Professional Documents

Culture Documents

Diesel Exhaust Soot PDF

Diesel Exhaust Soot PDF

Uploaded by

Chand NaiduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diesel Exhaust Soot PDF

Diesel Exhaust Soot PDF

Uploaded by

Chand NaiduCopyright:

Available Formats

How to reduce

black smoke and

carbon emissions

from diesel

engines

GenCat Diesel

Particulate Filters

GenCat Engineering Department

Copyright 2013 © GenCat Ltd Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

How to reduce black smoke

and carbon emissions from

diesel engines

GenCat Diesel Particulate Filters

GenCat Engineering Department

Contents

Introduction 2

What is Particulate Matter (PM)? 2

What are the concerns associated with DPM? 3

How can the black smoke be reduced? 4

What is a diesel particulate filter (DPF)? 4

Passive and Active regenerative systems 5

DPF Applications 6

Catalytic Converters 7

Useful Reading 7

Further Information 8

Copyright 2013 © GenCat Ltd -1- Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

Introduction

Diesel exhaust soot is the visible cloud of black carbon-containing

smoke that appears on engine start-up and during normal diesel

engine operation. Black carbon is hazardous to health and

presents a range of other issues, including visible product

contamination and soiling. It is also believed that black carbon is

a contributory factor in climate change. This technical paper aims

to clarify the issues surrounding exhaust soot and presents

information designed to assist in the decision-making process of

how best to reduce black carbon emissions from diesel exhausts.

Un-burnt carbon particles,

engine oils, debris, soot and ash What is Particulate Matter (PM)?

particulates are known as

particulate matter (PM).

In a theoretically perfect combustion, carbon dioxide, water and

nitrogen are the end products. In reality, the incomplete

combustion of diesel fuel results in emissions that include oxides

of nitrogen (NOx), carbon monoxide (CO), carbon dioxide (CO2),

water (H2O) and unburned hydrocarbons (HC). There are also un-

burnt carbon particles, as well as engine oils, debris, soot and

ash particulates, which are known as particulate matter (PM).

PM10 are particles from 2.5 This diesel particulate matter (DPM) is the visible cloud of black

microns to 10 microns, PM2.5

are particles less than 2.5 smoke that appears from engine start-up and continues to appear

microns. when the engine is running. DPMs can be categorised into two

groups:

PM10 - Particles of 2.5 microns to 10 microns, and

PM2.5 - Particles of less than 2.5 microns in size.

Although most Diesel Particulates are very small, more than 99%

are in the sub-micrometre range.

Copyright 2013 © GenCat Ltd -2- Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

What are the concerns associated with DPM?

Climate change is something that directly affects us all and is just

one of the concerns associated with diesel exhaust emissions.

The main issues surrounding black carbon soot being:

Long-term exposure can lead to Health DPM has been identified by health experts as

chronic, more serious health contributing to a variety of lung related illnesses.

problems such as

cardiovascular disease and lung Exposure to DPM has been linked to acute short-term

cancer. symptoms such as headaches, nausea, and irritation of

the eyes, nose and throat. Long-term exposure can lead

to chronic and more serious health problems such as

cardiovascular disease and lung cancer.

Inhalation The smallest particles have the worst health

implications because of their ability to penetrate deep

into lung tissue. They easily bind with other toxins in the

environment, thereby increasing the hazards of particle

inhalation.

Confined Spaces Machinery operating in confined or

enclosed spaces – for example in tunnels, mines, and

quarries, or in factories and warehouses where

ventilation is limited – pose a greater health risk to

operatives and anyone in the vicinity of that equipment.

Diesel exhaust contributes to

ozone formation, acid rain, and Air Quality In addition to the health concerns mentioned

global climate change.

above, the pollution emitted by diesel engines

contributes greatly to air quality problems such as haze

and smog, both of which restrict visibility and can cause

irritation of the eyes, nose and throat. Furthermore,

diesel exhaust fumes contribute to ozone formation, acid

rain, and climate change.

Contamination DPM can also contaminate products

and packaging in factories and warehouses where

DPMs are present in the atmosphere. In the wider

environment DPM contaminates foliage and soils

buildings, an all too common sight in urban areas.

Copyright 2013 © GenCat Ltd -3- Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

How can the black smoke be reduced?

The industry has been developing innovative ideas to reduce

Diesel Particulate Filters are exhaust emissions for many years. A number of solutions are

designed specifically to reduce

particulate emissions. available and these range from Exhaust Gas Recirculation (EGR)

to Dual Fuel conversions. The most effective solutions are

designed specifically to deal with particulates and can reduce the

DPM emissions in the exhaust by up to 99%, from startup. These

systems are known as Diesel Particulate Filters or Soot Filters.

What is a diesel particulate filter (DPF)?

A Diesel Particulate Filter is a device that traps the exhaust

stream particulate matter by means of physical filtration. This

process is an established, efficient and effective way of removing

DPM from the exhaust stream. Once captured, the accumulated

DPM must then be dealt with in a safe and secure manner.

All types of filters have a finite capacity. DPFs are no different

and must be cleared of the accumulated DPM, either at regular

intervals, or during operation. Failure to do so will eventually

cause the filter to block. This can damage or destroy the filter

and may also damage the engine due to increased backpressure.

Diesel particulate filters collect

the particulate matter in the There are two solutions to this problem. One is to remove and

exhaust stream by means of

physical filtration. replace the filter with a fresh one; the second method is to

regenerate the filter so it can be reused:

Non-Regenerative Generally constructed from fibre

A Non-Regenerative filter, once

blocked, must be replaced. matting in which materials such as steel wool and

fibreglass are used. Housed in a steel canister or similar,

the DPM is trapped within the fibre matting. When full,

the element must be replaced with a clean one. These

types of filter have a life of around 300 working hours.

Therefore they are suited to low usage applications such

as standby generator sets, or on equipment that is used

for short periods of time. Systems can also be bypassed

so that they are only used when required (e.g. operating

in confined spaces such as tunnels or warehouses).

Copyright 2013 © GenCat Ltd -4- Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

A regenerative filter collects the Regenerative Commonly produced from ceramic

DPM, the carbon deposits are materials such as cordierite or silicon carbide.

then burnt away.

Constructed as a honeycomb monolith, channels are

blocked at alternate ends (figure i) forcing the exhaust

gasses to flow through the walls between the channels,

known as ‘wall-flow’. The particulate matter cannot pass

through the walls and is deposited within the channels.

As DPM is collected in the filter the carbon deposits are

burnt away. This is known as ‘regeneration’. Due to the

high temperatures involved in regeneration, these filters

are suited to high-usage applications where the exhaust

Figure i gas temperature (EGT) is high (e.g. prime power

generators or high usage materials handling equipment).

Both Non-Regenerative and Regenerative solutions are effective

at cold temperatures and capable of trapping up to 99% of DPM.

The addition of either type of system will dramatically reduce

black smoke at start-up, as well as during normal operation.

Passive and Active regenerative systems

The DPM collected in a regenerative system burns at

approximately 600°C, which is a temperature rarely reached in a

diesel exhaust system. There are two main solutions to this

problem, namely 'active' or ‘passive’ regeneration.

A passive system requires no additional energy inputs and works

by lowering the temperature at which the DPM will combust. An

example of this is a fuel-borne catalyst, which reduces the

combustion temperature to around 280˚C.

An active system uses electric heating or a fuel burning system to

increase the temperature in the filter when required and allows

regeneration of the filter to occur.

Copyright 2013 © GenCat Ltd -5- Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

DPF Applications

Diesel Particulate Filters can be

Diesel Particulate Filters can be fitted to almost any piece of

fitted to almost any piece of machinery or vehicle, for on or off-road use, that uses a diesel

machinery that has a diesel

engine. engine, such as:

Materials handling equipment

Forklift trucks, side loaders and telescopic handlers.

Power generation equipment

Standby or prime power generators.

Construction equipment & non-road mobile

machinery (NRMM)

Excavators, dumpers and earth moving equipment.

On-road vehicles

On-road vehicles such as buses, coaches and HGVs.

The table below indicates which types of filters are

recommended, based on engine usage and the type of emissions

reduction required:

Standby/ Low usage Prime/ High usage

PM Non-regenerative Regenerative

CO Catalytic Converter Catalytic Converter

HC Catalytic Converter Catalytic Converter

PM, CO + Non-regenerative + Regenerative +

HC Catalytic Converter Catalytic Converter

As each application is unique, the above table is for guidance

only. GenCat engineers are happy to assist in the selection of

appropriate Diesel Particulate Filters or Catalytic Convertors

tailored to your specific requirements.

For more information please contact info@gencat.co.uk, or visit

our web site at: www.gencat.co.uk

Copyright 2013 © GenCat Ltd -6- Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

Catalytic Converters

Catalytic converters reduce Catalytic converters are separate systems that reduce carbon

carbon monoxide (CO), monoxide (CO), unburned hydrocarbons (HC) and aldehydes.

unburned hydrocarbons (HC)

and aldehydes. These exhaust emissions are generally associated with

contributing significantly to atmospheric pollution problems and

are responsible for irritation to the eyes and respiratory system.

They can also cause nausea, headaches and tiredness. These

effects are further compounded in enclosed spaces such as

warehouses, tunnels and mines. For further information

regarding catalytic converters contact info@gencat.co.uk or visit

our web site at: www.gencat.co.uk/catalysts

Further Reading

Health and Safety Guidance 187 HS(G)187

…details the use of diesel

This guide, provides practical advice to employers on how to

exhaust gas after treatment control exposure to diesel engine exhaust emissions (DEEE's) in

systems such as catalytic

converters and diesel soot the workplace, and so protects the health of employees and

particulate traps to remove others who may be exposed. The guidance also details the use of

particulate matter.

diesel exhaust gas after treatment systems such as catalytic

converters and diesel soot particulate traps to remove particulate

matter. ISBN: 0-7176-1662-2. www.hse.gov.uk

The Health and Safety Executive (HSE)

The Diesel Engine Exhaust Emissions guidelines have

recommendations for health protection against exposure to diesel

fumes. www.hse.gov.uk

Control of Substances Hazardous to Health Regulations 1994

(COSHH)

Employers should make a suitable and sufficient assessment of

the risks to the health of employees if they are exposed to diesel

fumes. www.hse.gov.uk/coshh

Copyright 2013 © GenCat Ltd -7- Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

Low Emissions Zone (LEZ)

To reduce the pollution into London’s air from vehicle exhausts,

vehicles such as HGVs, vans, coaches and buses will have to be

adapted to meet tightening standards or pay to drive through the

capital. In force from February 2008. www.tfl.gov.uk/roadusers/lez

Best Practice Guide (BPG)

Outlines guidance for the control of dust and emissions from

Fitting particulate filters to non-

road mobile machinery (NRMM) construction sites, paying particular attention to off-road

reduces particulate emissions.

machinery and plant. The guide also suggests fitting particulate

filters to non-road mobile machinery (NRMM) to reduce

particulate emissions. www.alg.gov.uk

Department for Transport

The Emission Standards for Non-Road Mobile Machinery is

dedicated to reducing emissions from NRMM is part of the EU’s

strategy to reduce air pollution. These legislations tighten

emissions from diesel engines. Directive 97/68/EC, 2002/88/EC &

2004/26/EC. www.dft.gov.uk

Further Information

GenCat Ltd GenCat engineers are happy to assist in providing specific

+44 (0) 20 7998 7702 information regarding our range of effective Diesel Particulate

info@gencat.co.uk

gencat.co.uk Filters and Catalytic Converters, and can advise or provide

quotations for any of your specific requirements or applications.

Please contact us by email at info@gencat.co.uk, or by telephone

on +44 (0) 20 7998 7702. Further information can also be found

on our web site at www.gencat.co.uk

Thank you for you interest in this paper, we hope it has proved

useful in increasing your understanding of the issues surrounding

DPFs, and the solutions available to address those issues. We

welcome any comments, feedback or suggestions you may have.

Copyright 2013 © GenCat Ltd -8- Diesel Particulate Filters

www.gencat.co.uk Ver. 1.4

You might also like

- LuK India AM Catalogue 2013 2014 Download PDFDocument60 pagesLuK India AM Catalogue 2013 2014 Download PDFharshal161987No ratings yet

- 08 Chapter 3Document23 pages08 Chapter 3Sahaya GrinspanNo ratings yet

- FD200 FD250Document8 pagesFD200 FD250Tulus Ztx ZaputroNo ratings yet

- Datasheet - DC03CDNC1ADocument1 pageDatasheet - DC03CDNC1AempmudithaNo ratings yet

- DPF GauravDocument14 pagesDPF GauravGaurav KukrejaNo ratings yet

- Diesel Particulate FilterDocument9 pagesDiesel Particulate FiltertotoNo ratings yet

- Diesel P (Articulate FilterDocument16 pagesDiesel P (Articulate FilterAbhishek Kala57% (7)

- Diesel Emissions Reduction: Regenerative Diesel Particulate Filter (RDPF)Document1 pageDiesel Emissions Reduction: Regenerative Diesel Particulate Filter (RDPF)harshal161987No ratings yet

- Vidya Vardhaka College of Engineering Mysuru: "Diesel Particulate Filter"Document15 pagesVidya Vardhaka College of Engineering Mysuru: "Diesel Particulate Filter"dhanalakshmi k sNo ratings yet

- Diesel Particulate FilterDocument4 pagesDiesel Particulate FiltersantosprsdNo ratings yet

- Donaldon General Brochure WideDocument20 pagesDonaldon General Brochure WidecivodulNo ratings yet

- Thermalysis-Converting Waste Plastic To DieselDocument8 pagesThermalysis-Converting Waste Plastic To DieselRavi KumarNo ratings yet

- Clean Fuel and Lubricant SolutionsDocument32 pagesClean Fuel and Lubricant SolutionsaresobscureNo ratings yet

- Diesel Engine Systems, Diesel SmokeDocument2 pagesDiesel Engine Systems, Diesel SmokeBradley LodderNo ratings yet

- Filtro de AireDocument2 pagesFiltro de AireAndres Uzzi GuzmanNo ratings yet

- Diesel Fuel Contamination and Fuel Filter Plugging: Technical Service Bulletin 95-1Document3 pagesDiesel Fuel Contamination and Fuel Filter Plugging: Technical Service Bulletin 95-1Prabu ArNo ratings yet

- Tyre Waste Recycle PlantDocument2 pagesTyre Waste Recycle PlantSusheel JalaliNo ratings yet

- Diesel Particulate Filters Regeneration of DPF Active DPF RegenerationDocument8 pagesDiesel Particulate Filters Regeneration of DPF Active DPF RegenerationalagurmNo ratings yet

- DonaldsonDocument8 pagesDonaldsonRoberto MarianoNo ratings yet

- Coal Gasification, Liquid Fuel Conversion (CTL), and CogenerationDocument66 pagesCoal Gasification, Liquid Fuel Conversion (CTL), and CogenerationVăn Đại - BKHNNo ratings yet

- Don GTS BrochureDocument8 pagesDon GTS BrochuresanigzlNo ratings yet

- EVS - Class 10 - Notes - 2. Vehicle Emission ControlDocument5 pagesEVS - Class 10 - Notes - 2. Vehicle Emission ControlPrasanna GopalNo ratings yet

- FD Series Gas Fume Diluter BrochureDocument2 pagesFD Series Gas Fume Diluter BrochureMisaghNo ratings yet

- Diesel Fuel Contamination and Fuel Filter Plugging: Technical Service Bulletin 95-1R2Document3 pagesDiesel Fuel Contamination and Fuel Filter Plugging: Technical Service Bulletin 95-1R2KannahFreiAbenGuzmanNo ratings yet

- Pollution 3Document4 pagesPollution 3maheswarimelam2004No ratings yet

- The Functions of Environmental Engineer in Environmental Protection - 090740Document7 pagesThe Functions of Environmental Engineer in Environmental Protection - 090740Taimori FadhiliNo ratings yet

- Catalytic Pressure-Less Depolymerization" (CLPD)Document29 pagesCatalytic Pressure-Less Depolymerization" (CLPD)Wan Zulkifli Wan Idris100% (1)

- C C C ! " # $ % & ! ! ' ' ) ) ) ! CDocument4 pagesC C C ! " # $ % & ! ! ' ' ) ) ) ! CKalai VenkatesanNo ratings yet

- Appendix E Portable Diesel Engine Emission Control TechnologyDocument6 pagesAppendix E Portable Diesel Engine Emission Control Technologyer_paramjeetgillNo ratings yet

- Diesel Particulate FiltersDocument4 pagesDiesel Particulate FiltersIrvan DahlanNo ratings yet

- Fuel Filtration: Solutions Designed For The Modern Diesel EngineDocument2 pagesFuel Filtration: Solutions Designed For The Modern Diesel EngineJohn GrayNo ratings yet

- Ford Tech Fap Tdci NLDocument12 pagesFord Tech Fap Tdci NLChetan Sanikoppa Akkis100% (1)

- A Catalytic ConDocument3 pagesA Catalytic ConMoti LemiNo ratings yet

- Donaldson, ToritGeneralBrochure PDFDocument16 pagesDonaldson, ToritGeneralBrochure PDFKuganesh SankaranNo ratings yet

- Mullite-Based FiltersDocument1 pageMullite-Based FiltersSlyther aceNo ratings yet

- 6Document6 pages6kongthewiseNo ratings yet

- International Refereed Journal of Engineering and Science (IRJES)Document11 pagesInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comNo ratings yet

- All About DPF Cleaning MachineyrydeDocument2 pagesAll About DPF Cleaning Machineyrydekevinburn82No ratings yet

- Donaldson WixDocument8 pagesDonaldson WixdionymackNo ratings yet

- Mann + Hummel Diesel Particulate Filters SMF AR New Filter Technology For Diesel EnginesDocument8 pagesMann + Hummel Diesel Particulate Filters SMF AR New Filter Technology For Diesel EnginesJunaid AhmedNo ratings yet

- All About DPF Cleaning MachineoxxwiDocument2 pagesAll About DPF Cleaning Machineoxxwibeardblow5No ratings yet

- Diesel Particulate Filter, DPFDocument2 pagesDiesel Particulate Filter, DPFharshal161987No ratings yet

- Protect Your Budget! Ask For S.I.T CD92-Homogenizer!Document2 pagesProtect Your Budget! Ask For S.I.T CD92-Homogenizer!Ishara Sanjeewa PereraNo ratings yet

- Zero Waste Approach From Scrap Tyre Recycling Major Project ReportDocument10 pagesZero Waste Approach From Scrap Tyre Recycling Major Project Reportsinghsanjeev0No ratings yet

- Diesel Particulate Filter WorksDocument7 pagesDiesel Particulate Filter WorksVijayaprabakar VNo ratings yet

- DPF CeramicDocument11 pagesDPF Ceramicelliott_wolfNo ratings yet

- Analysis On Synthesis, Storage & Combustion Characteristics of DME As Fuel in CI EnginesDocument8 pagesAnalysis On Synthesis, Storage & Combustion Characteristics of DME As Fuel in CI EnginesTanu SharmaNo ratings yet

- 188709the Environmental Impact of Scrapping Your Ford Transit in LondonDocument3 pages188709the Environmental Impact of Scrapping Your Ford Transit in Londonyo.ung.s.aint.2023No ratings yet

- Protect Fuel Tier4Document16 pagesProtect Fuel Tier4zae nurdinNo ratings yet

- Brochure RMF SystemsDocument48 pagesBrochure RMF SystemsAdvikNaguNo ratings yet

- Nordin Air Filters For TurbinesDocument12 pagesNordin Air Filters For TurbinesJorge Cuadros BlasNo ratings yet

- Central Jet Pulse FilterDocument4 pagesCentral Jet Pulse FilterEhab Sabry100% (1)

- ME ProductCatalogDocument20 pagesME ProductCatalogNoman Abu-FarhaNo ratings yet

- Biomethane by GreenlaneDocument3 pagesBiomethane by GreenlaneAshwani KumarNo ratings yet

- Delphi DieselMax and Turbocharger Extra Modules PDFDocument3 pagesDelphi DieselMax and Turbocharger Extra Modules PDFSherita Thomas100% (1)

- Operators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineDocument8 pagesOperators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineKrishnan SanthanarajNo ratings yet

- Global Trust CorporationDocument12 pagesGlobal Trust Corporationamolas22No ratings yet

- 5.2 Assignment ChemistryDocument3 pages5.2 Assignment Chemistrychai monsaleNo ratings yet

- Green Power Transformers Brochure GBDocument4 pagesGreen Power Transformers Brochure GBKali MuthuNo ratings yet

- Crankcase Ventilation Filtration Systems For Diesel Engines (TSB 05-1)Document2 pagesCrankcase Ventilation Filtration Systems For Diesel Engines (TSB 05-1)Jorge Cuadros BlasNo ratings yet

- Abatement TechniquesDocument24 pagesAbatement TechniquesTian NakNo ratings yet

- Pyrocrat Systems LLP - Pyrolysis PlantDocument35 pagesPyrocrat Systems LLP - Pyrolysis PlantjasonNo ratings yet

- Is 10774Document14 pagesIs 10774harshal161987No ratings yet

- MAHA USA Complete Product Catalog 2015 071717 PDFDocument31 pagesMAHA USA Complete Product Catalog 2015 071717 PDFharshal161987No ratings yet

- Fte Kupplungsbroschuere en WebDocument8 pagesFte Kupplungsbroschuere en Webharshal161987100% (1)

- TML LCV & MCV Catalogue Updated On June 2014Document136 pagesTML LCV & MCV Catalogue Updated On June 2014harshal161987No ratings yet

- General Technical PDFDocument40 pagesGeneral Technical PDFharshal161987No ratings yet

- East West Engineering Forklift AttachmentsDocument39 pagesEast West Engineering Forklift Attachmentsharshal161987No ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To Informationharshal161987No ratings yet

- EK Elastomer CouplingsDocument24 pagesEK Elastomer Couplingsharshal161987No ratings yet

- Micro Switch Hdls Limit Ps 002354-1-En FinalDocument39 pagesMicro Switch Hdls Limit Ps 002354-1-En Finalharshal161987No ratings yet

- Is 6051 1970Document15 pagesIs 6051 1970harshal161987100% (1)

- Handbook Longlok PDFDocument48 pagesHandbook Longlok PDFharshal161987100% (1)

- Forklift Vibration DataDocument86 pagesForklift Vibration Dataharshal161987No ratings yet

- ch07 PDFDocument17 pagesch07 PDFNarendra Reddy BhumaNo ratings yet

- EAT227-Lecture 2.3 - Continuous CastingDocument25 pagesEAT227-Lecture 2.3 - Continuous CastingSurya Da Rasta100% (1)

- Section 11 - Instrumentation & Process ControlDocument59 pagesSection 11 - Instrumentation & Process Controlaanouar77No ratings yet

- Tender Document For O & M of AHS & AuxiliariesDocument33 pagesTender Document For O & M of AHS & Auxiliariesvbmrvm100% (1)

- 6 Weeks Industrial Training ReportDocument97 pages6 Weeks Industrial Training Reportapi-1962138871% (14)

- Whitening The CloudsDocument3 pagesWhitening The CloudsMartin Wac HandNo ratings yet

- Current Trends in Explosive Detection Techniques PDFDocument16 pagesCurrent Trends in Explosive Detection Techniques PDFSandra LuizNo ratings yet

- Reservoir PDFDocument5 pagesReservoir PDFTruecaller CallerNo ratings yet

- Mechanism of Ultrafast Intersystem CrossingDocument9 pagesMechanism of Ultrafast Intersystem CrossingWilliam RodriguezNo ratings yet

- SUN2000-215KTL-H0 Datasheet - (20201027)Document1 pageSUN2000-215KTL-H0 Datasheet - (20201027)Reinaldo VillatoroNo ratings yet

- Avnet S6LX16 Evl BOM RevB 091214 PreliminaryDocument8 pagesAvnet S6LX16 Evl BOM RevB 091214 PreliminarylitoduterNo ratings yet

- United Kingdom Iafci - 20231206 - 162738 - 0000Document17 pagesUnited Kingdom Iafci - 20231206 - 162738 - 0000sandraNo ratings yet

- Atmscuw301 PDFDocument120 pagesAtmscuw301 PDFHeather CarterNo ratings yet

- JMD Dredger Hansel CSD: Principle ParticularsDocument3 pagesJMD Dredger Hansel CSD: Principle Particularshassan hamdyNo ratings yet

- Pargino PROFOKS KISA-ENDocument3 pagesPargino PROFOKS KISA-ENBora CanbolatNo ratings yet

- LVDT John Ramirez and Darwin ValenzuelaDocument15 pagesLVDT John Ramirez and Darwin Valenzuelanikhilrane91_7522800No ratings yet

- 17.2. Propeller Construction.Document10 pages17.2. Propeller Construction.Anuruddha Rukmal100% (1)

- Cement Manufacturing ProcessDocument13 pagesCement Manufacturing ProcessDovah KiinNo ratings yet

- N 2023 Unit Test-5 - (19-Sep-21)Document26 pagesN 2023 Unit Test-5 - (19-Sep-21)ThilshathNo ratings yet

- Ancillary ServicesDocument19 pagesAncillary ServicesModhagapriyan MNo ratings yet

- Gamow-Teller Strength and Nuclear Deformation: MotivationDocument62 pagesGamow-Teller Strength and Nuclear Deformation: MotivationdwyphyNo ratings yet

- PTE-A Fill in The BlanksDocument10 pagesPTE-A Fill in The BlanksNisheeth RanjanNo ratings yet

- Simar ProfileDocument35 pagesSimar ProfilePawan Kumar AgrawalNo ratings yet

- Deepwater Gulf of Mexico 2009 Interim Report of 2008 HighlightsDocument87 pagesDeepwater Gulf of Mexico 2009 Interim Report of 2008 HighlightsPaul AlvarezNo ratings yet

- Comparison: Design PointDocument25 pagesComparison: Design PointDan PopescuNo ratings yet

- Kewpump: OSP 2900RPMDocument1 pageKewpump: OSP 2900RPMIhya UlumudinNo ratings yet

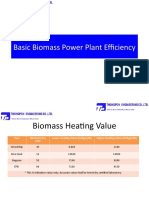

- Basic Biomass Power Plant EfficiencyDocument12 pagesBasic Biomass Power Plant EfficiencyRoger Antonio Urbina VallejosNo ratings yet

- Activity 2.3.6 Residential Electrical Systems: Ambient, Task, and AccentDocument3 pagesActivity 2.3.6 Residential Electrical Systems: Ambient, Task, and Accentapi-260940359No ratings yet

- Sounder PDFDocument2 pagesSounder PDFKalpa Helitha SilvaNo ratings yet