equipment Data SheetDocument1 pageVaporizador: Equipment Data SheetAlonso DIAZNo ratings yet

- Tight Binding PDFDocument72 pagesTight Binding PDFmajed nashaatNo ratings yet

- Modeling and SimulationDocument10 pagesModeling and Simulationoumaima ghzNo ratings yet

- ISTAM 2020 Brochure 29-8-2020Document5 pagesISTAM 2020 Brochure 29-8-2020bvs957946No ratings yet

- KAMA GEÇME TOLERANSLARI The Key To A Proper Fit For KeywaysDocument2 pagesKAMA GEÇME TOLERANSLARI The Key To A Proper Fit For Keywaysmustafa bulatNo ratings yet

- M1 January 2006 Mark SchemeDocument5 pagesM1 January 2006 Mark Schemesahiltourani5992No ratings yet

- DPP Vector Algebra Solution MathongoDocument8 pagesDPP Vector Algebra Solution MathongoSubhajit GoraiNo ratings yet

- Ja Delmas Catalogue Kencast ProtectionDocument20 pagesJa Delmas Catalogue Kencast Protectionjunaid jiNo ratings yet

- CO1-L2 - Measures of Central TendenciesDocument38 pagesCO1-L2 - Measures of Central TendenciesRAINIER DE JESUSNo ratings yet

- Tyre Flap (EPDM) Specification306 - 83 - SEP - 2016Document5 pagesTyre Flap (EPDM) Specification306 - 83 - SEP - 2016Purchase and Stores Officer Contract Cell-IINo ratings yet

- Container Handbook PDFDocument2 pagesContainer Handbook PDFRobin HillsonNo ratings yet

- BEP Shayan Farrokhi Final VersionDocument93 pagesBEP Shayan Farrokhi Final VersionShahad Hussain Kavassery SakeerNo ratings yet

- Datasheet IntegradoDocument4 pagesDatasheet Integradoalan segundo garcia chotaNo ratings yet

- Particle Damper: Department of Civil EngineeringDocument16 pagesParticle Damper: Department of Civil EngineeringShashi KumarNo ratings yet

- Student Text Answers: UNIT 23 Algebraic ManipulationDocument4 pagesStudent Text Answers: UNIT 23 Algebraic ManipulationCharlotte BNo ratings yet

- Irregular Flat SlabsDocument17 pagesIrregular Flat SlabsDaniel ReynoldsNo ratings yet

- Analysis of Piston, Connecting Rod and Crank Shaft Assembly: SciencedirectDocument10 pagesAnalysis of Piston, Connecting Rod and Crank Shaft Assembly: Sciencedirectvikek vikumarNo ratings yet

- The Effect of Generator's Shaft Mechanical Damping PDFDocument2 pagesThe Effect of Generator's Shaft Mechanical Damping PDFgilbertomjcNo ratings yet