Professional Documents

Culture Documents

Content: Software: Cimatron E Cimco Edit Machines: MCV300 First, EMCO PCMILL 3d Scanner: Next Engine 3D Scanner

Uploaded by

MadalinGarbacea0 ratings0% found this document useful (0 votes)

8 views2 pagesThe document outlines the steps for creating a 3D model and technological analysis of a part from a CAM perspective, including identifying surfaces, geometric features, surface integrity, clamping setup, workpiece definition, part positioning, cutting tool list with specifications, machining phases with parameters for roughing and finishing, NC file analysis, reports, machining time analysis, comparing CAD models to simulations and 3D scans, and proposing optimal CAM technologies. The analysis will be performed using CIMATRON E or CIMCO EDIT software and manufactured on MCV300 First or EMCO PCMILL machines, with parts scanned using a Next Engine 3D Scanner.

Original Description:

Original Title

CAM Project.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the steps for creating a 3D model and technological analysis of a part from a CAM perspective, including identifying surfaces, geometric features, surface integrity, clamping setup, workpiece definition, part positioning, cutting tool list with specifications, machining phases with parameters for roughing and finishing, NC file analysis, reports, machining time analysis, comparing CAD models to simulations and 3D scans, and proposing optimal CAM technologies. The analysis will be performed using CIMATRON E or CIMCO EDIT software and manufactured on MCV300 First or EMCO PCMILL machines, with parts scanned using a Next Engine 3D Scanner.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesContent: Software: Cimatron E Cimco Edit Machines: MCV300 First, EMCO PCMILL 3d Scanner: Next Engine 3D Scanner

Uploaded by

MadalinGarbaceaThe document outlines the steps for creating a 3D model and technological analysis of a part from a CAM perspective, including identifying surfaces, geometric features, surface integrity, clamping setup, workpiece definition, part positioning, cutting tool list with specifications, machining phases with parameters for roughing and finishing, NC file analysis, reports, machining time analysis, comparing CAD models to simulations and 3D scans, and proposing optimal CAM technologies. The analysis will be performed using CIMATRON E or CIMCO EDIT software and manufactured on MCV300 First or EMCO PCMILL machines, with parts scanned using a Next Engine 3D Scanner.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Content

1 Model 3D of the part – Short presentation , material characteristics

2 Technological Analyze form CAM point of view

2.1 Surface identification. Color code for surface roughness

2.2 Analyze of the geometrical feature :

2.3 Surface integrity ,Surface angle ,Wall thickness

2.4 Establish the clamping of the workpiece/stock

3 Workpieces definition, for each part position

4 Establish of part positioning

5 Establish of the cutting tool list

5.1 Geometrical characteristic of the tool, tool body.

5.2 Cutting parameters for each tool for each cutting phase (roughing, rerough

etc) for the part material (formula, values)

5.3 Holder definition

6 Machining phase for each part position (detail and justification of parameters)

6.1 Rough/rerough

6.2 Finishing

6.3 Remachine/clean up, pencil

6.4 Drilling /Taping

7 Postprocesing , NC file analysis

8 Reports

9 Machining time analysis

10 Part comparing (CAD-Simulation-3D Scan)

11 Proposal for optimum CAM technology

12 Machining presentation Movies, PowerPoint

Note: For each machining phase will be explain the each parameter change in CAM software.

Software: CIMATRON E; CIMCO EDIT;

Machines: MCV300 First, EMCO PCMILL

3d Scanner: Next Engine 3D Scanner

You might also like

- Printed Circuit Board DesignDocument60 pagesPrinted Circuit Board DesignUday Bhaskar100% (1)

- Manufacturing Surface Technology: Surface Integrity and Functional PerformanceFrom EverandManufacturing Surface Technology: Surface Integrity and Functional PerformanceRating: 5 out of 5 stars5/5 (1)

- CAM - Training (CNC Simulator)Document110 pagesCAM - Training (CNC Simulator)farid_a_dzNo ratings yet

- Reverse EngineeringDocument24 pagesReverse EngineeringAl Mutiry MuardNo ratings yet

- FastCAM TutorialDocument137 pagesFastCAM Tutorialvelu22100% (2)

- Material Forming Processes: Simulation, Drawing, Hydroforming and Additive ManufacturingFrom EverandMaterial Forming Processes: Simulation, Drawing, Hydroforming and Additive ManufacturingNo ratings yet

- New Module STAADPro RCDDocument41 pagesNew Module STAADPro RCDRionny BNo ratings yet

- NX CAM Post Processing Errors Machine Data File Ge PDFDocument7 pagesNX CAM Post Processing Errors Machine Data File Ge PDFSHARAD CHANDRANo ratings yet

- CNC Machining Report - Premounting BaseDocument19 pagesCNC Machining Report - Premounting BaseMichael M. W. de Silva50% (2)

- Ae503eDocument7 pagesAe503eVijay KumbharNo ratings yet

- A Comparitive Study of CNC Milling Cutting Path StrategiesDocument8 pagesA Comparitive Study of CNC Milling Cutting Path StrategiesNorbertoEsparzaNo ratings yet

- Mastercam Training Course CurriculumDocument4 pagesMastercam Training Course Curriculumpankaj_97No ratings yet

- Cad Cam 1Document9 pagesCad Cam 1Kush KumarNo ratings yet

- Introduction To CAD/CAM: Pankaj Chhabra Cad/Ca MDocument22 pagesIntroduction To CAD/CAM: Pankaj Chhabra Cad/Ca MPankaj ChhabraNo ratings yet

- CAD CAM Unit 4Document41 pagesCAD CAM Unit 4Ishank Singh SandhuNo ratings yet

- Intenship PresentationDocument22 pagesIntenship PresentationArpita FundeNo ratings yet

- V. S. B Engineering College, Karur - 639 111: Department of Mechanical EngineeringDocument121 pagesV. S. B Engineering College, Karur - 639 111: Department of Mechanical EngineeringvinodkumarNo ratings yet

- Cad/Cam Syllabus: B.Tech IV Year I Semester Examination (Mechanical Engineering)Document23 pagesCad/Cam Syllabus: B.Tech IV Year I Semester Examination (Mechanical Engineering)Mohammed SameerNo ratings yet

- Final Exam CADCAMFinal 2016FinalAnswersDocument10 pagesFinal Exam CADCAMFinal 2016FinalAnswerskhalil alhatabNo ratings yet

- CAM & Robotics Lab Manual+27-07-16 GVPCOEDocument29 pagesCAM & Robotics Lab Manual+27-07-16 GVPCOESaid kiranNo ratings yet

- CAM Program DissertationDocument110 pagesCAM Program DissertationjkruiseNo ratings yet

- MDM Lab ManualDocument63 pagesMDM Lab ManualDH Pachchinavar MechanicalNo ratings yet

- Tut2 FacemillingDocument5 pagesTut2 FacemillingPRABHU JNo ratings yet

- Mechanical Engg 19Document115 pagesMechanical Engg 19Harshul BrahmbhattNo ratings yet

- Full Text 01Document74 pagesFull Text 01Vu LeNo ratings yet

- 06mel77 - Cim - AutoDocument79 pages06mel77 - Cim - AutoPraveen KumarNo ratings yet

- Upgraded Technology and Application in Die CastingDocument12 pagesUpgraded Technology and Application in Die CastingSaurabhNo ratings yet

- Cadcam LabDocument83 pagesCadcam LabRachit VemulaNo ratings yet

- NX CAM Errors Machine DataDocument7 pagesNX CAM Errors Machine DataRamNo ratings yet

- CNC Machining Report - Wheel BaseDocument25 pagesCNC Machining Report - Wheel BaseMichael M. W. de SilvaNo ratings yet

- 7-Manual Process Planning (AMS May13 - 13) PDFDocument24 pages7-Manual Process Planning (AMS May13 - 13) PDFtadele10No ratings yet

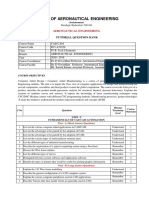

- Institute of Aeronautical EngineeringDocument7 pagesInstitute of Aeronautical EngineeringGGRNo ratings yet

- CADCAM Course OutlineDocument9 pagesCADCAM Course OutlineJibril JundiNo ratings yet

- Unit-15 CAPP For Forming ProcessesDocument23 pagesUnit-15 CAPP For Forming ProcessesFaizanNo ratings yet

- Tutorial CadcamDocument3 pagesTutorial CadcamBhavesh PatelNo ratings yet

- Mee2007 Cad CamDocument2 pagesMee2007 Cad CamSrivathson EswaranNo ratings yet

- Cad Cam HandoutDocument2 pagesCad Cam HandoutDinesh KilladaNo ratings yet

- Manufacturing: Cutting Tools Processing ParametersDocument18 pagesManufacturing: Cutting Tools Processing ParametershayasakaNo ratings yet

- PLA222Document5 pagesPLA222namasse.medamineNo ratings yet

- State of Cold Forging Technology in Global Competition - Net Shape PDFDocument20 pagesState of Cold Forging Technology in Global Competition - Net Shape PDFMustafa Mert SAMLINo ratings yet

- FFcam Lo-141E 081118 2Document12 pagesFFcam Lo-141E 081118 2Mathi Alagan0% (1)

- Cad Cam in Ship ConstructionDocument3 pagesCad Cam in Ship ConstructionkanavNo ratings yet

- Cad Cam - 22.12.15-1 PDFDocument87 pagesCad Cam - 22.12.15-1 PDFGuru MaheshNo ratings yet

- Entregable 2Document8 pagesEntregable 2Alain GarciaNo ratings yet

- Me8381-39.1 (2) - OkDocument21 pagesMe8381-39.1 (2) - OkPayum PuliNo ratings yet

- BEV 45401 E1 Design of 1 Phase 2S-2P PMSMDocument14 pagesBEV 45401 E1 Design of 1 Phase 2S-2P PMSMsedarNo ratings yet

- Mechanical - VI. Sem Syllabus GtuDocument115 pagesMechanical - VI. Sem Syllabus GtukishormechNo ratings yet

- Cad-Cam - Ittd2 - 2020Document3 pagesCad-Cam - Ittd2 - 2020Tafara DarangwaNo ratings yet

- Tut3 PocketMilling RoughingDocument5 pagesTut3 PocketMilling RoughingPRABHU JNo ratings yet

- Lab 3 Background On G-Code GenerationDocument4 pagesLab 3 Background On G-Code GenerationRaymond KwonNo ratings yet

- Structural Analysis and Design (Staad) : OverviewDocument2 pagesStructural Analysis and Design (Staad) : Overviewmd. alaul azmirNo ratings yet

- 3D Multizone Scaling Method of An NC Program For Sole Mould ManufacturingDocument5 pages3D Multizone Scaling Method of An NC Program For Sole Mould ManufacturingrajrythmsNo ratings yet

- Optimization of Machining Parameters in CNC Milling Machine Using Taguchi MethodDocument11 pagesOptimization of Machining Parameters in CNC Milling Machine Using Taguchi MethodAllaboyinamahidharNo ratings yet

- 1718sem1 Me5608Document4 pages1718sem1 Me5608Benedict ChinNo ratings yet

- CADCAM MinDocument91 pagesCADCAM MinBandi KumarreddyNo ratings yet

- Lecture01 - CAD CAM - CAE - Introduction of The CourseDocument21 pagesLecture01 - CAD CAM - CAE - Introduction of The CourseSameer shaikhNo ratings yet

- CAD CAM Syllabus CoverageDocument7 pagesCAD CAM Syllabus CoverageSubbu SuniNo ratings yet

- Syllabus: ME2309 Cad/Cam Lab LTPC 0 0 3 2 ObjectivesDocument26 pagesSyllabus: ME2309 Cad/Cam Lab LTPC 0 0 3 2 ObjectivesSenthilkumar SubbiahNo ratings yet

- 1 Block (Cutting) : Projects (Practical Lab)Document2 pages1 Block (Cutting) : Projects (Practical Lab)Malcolm DiamondNo ratings yet