Professional Documents

Culture Documents

Ajuste de Breake en Alpha RT PDF

Ajuste de Breake en Alpha RT PDF

Uploaded by

Rafa TejedaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ajuste de Breake en Alpha RT PDF

Ajuste de Breake en Alpha RT PDF

Uploaded by

Rafa TejedaCopyright:

Available Formats

Service Manual Performa, Alpha IQ, RT, ST, III

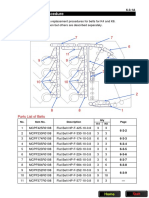

6.4.5 Replacing the magnetic brake and its assembly

Remove the side covers and pull out the electronic plate with the cables.

Disconnect all cable connectors and pull loose connectors through the center

axis on the C-arm.

Remove the four nuts behind the brake, and remove the other parts in the

following order:

- locking plate with the counter plate for magnetic brake.

- the disc springs

- the magnetic brake connected to the assembly plate.

See figures 6.7a, b and c.

Unscrew the friction plate and replace it with a new one. Replace the other

parts: magnetic brake, 4x7 pairs of disc springs, locking plate, and finally the

locking nuts.

Tighten the four nuts so that the locking plate is completely shut. Then

unscrew them half a turn.

The brake is adjusted using a 20 VDC power supply connected to the brake.

The adjustment is performed either by tightening or loosening the holding nuts.

The brake should be adjusted in such a way that the holding force measured

from the cassette holder should be less than 20 N (4 lbs.) with the brake off

and greater than 110 N (24 lbs.) with the brake on.

C-arm Brake adjustment

Check that the brake has 110N (27lbs) of

holding force measured at the cassette holder. If

not, open the side covers of the carriage and

tighten the nyloc nuts (3).

If the brake does not release properly, open the

nuts (1), and adjust the space (4) with the

screws (2). The space should be about 0.1 - 0.4

mm.

Figure 6.7a

June 2000 6-12 31687

Performa, Alpha IQ, RT, ST, III Service Manual

Figure 6.7b

Figure 6.7c

31687 6-13 June 2000

You might also like

- Schwinn Stingray OCC Chopper Bicycle Motor Kit PlansDocument38 pagesSchwinn Stingray OCC Chopper Bicycle Motor Kit PlansLiveFastMotors81% (16)

- Leece Neville 4000 Series Alternator Service ManualDocument21 pagesLeece Neville 4000 Series Alternator Service ManualOneil Campbell100% (1)

- 2012 Components Technical Manual UkDocument154 pages2012 Components Technical Manual UkBrummerNo ratings yet

- Sturmey Archer Hub TechnicalDocument8 pagesSturmey Archer Hub TechnicalbobnunleyNo ratings yet

- 1989 Garden Way Tomahawk Chipper Technical Manual WMDocument12 pages1989 Garden Way Tomahawk Chipper Technical Manual WMgodiboNo ratings yet

- Ignition - Replace Coil Units On An ES9J4S V6 EngineDocument8 pagesIgnition - Replace Coil Units On An ES9J4S V6 EngineLojan Coronel José HumbertoNo ratings yet

- Alternator 130a.xmlDocument16 pagesAlternator 130a.xmlAnjaliNo ratings yet

- Engine Removal/InstallationDocument10 pagesEngine Removal/Installationorly pocoateNo ratings yet

- Mini X Motor Replacement With Fan UpgradeDocument7 pagesMini X Motor Replacement With Fan UpgradeLucian ComanNo ratings yet

- (MG) Manual de Taller MG TF 2011 (392-497)Document106 pages(MG) Manual de Taller MG TF 2011 (392-497)Santa Rosa HuarocondoNo ratings yet

- W R H Main Manual PDFDocument14 pagesW R H Main Manual PDFjaikolangaraparambilNo ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- Ejes CompensadoresDocument3 pagesEjes CompensadoresNovers Ma RresNo ratings yet

- Grundfosliterature 5153653Document26 pagesGrundfosliterature 5153653Payden SewellNo ratings yet

- Acura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6Document200 pagesAcura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6CandieApple100% (1)

- 11susp. Tras y Parte Trasera Suzuki IntruderDocument22 pages11susp. Tras y Parte Trasera Suzuki Intruderbenjapana100% (2)

- Basic System Troubleshooting and RepairDocument20 pagesBasic System Troubleshooting and RepairCric CricNo ratings yet

- Kec-440-21 CCWDocument12 pagesKec-440-21 CCWBenjamin yealeyNo ratings yet

- 2006 2008 Cbf1000 A 8 Engine Removal InstallationDocument12 pages2006 2008 Cbf1000 A 8 Engine Removal InstallationMurariu IonutNo ratings yet

- Magpower Clutch Model CDocument4 pagesMagpower Clutch Model CJuan CaceresNo ratings yet

- Retro-Fitting L-Type Mudguards:: Aug-10 Mglret DsDocument4 pagesRetro-Fitting L-Type Mudguards:: Aug-10 Mglret DsmamatnamakuNo ratings yet

- Engine ElectricalDocument4 pagesEngine ElectricalAndres Herland Balderas MirandaNo ratings yet

- Replace Governor ActuatorDocument8 pagesReplace Governor ActuatorSteven ManuputtyNo ratings yet

- 6-3. Belt RepDocument28 pages6-3. Belt RepAbdul MuhidNo ratings yet

- Winding Machine Instruction ManualDocument67 pagesWinding Machine Instruction Manualkhaled abdalnaserNo ratings yet

- Spindle Belt ReplacementDocument3 pagesSpindle Belt ReplacementAshNo ratings yet

- Automatic Gearbox Removal1Document18 pagesAutomatic Gearbox Removal1JohnnoNo ratings yet

- Headstock Part 1Document10 pagesHeadstock Part 1api-327987286No ratings yet

- 7HB (A, B, C, D, E, X) Assembly-Disassembly ManualDocument33 pages7HB (A, B, C, D, E, X) Assembly-Disassembly ManualYavuz Ercanli100% (2)

- Rock Shox Judy Service Guide Rev - A PDFDocument9 pagesRock Shox Judy Service Guide Rev - A PDFee1993No ratings yet

- Awc Src3 Manual. 1Document5 pagesAwc Src3 Manual. 1ghionoiucNo ratings yet

- Boletin Codigo p0868 PDFDocument13 pagesBoletin Codigo p0868 PDFHania BarajasNo ratings yet

- DrivetrainDocument43 pagesDrivetrainfuckoffalreadyNo ratings yet

- 1953 Lucas Dynamos E3L E3LM E3NDocument7 pages1953 Lucas Dynamos E3L E3LM E3NedelapolloNo ratings yet

- MT Series - ServiceDocument8 pagesMT Series - ServiceВаня БойкоNo ratings yet

- 1966 Ford Mustang Breaker Points and Condenser Removal and InstallationDocument4 pages1966 Ford Mustang Breaker Points and Condenser Removal and InstallationOxgardNo ratings yet

- zxr400 H 10Document7 pageszxr400 H 10hugo_bikerNo ratings yet

- Canonet GIII 17Document4 pagesCanonet GIII 17Jose Paulo Martins NarcisoNo ratings yet

- Timing Belt Replacement 2008 Audi A4 20tdiDocument2 pagesTiming Belt Replacement 2008 Audi A4 20tdiJustinas RackauskasNo ratings yet

- Philips N2213-00-15 SMDocument13 pagesPhilips N2213-00-15 SMFranco DurantNo ratings yet

- Bullet 4 Speed Clutch Dismantling and ReassemblingDocument4 pagesBullet 4 Speed Clutch Dismantling and ReassemblingJon SmithNo ratings yet

- STC Series: Three-Phase Synchronous GeneratorsDocument9 pagesSTC Series: Three-Phase Synchronous GeneratorsReezka PutraNo ratings yet

- Syncro Trak Service ManualDocument26 pagesSyncro Trak Service ManualMelina SbhNo ratings yet

- Chassis: at LegDocument12 pagesChassis: at LegRinso PietersmaNo ratings yet

- Champ Manual NTDocument8 pagesChamp Manual NTPepe CarrNo ratings yet

- Constant Mesh Gear BoxDocument10 pagesConstant Mesh Gear BoxSummer Nelson0% (1)

- S4C-Product Manual IRB 6400 3HAC 2941-1 M98Document6 pagesS4C-Product Manual IRB 6400 3HAC 2941-1 M98Andrés M. ReyesNo ratings yet

- 2012 Polaris Service Manual Chapter 08 6x6Document18 pages2012 Polaris Service Manual Chapter 08 6x6Russell ReedNo ratings yet

- MIL ON WITH DTC P0741, P0744, P0746, P0776, P0841, P0965, P2857, P2858, P2859, AND/OR P285A STORED, and May Have Hesitation And/Or Lack of PowerDocument22 pagesMIL ON WITH DTC P0741, P0744, P0746, P0776, P0841, P0965, P2857, P2858, P2859, AND/OR P285A STORED, and May Have Hesitation And/Or Lack of Powerdamian berduscoNo ratings yet

- Suspension Mercedes 9Document1 pageSuspension Mercedes 9David RoberNo ratings yet

- Repair Information: Eaton Hydrualics DivisionDocument8 pagesRepair Information: Eaton Hydrualics DivisionZafiro Feliz GalanNo ratings yet

- 08 - Gearbox PDFDocument22 pages08 - Gearbox PDFdicksonNo ratings yet

- Hercus 260 Lathe Maintenance ManualDocument24 pagesHercus 260 Lathe Maintenance ManualNewNo ratings yet

- CGen GY6 50cc Service Manual PDFDocument199 pagesCGen GY6 50cc Service Manual PDFSharkykzn0% (1)

- 7 Frame and WheelDocument12 pages7 Frame and Wheelalsief1951No ratings yet

- Jeep Cherokee XJ 1988-1992 Transmission Servicing A - TDocument5 pagesJeep Cherokee XJ 1988-1992 Transmission Servicing A - Tjess230580No ratings yet

- V-6 Magnum: (Do Not Use Any Type of Gasket Sealer)Document2 pagesV-6 Magnum: (Do Not Use Any Type of Gasket Sealer)Gabriel ChiavettoNo ratings yet

- Cambelt and Water Pump Change MultiplaDocument12 pagesCambelt and Water Pump Change Multiplaa1037699No ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- EspectrofotometroDocument68 pagesEspectrofotometroRafa TejedaNo ratings yet

- Hologic Lorad M IV Series BrochureDocument8 pagesHologic Lorad M IV Series BrochureRafa Tejeda100% (1)

- Savina 300 BrochureDocument8 pagesSavina 300 BrochureRafa Tejeda100% (1)

- Control-X Company Profile Presentation For Distributors 1-26Document26 pagesControl-X Company Profile Presentation For Distributors 1-26Rafa TejedaNo ratings yet

- Lorad Elite Schematics Manual - 9-500-0223Document30 pagesLorad Elite Schematics Manual - 9-500-0223Rafa Tejeda100% (5)

- Temporizador ColimadorDocument1 pageTemporizador ColimadorRafa TejedaNo ratings yet

- Erbe Vio 200 S - User ManualDocument120 pagesErbe Vio 200 S - User ManualRafa Tejeda67% (3)

- Operation Manual: Diagnostic Audiometer AD229eDocument85 pagesOperation Manual: Diagnostic Audiometer AD229eRafa TejedaNo ratings yet

- 870 ManualDocument7 pages870 ManualRafa TejedaNo ratings yet

- Zoll E-Series - Service ManualsDocument96 pagesZoll E-Series - Service ManualsCristian CamiloNo ratings yet

- Satelec-X-Mind-Dc-User Manual PDFDocument39 pagesSatelec-X-Mind-Dc-User Manual PDFRafa Tejeda100% (2)

- Fuction Description X038IDocument12 pagesFuction Description X038IRafa TejedaNo ratings yet

- 1455 Delivery Unit Manual (Sds Biscayne)Document30 pages1455 Delivery Unit Manual (Sds Biscayne)Rafa Tejeda100% (1)

- Chatlog Basic I Class 2 2014-09-05 09 - 30Document3 pagesChatlog Basic I Class 2 2014-09-05 09 - 30Rafa TejedaNo ratings yet

- Catalogo de Baterias para Equipo MedicoDocument72 pagesCatalogo de Baterias para Equipo MedicoRafa TejedaNo ratings yet

- Test System: Certifier FADocument42 pagesTest System: Certifier FARafa TejedaNo ratings yet

- Certifier FA English 1980436 PDFDocument42 pagesCertifier FA English 1980436 PDFRafa TejedaNo ratings yet

- Instruction Manual: X-Ray Dose Meter / Exposure Time MeterDocument13 pagesInstruction Manual: X-Ray Dose Meter / Exposure Time MeterRafa TejedaNo ratings yet

- 251 Martin Me80 FolletoDocument12 pages251 Martin Me80 FolletoRafa TejedaNo ratings yet

- Mge - Ex11rt - Installation and User Manual PDFDocument38 pagesMge - Ex11rt - Installation and User Manual PDFRafa TejedaNo ratings yet

- Iics90 BR 9050454 enDocument8 pagesIics90 BR 9050454 enRafa TejedaNo ratings yet