Professional Documents

Culture Documents

Equipment and Process Control Design: Table 4.1 Physical and Chemical Characteristics of Influent and Effluent

Equipment and Process Control Design: Table 4.1 Physical and Chemical Characteristics of Influent and Effluent

Uploaded by

Princess Janine CatralOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment and Process Control Design: Table 4.1 Physical and Chemical Characteristics of Influent and Effluent

Equipment and Process Control Design: Table 4.1 Physical and Chemical Characteristics of Influent and Effluent

Uploaded by

Princess Janine CatralCopyright:

Available Formats

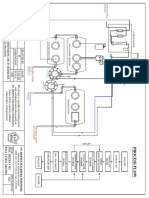

CHAPTER 4

EQUIPMENT AND PROCESS CONTROL DESIGN

4.1 Characteristics of Influent and Effluent

Based on the available data given by Metropolitan Tuguegarao Water District (MTWD),

the flowrate of grey water produced from the urban and rural areas of Barangay Carig Norte and

Sur with an estimated population of 7000 people. Data gathered showed that the sewage

produced from each person was 60 L/person/day. The treated wastewater will be received by a

water body belonging to Class C which will be used for agriculture, irrigation and livestock

watering (DAO, 2016). The physical and chemical constituents of the influent and effluent are

shown in Table 3.1.

Table 4.1 Physical and chemical characteristics of influent and effluent

Receiving Water

Constituents Grey Water (Influent) Unit

(Effluent)

BOD5 200 5-7 mg/L

Color Gray 75 (TCU)

o

Temperature 13-32 25-31 C

Total Suspended Solids 200 80 mg/L

pH 7.5 6.5-9.0

Nitrate as NO3-N 0.5 7 mg/L

Fecal coliform 30x106 200 MPN/100 mL

To meet the physical and chemical characteristics of the receiving water, the influent

must undergo a secondary water treatment using the conventional activated sludge process. This

process is the most versatile and widely used biological process of municipal waters and is low-

cost (Corbitt, 2004). The parameters that should be addressed in designing an activated sludge

process is shown in Table 3.2.

Table 4.2 Design Parameters for Convential Activated Sludge Reactor

Parameter Typical value

Organic loading 25–50 lb BOD5/day/1000 ft3 (0.4–0.8 kg BOD5/day/m3)

MLSS 1500–4000 mg/L

F/M ratio 0.2–0.5 lb BOD5/day/lb MLSS (0.2–0.5 kg BOD5/day/kg MLSS)

Detention time 4–8 h

Recycle 50–100%

Air supply

Diffused aeration 800–1500 scf/lb BOD5 removed (50–95 m3/kg BOD5 removed)

Mechanical aeration 0.8–1.1 lb O2/lb BOD5 removed (0.8–1.1 kg O2/kg BOD5

removed)

Mean Cell Residence 5–10 days

Time

Waste sludge 0.4–0.6 lb/lb BOD, removed (0.4–0.6 kg/kg BOD, removed)

Source: Corbitt, 2004

4.2 Activated Sludge Reactor

For the design of a conventional activated sludge reactor (CASP), the following data

were used.

Given:

Population = 7000 people

Individual sewage rate = 60 L/person/day

Flowrate= 60L/person/day(0.001)(7000)= 420 m3/day

Total nitrogen = 40 mg/L

Total phosphate = 15 mg/L

BOD5 concentration = 53g/person/day(1person/day/60L)(1000)=883 mg/L

BOD5/BODu = 1.04

Total Volatile Solids = 425 mg/L

Total Suspended Solids = 800 mg/L

Assumptions:

Mean Cell Residence Time, θc = 10 days

Mixed Liquor Suspended Solids, MLSS = 3000 mg/L

Recirculation Rate, Xr = 10,000 mg/L

Y = 0.23

Decay constant Kd = 0.07 per day

Specific substrate utilization rate, q = (0.038 mg/l)-1 (h)-1

Assume 35% BOD removal in primary clarifier therefore BOD 5 going into aeration tank

is 883(1-0.35) = 574 mg/L

Width to depth ratio = 1.2-2.2

Calculations:

Effluent BOD5 concentration

1 1

Substrate Concentration, S= ( 1/θ c +K d ) = (1/10+0.07)

qY 0.038(0.6)

S=7.46 mg/L

VSS 425

= =0.53

SS 800

Assume biodegradable fraction in VSS is 0.7 and BOD5 of effluent is 20mg/L

BOD5 of VSS in effluent=0.7(0.5)(20)=7mg/L

Total BOD5 in effluent = 7.46+7= 14.46 mg/L

Reactor Volume

QY θ c ( So −S ) 420(0 . 23)(10 )(574−14 . 46)

V r= =

(1+K d θ c ) X (1+0 .07 (10))(3000 )

V r = 106 m 3

Volume of excess solids, Qw

V r X 106 (3000 )

Qw = =

θ c X r 10(10000 )

m3

Q w =3 . 18

day

Mass of excess solids

kg

Qw X r =3 .18 (10 )=31 . 8

day

Recycled wasted sludge, Qr

QX−Qw X r 420(3000 )−31. 8(10000 )

Qr = =

X r −X 10000−3000

kg

Q r =134 .57

day

Recirculation Ratio

Q r 134.57

R= =

Q 420

R=0. 32 .

Aeration time

QS 420(0.574) kg BOD

OL= o = =0.74 3 5

V r 106 m day

Food to microorganism ratio

Q (S o −S) 420(574−14 . 46)

F /M= =

VrX 106(3000 )

kg BOD5

F /M=0. 74

kg MLSS day

Oxygen Requirement

Q(S 0 −S)

O2 required= −1. 42Qw X r

BOD5 /BOD u

420 (0.574-0.01446 )

O2 required= −1.42(3.18)(10)

1.04

kg

O2 required=180 .81

day

BOD removal efficiency

So −S 883−14 . 46

BOD removal= (100)= (100)

So 883

BOD removal = 98 . 4%

Reactor dimensions

Assume width to depth ratio = 1.5 and depth = 4.5 m

w=1.5(4.5m)

w=6.75m

4.3 Secondary clarifier

Basis: Flowrate, Q = 420 m3/day

Calculations:

Surface Area

QC 420

A= = ; assume overflow rate=20 .35 m3 /m2 /day

OR 20 .35

A=20. 64 m2

Volume

Assume automatic sludge removal therefore detention time, t = 4h

V=Qt=420( 4h)(1day /24 h)

3

V=70m

Depth

V 70

d= =

A 20.64

d=3 .39m

Width and Length

W=

V

√ √

=

70

4d 4(3.39)

W=2.27m

L=4W=4(2.27)

L=9.08m

Cross-sectional Area

A x=Wd=2.27 (3 .39)

A x=7.70 m2

References

Corbitt, R. A. (2004). Standard Handbook of Environmental Engineering. McGraw-Hill.

DENR-EMB. (2016, May 24). Water Quality Guidelines and General Effluent Standards of

2016. DENR ADMINISTRATIVE ORDER NO. 2016-08. Quezon City, Philippines:

Official Gazette.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Unit Operations and Processes in Environmental Engineering. Reynolds. 2nd Edition 1996. PWS PDFDocument814 pagesUnit Operations and Processes in Environmental Engineering. Reynolds. 2nd Edition 1996. PWS PDFSamir Cruzalegui Delgado67% (3)

- Sewerage Discharge CalculationDocument2 pagesSewerage Discharge CalculationAkhil VijaiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Log Book For Operation ETPDocument1 pageLog Book For Operation ETPkaushik_amit87638581% (37)

- Calibration of Rectangular NotchDocument4 pagesCalibration of Rectangular NotchPrincess Janine CatralNo ratings yet

- RAMP RESPONSE (Single Model) Ramp Parameters Values: Slope 1 Start Time 0 Initial Output 0 Tau 0.1 K 1Document7 pagesRAMP RESPONSE (Single Model) Ramp Parameters Values: Slope 1 Start Time 0 Initial Output 0 Tau 0.1 K 1Princess Janine CatralNo ratings yet

- Biodegradation in A Packed Bed ColumnDocument2 pagesBiodegradation in A Packed Bed ColumnPrincess Janine CatralNo ratings yet

- Comparison of Michaelis-MentenDocument2 pagesComparison of Michaelis-MentenPrincess Janine CatralNo ratings yet

- Quiz #3: Biochemical Engineering Fall 2003Document5 pagesQuiz #3: Biochemical Engineering Fall 2003Princess Janine CatralNo ratings yet

- DTI Project Proposal Edit 1Document9 pagesDTI Project Proposal Edit 1Princess Janine CatralNo ratings yet

- PUV Modernization ProgramDocument7 pagesPUV Modernization ProgramPrincess Janine CatralNo ratings yet

- Quiz #4: Biochemical Engineering Fall 2003Document5 pagesQuiz #4: Biochemical Engineering Fall 2003Princess Janine CatralNo ratings yet

- Dengvaxia IssueDocument11 pagesDengvaxia IssuePrincess Janine CatralNo ratings yet

- Vince F. Nonato @vincenonatoinq: Amid Boracay Sludge, House Probe Sought On Dot'S Plans For Sustainable TourismDocument12 pagesVince F. Nonato @vincenonatoinq: Amid Boracay Sludge, House Probe Sought On Dot'S Plans For Sustainable TourismPrincess Janine CatralNo ratings yet

- Wireless Power-The BasicsDocument18 pagesWireless Power-The BasicsPrincess Janine CatralNo ratings yet

- Supercritical CO2 ExtractionDocument6 pagesSupercritical CO2 ExtractionPrincess Janine CatralNo ratings yet

- Environmental Constraints and AnalysisDocument1 pageEnvironmental Constraints and AnalysisPrincess Janine CatralNo ratings yet

- Solved Problems in Fluid MechanicsDocument19 pagesSolved Problems in Fluid MechanicsPrincess Janine CatralNo ratings yet

- COURSE OUTLINE - Process IntegrationDocument3 pagesCOURSE OUTLINE - Process IntegrationPrincess Janine CatralNo ratings yet

- Activated Sludge Reactor Calculations Given Value UnitDocument2 pagesActivated Sludge Reactor Calculations Given Value UnitPrincess Janine CatralNo ratings yet

- A Plot of 1/D Vs 1/Cs: Dilution Rate (HR Inlet Concentration Steady State Concentration (G/L) Column1 Column2 1/D 1/CsDocument3 pagesA Plot of 1/D Vs 1/Cs: Dilution Rate (HR Inlet Concentration Steady State Concentration (G/L) Column1 Column2 1/D 1/CsPrincess Janine CatralNo ratings yet

- Amino Acid 2Document6 pagesAmino Acid 2Princess Janine CatralNo ratings yet

- Princess Janine B. Catral Bs Che Iv I. Michaelis-Menten EquationDocument1 pagePrincess Janine B. Catral Bs Che Iv I. Michaelis-Menten EquationPrincess Janine CatralNo ratings yet

- Bacillus Thuringiensis Is A Bacterium That Is Pathogenic For A Number of Insect Pests. Its LethalDocument1 pageBacillus Thuringiensis Is A Bacterium That Is Pathogenic For A Number of Insect Pests. Its LethalPrincess Janine CatralNo ratings yet

- Sickle Cell Anemia AssignmentDocument2 pagesSickle Cell Anemia AssignmentPrincess Janine CatralNo ratings yet

- Desalination of Seawater by Reverse Osmosis Ro MethodDocument3 pagesDesalination of Seawater by Reverse Osmosis Ro MethodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Lecture 4 SedimentationDocument6 pagesLecture 4 Sedimentationdania alnajiNo ratings yet

- Activated Sludge CalculationsDocument23 pagesActivated Sludge CalculationsDerek Kawaii100% (3)

- What Are The Parameters of An Extended Aeration Activated Sludge System - Water Tech Online PDFDocument9 pagesWhat Are The Parameters of An Extended Aeration Activated Sludge System - Water Tech Online PDFZoran KostićNo ratings yet

- P&ID-500 CMR-R1 (Original)Document1 pageP&ID-500 CMR-R1 (Original)Ahmed WagihNo ratings yet

- WWTR 3Document84 pagesWWTR 3AbelNo ratings yet

- NPCP Chapter 12 PDFDocument4 pagesNPCP Chapter 12 PDFCristian OmacNo ratings yet

- Project ADocument21 pagesProject Amustafabeda06No ratings yet

- Determination of Solids in WaterDocument7 pagesDetermination of Solids in WaterManoj KarmakarNo ratings yet

- Recoflo Integrated Water Treatment Systems: High Purity Simple Package Proven ReliabilityDocument2 pagesRecoflo Integrated Water Treatment Systems: High Purity Simple Package Proven ReliabilitysalcedopozasNo ratings yet

- Chapter 8: Oxygen DemandDocument12 pagesChapter 8: Oxygen DemandIra MejiaNo ratings yet

- Wabag Bioden: Nitrate Removal Biological Denitrifi Cation of Ground WaterDocument6 pagesWabag Bioden: Nitrate Removal Biological Denitrifi Cation of Ground WaterNguyen AnNo ratings yet

- STP Presentation - SBRDocument51 pagesSTP Presentation - SBRNoriel Luna100% (1)

- The World of Activated SludgeDocument21 pagesThe World of Activated SludgeBoon Chew100% (3)

- MCQs On Sewage TreatmentDocument14 pagesMCQs On Sewage TreatmentMuhammad Usman100% (2)

- Chapter 5 Sewage Treatment PlantDocument3 pagesChapter 5 Sewage Treatment PlantJasleneDimarananNo ratings yet

- Technical Service Bulletin: Startup and Usage Guidelines For Hydrasub - MBRDocument6 pagesTechnical Service Bulletin: Startup and Usage Guidelines For Hydrasub - MBRferg1980No ratings yet

- Al Multaqaa Presentation v2Document22 pagesAl Multaqaa Presentation v2Hasaan WaheedNo ratings yet

- EXP 6 - Fecal Coliform Test - StudentDocument8 pagesEXP 6 - Fecal Coliform Test - StudentAbo SmraNo ratings yet

- The Sewage Collected From The Municipal Area Consists of Wastewater Generated From TheDocument47 pagesThe Sewage Collected From The Municipal Area Consists of Wastewater Generated From Theranya doskiNo ratings yet

- Water Reuse in MexicoDocument10 pagesWater Reuse in MexicoDaniela RuizNo ratings yet

- Contoh Denah IpalDocument1 pageContoh Denah IpalRima UlNo ratings yet

- TratamientoBiologicoAerobio RevAfinidad2011 PDFDocument9 pagesTratamientoBiologicoAerobio RevAfinidad2011 PDFAlberto VELOSA ROANo ratings yet

- Stabilization PondsDocument2 pagesStabilization PondsAhoud AlhaimliNo ratings yet

- Wastewater Story QsDocument6 pagesWastewater Story QsTUSHAR DASHNo ratings yet

- Waste Water TreatmentDocument20 pagesWaste Water TreatmentPrakhar SrivastavaNo ratings yet