Professional Documents

Culture Documents

Mini X Motor Replacement With Fan Upgrade

Uploaded by

Lucian ComanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mini X Motor Replacement With Fan Upgrade

Uploaded by

Lucian ComanCopyright:

Available Formats

EPILOG LASER

16371 Table Mountain Parkway

Golden, Colorado 80403

Phone 303-215-9171

FAX 303-277-9669

www.epiloglaser.com

X Axis Motor Replacement

For the Epilog Mini / Helix - 10/26/2012

Requirements:

Tools:

Philips Head Screw Driver

Parts:

X Axis Motor Assembly (AS07000ATT-03-M-02)

Overview:

This procedure details steps to replacing the x-motor on the Helix. The X-motor drives the belt in

the I-beam.

X Axis Motor Replacement

Revision Date: 10/26/2012 pg. 1 of 7

Procedure A: Removing the Old Motor

Step 1 With the engraver

powered off, you can move

the I-Beam to any position on

Unplug the engraver from its power source the table. Feel free to move it

to a position that is easy for

Step 2 you to work with.

Remove both side panels.

Step 3

Remove cover on I-Beam by loosening the screws on the

front and rear of the beam (you do not need to remove the screws)

and pulling the cover up.

Step 4

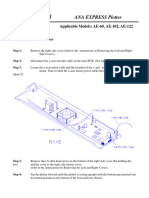

Loosen the X axis belt as follows.

a) On the left side of the I-Beam, locate the idler

pulley that the Belt wraps around. It is mounted to

a sliding plate which has two screws and a spring Step 4-B

attached.

b) Loosen the two Philips screws that hold the sliding

plate in place. (Do not remove the screws).

c) Push the pulley to the right hand side of the

engraver. The pulley should slide with the plate

towards the center of the machine forcing the

spring to stretch and loosening the tension on the

X axis belt.

d) While holding the pulley to the right hand side of

the engraver, tighten the screw towards the rear of Step 4-C & 4-D

the engraver. This will hold the pulley in place and

keep tension off of the X axis belt.

X Axis Motor Replacement

Revision Date: 10/26/2012 pg. 2 of 7

Step 5

Identify the Motor Assembly on the right side of the I-Beam. Locate the motor wires (red and

black twisted wire with a black quick disconnect at the end) and disconnect them by unplugging the black

quick disconnect which is connected to the circuit board just to the rear of the motor. Squeeze the

disconnect plug between your thumb and forefinger to release the connecter from its socket.

As of 10/26/2012 an

Step 6 upgrade has been released for

all 8000 model laser systems. If

Identify the power connection for the Fan assembly and the circuit board attached to the

I-Beam does not have a fan on

disconnect it from the circuit board. Squeeze the disconnect plug

top please contact Epilog Tech

between your thumb and forefinger to release the connecter from Support for your upgrade.

its socket.

Step 7

Unscrew and remove the fan assembly.

X Axis Motor Replacement

Revision Date: 10/26/2012 pg. 3 of 7

Step 8

Identify and unscrew the Captive Screws which mount the motor to the I-Beam.

NOTE: The captive screws will not release from the Motor Bracket.

Step 9

Remove the motor by pulling it straight up. You may need to angle the motor slightly so that the

belt falls from the drive pulley.

X Axis Motor Replacement

Revision Date: 10/26/2012 pg. 4 of 7

Procedure B: Installing the New Motor

Step 1

With your index finger, pull the belt and loop the belt around the silver pulley.

Step 2

Place the motor so that the captive screws are aligned with the mounting posts.

X Axis Motor Replacement

Revision Date: 10/26/2012 pg. 5 of 7

Step 3

Tighten the captive screws to hold the motor in place.

Step 4

Replace the Fan assembly over the circuit board. Fasten in place with the provided screws.

Step 5

Connect the motor wires (red and black twisted wire with a black quick disconnect at the end) by

plugging the black quick disconnect in to the circuit board just to the rear of the motor.

Motor

X Axis Motor Replacement

Revision Date: 10/26/2012 pg. 6 of 7

Step 6

Connect the Fan wires by plugging the black quick disconnect in to the circuit board just to the

rear of the motor.

Fan

Step 7

On the left side of the I-beam locate the Pulley which the belt wraps around. (See Procedure A -

Step 4.) Loosen the Philips screw holding the pulley in place. The spring will pull the belt tight. Retighten

both Philips screws to keep the belt tight as the engraver operates.

Conclusion

Check that the belt is on the center of both pulleys on the left and right sides of the machine and

then proceed to replace the covers on the engraver. If you encounter any further problems please contact

Epilog Tech Support at (303) 215-9171.

X Axis Motor Replacement

Revision Date: 10/26/2012 pg. 7 of 7

You might also like

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Performance Computer Chip Installation Instructions: 325i/is/ix 325ic 525i 535i 635csi 735i/ilDocument4 pagesPerformance Computer Chip Installation Instructions: 325i/is/ix 325ic 525i 535i 635csi 735i/ilandrija_ganzbergerNo ratings yet

- RepymotDocument4 pagesRepymotEngin UzunNo ratings yet

- Mekatronix: Mekatronix Servo Hack Create A D.C. Gearhead Motor From A ServoDocument3 pagesMekatronix: Mekatronix Servo Hack Create A D.C. Gearhead Motor From A ServoCésar FriendNo ratings yet

- BMW Paddle Instalação e AtivaçãoDocument32 pagesBMW Paddle Instalação e AtivaçãoNicolas MNo ratings yet

- Exp 9 Introduction To MachinesDocument11 pagesExp 9 Introduction To MachinesMuhammad AwaisNo ratings yet

- QX MaintenanceDocument24 pagesQX MaintenancePa-jokey Espinoza GutierrezNo ratings yet

- Suzuki GSX-R1000 2005-2006Document6 pagesSuzuki GSX-R1000 2005-2006Mr. TNo ratings yet

- Cetac Z Drive AssemblyDocument13 pagesCetac Z Drive AssemblyYanine Aranda MosqueraNo ratings yet

- Acumen Install Guide Rev 1Document13 pagesAcumen Install Guide Rev 1api-3706381No ratings yet

- Replace ignition coil on ES9J4S V6 210bhpDocument8 pagesReplace ignition coil on ES9J4S V6 210bhpLojan Coronel José HumbertoNo ratings yet

- A2 Drive Nut ReplacementDocument7 pagesA2 Drive Nut ReplacementJibjab7100% (1)

- 70 070 Autocreaser 50 Service ManualDocument31 pages70 070 Autocreaser 50 Service ManualWilliam John DavisonNo ratings yet

- Abs/A ASC T Pum MP Block R Refurbish: Part 1: D Disassemb LyDocument10 pagesAbs/A ASC T Pum MP Block R Refurbish: Part 1: D Disassemb LyEd MoralesNo ratings yet

- Allegra X-12, X-15R Section 3Document22 pagesAllegra X-12, X-15R Section 3fibmetNo ratings yet

- Fireball Ignition PDFDocument14 pagesFireball Ignition PDFLucian LeonteNo ratings yet

- Suspension - FrontDocument5 pagesSuspension - FrontHans OosthuizenNo ratings yet

- Section 5 - Repair/Replacement Procedures: Part Number/ Nomenclature DescriptionDocument4 pagesSection 5 - Repair/Replacement Procedures: Part Number/ Nomenclature DescriptionGregorio1927No ratings yet

- 1953 Lucas Dynamos E3L E3LM E3NDocument7 pages1953 Lucas Dynamos E3L E3LM E3NedelapolloNo ratings yet

- Alloytec Mi Installation PDFDocument22 pagesAlloytec Mi Installation PDFMaverick MacdonaldNo ratings yet

- 600ae 28Ae-Ribbon Cable ReplacementDocument4 pages600ae 28Ae-Ribbon Cable ReplacementcARLOSNo ratings yet

- RAM Remote Start Installation GuideDocument54 pagesRAM Remote Start Installation GuideJose Saucedo OlanNo ratings yet

- Paddle Shift InstallationDocument9 pagesPaddle Shift Installationpenavi5687No ratings yet

- Arosa 5i Infrared Spark Detector Installation ManualDocument23 pagesArosa 5i Infrared Spark Detector Installation ManualmamuntextileNo ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- Epilog Laser Helix Replacing Instructions X AxisDocument4 pagesEpilog Laser Helix Replacing Instructions X AxisLucian ComanNo ratings yet

- Suzuki GSX-R1000 2009-2010Document6 pagesSuzuki GSX-R1000 2009-2010Mr. TNo ratings yet

- Uconnectweb InstallationSheetsDocument166 pagesUconnectweb InstallationSheets#1973#No ratings yet

- 97-1 Relay Panel, Fuse Panel PDFDocument5 pages97-1 Relay Panel, Fuse Panel PDFmefisto06cNo ratings yet

- Suzuki Hayabusa Gear Indicator Installation GuideDocument6 pagesSuzuki Hayabusa Gear Indicator Installation GuidegigihNo ratings yet

- Install Curtis 1266 Controller in 2007-2009 E-Z-GO RXV Golf CartDocument9 pagesInstall Curtis 1266 Controller in 2007-2009 E-Z-GO RXV Golf CartSayed KhlileNo ratings yet

- GE 175d2750g313Document2 pagesGE 175d2750g313Emmanuel Vieira Villasana100% (1)

- Adaptive Cruise Installation for 2015+ F150Document9 pagesAdaptive Cruise Installation for 2015+ F150Night WolfNo ratings yet

- Eaton CM-52 Remote Racking IL02400003EDocument16 pagesEaton CM-52 Remote Racking IL02400003EadvancedmotorNo ratings yet

- Kia Sportage Remote StartDocument22 pagesKia Sportage Remote StartJONATHAN100% (1)

- 7 Frame and WheelDocument12 pages7 Frame and Wheelalsief1951No ratings yet

- Manette 4SNDocument13 pagesManette 4SNOthmanNo ratings yet

- Sierra Automática Om-h-8276vDocument40 pagesSierra Automática Om-h-8276vCristian MatelunaNo ratings yet

- HP CP6015 and CM6030/CM6040 50.7 Fuser Error FixDocument1 pageHP CP6015 and CM6030/CM6040 50.7 Fuser Error FixJY96No ratings yet

- V11 SensorModule FRUDocument3 pagesV11 SensorModule FRUCAM CAMELNo ratings yet

- Leveling Arm Replacement: Service InstructionsDocument4 pagesLeveling Arm Replacement: Service InstructionskevinalleinNo ratings yet

- Distox2 Assembly ManualDocument6 pagesDistox2 Assembly ManualVlad AdrianNo ratings yet

- Technical Bulletin: CopierDocument22 pagesTechnical Bulletin: CopiernickypanzeNo ratings yet

- YOSHIMURA EXHAUST INSTALLATION GUIDE FOR 2007 SUZUKI GSX-R1000Document6 pagesYOSHIMURA EXHAUST INSTALLATION GUIDE FOR 2007 SUZUKI GSX-R1000Daniel MartínNo ratings yet

- SERVICE BULLETIN No. 012-2009 21-12-2009Document13 pagesSERVICE BULLETIN No. 012-2009 21-12-2009Bert SmitNo ratings yet

- CGen GY6 50cc Service Manual PDFDocument199 pagesCGen GY6 50cc Service Manual PDFSharkykzn0% (1)

- Richards Lock Up Kit For 2016+200Document7 pagesRichards Lock Up Kit For 2016+200chrisNo ratings yet

- 2cv Manual3Document9 pages2cv Manual3alfonsoNo ratings yet

- How To Fine Tune Your 3D Printer ENDER 3Document87 pagesHow To Fine Tune Your 3D Printer ENDER 3Michaël Memeteau100% (5)

- Headliner Removal and InstallationDocument6 pagesHeadliner Removal and InstallationMichael HernandezNo ratings yet

- IH UK Ferrari Mondial V1Document8 pagesIH UK Ferrari Mondial V1paolo zNo ratings yet

- Firecharger Installation ADocument10 pagesFirecharger Installation AAugmotorsNo ratings yet

- Nissan TSB'sDocument9 pagesNissan TSB'sPMNo ratings yet

- SERVICE MANUAL FOR PERMOBIL C500Document68 pagesSERVICE MANUAL FOR PERMOBIL C500wilson de jesus mirandaNo ratings yet

- BA/BF ICC Install InstructionsDocument8 pagesBA/BF ICC Install InstructionsLeiden O'SullivanNo ratings yet

- Xserve Intel DIY OpticalDriveDocument6 pagesXserve Intel DIY OpticalDriveApple Johnnyseed100% (1)

- 8th Gen Shifter Cables Install GuideDocument15 pages8th Gen Shifter Cables Install GuideHybrid Racing100% (1)

- MX960-PSU Replacement Guide - IqDocument5 pagesMX960-PSU Replacement Guide - Iqiqbal apriansyahNo ratings yet

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Install wind sensor correctlyDocument7 pagesInstall wind sensor correctlyDuy KhaNo ratings yet

- As 70660 LV-N SG 469GB GB WW 1056-2Document4 pagesAs 70660 LV-N SG 469GB GB WW 1056-2mhafizanNo ratings yet

- Wiring Inspection ChecklistDocument7 pagesWiring Inspection ChecklistJesus Bedriñana Gascon100% (2)

- HC-X2000 Camcorders - Panasonic Middle EastDocument7 pagesHC-X2000 Camcorders - Panasonic Middle EastMr FarukNo ratings yet

- S 2251030Document52 pagesS 2251030M Abdullah Al MamunNo ratings yet

- Ervor ApuDocument41 pagesErvor ApuEngr Mohammed UsmaniaNo ratings yet

- Pe, QuizDocument5 pagesPe, QuizJoanne Ico MagnayeNo ratings yet

- Parts Catalog-Honda Navi110Document45 pagesParts Catalog-Honda Navi110Josue Sosa SosaNo ratings yet

- HD Materi Operator Competency Assessment (OCA)Document74 pagesHD Materi Operator Competency Assessment (OCA)Mel MelisaNo ratings yet

- IP 60-75 Cosmic Motor Starter - New PDFDocument16 pagesIP 60-75 Cosmic Motor Starter - New PDFAshok Kumar JenaNo ratings yet

- Inductive sensor technical specifications in 40 charactersDocument3 pagesInductive sensor technical specifications in 40 charactersBasarNo ratings yet

- Catalogo ToolfloDocument236 pagesCatalogo ToolfloRafael Enrique Zhicay OrdoñezNo ratings yet

- Troubleshooting Guide for InvertersDocument4 pagesTroubleshooting Guide for InvertersAkram LamaNo ratings yet

- Juta CMP-03Document2 pagesJuta CMP-03Sergey DNo ratings yet

- Lab 1 Introduction To Power System Protection UpdatedDocument21 pagesLab 1 Introduction To Power System Protection UpdatedKhadijaNo ratings yet

- TS300 1800OperationManualDocument120 pagesTS300 1800OperationManualДмитрий ДехановNo ratings yet

- LDP Series Actuator - DEMBLADocument4 pagesLDP Series Actuator - DEMBLAKamitkumar PatelNo ratings yet

- Stalker Radar Equipment Prices and Part NumbersDocument32 pagesStalker Radar Equipment Prices and Part NumbersJunior DuraznoNo ratings yet

- Wiring A Generator Transfer SwitchDocument7 pagesWiring A Generator Transfer Switchtidjani86No ratings yet

- BBS Cables Price List July 2020Document8 pagesBBS Cables Price List July 2020Md. Manirul Islam100% (1)

- Silencers: Series: 2901 - 2903 - 2921 - 2931 - 2938 - 2939 - 2905 - RSW Ports: M5, G1/8, G1/4, G3/8, G1/2, G3/4, G1Document4 pagesSilencers: Series: 2901 - 2903 - 2921 - 2931 - 2938 - 2939 - 2905 - RSW Ports: M5, G1/8, G1/4, G3/8, G1/2, G3/4, G1icsNo ratings yet

- TENDER CLARIFICATION NO. 1 - HYDRANT AND FOAM PIPELINE REPLACEMENT AT LBT at LB1 AND LB2Document6 pagesTENDER CLARIFICATION NO. 1 - HYDRANT AND FOAM PIPELINE REPLACEMENT AT LBT at LB1 AND LB2Sathya SeelanNo ratings yet

- 01-Test-Equipment ManualDocument30 pages01-Test-Equipment ManualZamriNo ratings yet

- Grundfosliterature 829843 PDFDocument32 pagesGrundfosliterature 829843 PDFcodefinderNo ratings yet

- 00543000Document172 pages00543000Dhilip AnNo ratings yet

- Bentek Remote Caller B1290 - Manual PDFDocument63 pagesBentek Remote Caller B1290 - Manual PDFBrooke EdwardsNo ratings yet

- Commercial Cooling Load CalculationDocument6 pagesCommercial Cooling Load CalculationMuhammad Kamran MalikNo ratings yet

- Desert Eagle ExcerptDocument19 pagesDesert Eagle Excerptmihailbatyra9No ratings yet

- D4SL-N / D4SL-NSK10-LK@: World's Smallest Class 6-Contact Guard Lock Safety-Door SwitchDocument28 pagesD4SL-N / D4SL-NSK10-LK@: World's Smallest Class 6-Contact Guard Lock Safety-Door SwitchMarco TàiNo ratings yet

- Rheem Commercial Value Series Package Air Conditioner: RLKL-B Standard Efficiency SeriesDocument48 pagesRheem Commercial Value Series Package Air Conditioner: RLKL-B Standard Efficiency SeriesJesus RequenaNo ratings yet