Professional Documents

Culture Documents

Spec 2.3 Steel Building Structural Design Criteria

Uploaded by

Abu Hena Mostofa Kamal0 ratings0% found this document useful (0 votes)

6 views3 pagesSpec 2.3 Steel Building Structural Design Criteria

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSpec 2.3 Steel Building Structural Design Criteria

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesSpec 2.3 Steel Building Structural Design Criteria

Uploaded by

Abu Hena Mostofa KamalSpec 2.3 Steel Building Structural Design Criteria

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

ATCO Energy Solutions Ltd. Performance Specification

Intermediate Pumphouse and Pre-Packaged

Storage Facilities Intermediate Pumphouse

Page 5 of 18.

©) Space for larger VFDs

4) Space for one additional VFD for the third booster pump

€) Spare electrical equipment capacity

1) Spare controls connections for additional pumps

12 System minimum design pressure shall be 1,861 kPa (270 psi). Hydrostatic test

pressure shall be 2,070 kPa (300 psi)

13 The pipe material to be used throughout the process piping system shall be ANS!

Class 150 carbon steel. Refer to the Line Class Specification included in

Appendix E.

-14 Exterior piping is to be insulated and heat traced. This will be installed under a

separate contract; however, all wall penetrations must be oversized to allow for

50 mm of insulation to be installed on the pipe.

i al Desian Cri

1 Design shall be in accordance with the following codes and most recently issued

standards!

a) Alberta Building Code 2006

b) — CAN/CSA-A660

c) CAN/CSA-S16

@) — CANICSA-S136

2 For the determination of specified loads and effects, consider:

a) Building Importance Category: Post-Disaster

b) Climatic design data for Bruderheim, AB and Fort Saskatchewan, AB

©) Wind Loading:

i) Wind Importance Factor (ULS), !W=1.25

ii) Reference velocity pressure, 1/10 years=0.31 kPa

) Reference velocity pressure, 1/50 years=0.43 kPa

d) Snow and Rain Loading:

‘Snow Importance Factor (ULS}, IS=1.25

) Ground snow load, 1/50 years Ss=1.8 kPa

iii) Rain load, 1/50 years Sr=0.1 kPa

iv) One day rain 1/50 years=95mm

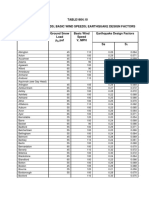

) Earthquake Loading:

i) Earthquake Importance Factor (ULS), IE=1.5

ii) Site Classification D

ii) — Sa(0.2)=0.12

ATCO Energy Solutions Ltd. Performance Specification

Intermediate Pumphouse and Pre-Packaged

Storage Facilities

)

Intermediate Pumphouse

Page 6 of 18,

Ww) Sa(0.5)=0.06

v) — Sa(1.0)=0.02

vi) Sa(2.0)=0.01

vil) PGA=0.06

vii) Fa=t.3

ix) Fvet.4

Collateral loads induced by additional dead loads other than the weight of

steel building system for permanent items such as sprinklers, mechanical

systems, electrical systems, and ceilings.

9) Vertical loads induced by building occupancy including loads induced by

maintenance workers, materials, and equipment for roof live loads.

hy The building floor shall be designed to resist whichever of the following

live loads has the maximum effect:

i) Auniform load of 3.6 kPa

) concentrated load of 9 kN applied over an area of 750 mm by

750 mm at any location

ii) The loads associated with the specified equipment

3 Steel building systems and associated members shall be designed for:

a) Strength and stability:

i) Consider critical effects using resistance factors, load factors, and

load combinations

b) Fatigue

©) Serviceabilty

@) Deflection:

i) Maximum deflection of /240 of clear span for roofing under full

specified live or snow load

ji) Maximum deflection of L/360 of clear span for floors under live

loads, or smaller if required to accommodate equipment

requirements,

ii) Maximum deflection of L/180 of clear span for exterior cladding

under full specified exterior wind induced loads

fv) Maximum deflection of h/200 of building height for total building

rift

) Vibration:

i) Consider vibration effec's of specitied equipment on building floor

4 Flooring is to be non-slip.

ATCO Energy Solutions Ltd. Performance Specification

Intermediate Pumphouse and Pre-Packaged

Storage Facilies

Intermediate Pumphouse

Page 7 of 18,

.5 Floor drains are to be provided to allow for drainage of water to the exterior of the

building.

6 Note that this structure

is anticipated to be installed on piles. Provide an exterior

staircase to allow for access to the building man-doors. Provide a surrounding

skirt to obscure the foundation.

2. ral ri

Design shall be in accordance with the following codes and most recently issued

standards:

a) Alberta Building Code 2008

b) Alberta Fire Code

©) _ ASTM A@53/A653M — Standard specifications for steel sheet, zinc coated

(galvanized) or Zinc-ron alloy-coated (galvanealed) by the hot dip process

) Steel sections and plates: to CAN/CSA-G40,20/G40.21

) Paint: Prepare the Work and paint in accordance with CANICSA-S16

) Vapour Retarder (Underslab) to be puncture resistant polyethylene sheet

in accordance with ASTM £1745 and CAN/CGSB-51.34

9) Foundation wall Insulation as XPS to meet CAN/ULG $701

5) Spray Applied Polyurethane Foam in accordance wih CANUULC $705.1,

ype

i) _Non-structural metal framing and non-load bearing channel stud framing:

to ASTM C645

}) Zine coated galvanized steel sheet (pre-finished): Type A commercial

quality to ASTM AB53/A653M

k) Sealants to comply with ASTM C920-11, CGSB 19-GP-5M-84

) Hardware to comply with ANSVBHMA A156 Series of Standards.

‘m) All materials to comply with current LEED standards.

n) Pre-Engineered Building Structure to comply with CSSBISOM-06,

Certificate of Design and Manufacturing Conformance with NBG 2010.

.2 General architectural requirements are as follows:

a)

b)

°)

The VENDOR shall be responsible for the design, supply and installation

of the heating, cooling, and fire protection systems as outlined in this

document.

The soope of supply includes, but is not limited to, the design, supply and

installation for meeting all governing codes, standards and specifications.

Allwork shall also conform to the codes and standards listed above.

Provide design calculations and stamped drawings by a Professional

Registered in Alberta,

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Adfreeze and TensionDocument1 pageAdfreeze and TensionAbu Hena Mostofa KamalNo ratings yet

- Deep Foundations - Barrette Piles: Retaining Wall and Foundations For 36-Storey Property With Four Basement LevelsDocument2 pagesDeep Foundations - Barrette Piles: Retaining Wall and Foundations For 36-Storey Property With Four Basement LevelsAbu Hena Mostofa KamalNo ratings yet

- Deep Foundations - Barrette Piles: Tutorial 2 Episode 1Document1 pageDeep Foundations - Barrette Piles: Tutorial 2 Episode 1Abu Hena Mostofa KamalNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- 16 Table1604Document8 pages16 Table1604Abu Hena Mostofa KamalNo ratings yet

- Footing Detail PDFDocument1 pageFooting Detail PDFAbu Hena Mostofa KamalNo ratings yet

- Sure Fire Hedging StrategyDocument3 pagesSure Fire Hedging StrategyAbu Hena Mostofa KamalNo ratings yet

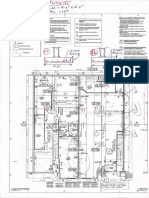

- 61301r2 Floor LayoutDocument1 page61301r2 Floor LayoutAbu Hena Mostofa KamalNo ratings yet

- View Map JobDocument1 pageView Map JobAbu Hena Mostofa KamalNo ratings yet