Professional Documents

Culture Documents

Hydraulic Pulley Puller

Uploaded by

Tanvi KhuranaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Pulley Puller

Uploaded by

Tanvi KhuranaCopyright:

Available Formats

HYDRAULIC PULLEY PULLER

SYNOPSIS

This project is deals with design and fabrication of a hydraulic pulley puller,

which is used for removing pulleys from the shaft and the pulley cup with the help of a

hydraulic

Initially the pulley shaft is held between two fixtures. The hydraulic is passed to

the direction control valve. The top fixture is moves up wards, so that the pulley is

removed from the shaft.

INTRODUCTION

The hydraulic pulley puller is used to removing the pulleys in the shaft by holding

the pulley shaft in between two fixtures. One of the fixtures is movable and the other one

is fixed. The principle of operation is the same as the conventional simple press. The

difference is being only in the type of drive and the type of fixtures used.

The following points reveals why we have to make use of this type of press for

removing pulleys.

Hydraulic pulley puller reduces the manual work.

This type of machine reduces working time in removing

pulleys.

By using this machine the pulleys can be removed in the various lengths of shat

(up to 600mm).

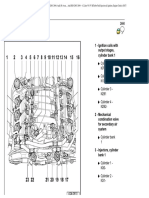

PRINCIPLE OF OPERATION

The hydraulic pulley puller is used to removing pulleys in the shaft up to a

length of 600mm. In the hydraulic pulley puller the main thing being the pressure

developed is done with the help of a pump. The oil in that pump is passed to the

cylinder.

When the oil is passed to the valve, the required speed of the piston is

obtained by adjusting its knob. When the oil is passed to the valve, the up/downward

movement of piston is controlled by the hand liver. The pulley shaft is connected to

the top fixture. A bottom fixture is fixed on the bottom plate by using bolts and nuts.

Pulley Removing procedure:

The shaft is kept vertically between the top fixture. The pulley shaft is kept in the

top of the fixture. The remaining portion of the shaft touches the bottom fixture.

At the same time the pump is loaded to get the pressure required and the hand

operated valve is manually to move the piston. The top fixture in the piston had

inserted to its required position rod pushes the pulley which is placed on the shaft.

When the pulley has removed to its original position, there will not be any further

down ward movement. Then the valve is brought to the output position in which the

air moves the piston upward and the shaft is removed.

ADVANTAGES

1. It reduces the manual work

2. It reduces the production time

3. Uniform application of the load gives perfect removing of the pulley.

4. Damages to the pulley due to the hammering is prevented

5. It occupies less floor space

6. Less skilled operator is sufficient

DISADVANTAGES

1. Initial cost is high

2. Cylinder stroke length is constant

3. Need a separate compressor

APPLICATIONS

Pulley Pressing Operation in all industries

Pulley Removing operation in all Industries

Sheet metal bending in sheet metal industries

Sheet metal bend removing in all industries

Punching operation also done

Riveting and metal forming also done with the help of separated

male and female die.

pull

You might also like

- Decorator 2 Actual Machine ManualDocument386 pagesDecorator 2 Actual Machine ManualAhmed NabilNo ratings yet

- Pipework Energy Loses ExperimentDocument27 pagesPipework Energy Loses Experimentmoaaz100% (1)

- CNV 03 BDocument4 pagesCNV 03 BMaitry ShahNo ratings yet

- Longitudinal Oscillations of Vehicle/Trailer CombinationsDocument20 pagesLongitudinal Oscillations of Vehicle/Trailer CombinationsSteven SunNo ratings yet

- MTA-2000 Paper and Board Bursting Strength TesterDocument1 pageMTA-2000 Paper and Board Bursting Strength TesterAndi FebriantoNo ratings yet

- Merle C. Potter - Termodinâmica - Soluções em InglêsDocument11 pagesMerle C. Potter - Termodinâmica - Soluções em InglêsAdautozanata0% (2)

- 4 Versus 8 Counterweights For An I4 Gasoline Engine CrankshaftDocument12 pages4 Versus 8 Counterweights For An I4 Gasoline Engine CrankshaftKillgusNo ratings yet

- Aluminum electrolytic capacitors data sheet overviewDocument8 pagesAluminum electrolytic capacitors data sheet overviewEdson100% (1)

- FV609-Simulation Using ProModel - Charles HarrellDocument703 pagesFV609-Simulation Using ProModel - Charles HarrellRheza Nugraha PrabareswaraNo ratings yet

- Development of Analytical Process To Reduce Side Load in Strut-Type SuspensionDocument6 pagesDevelopment of Analytical Process To Reduce Side Load in Strut-Type SuspensionJessica OwensNo ratings yet

- Instruction ManualDocument34 pagesInstruction ManualARTURO TZITZIHUA HERNANDEZ100% (1)

- Pneumatic Bearing PullerDocument4 pagesPneumatic Bearing PullerMANIKANDAN B100% (1)

- Pneumatic Bearing PullerDocument4 pagesPneumatic Bearing PullerShankar G50% (2)

- Pneumatic Riveting Machine - Project ReportDocument48 pagesPneumatic Riveting Machine - Project ReportTanvi Khurana82% (11)

- Automatic Side StandDocument32 pagesAutomatic Side StandTanvi Khurana50% (2)

- Automatic Side StandDocument32 pagesAutomatic Side StandTanvi Khurana50% (2)

- Football StadiumDocument31 pagesFootball StadiumTanvi Khurana100% (4)

- 360 Degree Flexible Drilling MachineDocument26 pages360 Degree Flexible Drilling MachineSTAR PRINTING75% (16)

- Calculation of Water Current ForcesDocument4 pagesCalculation of Water Current Forcesvasu7900No ratings yet

- CCDP ARCH 300-320, 4th Edition-2016 PDFDocument902 pagesCCDP ARCH 300-320, 4th Edition-2016 PDFCarlos Trujillo Rojas100% (2)

- Total Drill Cost CalculatorDocument3 pagesTotal Drill Cost CalculatorRenéAlvarezPolo100% (2)

- MOFFETT M8 55.3: Built To PerformDocument2 pagesMOFFETT M8 55.3: Built To PerformAlejandro VelásquezNo ratings yet

- ASTM D2270 - 11 - Standard Practice For Calculating Viscosity Index From Kinematic Viscosity at 40 DegC and 100 DegCDocument6 pagesASTM D2270 - 11 - Standard Practice For Calculating Viscosity Index From Kinematic Viscosity at 40 DegC and 100 DegCnam88100% (1)

- RS425 TerexDocument2 pagesRS425 TerexMAQUINARIA 2022No ratings yet

- Iso5167 4Document32 pagesIso5167 4Alessio NardiniNo ratings yet

- Ospb, Ospc, Ospr, OSPD Open Center Steering Units OSPB Closed Center Steering Units TAD Torque AmplifiersDocument32 pagesOspb, Ospc, Ospr, OSPD Open Center Steering Units OSPB Closed Center Steering Units TAD Torque Amplifiersmartin melchorNo ratings yet

- WCFX EvDocument31 pagesWCFX EvhjmmNo ratings yet

- Civacon 8130 Optic Rack MonitorDocument16 pagesCivacon 8130 Optic Rack MonitorGusukuma JGNo ratings yet

- 02 Norma Asae Maquinas Agricolas DimensionamentoDocument9 pages02 Norma Asae Maquinas Agricolas DimensionamentoBF DalmagroNo ratings yet

- An Exhaust Manifold Pressure Estimator For A Two-Stage Turbocharged Diesel Engine - 0409Document6 pagesAn Exhaust Manifold Pressure Estimator For A Two-Stage Turbocharged Diesel Engine - 0409Carlos Eduardo MarrascaNo ratings yet

- Drive Wheel Motor Torque Calculations for Mobile VehiclesDocument2 pagesDrive Wheel Motor Torque Calculations for Mobile VehiclesvesselNo ratings yet

- Lambda Sensor LSU 49 Datasheet 51 en 2779147659pdfDocument4 pagesLambda Sensor LSU 49 Datasheet 51 en 2779147659pdfRsl AliNo ratings yet

- Tipping Solutions Oil Tank Component CatalogDocument32 pagesTipping Solutions Oil Tank Component CatalogIgor Ferreira dos SantosNo ratings yet

- Catalogo RacorDocument179 pagesCatalogo RacorEdwin Maldonado Castro100% (1)

- Ficha Gerador Olympian GEP550Document6 pagesFicha Gerador Olympian GEP550Geetha_jagadish30100% (1)

- Hydro Leduc - Hydraulic Pumps Xpi Series PDFDocument7 pagesHydro Leduc - Hydraulic Pumps Xpi Series PDFteodorescu MARIUSNo ratings yet

- Motors | Automation | Energy | Transmission & Distribution | Coatings | CFW500 User's ManualDocument134 pagesMotors | Automation | Energy | Transmission & Distribution | Coatings | CFW500 User's ManualLeandroNo ratings yet

- Moog ServoDrives RMC - T161 - CAN - Profile Manual enDocument104 pagesMoog ServoDrives RMC - T161 - CAN - Profile Manual enJorge Sarmiento100% (1)

- Axial Piston Pumps: Maximum Operating Pressure Maximum Displacement Series Model RemarksDocument5 pagesAxial Piston Pumps: Maximum Operating Pressure Maximum Displacement Series Model RemarksGatuquilloNo ratings yet

- 6 Acceleration PolygonDocument10 pages6 Acceleration Polygonalibaba011No ratings yet

- 01 Grove YB7722XL - 22Document16 pages01 Grove YB7722XL - 22Tom CoxNo ratings yet

- HydronitDocument80 pagesHydronitAnuradha Chathuranga100% (2)

- SMHS7531 - Uso Del Kit de Reparacion de Conectores Sure Seal 6v3000Document10 pagesSMHS7531 - Uso Del Kit de Reparacion de Conectores Sure Seal 6v3000Sergio Velarde RomayNo ratings yet

- 3 Rear Suspension-N900 Series JMCDocument17 pages3 Rear Suspension-N900 Series JMCRusonegroNo ratings yet

- W1500 Series Hydraulic Pump: Concentric ABDocument12 pagesW1500 Series Hydraulic Pump: Concentric ABvut73 a100% (1)

- OPM 4000 Owners Manual EnglishDocument63 pagesOPM 4000 Owners Manual EnglishJean Lucas ZanattaNo ratings yet

- Torque Measurement FundamentalsDocument17 pagesTorque Measurement FundamentalsVaibhavNo ratings yet

- Plano de Manutenção VolareDocument4 pagesPlano de Manutenção Volareshirley sandraNo ratings yet

- Cogging Torque MeasurementDocument3 pagesCogging Torque MeasurementIon TrifuNo ratings yet

- 2 Front Axle, Front Suspension-N900 Series JMCDocument41 pages2 Front Axle, Front Suspension-N900 Series JMCRusonegroNo ratings yet

- BCA Radial BearingsDocument29 pagesBCA Radial BearingsJosé ReinaldoNo ratings yet

- Astm e 516 Rev A 1995 R 2005 PDFDocument10 pagesAstm e 516 Rev A 1995 R 2005 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Manual Vortex FoxboroDocument56 pagesManual Vortex FoxboroYadir SánchezNo ratings yet

- Parker T6CC-I 叶片泵手册Document15 pagesParker T6CC-I 叶片泵手册xxshNo ratings yet

- Chapter 05 Mark 8Document60 pagesChapter 05 Mark 8Anonymous vdjEcBNo ratings yet

- RS6 FuelInjection ComponentLayoutDocument15 pagesRS6 FuelInjection ComponentLayoutgrushe100% (1)

- Operation and Maintenance Manual: Maxp Series AnsiDocument40 pagesOperation and Maintenance Manual: Maxp Series AnsiCarlos GomezNo ratings yet

- 1SDA071192R1 E4 2n 4000 Ekip Dip Lsi 3p F HRDocument3 pages1SDA071192R1 E4 2n 4000 Ekip Dip Lsi 3p F HRjunior_jazzzNo ratings yet

- 4.XJ250 Convenio Tecnico de FlushbyDocument11 pages4.XJ250 Convenio Tecnico de FlushbyGabriel Alejandro JoaquinNo ratings yet

- Precision Machinery Swash Plate Axial Piston PumpDocument76 pagesPrecision Machinery Swash Plate Axial Piston Pumprbdubey2020No ratings yet

- Eaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKDocument64 pagesEaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKdoanmdatNo ratings yet

- Omron Photoelectric Sensor E3jk 5M1Document8 pagesOmron Photoelectric Sensor E3jk 5M1harishsharma22No ratings yet

- Subaru Forester Manuals 2010 Forester Owner's Manual PDFDocument404 pagesSubaru Forester Manuals 2010 Forester Owner's Manual PDFPaul PCNo ratings yet

- OPEL INSIGNIA 2013 - Engine Mechanical - 2.0L (LTG) - Repair Instructions - On VehicleDocument272 pagesOPEL INSIGNIA 2013 - Engine Mechanical - 2.0L (LTG) - Repair Instructions - On VehicleGedas GvildysNo ratings yet

- Remove bearings quickly with hydraulic pullerDocument4 pagesRemove bearings quickly with hydraulic pullerRvenkatesan Venkatesan100% (1)

- Pneumatic Bearing PullerDocument10 pagesPneumatic Bearing PullerTjNo ratings yet

- Automatic Pneumatic Multi Purpose PressDocument3 pagesAutomatic Pneumatic Multi Purpose Pressदेवेश सिंह राजपूतNo ratings yet

- Pneumatic Rod Bending Machine Project ReportDocument3 pagesPneumatic Rod Bending Machine Project ReportJeyakumar NNo ratings yet

- CNC Pipe Cutting Machine - Project ReportDocument28 pagesCNC Pipe Cutting Machine - Project ReportTanvi KhuranaNo ratings yet

- Synopsis Bottle Filling PlantDocument5 pagesSynopsis Bottle Filling PlantTanvi KhuranaNo ratings yet

- Automated Portable Hammering MachineDocument2 pagesAutomated Portable Hammering MachineTanvi KhuranaNo ratings yet

- Angle and Tilting Vice - SynopsisDocument6 pagesAngle and Tilting Vice - SynopsisTanvi Khurana100% (3)

- MWM Project M 3Document3 pagesMWM Project M 3Tanvi KhuranaNo ratings yet

- Lapping and Polishing Techniques for Precision Surface FinishingDocument7 pagesLapping and Polishing Techniques for Precision Surface FinishingNagi NayakNo ratings yet

- EDM (Electric Discharge Machine)Document29 pagesEDM (Electric Discharge Machine)Tanvi KhuranaNo ratings yet

- Pneumatic BikeDocument7 pagesPneumatic BikeavisuNo ratings yet

- Topic: Starter of Engine Branch: Electrical Engineering: Prepared By:-Guided ByDocument16 pagesTopic: Starter of Engine Branch: Electrical Engineering: Prepared By:-Guided ByTanvi KhuranaNo ratings yet

- Mahavir Swami College ZNEB ProjectDocument26 pagesMahavir Swami College ZNEB ProjectTanvi KhuranaNo ratings yet

- Automatic Drain CleanerDocument18 pagesAutomatic Drain CleanerTanvi KhuranaNo ratings yet

- Pneumatic BikeDocument7 pagesPneumatic BikeavisuNo ratings yet

- Make New Innovation: An Iso 9001:2008 Certitfied CoDocument2 pagesMake New Innovation: An Iso 9001:2008 Certitfied CoTanvi KhuranaNo ratings yet

- Three Axis Pneumatic Modern TrailerDocument16 pagesThree Axis Pneumatic Modern TrailerTanvi KhuranaNo ratings yet

- Filtrate Tank ModelDocument1 pageFiltrate Tank ModelTanvi KhuranaNo ratings yet

- BSNL Summer Training ProjectDocument41 pagesBSNL Summer Training Projecttazzyrocks60% (5)

- Report Wheel Chair Cum StretcherDocument42 pagesReport Wheel Chair Cum StretcherTanvi KhuranaNo ratings yet

- (##) Pneumatic Bumper For Four WheelerDocument60 pages(##) Pneumatic Bumper For Four WheelerRaj EndranNo ratings yet

- Pneumatic BikeDocument7 pagesPneumatic BikeavisuNo ratings yet

- Automatic Gate SystemDocument32 pagesAutomatic Gate SystemTanvi KhuranaNo ratings yet

- Motorized ShutterDocument38 pagesMotorized ShutterTanvi KhuranaNo ratings yet

- 335424718-Report-Wheel-Chair-Cum-HYDRAULIC BEDDocument44 pages335424718-Report-Wheel-Chair-Cum-HYDRAULIC BEDTanvi KhuranaNo ratings yet

- Gravity Sand FilterDocument6 pagesGravity Sand FilterTanvi KhuranaNo ratings yet

- Welding Machine - Project ReportDocument62 pagesWelding Machine - Project ReportTanvi KhuranaNo ratings yet

- Modified Sprinkler TurbineDocument18 pagesModified Sprinkler TurbineTanvi KhuranaNo ratings yet

- Pail 5142811 40Document3 pagesPail 5142811 40Ryan ColeNo ratings yet

- Embedded System PracsDocument7 pagesEmbedded System PracssayajiNo ratings yet

- Maintenance IndicatorsDocument12 pagesMaintenance IndicatorssatfasNo ratings yet

- Metode Ugradnje Tunelske FolijeDocument7 pagesMetode Ugradnje Tunelske FolijeIzetNo ratings yet

- DSE86xx PC Software ManualDocument166 pagesDSE86xx PC Software ManualbrawijayaNo ratings yet

- CP76 and CS76 Vibratory Compactor Hydraulic System 262-0883-01Document2 pagesCP76 and CS76 Vibratory Compactor Hydraulic System 262-0883-01Tom SouzaNo ratings yet

- Viewpoint User Manual SEODocument7 pagesViewpoint User Manual SEOkimura takuyaNo ratings yet

- 3.6.3 Column and Beam Fire ProtectionDocument10 pages3.6.3 Column and Beam Fire Protectionodemircioglu2No ratings yet

- TOFD - Study Material, Rev.1, 24.05.2019Document125 pagesTOFD - Study Material, Rev.1, 24.05.2019Agung Prastyo Wibowo100% (2)

- Computer Vision & Image ProcessingDocument34 pagesComputer Vision & Image Processingbasab_ecens100% (2)

- Journal GodwinDocument13 pagesJournal GodwinLoRenzNo ratings yet

- Serpentine Pavilion Press PackDocument21 pagesSerpentine Pavilion Press PackAlvaro RosaDayerNo ratings yet

- Design Standards For Offshore Wind Farms-ABSDocument224 pagesDesign Standards For Offshore Wind Farms-ABSAsid ZullahNo ratings yet

- DHP453Document4 pagesDHP453wzsdqciqNo ratings yet

- NTC Thermistors Type RL30: Uncoated Disc With Radial LeadsDocument2 pagesNTC Thermistors Type RL30: Uncoated Disc With Radial LeadsJonh G. GonzálezNo ratings yet

- Iapmo 4197 PDFDocument15 pagesIapmo 4197 PDFIvan FlorezNo ratings yet

- RC Roof Beam DesignDocument5 pagesRC Roof Beam DesignSujay SantraNo ratings yet

- Manual de Servicio MK4-5 (Parte 2) PDFDocument117 pagesManual de Servicio MK4-5 (Parte 2) PDFJosé SchumanNo ratings yet

- Series 60 Crank Seal11-60-04aDocument22 pagesSeries 60 Crank Seal11-60-04aKeyser SözeNo ratings yet

- 4-Way Reversing ValvesDocument3 pages4-Way Reversing ValvesAbdulSattarNo ratings yet

- A Synopsis On Mini Project: "Criminal Face Identification System"Document5 pagesA Synopsis On Mini Project: "Criminal Face Identification System"Srikrishna Sharma KashyapNo ratings yet

- Junior Resume EEDocument1 pageJunior Resume EESudeep AbhyankarNo ratings yet

- Extreme Weather Concreting and Chemical Admixtures in ConcreteDocument8 pagesExtreme Weather Concreting and Chemical Admixtures in ConcretetyashraniNo ratings yet

- Turbo RamjetDocument16 pagesTurbo RamjetDhana JayanNo ratings yet

- Improve Audio Circuit Board PerformanceDocument2 pagesImprove Audio Circuit Board PerformancemariopilarNo ratings yet

- PDN ConnectivityDocument1 pagePDN Connectivityjohncena90No ratings yet

- Cabling Best Practices GA BP 036 02Document35 pagesCabling Best Practices GA BP 036 02Justin FisherNo ratings yet