Professional Documents

Culture Documents

Project HSE Plan

Uploaded by

Winnie EldamaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project HSE Plan

Uploaded by

Winnie EldamaCopyright:

Available Formats

PROJECT HSE PLAN

Quality Management Page 1 of 33

Version Implementation date Purpose

04 07/11/2017 First issue

Function/Name Date/Signature

Written by: Rob Bryson 20/02/2018

HSE Manager

Verified by: Jasminko

Quality Manager

Approved by: Alessandra Moseriti

Risk Manager

1. Purpose

1.1. To standardise the format used site HSE plans across all ES-KO projects, irrespective of the

industry.

1.2. To provide a proactive approach to protecting all people on the site. The Project health,

safety and environmental management plan in line with the project risk assessments

identifies what hazards and risks hazards are involved in the project, and the methodology

used to control the identified hazards and risks. The HSE plans will differ from industry to

industry, but the underlying theme of every HSE plan is that it should not only take care of

the employees, but also the visitors of the premises and the passers-by.

1.3. To inform personnel of their responsibility and accountability for Health, Safety and

Environmental matters, and of their legal duties towards those either directly or indirectly

under their charge, and towards those who may be affected by their acts or omissions.

2. Scope

The Project HSE plan applies to all ES-KO operations globally, and should be adapted to suit the

individual project.

3. Responsibilities

ROLE RESPONSIBILITIES

SITE MANAGER Overall responsibility for the hygiene of all site

(Catering/Rations/Operations/Retail) areas

Ensure that suitable and sufficient resources

are available at all times to ensure the

constant compliance of this procedure

Ensure that all personnel involved in cleaning

and disinfection activities understand the

content of this procedure

Ensure that all personnel involved in cleaning

and disinfection activities receive the correct

information, instruction and training related

to their work activities

Ensure that cleaning and disinfection staff

undertake the correct health screening for

workers using cleaning agents

MAINTENANCE Provide suitable and sufficient storage

(Manager/Supervisor/Technician) facilities for cleaning agents

Provide suitable and sufficient storage

facilities for cleaning equipment

DEPARTMENTAL HEADS Production of cleaning plans for their areas of

(Managers/Supervisors/team leaders) responsibility

Production of safe systems of work for all

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 2 of 33

cleaning and disinfection tasks

Provide suitable and sufficient PPE and

clothing as per the findings of the risk

assessment

QUALITY ASSURANCE/HSE Ensure suitable and sufficient risk assessments

(Evaluator/Officer/Representative) are completed

Provide suitable and sufficient training and

assessments

Verification of the implementation and

following of this procedure

Provide advice and guidance as to industry

best practice

Assist departmental heads to produce

effective cleaning plans

CLEANERS Request replacement cleaning equipment as

and when required

Perform cleaning activities in line with the

requirements of this procedure and cleaning

plans

Record all cleaning activities in line with the

requirements of this procedure

Use all cleaning equipment, cleaning agents

and PPE as instructed

The Health and Safety at Work etc Act 1974 (HASAWA), and the Management of Health and

Safety at Work Regulations 1999 (MHSWR) lay down some of the main responsibilities and

duties of people at work.

Among the duties the HASAWA places on employers are:

• the requirements to ensure the health and safety at work of their employees and that of

any other person who may be affected by their activities; and

• to have a written health and safety policy.

It also places duties on employees to:

(a) take reasonable care of their own health and safety and that of others who may be

affected by their acts or omissions;

(b) to co-operate with their employer so the latter can comply with all necessary legal

duties; (c) not to interfere or misuse anything provided in the interests of health, safety or

welfare.

The main requirements of the MHSWR are that employers must:

• assess the risks to the health and safety of anyone who may be affected by their activities;

and

• ensure adequate arrangements are in place for the “planning, organisation, control,

monitoring and review” of the safety measures that follow from those assessments.

The following table identifies the main responsibilities within ES-KO storage and warehousing

facilities;

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 3 of 33

Functions Activities

Project Manager/Deputy PM Allocate suitable & sufficient resources to

allow implement and maintain the

operations health and safety training

program.

Ensure that accidents/incidents are fully

investigated and corrective action taken to

prevent the hazardous conditions or

behaviors from happening again.

Set a good example by following established

safety rules and attending required training.

Ensure that every site under his jurisdiction

understand and comply with this procedure.

Risk Assessment has been carried out.

Established a good health & safety culture.

Ensure Equipment are well maintained and

in good running condition.

Ensure that safe system of work is in place.

Ensure appropriate & suitable personal

protective equipment are available at all

area of the workplace.

Managers and Supervisors Ensure the health and safety training

program is followed and all staff attend the

scheduled training.

Communicate health & safety issues to

project management.

Risk assessment has been carried out to all

hazardous activity.

Ensure availability of personal protective

equipment.

Cascade all health and safety concerns to all

staff under his jurisdiction.

Accident/Incident Reporting

Quality Task Force Ensure a high level of productivity and safety

performance and hold project management

staff accountable.

Provide effective training, which is required

by the contract, as a minimum for the

employees.

Periodically review health & safety rules and

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 4 of 33

standards with employees to confirm that

the company is meeting its goals and

objectives.

Guide and advise QA/HSE pertaining to

additional training and update.

Manage all HSE concern at all areas of this

coverage.

Provide a regular report to upper

management on Health & Safety.

QAE/HSE Conduct a health and safety induction

training to all newly hired workers and

personnel.

Laisse with project and operations managers

to plan and schedule the HSE training

program.

Assist departmental manager in writing safe

systems of work.

Physically conduct site HSE inspections.

Promotion of health & safety awareness,

campaigns and devising safety training and

education for all employees.

Review procedures for compliance with

applicable health and safety laws &

regulations.

Employees Should read and understand this procedure.

Follow HSE procedure & policy.

Wear appropriate PPE at all times while in

warehouse.

Report unsafe act & condition to site

manager or QAE.

Report personal accident or injuries and get

immediate medical attention.

Report all accident/incident witness to site

manager or QHSE.

Report all near-miss incidents to your site

manager promptly.

Ensure personal safety & the others who

might be affected by his undertakings.

Do not remove any safety device or

safeguard provided for employee protection.

Encourage co-workers by your words and

example to use safe work practices on the

job.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 5 of 33

4. Preliminaries

Protecting people from harm and illness is a primary concern. At ES-KO, our employees are

our most important assets, and, without them there is no ES-KO, it is therefore, paramount

that their health, safety and welfare is always the number one priority and no task is so

important that it will compromise the safety or health of our employees.

« Make Safety a part of every meeting, every

Considering the above, Health and Safety policy and procedures will be endorsed by top

management, and will be signed by the CEO to show they are committed to supporting and

improving a positive health and safety culture throughout ES-KO.

To enable this;

conversation.

Suitable and sufficient resources will be made available always to

Any time it is possible, talk about improving

- Identify, control and manage risks effectively

- Promote a positive safety culture

your culture of Safety. »

- Provide the required protective equipment and clothing

- Provide suitable, and sufficient plant and equipment

- Provide a robust planned preventative maintenance program

- Provide adequate health and safety related training

- Provide professional information, advice and guidance

To assist further;

Employees will play an important part of the health and safety culture

A safety comity will be formed in every site

Safety representatives will be appointed from the local work force, including first

aiders and fire wardens

All health and safety concerns will be communicated to all employees

Time will be available during working hours for safety representatives and comity

members to undertake extra training and development

Management has the authority to provide the necessary resources to implement the

objectives of our company’s Health & Safety Policy.

ES-KO International Inc

Project HSE Plan

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

Warning Letter

low potential impact Final

Rule is broken for the

first time

Warning Dismissal

Final Warning Letter

PROJECT HSE PLAN

Quality Management Page 6 of 33

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 7 of 33

CONTENTS

1.0 INTRODUCTION ........................................................................................................................ 10

2.0 PERFORMANCE MONITORING .................................................................................................. 10

2.1 HSE Targets ........................................................................................................................................... 10

2.2 HSE Key Performance Indicator (KPI) ................................................................................................... 10

3.0 LEADERSHIP AND COMMITMENT ............................................................................................. 11

3.1 Visibility ................................................................................................................................................ 11

4.0 POLICY AND OBJECTIVES .......................................................................................................... 12

4.1 HSE Policy Statement ........................................................................................................................... 12

4.2 Distribution and availability .................................................................................................................. 12

4.3 HSE Policy Dissemination ..................................................................................................................... 12

4.4 Review of HSE Policy ............................................................................................................................ 12

4.5 Objectives ............................................................................................................................................. 12

4.6 Challenges ............................................................................................................................................ 13

5.0 ORGANISATION, RESPONSIBILITIES, RESOURCES, STANDARDS AND DOCUMENTS ................... 13

5.1 Organization chart ................................................................................................................................ 13

5.2 Roles and Responsibilities .................................................................................................................... 13

5.3 Resources ............................................................................................................................................. 14

5.4 Competence ......................................................................................................................................... 14

5.5 HSE in-house Training ........................................................................................................................... 15

5.6 HSE Mandatory Training ....................................................................................................................... 15

5.7 Occupational Health Awareness ........................................................................................................... 16

5.8 Environmental Protection .................................................................................................................... 16

5.9 Sub-Contractors .................................................................................................................................... 16

5.10 Communication ............................................................................................................................... 18

5.11 HSE Meeting Programme ................................................................................................................ 18

5.12 HSE Performance ............................................................................................................................ 19

5.13 Standards and Document Control ................................................................................................... 19

6.0 HAZARDS AND EFFECTS MANAGEMENT PROCESS .................................................................... 20

6.1 METHODS AND PROCEDURES FOR HAZARDS AND EFFECTS MANAGEMENT ................................................. 20

6.2 ROAD TRANSPORT/JOURNEY MANAGEMENT ....................................................................................... 20

6.3 STOP .......................................................................................................................................... 21

6.4 CHEMICAL HANDLING...................................................................................................................... 21

7.0 PLANNING AND PROCEDURES .................................................................................................. 22

7.1 HSE PLAN ..................................................................................................................................... 22

7.2 EMERGENCY RESPONSE ................................................................................................................... 22

7.3 EMERGENCY DRILL .......................................................................................................................... 23

7.4 MEDICAL FACILITIES ........................................................................................................................ 23

7.5 HYGIENE ....................................................................................................................................... 23

7.6 FIRST AID ...................................................................................................................................... 25

8.0 IMPLEMENTATION, MONITORING & CORRECTIVE ACTION....................................................... 25

Feedback / Analysis: ............................................................................................................................ 25

Comparison of performance: .............................................................................................................. 26

8.1 IMPLEMENTATION .......................................................................................................................... 27

8.2 MONITORING ................................................................................................................................ 27

8.3 CORRECTIVE ACTION ....................................................................................................................... 27

8.4 ACCIDENT/INCIDENT ....................................................................................................................... 29

9.0 AUDIT & INSPECTION ............................................................................................................... 29

9.1 AUDIT PLAN .................................................................................................................................. 29

9.2 INSPECTIONS.................................................................................................................................. 31

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 8 of 33

10.0 REVIEW .................................................................................................................................... 31

COPY HOLDERS

HELD BY Company Control Copy Location

No.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 9 of 33

Scope of the Contract HSE Plan:

The HSE Plan is prepared for XXXXXXX XXXXXXX for carrying out work on contract No.1111111111

(Insert Catering, Maintenance, Construction etc). The scope includes:

Maintenance services for camp related facilities and A/c systems at XXXXXX.

Gardening services

T.V. System maintenance and pay satellites. (Deploying sub-contractor- Management and

control of all furnishings (except office furniture)

Catering services

STP operation & Maintenance

Civil project Works

Control of the Contract HSE Plan:

The contract HSE Plan is prepared by the HSE Manager, reviewed by Contract Manager and

approved by the General Manager.

Controlled copies of the HSE Plan shall be issued to above copy holders, Suggestions to amend the

HSE Plan shall be addressed to the HSE Manager.

The copy holders shall be responsible for maintenance of their respective copies of the HSE Plan.

On receipt of year 20XX HSE plan, the copy holder is responsible to remove and destroy old copy of

the HSE Plan.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 10 of 33

1.0 INTRODUCTION

This contract HSE Plan sets targets and action items for ES-KO International Inc and its

subcontractors to improve HSE performance. This HSE Plan revised from the action items derived

from ES-KO Incorporated Inc& client’s workshop, ES-KO Incorporated IncHSE Management System

review held at corporate level and ES-KO Incorporated Incand sub-contractors interior review

meeting held in ?

2.0 PERFORMANCE MONITORING

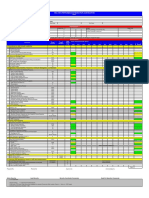

2.1 HSE Targets

Target Target Target

No Performance Indicator Remarks

2018 2019 2020

1 Fatality 0 0 0

2 Lost Time Incident Frequency (LTIF) 0.4 0 0.3

3 Total Reportable Case Frequency (TRCF) 4.5 0 4

4 Road Traffic Accident Frequency (RTAF) 0.65 0 0.5

5 Food Poison Case 0 0 0

Total Reportable Occupational Illness

6 4.5 0 4

Frequency (TROIF)

7 Environmental Incidents 0 0 0

2.2 HSE Key Performance Indicator (KPI)

Target

No Performance Indicator

2018

Mandatory HSE Training

1 100%

Report Mandatory HSE Training Compliance.

Planned in-house training

2 95%

Follow in-house training plan included in HSE plan.

3 Execution of Planned HSE Audits

95%

HSE audit plan implementation

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 11 of 33

4 HSE Plan action

90%

Close-out actions specified in the HSE Plan.

5 Drivers/Operators Competent

Ensure drivers/operators are assessed and confirmed as competent to 100%

work.

6 Vehicle RAS Compliance 100%

7 Employee medical Check-up 100%

8 Food safety and work hazards 15 different poster preparation. 90%

3.0 LEADERSHIP AND COMMITMENT

The Management of ES-KO International Inc and various section heads are firmly committed to

maintaining and continuously improving of HSE management system and to protect health, safety of

ES-KO employees and also others who may be affected by its activities and to the protection of

environment at all work places and will ensure that no environmental hazard will be created by the

activities of ES-KO Incorporated Incand sub-contractors.

3.1 Visibility

No Action Action Party Target

Management visit to convey safety message, General

1 Monthly

staff meeting and inspection/audit. Manager/Contract Mgr

HSE Manager/Quality Manager visit for

HSE Manager/Quality

2 inspection, compliance audit, meeting, Monthly

Manager

training, QHSE workshop.

Prepare new 15 QHSE posters to spread food

HSE Manager/Quality

3 safety and work hazards message among Feb-2018

Manager

employees.

Continuation of award scheme and reward Operations

4

best employee of the month award to staff. Manager/HR Manager Monthly

Director of Operations/

5 Select best location for the year 2008 award. Feb-2018

Quality Manager

Meet the criteria of evaluation process for HSE Manager/Quality March-

6

zonal safety award 2008. Manager 2018

Distribute HSE Diary-2018 to functional heads January-

7 HSE Manager

and locations. 2018

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 12 of 33

4.0 POLICY AND OBJECTIVES

4.1 HSE Policy Statement

No changes in HSE policy same policy will be continued for the year 2018.

4.2 Distribution and availability

ES-KO International Inc, will ensure that all concerned parties (including subcontractors and ES-KO)

are provided with a copy of the HSE policy statement. The policy shall be displayed on relevant

notice boards, and made available in the relevant working languages of the employees.

No Action Action Party Schedule

Distribute new HSE Slogans for the year 2018 HSE Manager/

1 Feb 2018

and display at locations. HSE Advisor

Set QHSE objectives, targets and KPI for the General Manager/

2 Jan-2018

year 2018. Contract Manager

4.3 HSE Policy Dissemination

No Action Action Party Schedule

Communicate HSE Policy, Alcohol & Drug Policy,

Project HSE For new

1 Medical Policy and No-smoking policy to new

Officer arrivals

employees.

4.4 Review of HSE Policy

No Action Action Party Schedule

Contract

Revise commuting policy in line with PDO new Manager/

1 Mar-2018

commuting policy and communicate to staff. Project HSE

Officer

4.5 Objectives

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 13 of 33

The main objective of this plan is to drive HSE improvement throughout the contract in all ES-KO

Incorporated Inclocations in a consistent manner and to ensure that the HSE performance targets

set out in this plan are achieved through action items planned.

Achieve continuous improvement of all HSE matters

Attain improvement in Road Safety through the agreed action items from workshop and

meetings with client and Sub-contractors.

Manage sub-contractors/vendors more effectively for the minimization of incidents through

hazard elimination and control measures.

Training to ensure competent workforce.

Meeting the Key Performance Indicators (KPI) targets.

4.6 Challenges

Road Safety

Improving QHSE awareness of staff

Compliance to ISO/HACCP requirements

5.0 ORGANISATION, RESPONSIBILITIES, RESOURCES, STANDARDS AND DOCUMENTS

ES-KO INCORPORATED INCrecognizes that to fulfill the requirement of HSE is the responsibility of

line management, hence the Contract Manager/Operations Managers, being overall in charge, is

responsible for the implementation and maintaining HSE and Hygiene requirements. Operations

Manager, Site Manager, Camp Boss, Section Heads is held responsible for their respective areas. The

role played by the corporate HSE Manager, and Project HSE officers are for consultation, guidance

and monitoring of the implementation of the HSE plan and for developing and maintaining HSE

Management System including employee and contactor training where required.

5.1 Organization chart

No Action Action Party Schedule

Update site organization chart Contract Manager/

1 Feb-2018

Operations Manager

5.2 Roles and Responsibilities

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 14 of 33

Operations Manager being overall in charge is accountable for the Management of HSE throughout

the contract. However, the team of Operations Manager, Site Manager, Supervisors, Camp Boss and

work co-coordinators, Permit Applicant, Permit Holders and Foreman are responsible for ensuring

that activities are carried out in accordance with the ES-KO Incorporated IncHSE Plan.

HSE Manager shall be responsible for monitoring of HSE Plan in the contract and providing

professional HSE advice to the line management. HSE Advisors, Hygienist are responsible to provide

professional HSE & Hygiene advice to the line management, monitoring implementation of HSE Plan

of the respective location, facilities and line management for continuous improvement in HSE across

the operation.

No Action Action Party Schedule

Ensure availability of tasks and targets for all Operations

1 May-2018

employees at site. Manager

5.3 Resources

ES-KO International Inc shall provide adequate competent human resources, equipment, vehicles,

tools and financial resources for the effective HSE Management System throughout the project.

5.4 Competence

No Action Action Party Schedule

Conduct a HSE workshop on supervision of HSE Contract

1 for supervisory level of staff. Manager/HSE May-2018

Manager

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 15 of 33

5.5 HSE in-house Training

Training Type Trainer

Personal Hygiene FQCO Feb-2018 Jan-2018 Mar-2018 Feb-2018

May-

HACCP FQCO Apr-2018 May-2018 Jan-2018

2018

Work hazards (HEMP) HSE Advisor Aug-2018 Sep-2018 July-2018 Aug-2018

Nov-

5-S Refresher Training Hygienist Dec-2018 Oct-2018 Dec-2018

2018

Road Safety HSE Advisor Jan-2018 Feb-2018 Jan-2018 Mar-2018

Mar- Mar-

Emergency Procedures HSE Advisor Feb-2018 Apr-2018

2018 2018

Apr- June-

Fire Safety HSE Advisor Apr-2018 May-2018

201807 2018

May-

Health Hazards (HRA) HSE Advisor Jun-2018 June-2018 Nov-2018

2018

Food Poison & Control FQCO July-2018 July-2018 Aug-2018 Sep-2018

Environmental Awareness HSE Advisor Sep-2018 Aug-2018 Sep-2018 July-2018

HSE Advisor Oct-2018 Oct-2018 Nov-2018 June-2018

Manual Nov-

HSE Advisor Dec-2018 Dec-2018 Oct-2018

Handling/Equipment Safety 2018

5.6 HSE Mandatory Training

No Action Action Party Schedule

Mandatory training of employees (As required in C-9) Site Mgr/

1 or as per contractual requirement. Monthly

HSE Advisor

Update HSE training records and verify that all HSE Advisor/

2 employees attended mandatory HSE training courses. Monthly

Hygienist

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 16 of 33

Arrange food safety mandatory training for Hygienist/Quali

3 Quarterly

supervisory staff. ty Manager

Executives attend the ‘HSE for Senior Executive As scheduled

4 Executives

Training in 2018’ arranged by PDO. by PDO

Managerial positions staff attend the “HSE for As scheduled

5 Managers

Managers training’ arranged by PDO by PDO

Supervisory staff/charge-hand/foreman attend the As scheduled

6 Supervisors

‘HSE for Supervisors Course’ arranged by PDO by PDO

5.7 Occupational Health Awareness

No Action Action Party Schedule

Prepare alcohol abuse alert and distribute to the

1 location to alert the staff about the hazards of HSE Manager May-2018

alcohol consumption.

5.8 Environmental Protection

No Action Action Party Schedule

Monitor and report water and electricity Site

Each month

1 consumption. Manager/HSE

before 5th

Advisor

Induct new staff on environmental protection. HSE Manager/

2 New arrivals

Quality Manager

Collect renewed license/certificates (STP, scrap Site

3 yard, sludge farm) from authorities and display at Manager/HSE August-2018

prominent places. Advisor

5.9 Sub-Contractors

The sub-contractors shall be subject to the same standard, as ES-KO INCORPORATED INCis required

to comply in the performance of contract. Regular audits/inspections will be planned and conducted

to verify and assess sub-contractors compliance to HSE Management System.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 17 of 33

The HSE Advisor will monitor sub-contractors compliance at site and non-compliance shall be

reported to site manager and contract manager for appropriate action.

Related HSE statistics of sub-contractors shall be included into ES-KO INCORPORATED INCstatistics.

All sub-contractors are accountable for their respective HSE performance and shall be required to

meet Key Performance Indicator and targets in line with ES-KO Incorporated Incand PDO HSE

objectives.

The sub-contractors HSE Statistics shall be included into contract HSE Statistics. Sub-contractors

performance shall be closely monitored and incorporated in the ES-KO Incorporated Incoverall HSE

performance/Statistics.

The sub-contractor HSE Performance will also be included on the agenda of regular ES-KO

Incorporated Inc HSE Management System reviews for this contract.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 18 of 33

No Action Action Party Schedule

Revise sub-contractors HSE assessment check-list

1 HSE Manager March-2018

and distribute to the location.

Monitor sub-contractor compliance to contract Site Manager/

2 Monthly

HSE requirement. HSE Advisor

Assess sub-contractors HSE-MS system prior to Contract Mgr/ Prior to

3

awarding contract. Site Manager contract award

Control of Suppliers: Vendor/Supplier/Third Party Performing Services for ES-KO Incorporated Incor

its sub-contractors that involve Journeys to site and irregular presence on site will not be required to

prepare HSE Plan. They will be monitored by Site Manager/Operations Manager.

5.10 Communication

Communication is a two-way process to ensure that relevant HSE information is communicated to all

concerned.

5.11 HSE Meeting Programme

5.11.1 Objectives:

Review previous Minutes of meeting and ensure that actions are closed-out.

Active participation and commitment to the HSE-MS.

Communicate HSE performance and resolve any HSE issues and outstanding items

Interact between ES-KO Incorporated Incand Sub-contractors key personals to cascade the HSE

messages to the staff.

Discuss and find way to control hazards, unsafe acts & conditions.

Get the feed back from employees and pass appropriate message

Encourage communication and debate

5.11.2 Code of conduct:

1) Quarterly HSE Meetings: Incorporated with quarterly Management meeting, General

Manager, top management, contract manager, operational team, and HSE teams will

participate.

2) Site Specific HSE Meeting: Interior HSE meeting will be held in XXXXX,XXXX, XXXX, XXXXX, ES-

KO and sub-contractors key personnel will participate. Meeting will be held monthly.

All proceedings will be minuted, distributed and filed.

Attendance will be recorded for all meetings

All action items arising from meetings will be tracked and closed within target dates

Preparation of Agenda will be decided with the discussion of concerned persons.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 19 of 33

5.11.3 Meeting Structure:

Area Timing Participants

Jan-2018, May-2018, Management Team, Operations

Quarterly HSE Meeting

August-2018, Nov-2018 Team & HSE Team

Key personals group

Weekly Location staff

meeting

ES-KO Incorporated Inc& Sub-

Location HSE Meeting Monthly

contractors Key personals

QHSE Alert discussion

Quarterly Location Staff

and communication

5.12 HSE Performance

HSE LTI notice boards will be updated at corporate and location daily and the project HSE

performance shall be communicated with the employees during the HSE meeting.

No Action Action Party Schedule

HSE Advisor/

1 Update HSE LTI board on daily basis Daily

HSE Assistant

Arrange celebration and award gift to staff

2 Contract Manager March-2018

for the achievement of 2 years LTI free.

Update HSE performance data and HSE Manager/

3 communicate to management and contract Monthly

holder. Contract Manager

5.13 Standards and Document Control

Applicable ES-KO Incorporated IncHSE Procedures, standards, guidelines and documents shall be

used for the entire scope of work in different locations. ES-KO Incorporated Incdocuments shall be

revised as and when required. HSE Manager shall maintain these documents for reference and use.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 20 of 33

6.0 HAZARDS AND EFFECTS MANAGEMENT PROCESS

6.1Methods and Procedures for Hazards and Effects Management

Hazards have been identified and assessed for all activities including sub-contractors activities in the

contract and documented on HEMP Register. Copies of the Hazard and Control Sheets will be

distributed to Site Managers and sub-contractors for reference in their respective activities.

The work coordinators and Supervisors will ensure that control measures mentioned on the HEMP

sheets are implemented. The HSE Advisor will carry out periodic check on awareness among site

personnel of the hazards and report any non-compliance for corrective action. The HEMP sheets will

be reviewed for the changes required and will be updated accordingly.

No Action Action Party Schedule

Prepare HEMP for accommodation /desert living and

1 HSE Manager Feb-2018

distribute to location.

Conduct a HSE workshop on HEMP for supervisory

2 HSE Manager May-2018

staff.

Presentation to Operations Manager on critical Quality

3 Feb-2018

control points amendment. Manager

4 Refer to Hazard Register for preparing Job HSE Plans. Supervisor Every PTW

6.2 Road Transport/Journey Management

No Action Action Party Schedule

Execute inspection/audit on each vehicle including sub- Site Manager/

1 Monthly

contractors vehicles for the compliance with SP-2000 HSE Advisor

Make available updated light and heavy vehicles (May HSE Manager/

2 2007) Journey Management MAP at journey managers Mar-2018

office. Journey Mgr

Carry out drivers on job assessment and analyze the May-2018,

3 HSE Advisor

result. Nov-2018

Before

4 Update RAS sticker once it gets expires. HSE Advisor

expiry

5 Effectively monitor the use of shift commuting buses by Site Manager On each

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 21 of 33

logging passengers and random verification. /Journey Mgr trip

Mar-2018,

Continue with campaign to promote awareness about Operation Mgr June-2018,

6 the use of private vehicle hazards and encourage to use

/HSE Advisor Sep-2018,

company provided transport.

Dec-2018

Journey

Ensure sub-contractor vehicle and drivers comply with Project

7 Manager, Site

Journey Management System Duration

Manager

6.3STOP

No Action Action Party Schedule

Analyze STOP findings and report to contract

1 HSE Manager Monthly

holder.

Site Manager/

2 Carry out STOP observation. Supervisor/ Monthly

HSE Advisor

6.4COSHH

No Action Action Party Schedule

Ensure SHOC/MSDS are available at site for the HSE Advisor/Camp

1 Monthly

chemical in use, update chemical list Boss

Conduct Toolbox talks on risks of chemical HSE Advisor/Camp Selected

2

exposure. Boss Week

Ensure all staff and sub-contractors staff issued Supervisors/Camp Project

3

the right PPE for handling of chemicals. Boss Duration

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 22 of 33

7.0 PLANNING AND PROCEDURES

Emergency Drills shall be conducted as scheduled to test the proficiency of the workforce to handle

the specific emergency. Any action points arising out of the drill will be discussed with the

employees and corrective actions will be taken.

7.1 HSE Plan

No Action Action Party Schedule

Conduct HSE workshop to set the action items for Contract Manager/

1 Jan-2018

2018 HSE plan with location key staff. HSE Manager

2 Distribute HSE Plan to the concerned. HSE Manager Feb-2018

Arrange a workshop to communicate HSE Plan Site Manager/

3 Feb-2018

action items to staff. HSE Advisor

Prepare HSE Plan compliance report and submit

4 HSE Manager Monthly

to contract holder.

7.2 Emergency Response

No Action Action Party Schedule

1 Conduct emergency drills with observers as scheduled. HSE Manager Refer 7.3

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 23 of 33

7.3 Emergency Drill

Responsible

Emergency Type Fahud Yibal Lekhwair Qarn Alam

Person (Leader)

Site Manager/

Evacuation Jan-2018 July-2018 Apr-2018 Oct-2018

HSE Advisor

HSE Advisor/

Man Lost Mar-2018 Sep-2018 June-2018 Dec-2018

Journey Manager

Fire At work Supervisor/HSE

May-2018 Nov-2018 Feb-2018 July-2018

place Advisor

Medical HSE Advisor/

July-2018 Jan-2018 Aug-2018 Mar-2018

Emergency Hygienist

Catering Mgr/

Food Poison Nov-2018 May-2018 Dec-2018 Jan-2018

Hygienist

Road Traffic HSE Advisor/

Sep-2018 Mar-2018 Oct-2018 May-2018

Accident Journey Mgr

7.4 Medical Facilities

No Action Action Party Schedule

1 Record and report sickness to Management. HSE Advisor Monthly

Arrange Routine Medical Fitness examinations to

2 HSE Advisor Monthly

employees.

Renew medical examination for catering employees

3 HR Manager Aug-2018

with Ministry.

7.5 Hygiene

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 24 of 33

No Action Action Party Schedule

Hygienist/ Daily/Weekly/

1 Verify HACCP compliance and HACCP records.

Catering Manager Monthly

Catering

Monitor and record temperature in given chart Supervisor/

2 Daily

thee times in a day.

Hygienist

Catering

Preserve food sample for 96 hours in specified Supervisor/

3 Daily

cold unit.

Hygienist

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 25 of 33

7.6 First Aid

No Action Action Party Schedule

Refresh first aiders training and display first aiders Site Manager/

1 Monthly

name at prominent places. HSE Advisor

Inspect first aid kits are available at worksite, office, HSE Advisor/

2 Monthly

camp, vehicle, workshop. Hygienist

8.0 IMPLEMENTATION, MONITORING & CORRECTIVE ACTION

Line management and as a team all employees shall be held responsible for HSE performance. HSE

personnel will assist in implementing various activities and will monitor HSE performance by visits,

inspections and audits.

Performance Indicators: HSE Manager will monitor the compliance every month. Contract Manager

will check the compliance every month and performance will be discussed in corporate quarterly

HSE meeting.

Achievement of Milestones: The HSE Manager will specify achievement of milestone in the month

end report. Achievement will be discussed in Quarterly HSE meeting.

Close out action items: The reports of closing items from inspections and audits shall be sent to the

particular location Operations Managers for action and the HSE Manager will monitor the actions.

Road Safety Checks: Daily and monthly vehicle checks will be conducted at site and report will be

maintained by HSE Advisor and for further action report will be sent to transportation manager

through HSE Manager.

Compliance against targets: ES-KO INCORPORATED INCHSE plan sets the targets for the contract. The

HSE Manager shall monitor and update the performance achieved against targets on monthly basis.

Feedback / Analysis:

The results of performance indicators shall be reviewed in management review meeting and

corrective actions shall be allocated to the responsible persons.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 26 of 33

Comparison of performance:

The HSE Manager shall maintain comparison of performance between different locations.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 27 of 33

8.1Implementation

No Action Action Party Schedule

Ensure that all control and recovery measures are in

Supervisors/

1 place at site during the execution of work and tool Daily

Site Manager

box talk is conducted.

Develop HSE plan monitoring chart and ensure the HSE Manager/ Monthly

2

implementation. HSE Advisor

Prepare trend analysis on HSE performance

indicators, STOP, incident analysis, occupational

3 Quarterly

illness, sickness absenteeism and recommend HSE Manager

improvement and initiate action.

Develop HSE activity program for HSE meetings, HSE

4 HSE Advisor Monthly

inspections, audits, emergency drills, HSE trainings.

8.2 Monitoring

No Action Action Party Schedule

Monitor HSE Performance Indicator, identify areas for HSE Manager/

1 improvement and recommend corrective action in Quarterly

corporate Management HSE Meeting Quality Mgr

Monitor and report the progress on HSE compliance

2 Site Manager Monthly

of sub-contractors in HSE meeting.

8.3 Corrective Action

No Action Action Party Schedule

Prepare inspection/audit report and distribute to HSE Manager/ After the

1 the concerned locations site manager for corrective Quality inspection/

actions. Manager Audit

HSE Manager/ on agreed

2 Follow-up and close out actions items

Quality target date

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 28 of 33

Manager

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 29 of 33

8.4Accident/incident

No Action Action Party Schedule

Written report will be passed to HSE

Site Manager/ Within 24 hrs

Manager on all accidents/incidents

1 of

occurring at site or any other concerned HSE Advisor occurrence

work places.

Contract Manager/

Within a

Investigate medium and high potential

2 HSE Manager/ week after

accidents/incidents and prepare report.

occurrence

Quality Manager

Review and close out the recommended Contract Manager/ On agreed

3

action items. HSE Manager target date

9.0 AUDIT & INSPECTION

9.1 Audit and Inspection Plan

Four types of audits will be carried out as shown below:

Inspection Site Specific Self Check Inspection

Responsible

Site Manager

Person

Send to Report to HSE Officer by 5 of every month

Beni Bukavu Bunia Dungu Goma Kampala Kinshasa Uvira

Location

X X X X X X X X

Internal Audits: Organised and run by ES-KO Corporate Risk Management Team

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 30 of 33

Responsible

Audit Fahud Yibal Lekhwair Qarn Alam

Person (Leader)

Carry out food safety HSE Manager/

Mar-

& QHSE Compliance Nov-2018 June-2018 Aug-2018

2018

audit in the locations. Quality Manager

Conduct audit on

head office journey HSE Manager May-2018

management system.

Internal Audits: Organised and run by ES-KO Corporate Risk Management Team of Qualified

Auditors

Responsible

Audit Fahud Yibal Lekhwair Qarn Alam

Person (Leader)

Carry out ISO/HACCP Certified internal

Sep-2018 Nov-2018 Sep-2018 Oct-2018

internal audit. auditor

Third Party Audits: External Audit Organised by ES-KO and conducted by DNV ISO audit team

Responsible

Audit Fahud Yibal Lekhwair Qarn Alam

Person (Leader)

Arrange to carry out

External Certified

ISO external Mar-2018

auditor

compliance audit.

Level-4 Audits: Sub-contractors Audit by HSE Team

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 31 of 33

Responsible Qarn

Audit Fahud Yibal Lekhwair

Person (Leader) Alam

Carry out journey management

audit on commuting bus

HSE Manager June-2018

services at Cold Line Trading,

Adam.

Conduct audit on Gardening

HSE Manager July-2018

Services at Rabou office, Fahud.

Carry out Environmental

Services Compliance audit at HSE Manager Mar-2018

Al-Katheery office, Fahud.

9.2 Inspections

No Action Action Party Schedule

Carry out inspection in location during site

1 HSE Manager/ Monthly

visit.

Quality Manager

Conduct inspection in sub-contractors HSE Advisor/

2 worksite, maintenance workshop, sludge Monthly

farm, waste yard, STP and call of work. Site Manager

Carry out inspection in catering facilities and

3 Hygienist Monthly

accommodations.

10.0 REVIEW

Management review meeting will be held quarterly at ES-KO INCORPORATED INChead office.

Effectiveness of the HSE activities will be reviewed. Senior Management, Operations team and QHSE

team will be participated in the review meeting and reviews HSE Management System, its

effectiveness and suitability in:

Managing HSE risks

Reinforcing efforts to continually improve HSE performance

Ensuring its continuing suitability and effectiveness

The issues to be addressed as part of the review process typically include:

Any recommendations which have been made in audit reports.

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 32 of 33

Any recommendations made in investigating incidents.

Extent of follow-up on audit and incident action items

The continuing suitability of ES-KO Incorporated Inc HSE policy

The continuing suitability of ES-KO Incorporated Inc HSE objectives and consequent

amendments to the HSE Plan and HSE Management System documentation if necessary

Performance against targets

Resources allocated to achieve HSE objectives.

No Action Action Party Schedule

Jan-2018,

Contract Manager/

April-2018,

Review HSE Management System, QHSE

1 HSE Manager/ July-2018,

Performance, and Accident/incident review.

October-

Quality Manager

2018

Review critical control point of food

2 operation and prepare documentation for Quality Manager March-2018

implementation.

Contract Manager/

3 HSE Plan compliance review of PDO contract. Monthly

HSE Manager

4 Review HSE Plan and its implementation. HSE Manager Jan-2018

5. Corrective action

All employees will adopt a ‘buddy, buddy’ system to correct each other during work

activities

All employees will stop hazardous situations, incidents and dangerous equipment

Any breach of these procedures will result in corrective training

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

PROJECT HSE PLAN

Quality Management Page 33 of 33

Repeat offenders will be dealt in accordance with ES-KO disciplinary procedures.

6. Verification and record keeping

QAE verifies compliance through site monthly inspection reinforced by HSE checklist.

HSE Checklist must be held for the duration of the contract

Internal audits will be performed Bi-annually

7. Related documents

HSE POLICY

COSHH POLICY

PPE POLICY FIRE POLICY

FIRST AID POLICY

WORK AT HEIGHT POLICY

CONFINED SPACES POLICY

HEALTH & SAFETY CHECKLIST

ES-KO PROPRIETARY DOCUMENT

You may NOT copy, share or distribute this document without written authorization from ES-KO

You might also like

- Hse PlanDocument61 pagesHse Planyasser magdy100% (1)

- Project Hse Execution PlanDocument15 pagesProject Hse Execution PlanLuqman Osman25% (4)

- Project HSE PlanDocument71 pagesProject HSE Planabdul jabbar100% (1)

- HSE Management SystemDocument31 pagesHSE Management Systemtaufik100% (4)

- Project Hse Plan Rev2 - ScribdDocument35 pagesProject Hse Plan Rev2 - ScribdPaulSwinbank94% (36)

- Health, Safety & Environment Management System Health, Safety & Environment Management System (Hsems) (Hsems) Manual ManualDocument70 pagesHealth, Safety & Environment Management System Health, Safety & Environment Management System (Hsems) (Hsems) Manual ManualQhsef Karmaveer Jyoteendra Vaishnav100% (4)

- HSE ManualDocument57 pagesHSE Manualfrancis50% (2)

- 2013 HSE Annual Report - Web FINAL PDFDocument74 pages2013 HSE Annual Report - Web FINAL PDFarunradNo ratings yet

- HSE ProgramDocument3 pagesHSE ProgramNadiah Abdul Rahaman100% (16)

- Project HSE Performance Monitoring ProcedureDocument12 pagesProject HSE Performance Monitoring ProcedureWinnie Eldama0% (1)

- HSE Management System ManualDocument6 pagesHSE Management System ManualasmaNo ratings yet

- HSE ManualDocument30 pagesHSE ManualJuan Jeronimo Morales75% (4)

- HSE PlanDocument80 pagesHSE Planpandaprasad88% (8)

- HSE Statistics PDFDocument5 pagesHSE Statistics PDFRashid100% (1)

- HSE Action PlanDocument5 pagesHSE Action PlansantosoNo ratings yet

- DOMEMSP004 - R03 - HSE Management System ManualDocument27 pagesDOMEMSP004 - R03 - HSE Management System ManualCarolyne Ndeverah KaloNo ratings yet

- SAMPLE HSE PlanDocument28 pagesSAMPLE HSE PlanRahmat Adi Saputra100% (4)

- HSE MANAGEMENT PLAN 2019-Rev1Document4 pagesHSE MANAGEMENT PLAN 2019-Rev1Nadiatul Aisyah Mohd Amirul Hakim86% (14)

- Gbemich Services: Health, Safety and Environmental Management Systems Plan For Construction of SNEPCO FACILITYDocument20 pagesGbemich Services: Health, Safety and Environmental Management Systems Plan For Construction of SNEPCO FACILITYJames Adekunle OgunsolaNo ratings yet

- Standard Field HSE PlanDocument89 pagesStandard Field HSE PlanMalik Nasar Ali100% (1)

- HSE Monthly Report For XXXX2 ProjectDocument30 pagesHSE Monthly Report For XXXX2 ProjectAhmed Hassan Sabry80% (5)

- Hse PlanDocument163 pagesHse PlanEnabulele Osakpamwan100% (10)

- Job Procedure FOR: Hse PlanDocument48 pagesJob Procedure FOR: Hse PlanJatin V Paliwal90% (39)

- HSE Program Plan DAILYDocument5 pagesHSE Program Plan DAILYdefidmsp39100% (1)

- HSE DocumentsDocument20 pagesHSE DocumentsVelmurugan Balasubramanian100% (3)

- Facility Health, Safety & Environmental ManagementDocument41 pagesFacility Health, Safety & Environmental ManagementAhmad Saiful Ridzwan Jaharuddin100% (3)

- Hse PolicyDocument1 pageHse PolicysushantvatsaNo ratings yet

- Hse PlanDocument62 pagesHse Plannsadnan91% (11)

- 2.2.7 - Construction HSE PlanDocument36 pages2.2.7 - Construction HSE PlanSayed Darwish100% (3)

- Abc Hse PlanDocument68 pagesAbc Hse PlanSayed DarwishNo ratings yet

- Project Health Safety & Environment Manual: Scope of WorkDocument101 pagesProject Health Safety & Environment Manual: Scope of WorkGovind Chhawsaria100% (5)

- CCAD - Project HSE PlanDocument187 pagesCCAD - Project HSE Plansergio1234567890100% (7)

- General Program HSEDocument8 pagesGeneral Program HSEardi100% (1)

- Training Matrix ProcedureDocument5 pagesTraining Matrix ProcedureSérgio CoutoNo ratings yet

- HSE PlanDocument161 pagesHSE PlanAlai Abdel FattahNo ratings yet

- Sample Hse Plan OilngasDocument20 pagesSample Hse Plan OilngasmrjusNo ratings yet

- HSE MGT - System PDFDocument70 pagesHSE MGT - System PDFNaveen Chaudhary100% (1)

- HSE Procedure PDFDocument186 pagesHSE Procedure PDFAndreas Schlager100% (4)

- HSE Manual - V3Document81 pagesHSE Manual - V3Thanh Nguyen100% (3)

- HSE Plan Subcontractor # 3Document81 pagesHSE Plan Subcontractor # 3Fauzi Awalludin100% (3)

- HSE Inspection Matrix - c416Document1 pageHSE Inspection Matrix - c416Venkadesh PeriathambiNo ratings yet

- Annual HSE Program ContohDocument2 pagesAnnual HSE Program ContohSigit Wiyono100% (1)

- Hse PlanDocument23 pagesHse Planlê ngọc tùng100% (1)

- Seplat Safe System of Work Scheme: Seplat Petroleum Development CompanyDocument16 pagesSeplat Safe System of Work Scheme: Seplat Petroleum Development CompanySegun Rufai100% (6)

- 08-Construction HSE Management PlanDocument19 pages08-Construction HSE Management PlanMian100% (1)

- HSE Statistics Presentation ExampleDocument23 pagesHSE Statistics Presentation ExampleKhuda BukshNo ratings yet

- Prequalification For HSE KPIDocument81 pagesPrequalification For HSE KPIBabu100% (1)

- Att 1 HSE Objectives & TargetsDocument1 pageAtt 1 HSE Objectives & TargetsAbdul Hakam Mohamed Yusof100% (1)

- Hse Management Plan 1Document93 pagesHse Management Plan 1Khuda BukshNo ratings yet

- Monthly HSE Report April .2013Document8 pagesMonthly HSE Report April .2013sakthivelNo ratings yet

- HSE PolicyDocument1 pageHSE PolicyHassan Ali Hassan100% (1)

- Hse Key Performance Indicator Contractor 2021: Trailling Metric ( )Document1 pageHse Key Performance Indicator Contractor 2021: Trailling Metric ( )Dipendra Satya100% (4)

- IPP HSE Section Robby Template 2017 RevDocument58 pagesIPP HSE Section Robby Template 2017 Revrobby damanikNo ratings yet

- Health, Safety & Environmental PlanDocument32 pagesHealth, Safety & Environmental PlanMihirdutta100% (1)

- 05 Project Safety PlanDocument32 pages05 Project Safety Planrudiawan100% (3)

- Annual Hse Performance ReportDocument21 pagesAnnual Hse Performance ReportWealth OSIOBE100% (1)

- Project HSE Plan UNDOF IsraelDocument29 pagesProject HSE Plan UNDOF IsraelWinnie EldamaNo ratings yet

- Environmental Management Plan For Hotel BuildingDocument8 pagesEnvironmental Management Plan For Hotel BuildingGt Madan100% (1)

- JBT HSE Management SystemDocument21 pagesJBT HSE Management Systemsefina mecNo ratings yet

- Incident Action PlanDocument5 pagesIncident Action Planlade45735No ratings yet

- Project HSE Plan UNDOF IsraelDocument29 pagesProject HSE Plan UNDOF IsraelWinnie EldamaNo ratings yet

- Project HSE Performance Monitoring ProcedureDocument12 pagesProject HSE Performance Monitoring ProcedureWinnie Eldama0% (1)

- Contractor HSE Management ProcedureDocument9 pagesContractor HSE Management ProcedureWinnie Eldama100% (1)

- HSE Training Evaluation Form: Project: Training Session Title: Instructor: DateDocument1 pageHSE Training Evaluation Form: Project: Training Session Title: Instructor: DateWinnie Eldama100% (1)

- HSE Training ProcedureDocument8 pagesHSE Training ProcedureWinnie Eldama100% (2)

- Employee Operator Competence Training AssessmentDocument3 pagesEmployee Operator Competence Training AssessmentWinnie EldamaNo ratings yet

- HSE Induction RecordDocument2 pagesHSE Induction RecordWinnie Eldama100% (2)

- Automobile SafetyDocument23 pagesAutomobile SafetyPrathmeshBhokariNo ratings yet

- Crossword Book of Excerpts 2004 - 2010aDocument368 pagesCrossword Book of Excerpts 2004 - 2010aMohammad Johar50% (2)

- Brahma Sukhi-Out Out - by Robert Frost-An AnalysisDocument7 pagesBrahma Sukhi-Out Out - by Robert Frost-An AnalysisParvathy SubramanianNo ratings yet

- SRC PDFDocument86 pagesSRC PDFronaldNo ratings yet

- Pages From Pap Air Law PWB 2016Document5 pagesPages From Pap Air Law PWB 2016Paul KostukovskyNo ratings yet

- Final Report PK-VSEDocument25 pagesFinal Report PK-VSEIlham NugrohoNo ratings yet

- LCM 6. Incident Investigation - CompressedDocument82 pagesLCM 6. Incident Investigation - CompressedKevin RiveraNo ratings yet

- The Go Around Procedure: David OwensDocument8 pagesThe Go Around Procedure: David OwensJerome Cardenas TablacNo ratings yet

- Integrating Aircraft Warning Systems PDFDocument5 pagesIntegrating Aircraft Warning Systems PDFDurai Raj KumarNo ratings yet

- What Would You Do If...Document1 pageWhat Would You Do If...bestatemanNo ratings yet

- Fundamentals of Legal Writing: Chapter 9Document1 pageFundamentals of Legal Writing: Chapter 9Caren Que ViniegraNo ratings yet

- (Krytyk) Omae Wo Onii-Chan Ni Shiteyarouka! - Volume 03Document180 pages(Krytyk) Omae Wo Onii-Chan Ni Shiteyarouka! - Volume 03Julius TijamNo ratings yet

- The Copperbelt University School of Engineering Civil and Construction DepartmentDocument12 pagesThe Copperbelt University School of Engineering Civil and Construction DepartmentchileNo ratings yet

- AV9832 19JUN BOGMTR - Provisional Loadsheet Edno 1Document2 pagesAV9832 19JUN BOGMTR - Provisional Loadsheet Edno 1brayan osorioNo ratings yet

- Vca EngelsDocument15 pagesVca EngelsSorin TecNo ratings yet

- Sample Exercise in TortsDocument6 pagesSample Exercise in TortsJonil CaninoNo ratings yet

- Martinez v. Van BuskirkDocument2 pagesMartinez v. Van Buskirknichols greenNo ratings yet

- Buffalo Police ReportDocument2 pagesBuffalo Police ReportWGRZ-TVNo ratings yet

- Take Off and Destination Alternate AerodromeDocument2 pagesTake Off and Destination Alternate AerodromeGilo95No ratings yet

- InstructorBriefing - ThomasCook Simulator Assessment B757Document4 pagesInstructorBriefing - ThomasCook Simulator Assessment B757Manny ManNo ratings yet

- The Irretrievable PastDocument3 pagesThe Irretrievable PastCameron Wesley CarpenterNo ratings yet

- Crash To Desktop (CTD) Cure-All - Fallout 4 Technical Support - The Nexus ForumsDocument7 pagesCrash To Desktop (CTD) Cure-All - Fallout 4 Technical Support - The Nexus ForumsluinksNo ratings yet

- 07 Group Exercise 1 RiskDocument2 pages07 Group Exercise 1 RiskTokemi MoariNo ratings yet

- Man Rec Severing ToolDocument10 pagesMan Rec Severing ToolNgoc NguyenNo ratings yet

- Avoiding Hard Landings: Capt. Marc PARISISDocument30 pagesAvoiding Hard Landings: Capt. Marc PARISISAnonymous 69rsr6yP7No ratings yet

- Notice: Meetings: Human Factors Research Necessary To Support Advanced Vehicle Safety Technologies ForumDocument2 pagesNotice: Meetings: Human Factors Research Necessary To Support Advanced Vehicle Safety Technologies ForumJustia.comNo ratings yet

- Malaysia - Nuclear Regulatory InfrastructureDocument22 pagesMalaysia - Nuclear Regulatory InfrastructureMohd Zulhairi Mohd NoorNo ratings yet

- 2.310-Accident Investigation & Reporting1Document23 pages2.310-Accident Investigation & Reporting1kirandevi1981No ratings yet

- Special Emphasis Areas: Positive Aircraft ControlDocument4 pagesSpecial Emphasis Areas: Positive Aircraft ControlYeison ChavezNo ratings yet

- Summary Tristram ShandyDocument2 pagesSummary Tristram ShandylsacnoattNo ratings yet