Professional Documents

Culture Documents

PMK M 12010

Uploaded by

pauloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PMK M 12010

Uploaded by

pauloCopyright:

Available Formats

PMKM 12010 TD - Rev.

1/2012- Page 1 of 4

...the people who care !

Main Features

Carrier – Main Features

The PAUS PMKM 12010 is a compact, maneuverable, powerful, highly productive and reliable machine with a

max. payload of 25 t. The PMKM is designed for medium sized mines and tunneling worksites with gallery width

of 4.9 m. The dump truck convinces by its compact design, powerful engine and high power to weight ratio for ex-

cellent performance in ramp operations. The Paus PMKM is keeping the development costs down due to high ca-

pacity and short turning radius and high speed performance.

The machine is equipped with a Caterpillar C11 ACERT water-cooled diesel engine with max. power of 287 kW

complied with COM III.

The Paus PMKM 12010 is a highly productive dump truck designed for rough and tough conditions. The drive

compartment is designed with a bi-directional seat with two steering wheels for both driving directions. Due to this

design feature the operator can drive the dump truck in both directions with max. speed; it also shortens the cycle

times.

Fast dumping – New dump box:

The new dump box is made for clean and fast dumping especially for sticky material. The used radius of the body

shape is made in a smoother way to avoid cackings in the box. The box is reinforced for LHD operation to guaran-

tee a higher lifetime and higher productivity. The dump box is also available in push wall design for applications

with low gallery height.

Safety:

The Paus PMKM 12010 is equipped with the latest safety devices like front axle, ROPS/FOPS cabin/canopy,

Posi-Stop brake system and fire suppression system.

Flexibility:

The Paus PMKM 12010 is also available with a quick change frame for different cassettes to use this machine in

a flexible way for different kind of application. Due to this device the fleet investment costs will be much lower.

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

PMKM 12010 TD - Rev. 1/2012- Page 2 of 4

...the people who care !

Technical Data

DUMP BOX LIGHTING

Rear dump box made of Hardox 400 wear plate, Four working lights at the front and two at the rear,

reinforced, Automatically opening tailgate during 1 working light, yellow flashlight, lighting in the en-

tipping process gine compartment for maintenance work. All light-

Dump box volume: ings are in LED design.

Level: 12.5 m³ TRACTION DRIVE

SAE Heaped: 11.0 m³ Hydrodynamic “full power shift”

Payload: 25,000 kg 4 gears forward/reverse, all-wheel drive 4 x 4

Discharging time: 18 sec Single stage converter with lock-up (C8000) and

Dump box support for repair works automatic supervision, electrically operated

WEIGHTS Automatic lockup APC 120

Empty weight 25,500 kg

DRIVING PERFORMANCES

Payload 25,000 kg st

1 gear 5 km/h

Total weight 50,500 kg nd

2 gear 9 km/h

Permissible axle load front: 20,500 kg rd

3 gear 16 km/h

rear: 30,000 kg th

4 gear 25 km/h

CHASSIS

AXLES

Articulated chassis with oscillating axle +/- 10°

Planetary rigid axles with oil-immersed multiple

Front axle hydro-pneumatically suspended

disc brakes (Posi-Stop),Type: Kessler D91

Central lubrication bar for all inaccessible lubrica-

tion points TIRES

18.00 R25, Mining tires

DIESEL-ENGINE BRAKES

Caterpillar diesel engine, type C11, water-cooled Service brakes are designed as spring ap-

Power rating @ 2,100 RPM 287 kW/390 PS plied/hydraulically released, liquid cooled multiple-

Temperature-controlled cooling system disc brakes, system Posi-Stop

ENGINE SUPERVISION SYSTEM

Parking brake/auxiliary brake effective on the liq-

Engine supervision system with acoustic and opti-

uid cooled multiple-disc brakes of the service

cal indication in case of malfunctions

brake, Posi-Stop-system

(temperature and oil indication analogous)

EXHAUST SYSTEM Hand pump to release the brake for haul drive

Catalytic purifier with spiral silencer STEERING

AIR INLET SYSTEM Hydraulic articulated steering with two double act-

Dry-air filter Caterpillar incl. safety cartridge and ing hydraulic cylinders. Hydraulic steering by

cyclone steering wheel, steering obitrol, emergency steer-

ing

FUEL SYSTEM

Fuel tank capacity 400 ltrs Steering angle ±42°

Fuel pre-filter with fine filter and water separator DRIVER’S COMPARTMENT

HYDRAULIC SYSTEM Driver’s canopy acc. to ROPS/FOPS, entrance at

Hydraulic tank capacity 300 ltrs the side, secured by half door, handrail for access

Return filter mash size 10 µ Driver’s seat turntable by 180°, with safety belt

JIC 37° fittings Comfortable driver’s seat with 3P safety belt, hy-

ELECTRIC SYSTEM draulically damped, adjustable

Operating voltage 24 V

Open door contact: parking brake activated, no

Alternator 28 V 80 A

function for steering, working hydraulics and gear

Batteries 2 x 12 V 180 Ah

shifting

Electric system, switch box and cable insertion ACCESSORIES

protected against humidity Hand-fire extinguisher, Ansul Redline

Cable in mining approved design Manual lubrication bar

Acoustic back-up alarm 2 x emergency stop (articulation area)

Chock holders, mounted on drivers cabin side

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

PMKM 12010 - Rev. 1/2012- Seite 3 von 4

...the people who care !

Variants, Options and Accessories

DRIVER’S COMPARTMENT

Closed cabin with sliding windows

Single-direction compartment

Air-conditioning

CAMERA SYSTEM

Camera system consists of a camera installed at

the rear of the machine and two displays in the

compartment

FIRE SUPPRESSION SYSTEM

Fire Suppression System, full automatic

Fire Suppression System, semi-automatic

LUBRICATION SYSTEM

Central lubrication system, full automatic

TAIL GATE

Automatic open tail gate

TYRES

Spare wheel 18.00 R 25

HYDRAULIC QUICK CHANGE FRAME

Hydraulic changeable frame for different cassettes

mounted on the rear chassis of the basic vehicle

CASSETTES “RE-MIXER”

Changeable cassette mounted on a stabil frame

Hydraulically driven by the diesel engine

Loading from the top, discharging from the rear

Manual adjustable supports

Volume: 7m³

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

PMKM 12010 - Rev. 1/2012- Seite 4 von 4

...the people who care !

Dimensions

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

You might also like

- Nissan Navara Electrical DiagramsDocument109 pagesNissan Navara Electrical DiagramsCreative0112 (Creative0112)100% (2)

- 8654002-Scania 4 Series Electronic Diesel Control Edc ManualDocument89 pages8654002-Scania 4 Series Electronic Diesel Control Edc ManualJorgeBarreiras81% (58)

- Instruction Manual Charmec MF 605 DADocument910 pagesInstruction Manual Charmec MF 605 DAxiping ding100% (2)

- MP4500 6x4 Cursor 13Document4 pagesMP4500 6x4 Cursor 13brayandparavicinoNo ratings yet

- Cat TH83Document4 pagesCat TH83Richard TorresNo ratings yet

- WWW - Incar.tw-1989 Ford F250 Diesel Repair Manual PDFDocument5 pagesWWW - Incar.tw-1989 Ford F250 Diesel Repair Manual PDFkenneth0% (3)

- SEM636D T2 Parts Manual (国二零部件图册)Document166 pagesSEM636D T2 Parts Manual (国二零部件图册)Dhika Laudy100% (1)

- PMK T 10010Document4 pagesPMK T 10010Andrea ZagastizabalNo ratings yet

- Type PMK-M 12010 Drawing No.: 367699 TD No.: 12159: Projekt Nr. XXXXXXDocument3 pagesType PMK-M 12010 Drawing No.: 367699 TD No.: 12159: Projekt Nr. XXXXXXIbeth Valentina Abal MendozaNo ratings yet

- Paus-853-Tsl MantenimientoDocument8 pagesPaus-853-Tsl MantenimientoYoel Gabriel QuispeNo ratings yet

- pmk-m-8010 PAUSDocument4 pagespmk-m-8010 PAUSRAUL PEREZ NEGREIROSNo ratings yet

- PMK T 8010Document4 pagesPMK T 8010pauloNo ratings yet

- Elevacion Camion PausDocument6 pagesElevacion Camion PausMiguel FarahNo ratings yet

- 853 s8 ScaleDocument5 pages853 s8 ScaleMauro GalgoNo ratings yet

- 1253 s10 ScalerDocument5 pages1253 s10 ScalerpauloNo ratings yet

- Technical InformationDocument7 pagesTechnical InformationsecretariotecNo ratings yet

- 11. Самоходная Машина Scamec 2000SDocument7 pages11. Самоходная Машина Scamec 2000SHukiro ItachiNo ratings yet

- Utimec MF 328 Per 100063292Document6 pagesUtimec MF 328 Per 100063292RESEMIN SANo ratings yet

- Manual NormetDocument507 pagesManual Normetcarlos arturo coral peñaNo ratings yet

- Charmec MF 605 DA 100038660Document7 pagesCharmec MF 605 DA 100038660Diego GonzálezNo ratings yet

- HarvestersDocument132 pagesHarvestersLeTraitimbenletkNo ratings yet

- Material Handler - F-Series: Preliminary BrochureDocument12 pagesMaterial Handler - F-Series: Preliminary BrochureVent system СервисNo ratings yet

- 1378 225FHP TeleLogger - English (Web) PDFDocument2 pages1378 225FHP TeleLogger - English (Web) PDFmarceloNo ratings yet

- BH 50M PDFDocument4 pagesBH 50M PDFAnbarasanNo ratings yet

- Gradall G6-42PDocument2 pagesGradall G6-42Phaiccdk6No ratings yet

- Charmec SF 405 DV 100056996Document10 pagesCharmec SF 405 DV 100056996Roger Rojas PrimoNo ratings yet

- LIEBHERR R934-Tier4Final-US-PI-2021-01Document16 pagesLIEBHERR R934-Tier4Final-US-PI-2021-01ganendra santantikaNo ratings yet

- Charmec SF 605 DA (V) : Technical Data SheetDocument10 pagesCharmec SF 605 DA (V) : Technical Data SheetJohn VergaraNo ratings yet

- Instruction ManualDocument585 pagesInstruction Manualthiagoluz2015No ratings yet

- Specifications: G Andler ElehandlerDocument4 pagesSpecifications: G Andler ElehandlerDietz LaNo ratings yet

- Manual Martillo Atlas Copco 2200 7000 3390500505Document3 pagesManual Martillo Atlas Copco 2200 7000 3390500505Cesar QuintanillaNo ratings yet

- Tractors For Specialists: - CompactDocument4 pagesTractors For Specialists: - CompactB de JongNo ratings yet

- Tatra Military Vehicles - enDocument68 pagesTatra Military Vehicles - enTonyo Lina100% (1)

- P460ca 6x6 FinalDocument2 pagesP460ca 6x6 FinalYudha LegendarisNo ratings yet

- Magni HTH 1010 enDocument2 pagesMagni HTH 1010 enRyo ArdhiNo ratings yet

- 426F2 Backhoe LoaderDocument4 pages426F2 Backhoe LoaderArvind Harry100% (1)

- S850&T870 Brochure ENDocument6 pagesS850&T870 Brochure ENMacrotek ArequipaNo ratings yet

- CorinsaDocument6 pagesCorinsaozanozerenNo ratings yet

- Technical Description PR 756 G8 LitronicDocument10 pagesTechnical Description PR 756 G8 LitronicHanafi AhmadNo ratings yet

- Franna UC 15Document2 pagesFranna UC 15Osha Prima100% (1)

- Sandvik Lh115L Low Profile Loader: Technical SpecificationDocument6 pagesSandvik Lh115L Low Profile Loader: Technical SpecificationDiego PauccaNo ratings yet

- Technical Data: TimberjackDocument4 pagesTechnical Data: TimberjackOgnjen KovacevicNo ratings yet

- NEUS Dump 1601 eDocument1 pageNEUS Dump 1601 eJamal HabbasNo ratings yet

- XCMG All Terrain Cranes SpecDocument36 pagesXCMG All Terrain Cranes Specnicolae mureaNo ratings yet

- Specifications: Ackhoe OaderDocument4 pagesSpecifications: Ackhoe OaderJUNIOR OLIVO0% (1)

- Mining Excavator: Operating Weight With Backhoe Attachment: Shovel Attachment: Engine: Bucket Capacity: Shovel CapacityDocument10 pagesMining Excavator: Operating Weight With Backhoe Attachment: Shovel Attachment: Engine: Bucket Capacity: Shovel CapacityWita ManaluNo ratings yet

- 734 4Document10 pages734 4shekhar100% (1)

- w130c Spec PDFDocument14 pagesw130c Spec PDFSebastian SaltosNo ratings yet

- BR350 English Jan 2011Document6 pagesBR350 English Jan 2011ddionneNo ratings yet

- M726G 1.4 CV723 EN 1020 Hi ResDocument2 pagesM726G 1.4 CV723 EN 1020 Hi ReskleephNo ratings yet

- Tatra Force t815Document2 pagesTatra Force t815Murugesh Balaguru100% (1)

- HD5395TS: Technical SpecificationDocument10 pagesHD5395TS: Technical Specificationdaniel_jorge_10No ratings yet

- Specifications: G AndlerDocument4 pagesSpecifications: G AndlerDietz LaNo ratings yet

- AA PROD 12749 01 DD 110 Sales Sheet 2021 - v4 WebDocument2 pagesAA PROD 12749 01 DD 110 Sales Sheet 2021 - v4 WeblrausseoNo ratings yet

- Technical Description R 954 C SME 1Document12 pagesTechnical Description R 954 C SME 1equipment9278No ratings yet

- Excavator Liebherr R920Document16 pagesExcavator Liebherr R920ganendra santantikaNo ratings yet

- CX140E Spec SheetDocument6 pagesCX140E Spec SheetthomasNo ratings yet

- 2390 - 9 Tonne Front Tip - Shuttle - UKDocument2 pages2390 - 9 Tonne Front Tip - Shuttle - UKZHS MixerNo ratings yet

- R 920 Compact: Product Information Crawler ExcavatorDocument16 pagesR 920 Compact: Product Information Crawler Excavatorpebi liveNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- DIA Hora Tajo Placa #Peso TMHDocument15 pagesDIA Hora Tajo Placa #Peso TMHpauloNo ratings yet

- DG ConverterDIP DIPDirectionDocument1 pageDG ConverterDIP DIPDirectionpauloNo ratings yet

- 1253 s10 ScalerDocument5 pages1253 s10 ScalerpauloNo ratings yet

- Made in Abyss Tomo - 3Document157 pagesMade in Abyss Tomo - 3paulo100% (2)

- T1A-Trailer-Axle GuideDocument14 pagesT1A-Trailer-Axle Guidenathaniel perryNo ratings yet

- History of Indian Automobile IndustryDocument17 pagesHistory of Indian Automobile IndustryHanan AhammedNo ratings yet

- Ranger.2012. (08 2011-)Document120 pagesRanger.2012. (08 2011-)Brent Rutherford100% (1)

- XL FW10066SG - en USDocument92 pagesXL FW10066SG - en USBrijith ShenoiNo ratings yet

- Wheel Loader: Choose Shantui Choose The FutureDocument4 pagesWheel Loader: Choose Shantui Choose The FutureRS Rajib sarkerNo ratings yet

- Micro TransportationDocument6 pagesMicro TransportationJim100% (3)

- Power Steering SpecDocument2 pagesPower Steering SpecCarlos RibeiroNo ratings yet

- POWER SEATS - Mitsubishi Outlander Sport ES 2011 - SYSTEM WIRING DIAGRAMSDocument2 pagesPOWER SEATS - Mitsubishi Outlander Sport ES 2011 - SYSTEM WIRING DIAGRAMSRavi VarakalaNo ratings yet

- TMR Information Brochure PDFDocument14 pagesTMR Information Brochure PDFSaurabh NainNo ratings yet

- Palio Siena Strada 10 16v Fire-13 16v FireDocument2 pagesPalio Siena Strada 10 16v Fire-13 16v FireCristian HidalgoNo ratings yet

- Greater Working Efficiency and Versatility For Railway Construction and MaintenanceDocument2 pagesGreater Working Efficiency and Versatility For Railway Construction and MaintenanceBubbaNo ratings yet

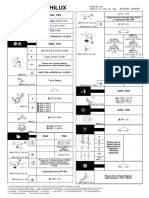

- Hilux: GGN, TGNDocument26 pagesHilux: GGN, TGNbelkaidaNo ratings yet

- Hurst Shifters CatalogDocument38 pagesHurst Shifters CatalogibagciNo ratings yet

- AC Touring Car Legends v1.0Document31 pagesAC Touring Car Legends v1.0Agustin IzquierdoNo ratings yet

- 2014 Stellar Catalog V5 PDFDocument646 pages2014 Stellar Catalog V5 PDFCarlos JR CasanovaNo ratings yet

- XRM125 18kpylp1 1Document151 pagesXRM125 18kpylp1 1Jonard SayodNo ratings yet

- CCR PowerTrain PRINTDocument2 pagesCCR PowerTrain PRINTJean Claude EidNo ratings yet

- Thunderbird X 350 Spare PartsDocument16 pagesThunderbird X 350 Spare PartsArihant BothraNo ratings yet

- Volvo Accessories PDFDocument16 pagesVolvo Accessories PDFDougNewNo ratings yet

- ZF 4HP20 (LMO) : 4 SPEED FWD (Electronic Control) Code: 1019 000 XXXDocument5 pagesZF 4HP20 (LMO) : 4 SPEED FWD (Electronic Control) Code: 1019 000 XXXМихаил КаминскийNo ratings yet

- Airbag For Side/Rear Side Collision 1. General: Body Electrical - Srs Airbag System BE-86Document2 pagesAirbag For Side/Rear Side Collision 1. General: Body Electrical - Srs Airbag System BE-86Maxi SardiNo ratings yet

- Hyundai 25 30 33LF 7Document6 pagesHyundai 25 30 33LF 7satcomerNo ratings yet

- Bigy 150MX - 2019Document25 pagesBigy 150MX - 2019Kamila KNo ratings yet

- Spoiler (Car)Document6 pagesSpoiler (Car)phutd09No ratings yet

- Ssangyong Vehicle CoverageDocument6 pagesSsangyong Vehicle CoverageEsquisofNo ratings yet

- Manitou 200 AtjDocument2 pagesManitou 200 AtjNeil Desai100% (1)