Professional Documents

Culture Documents

FRM-HSE-01 Form JSA

Uploaded by

robby damanikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FRM-HSE-01 Form JSA

Uploaded by

robby damanikCopyright:

Available Formats

Doc.

No : FRM/HSE/01

FORMULIR Revision :0

Effective Date : 01 APRIL 2017

JOB SAFETY ANALYSIS (JSA) Halaman : 01

Ref. SOP/HSE/02

WORK-SITE / PROJECT NAME :

LOCATION / Lokasi :

DEPT / SECTION (Penanggung Jawab Pelaksana):

NAME OF SUB-CONTRACTOR(S) : Supervisor/Leader :

TASK / ACTIVITY (Kegiatan): Supervisor/Leader :

Check all applicable anticipated or potential hazard (Centang semua bahaya potensial atau yang akan diantisipasi ):

Work affecting integrity of Critical Control System Heavy Equipment Lifting Work At Height (Scaffolds, ladders, roofs, etc…)

Electrical (Live) Traffic Pattern (Mobile Equipment / Pedestarian) Underground Tank Removal / Disposal

Electrical (Isolation) Temporary Pumping & Transfer Facilities Demolition

Hot Work Extreme Weather Exposed Handling of Petroleum Product

Confined Space Entry Pile Driving / Drilling Equipment Mobile Equipment

Equipment Handling & Dismantling Bore-hole Drilling / Test Pit Excavation Drilling, Grinding. Cutting

Excavation Pressure Testing Work in Hazardus Areas

Stored Pressure System (e.g. - Propane, NH3) Overhead Power-lines (e.g. - Designated Substances)

Radiography / X-Ray Testing Hydro-blasting / Sand-blasting Other :

Ensure that all hazards identified - are addressed in the JSA below (refer to Safety Method Statements as required)

Safety Control to Reduce or Eliminate Hazard

Sequence of Basic Job Steps (Urutan Pekerjaan) Potential Hazard (Bahaya Potensial) (Pengendalian untuk mengurangi atau menghilangkan

bahaya potensial)

1.

2.

Distribusi MSI-Master (DCR), Copy (User/Pihak Terkait)

Doc. No : FRM/HSE/01

FORMULIR Revision :0

Effective Date : 01 APRIL 2017

JOB SAFETY ANALYSIS (JSA) Halaman : 02

Ref. SOP/HSE/02

Safety Control to Reduce or Eliminate Hazard

Sequence of Basic Job Steps (Urutan Pekerjaan) Potential Hazard (Bahaya Potensial) (Pengendalian untuk mengurangi atau menghilangkan

bahaya potensial)

3.

4.

5.

6.

7.

8.

9.

10.

Distribusi MSI-Master (DCR), Copy (User/Pihak Terkait)

Doc. No : FRM/HSE/01

FORMULIR Revision :0

Effective Date : 01 APRIL 2017

JOB SAFETY ANALYSIS (JSA) Halaman : 03

Ref. SOP/HSE/02

Tools / Equipment (Peralatan/perlengkapan yang diperlukan, terkait dengan safety) :

Personal Protective Equipment :

PPE Specifics : Hard-hat (CSA side-protection) Eye Protection (CSA safety glasses) Safety Boots (Steel-toed CSA approved)

Hearing Protection (Class A) Gloves (puncture / cut resistant) Coveralls (Reflective - Non-Fire-rated)

Other

Outside Authorities (Pihak berwenang yang perlu diberi saran) :

Disposal of Surplus or Contaminated Materials (Metode pembuangan sampah/limbah termasuk yang terkontaminasi B3):

SAFETY PROCESS INFORMATION REGARDING THIS JSA

Prepared By : Position : Date :

Person(s) Carying Out This Process On The Actual Work-Site (personel yang akan melakukan pekerjaan ini )

Name(s) : Signed : Date :

Verified By : Position : Date :

Verified By : Position : Date :

Distribusi MSI-Master (DCR), Copy (User/Pihak Terkait)

You might also like

- Coe Ims PlanDocument19 pagesCoe Ims Planraphael damanikNo ratings yet

- Inilah Rinduku KepadamuDocument1 pageInilah Rinduku Kepadamurobby damanikNo ratings yet

- SIMS Target 2017Document27 pagesSIMS Target 2017robby damanikNo ratings yet

- Summary Safety Induction-RevDocument3 pagesSummary Safety Induction-Revrobby damanikNo ratings yet

- HACCP TemplateDocument28 pagesHACCP Templateraphael damanikNo ratings yet

- Fall Within The Scope (Boundary) of Your EMS Fall Within The Scope (Boundary) of Your EMS Fall Within The Scope (Boundary) of Your EMS Context EMSDocument6 pagesFall Within The Scope (Boundary) of Your EMS Fall Within The Scope (Boundary) of Your EMS Fall Within The Scope (Boundary) of Your EMS Context EMSrobby damanikNo ratings yet

- Book 1Document7 pagesBook 1robby damanikNo ratings yet

- Business Process MSI - UpdatedDocument1 pageBusiness Process MSI - Updatedrobby damanikNo ratings yet

- IPP HSE Section Robby Template 2017Document57 pagesIPP HSE Section Robby Template 2017robby damanikNo ratings yet

- FRM-HSE-01 Form JSADocument3 pagesFRM-HSE-01 Form JSArobby damanikNo ratings yet

- Env Audit - TimetableDocument1 pageEnv Audit - Timetablerobby damanikNo ratings yet

- IPP HSE Section Robby Template 2017Document57 pagesIPP HSE Section Robby Template 2017robby damanikNo ratings yet

- IPP HSE Section Robby Template 2017 RevDocument58 pagesIPP HSE Section Robby Template 2017 Revrobby damanikNo ratings yet

- Safety Shoes Pak David AtmodjoDocument1 pageSafety Shoes Pak David Atmodjorobby damanikNo ratings yet

- Request Work Order (RWO) - Expansi Fire AlarmDocument2 pagesRequest Work Order (RWO) - Expansi Fire Alarmrobby damanikNo ratings yet

- Denah Atap PDFDocument1 pageDenah Atap PDFrobby damanikNo ratings yet

- Inilah Rinduku KepadamuDocument1 pageInilah Rinduku Kepadamurobby damanikNo ratings yet

- Working Schedule SeptemberDocument17 pagesWorking Schedule Septemberrobby damanikNo ratings yet

- Monitoring Alat Pelindung Diri (Apd) : Bulan: Agustus 2017Document6 pagesMonitoring Alat Pelindung Diri (Apd) : Bulan: Agustus 2017raphael damanikNo ratings yet

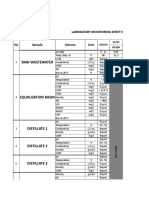

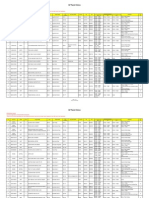

- Raw Wastewater: Laboratory Monitoring Sheet-Wwtp Comissioning No Sample UnitDocument6 pagesRaw Wastewater: Laboratory Monitoring Sheet-Wwtp Comissioning No Sample Unitraphael damanikNo ratings yet

- Request Work Order (RWO) - Disposal LB3Document5 pagesRequest Work Order (RWO) - Disposal LB3robby damanikNo ratings yet

- Ijin Tps Lb3Document6 pagesIjin Tps Lb3robby damanikNo ratings yet

- Working Schedule SeptemberDocument17 pagesWorking Schedule Septemberrobby damanikNo ratings yet

- DenahDocument1 pageDenahrobby damanikNo ratings yet

- Portal As A Portal As A': Medan - IndonesiaDocument1 pagePortal As A Portal As A': Medan - Indonesiarobby damanikNo ratings yet

- Medan - Indonesia: Pt. Medan Sugar IndustryDocument1 pageMedan - Indonesia: Pt. Medan Sugar Industryrobby damanikNo ratings yet

- Departmetit: Malrtehance Cost t5% Expenditurc BudsetDocument1 pageDepartmetit: Malrtehance Cost t5% Expenditurc Budsetrobby damanikNo ratings yet

- IPP HSE Section Robby Template 2017 RevDocument58 pagesIPP HSE Section Robby Template 2017 Revrobby damanikNo ratings yet

- IPP HSE Section Robby Template 2017Document57 pagesIPP HSE Section Robby Template 2017robby damanikNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- STS CRFDocument38 pagesSTS CRFYosoy LomasNo ratings yet

- CDCS French Forein MinistryDocument36 pagesCDCS French Forein MinistryZakaria ABBIOUINo ratings yet

- Bed Making LectureDocument13 pagesBed Making LectureYnaffit Alteza Untal67% (3)

- NBR Leaflet Krynac 4955vp Ultrahigh 150dpiwebDocument2 pagesNBR Leaflet Krynac 4955vp Ultrahigh 150dpiwebSikanderNo ratings yet

- TCVN 6560-1999 Air Quality For Incinerator (En)Document2 pagesTCVN 6560-1999 Air Quality For Incinerator (En)Pn ThanhNo ratings yet

- Wu 2008Document8 pagesWu 2008SergioNo ratings yet

- Part-IDocument507 pagesPart-INaan SivananthamNo ratings yet

- Urbanization and HealthDocument2 pagesUrbanization and HealthsachiNo ratings yet

- STEVENS DRRR Module 6 Opon Christian Joy ADocument7 pagesSTEVENS DRRR Module 6 Opon Christian Joy AAnthony Bryan Cartujano100% (1)

- Villegas Lucero 1Document8 pagesVillegas Lucero 1api-213921706No ratings yet

- Laminar AirflowDocument15 pagesLaminar AirflowKamran AshrafNo ratings yet

- Attitude of EMPLOYEES in Terms of Compliance of Health and SafetyDocument6 pagesAttitude of EMPLOYEES in Terms of Compliance of Health and SafetyJanice KimNo ratings yet

- GP Panel ClinicsDocument9 pagesGP Panel ClinicsKoh WYhowNo ratings yet

- Sample FNCP For InfectionDocument3 pagesSample FNCP For InfectionAnonymous gHwJrRnmNo ratings yet

- Module 3A: Designing Instruction in The Different Learning Delivery ModalitiesDocument30 pagesModule 3A: Designing Instruction in The Different Learning Delivery Modalitiesnel baradi67% (9)

- Armand Barbault Gold of A Thousand Mornings PDFDocument89 pagesArmand Barbault Gold of A Thousand Mornings PDFtravellerfellowNo ratings yet

- AishwaryaDocument52 pagesAishwaryamohitNo ratings yet

- Final Sheet MotalityDocument69 pagesFinal Sheet MotalityAshima GabgotraNo ratings yet

- Fever Nursing Care PlanDocument3 pagesFever Nursing Care PlanMarie Anne T85% (39)

- Introduction To Epidemiology: The Basic Science of Public HealthDocument34 pagesIntroduction To Epidemiology: The Basic Science of Public Healthapi-19641337100% (1)

- SigmaDur 188-520-550 Msds Hardener PDFDocument17 pagesSigmaDur 188-520-550 Msds Hardener PDFMarcos LaraNo ratings yet

- Clinical Teaching Plan On Ncm-105 Psyhciatric NursingDocument13 pagesClinical Teaching Plan On Ncm-105 Psyhciatric NursingHazel RoseNo ratings yet

- Crisis Management and Human Behaviour Mca ApprovedDocument2 pagesCrisis Management and Human Behaviour Mca ApprovedVinil Gupta100% (1)

- Stanford CWLP HandbookDocument60 pagesStanford CWLP HandbookDon DoehlaNo ratings yet

- Predictive Models Receiver-Operating Characteristic Analysis For Evaluating Diagnostic Tests andDocument5 pagesPredictive Models Receiver-Operating Characteristic Analysis For Evaluating Diagnostic Tests andLucila Figueroa GalloNo ratings yet

- RSPCA Shuts Down Another Animal SanctuaryDocument10 pagesRSPCA Shuts Down Another Animal SanctuaryGlynne SutcliffeNo ratings yet

- Group 3 Oral Bioavailability EditedDocument10 pagesGroup 3 Oral Bioavailability EditedBaguma MichaelNo ratings yet

- Tonsillectomy and Adenoidectomy - Pediatric Clinics of North AmericaDocument13 pagesTonsillectomy and Adenoidectomy - Pediatric Clinics of North AmericayosefNo ratings yet

- Hazop PDFDocument18 pagesHazop PDFLuiz Rubens Souza Cantelli0% (1)

- De La Cruz, Et Al. (2015) Treatment of Children With ADHD and IrritabilityDocument12 pagesDe La Cruz, Et Al. (2015) Treatment of Children With ADHD and Irritabilityjuan100% (1)