50% found this document useful (2 votes)

1K views2 pagesInsulation Thickness Calculation

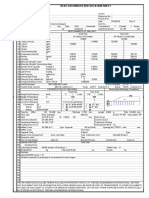

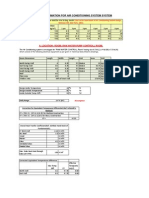

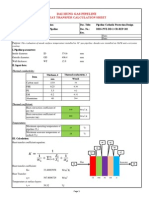

This document summarizes the insulation calculations for a 1m long horizontal steel chilled water pipe with an outer diameter of 355.6mm. It calculates the minimum required insulation thickness as 24mm and selects a 25mm thick NBR insulation material. Intermediary results show the old total heat loss was -503.5W, new total is -49.42W, for a 90.19% performance improvement. External surface temperature is calculated as 32.24°C, above the dew point of 32.09°C.

Uploaded by

Lepanto SakyodCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

50% found this document useful (2 votes)

1K views2 pagesInsulation Thickness Calculation

This document summarizes the insulation calculations for a 1m long horizontal steel chilled water pipe with an outer diameter of 355.6mm. It calculates the minimum required insulation thickness as 24mm and selects a 25mm thick NBR insulation material. Intermediary results show the old total heat loss was -503.5W, new total is -49.42W, for a 90.19% performance improvement. External surface temperature is calculated as 32.24°C, above the dew point of 32.09°C.

Uploaded by

Lepanto SakyodCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd