Professional Documents

Culture Documents

pmk-m-8010 PAUS

Uploaded by

RAUL PEREZ NEGREIROSOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pmk-m-8010 PAUS

Uploaded by

RAUL PEREZ NEGREIROSCopyright:

Available Formats

PMK-M 8010 –Rev.

0/2016- Page 1 of 4

...the people who care !

Main Features

Carrier – Main Features

PAUS PMK-M 8010 Dump Trucks is designed for the mining and tunneling sector with a max payload

of 17 tons and a skip capacity of 7 m³ (heaped), the PMK-M 8010 is the smallest dumper of the PMK-M

series.

Due to its small width of merely 2 m and its height of 2.4 m, the PMK-M 8010 can excellently be used

on roadways with two-way traffic and with low gallery heights.

Special feature of the series PMK-M is driver’s seat that can be turned by 180° and the two operating

panels. During reverse movement, the driver is looking through the empty skip. After filling of the skip,

the driver’s seat is turned by 180° for forward movement. This offers optimum view as well as great

seating and operating comfort to the driver.

Great maneuverability is achieved by means of the articulated steering (±42°) that merely a track width

of 3.8 m is required for a 90° corner. The oscillating front axle (±10°) safely compensates unevenness

of the ground and ensures that all wheels of the all-wheel drive have ground contact. Shocks in end po-

sition are absorbed by plunger cylinder so operator and vehicle are prevented from injury / damage.

The PMK-M 8010 is driven by a powerful, water-cooled, turbo-charged Caterpillar diesel engine with

168 kW. On level track, you can achieve speeds up to 25 km/h in 4th gear stage ensuring - together

with low tipping times - high productivity.

Easy maintenance is a special feature of the PMK-M. Filters and other maintenance points are easily

accessible and mounted in well protected position. Central lubrication bars facilitate greasing. Mainte-

nance flaps ensure comfortable accessibility of the hydraulic and electric system.

Besides the exhaust-gas treatment systems, the driver’s cabin acc. to ROPS/FOPS the change system

for several attachments like concrete mixer, platform, scissor platform, are available as options, too.

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

PMK-M 8010 –Rev. 0/2016- Page 2 of 4

...the people who care !

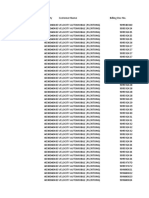

Technical Data

TRANSPORTATION CAPACITY DRIVING PERFORMANCES, LOADED

Payload 17,000 kg 1st gear 4.0 km/h

Skip capacity, heaped 7.0 m³ 2nd gear 9.0 km/h

str. 6.5 m³ 3rd gear 15.0 km/h

th

Lifting time 18.0 sec 4 gear 25.0 km/h

Lowering time 9.0 sec TRACTION, LOADED, MAX

SKIP 1st gear 110 kN

Rear-tipping skip with two double-acting lifting 2nd gear 50 kN

rd

cylinders 3 gear 30 kN

Operating pressure 180 bar 4th gear 15 kN

WEIGHTS TANK CAPACITIES

Operating weight 15,000 kg Fuel 200 l

Total weight 32,000 kg Hydraulic oil 150 l

Front axle load, empty 10,000 kg All hydraulic fittings are made in JIC 37°

Rear axle load, empty 5,000 kg STEERING

Front axle load, loaded 13,000 kg Hydraulic articulated steering, two double-

Rear axle load, loaded 19,000 kg acting steering cylinder; steering wheel (dou-

CHASSIS FRAME ble),steering angle ±42°

Welded frame with articulated steering. ELECTRIC SYSTEM

DIESEL ENGINE Battery main switch

Model C7.1 Acert Operating voltage 24 V

water-cooled diesel engine Generator 28 V 80 A

Power 168kW at 2,200 rpm, Tier3 Battery 2 x 12 V 152 Ah

Automatic engine monitoring.

Dry air filter LED LIGHT PACKAGE

Two working lights each at the front and rear,

DRIVE UNIT

1 working light, yellow flashlight, all lights in

Dana Spicer hydrodynamic drive unit, full

LED design

power shift;

DRIVER’S STAND

4-speed-transmission forward / reverse;

Open canopy acc. to ROPS/FOPS directives;

all-wheel drive.

Driver’s seat rotating by 180° for both driving

AXLES directions, safety belt;

Kessler planetary rigid axles, oscillating front clearly arranged supervisory devices and eas-

axle (±10°) and rear axle firmly mounted to ily accessible operating elements for both

the chassis frame. driving directions.

WHEELS

ACCESSORIES

Mining tires 14.00 R 24,

Hand fire extinguisher

BRAKES Reversing signal.

Service brake designed as hydraulic two- Documentation.

circuit pump-storage brake system, with oil-

immersed multiple-disc brakes, system “Posi- DOCUMENTATION

Stop” brakes (negative brakes). Operational instructions

Spare parts list

Parking brake / auxiliary brake acting on the

oil-immersed multiple-disc brakes of the ser-

vice brake.

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

PMKM 8010 Rev. 0/2016- Seite 3 von 4

...the people who care !

Variants, Options and Accessories

DIESEL ENGINE

Deutz TCD2013- Tier3-173KW

CAT C7.1- Tier4-168KW

DUMP BOX

Automatically opening tailgate during tipping

pro-cess

DRIVER’S COMPARTMENT

Closed cabin

Air-conditioning

FIRE SUPPRESSION SYSTEM

Fire Suppression System, full-automatic

LUBRICATION SYSTEM

Central lubrication system, full automatic

TYRES

Spare wheel 14.00 R 24

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

PMKM 8010 Rev. 0/2016- Seite 4 von 4

...the people who care !

Dimensions

According technical drawing 12741-1

Hermann Paus Maschinenfabrik GmbH, Siemensstr. 1 – 9, 48488 Emsbüren, Germany

Tel.: +49-5903-707-0, Fax.: -33, email: info@paus.de, internet: www.paus.de

You might also like

- Elektronikon I and II ManualDocument44 pagesElektronikon I and II Manualaircenter100% (18)

- Atlas Copco GA 15 To GA 30 Part ListDocument46 pagesAtlas Copco GA 15 To GA 30 Part ListMohamad Bahrodin78% (50)

- E90 Code List PDFDocument3 pagesE90 Code List PDFCiprian100% (1)

- Instruction Manual Charmec MF 605 DADocument910 pagesInstruction Manual Charmec MF 605 DAxiping ding100% (2)

- Howo Tipper Truck 6x4 371HP PDFDocument2 pagesHowo Tipper Truck 6x4 371HP PDFIbrahim Fadhl KalajengkingNo ratings yet

- Atlas Copco Ga7 Service ManualDocument36 pagesAtlas Copco Ga7 Service ManualRamon Sanhueza75% (4)

- Manual de Usuario Leon Circuitos - Seat Super CopaDocument92 pagesManual de Usuario Leon Circuitos - Seat Super CopaSamuel ChauchefoinNo ratings yet

- CATERPILLAR Wheel Loader SpecsDocument6 pagesCATERPILLAR Wheel Loader SpecsgzapasNo ratings yet

- MP4500 6x4 Cursor 13Document4 pagesMP4500 6x4 Cursor 13brayandparavicinoNo ratings yet

- Cat TH83Document4 pagesCat TH83Richard TorresNo ratings yet

- Atlas Copco ZT22 Manual 1Document51 pagesAtlas Copco ZT22 Manual 1juaroz77% (13)

- Atlas Copco ZT22 Manual 1Document51 pagesAtlas Copco ZT22 Manual 1juaroz77% (13)

- Atlas Copco ZT22 Manual 1Document51 pagesAtlas Copco ZT22 Manual 1juaroz77% (13)

- Atlas Copco Ewd 330 Manual PDFDocument6 pagesAtlas Copco Ewd 330 Manual PDFMahammadhusain100% (3)

- Fuse Box Diagram Land Rover Freelander 2 - LR2 (2006-2014)Document23 pagesFuse Box Diagram Land Rover Freelander 2 - LR2 (2006-2014)Ramsay AbrahamNo ratings yet

- PMK T 8010Document4 pagesPMK T 8010pauloNo ratings yet

- Project and Technical Specifications for PMK-M 12010 Dump TruckDocument3 pagesProject and Technical Specifications for PMK-M 12010 Dump TruckIbeth Valentina Abal MendozaNo ratings yet

- PMK T 10010Document4 pagesPMK T 10010Andrea ZagastizabalNo ratings yet

- PMK M 12010Document4 pagesPMK M 12010pauloNo ratings yet

- Manual Martillo Atlas Copco 2200 7000 3390500505Document3 pagesManual Martillo Atlas Copco 2200 7000 3390500505Cesar QuintanillaNo ratings yet

- Manual NormetDocument507 pagesManual Normetcarlos arturo coral peñaNo ratings yet

- Paus-853-Tsl MantenimientoDocument8 pagesPaus-853-Tsl MantenimientoYoel Gabriel QuispeNo ratings yet

- Technical InformationDocument7 pagesTechnical InformationsecretariotecNo ratings yet

- 11. Самоходная Машина Scamec 2000SDocument7 pages11. Самоходная Машина Scamec 2000SHukiro ItachiNo ratings yet

- Elevacion Camion PausDocument6 pagesElevacion Camion PausMiguel FarahNo ratings yet

- Specifications 20 TON DTDocument3 pagesSpecifications 20 TON DTCesar QuintanillaNo ratings yet

- Charmec MF 605 DA 100038660Document7 pagesCharmec MF 605 DA 100038660Diego GonzálezNo ratings yet

- HD5395TS: Technical SpecificationDocument10 pagesHD5395TS: Technical Specificationdaniel_jorge_10No ratings yet

- 853 s8 ScaleDocument5 pages853 s8 ScaleMauro GalgoNo ratings yet

- Utimec MF 328 Per 100063292Document6 pagesUtimec MF 328 Per 100063292RESEMIN SANo ratings yet

- Technical Data Sheet NORMET Variomec MF 050 MDocument7 pagesTechnical Data Sheet NORMET Variomec MF 050 MmariaandreagfNo ratings yet

- Charmec SF 605 DA (V) : Technical Data SheetDocument10 pagesCharmec SF 605 DA (V) : Technical Data SheetJohn VergaraNo ratings yet

- Sandvik Lh518B: Battery Electric LoaderDocument8 pagesSandvik Lh518B: Battery Electric LoaderHukiro ItachiNo ratings yet

- Instruction ManualDocument585 pagesInstruction Manualthiagoluz2015No ratings yet

- Sandvik Lh115L Low Profile Loader: Technical SpecificationDocument6 pagesSandvik Lh115L Low Profile Loader: Technical SpecificationDiego PauccaNo ratings yet

- Specifications: G AndlerDocument4 pagesSpecifications: G AndlerDietz LaNo ratings yet

- NEUS Dump 1601 eDocument1 pageNEUS Dump 1601 eJamal HabbasNo ratings yet

- WJ-1.5G UG Production Loader KamachDocument5 pagesWJ-1.5G UG Production Loader KamachMiguel MaturinoNo ratings yet

- Utilift SF 330 100043449Document9 pagesUtilift SF 330 100043449RESEMIN SANo ratings yet

- Underground Mining Charger Technical SpecificationsDocument10 pagesUnderground Mining Charger Technical SpecificationsRoger Rojas PrimoNo ratings yet

- Technical Specification Sandvik TH320-03Document6 pagesTechnical Specification Sandvik TH320-03abadNo ratings yet

- 426F2 Backhoe LoaderDocument4 pages426F2 Backhoe LoaderArvind Harry100% (1)

- th315 Specification Sheet EnglishDocument8 pagesth315 Specification Sheet EnglishEmrah MertyürekNo ratings yet

- 1253 s10 ScalerDocument5 pages1253 s10 ScalerpauloNo ratings yet

- Shantui SG17-B6 Motor Grader enDocument2 pagesShantui SG17-B6 Motor Grader enFranco SartoriNo ratings yet

- Komatsu GD705A-4 Motor Grader SpecsDocument19 pagesKomatsu GD705A-4 Motor Grader SpecsPro Jepr0% (1)

- Charmec LC 605 D (V) : Technical Data Sheet 100064402 23.06.2014 AustraliaDocument8 pagesCharmec LC 605 D (V) : Technical Data Sheet 100064402 23.06.2014 Australiajuan eduardo rodriguezNo ratings yet

- Magni HTH 1010 enDocument2 pagesMagni HTH 1010 enRyo ArdhiNo ratings yet

- Cukurova - Backhoe Loader 880 (NEW)Document2 pagesCukurova - Backhoe Loader 880 (NEW)Felipe Douglas da Silva100% (1)

- Hydrema MX20 Rail BrochureDocument2 pagesHydrema MX20 Rail BrochuredkNo ratings yet

- Engine Hydraulic System: TipshiftDocument2 pagesEngine Hydraulic System: TipshifttwrwtrtrNo ratings yet

- C10436823Document4 pagesC10436823jkkjmb6No ratings yet

- LH410Document9 pagesLH410Anonymous XTsbOs4oUWNo ratings yet

- Gradall G6-42PDocument2 pagesGradall G6-42Phaiccdk6No ratings yet

- Specifications: KID Teer OaderDocument4 pagesSpecifications: KID Teer OaderAbdullo BaxritdinovNo ratings yet

- Utimec LF 700 Agitator: Technical Data SheetDocument7 pagesUtimec LF 700 Agitator: Technical Data SheetBBBBBBNo ratings yet

- Specifications: G Andler ElehandlerDocument4 pagesSpecifications: G Andler ElehandlerDietz LaNo ratings yet

- LGMRT Uk-20 Tech Specs 202101Document4 pagesLGMRT Uk-20 Tech Specs 202101Ricardo Vega CoronelNo ratings yet

- Specifications: Ackhoe OaderDocument4 pagesSpecifications: Ackhoe OaderJUNIOR OLIVO0% (1)

- ARBOS 2000 3000 Technical FeaturesDocument6 pagesARBOS 2000 3000 Technical FeaturesCatalin Adrian PintilieNo ratings yet

- Cat 272CDocument4 pagesCat 272CForomaquinasNo ratings yet

- BR350 English Jan 2011Document6 pagesBR350 English Jan 2011ddionneNo ratings yet

- Wheel Loader 835H-EDocument2 pagesWheel Loader 835H-EHerry ArsevenNo ratings yet

- 299D2 XHP: SpecificationsDocument4 pages299D2 XHP: SpecificationsYoel Delgado LopezNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Atlas Copco Xrvs 476 Manual PDFDocument104 pagesAtlas Copco Xrvs 476 Manual PDFpowermanagerNo ratings yet

- Service Manual: Spicer Tandem Drive AxlesDocument114 pagesService Manual: Spicer Tandem Drive AxlesIvan AvalosNo ratings yet

- Service Manual: Spicer Single Drive AxlesDocument54 pagesService Manual: Spicer Single Drive AxlesRAUL PEREZ NEGREIROSNo ratings yet

- B7100 Ops and Mant ManualDocument102 pagesB7100 Ops and Mant ManualRAUL PEREZ NEGREIROSNo ratings yet

- Truc Vit Dau R90-160kw PDFDocument12 pagesTruc Vit Dau R90-160kw PDFTuấn NguyễnNo ratings yet

- ACXDocument58 pagesACXEzequiel Juarez BenítezNo ratings yet

- Atlas Copco Xrvs 476 Manual PDFDocument104 pagesAtlas Copco Xrvs 476 Manual PDFpowermanagerNo ratings yet

- Nr-3h-h10lb - (Caraveli 2014) Ensamble GeneralDocument1 pageNr-3h-h10lb - (Caraveli 2014) Ensamble GeneralRAUL PEREZ NEGREIROSNo ratings yet

- Atlas Copco ZT 55 ManualDocument90 pagesAtlas Copco ZT 55 ManualChristian H OrtizNo ratings yet

- FD 7 120 Modelos de Secadores Atlas Copco PDFDocument20 pagesFD 7 120 Modelos de Secadores Atlas Copco PDFelaineurbNo ratings yet

- 2935 0724 30 - tcm30-1628027Document54 pages2935 0724 30 - tcm30-1628027Hossam Mohi EldinNo ratings yet

- Zipline Conveyor: / Superior IndustriesDocument4 pagesZipline Conveyor: / Superior IndustriesRAUL PEREZ NEGREIROSNo ratings yet

- Bombas Galigher Serie VRADocument7 pagesBombas Galigher Serie VRARAUL PEREZ NEGREIROSNo ratings yet

- Weir Minerals Catálogo GeneralDocument16 pagesWeir Minerals Catálogo GeneralRAUL PEREZ NEGREIROSNo ratings yet

- Atlas Copco Electronic Condensate Drains: EWD SeriesDocument1 pageAtlas Copco Electronic Condensate Drains: EWD SeriestariqNo ratings yet

- Stingray Mobile Shiploader: Self-Contained, Highly Portable Machine For Fast Vessel LoadingDocument2 pagesStingray Mobile Shiploader: Self-Contained, Highly Portable Machine For Fast Vessel LoadingRAUL PEREZ NEGREIROSNo ratings yet

- OEE Calculator - Keith Mobley - LCEDocument1 pageOEE Calculator - Keith Mobley - LCERAUL PEREZ NEGREIROSNo ratings yet

- RazerTail Truck UnloaderDocument4 pagesRazerTail Truck UnloaderRAUL PEREZ NEGREIROSNo ratings yet

- Passport Mobile ShiploaderDocument6 pagesPassport Mobile ShiploaderRAUL PEREZ NEGREIROSNo ratings yet

- RUBBER PRODUCTS APPLICATIONS AND USESDocument12 pagesRUBBER PRODUCTS APPLICATIONS AND USESjhon jairo arango100% (1)

- Razerlink Conveyor: Multi-Functional Machine Customize Maintains High Quality Material Limits DowntimeDocument2 pagesRazerlink Conveyor: Multi-Functional Machine Customize Maintains High Quality Material Limits DowntimeRAUL PEREZ NEGREIROSNo ratings yet

- Geotrek ConveyorDocument2 pagesGeotrek ConveyorRAUL PEREZ NEGREIROSNo ratings yet

- Overland ConveyorDocument4 pagesOverland ConveyorRAUL PEREZ NEGREIROSNo ratings yet

- Afs110sp (13K92H01)Document134 pagesAfs110sp (13K92H01)José LuisNo ratings yet

- Automotive Business Review April 2009Document88 pagesAutomotive Business Review April 2009MadhouseEnterprises100% (2)

- 2010-2011 Mopar Accessories September 2010 DatabookDocument432 pages2010-2011 Mopar Accessories September 2010 DatabookRamonNo ratings yet

- VW (Cod Eroare Diagnostic) - 982691461210 - 20220923143809Document2 pagesVW (Cod Eroare Diagnostic) - 982691461210 - 20220923143809Marius ButaciuNo ratings yet

- Fuse Box Diagram Toyota Corolla Spacio 1G and Relay With Assignment and LocationDocument1 pageFuse Box Diagram Toyota Corolla Spacio 1G and Relay With Assignment and LocationKhyle PeltierNo ratings yet

- Tesla Case StudyDocument17 pagesTesla Case StudykaranNo ratings yet

- SF303 PDFDocument342 pagesSF303 PDFcarrod1968No ratings yet

- Stock Car Weight Reduction Track Day ModsDocument4 pagesStock Car Weight Reduction Track Day ModsJorge Florian OrtizNo ratings yet

- Toyota 8FBDocument6 pagesToyota 8FBtomy112No ratings yet

- 50 Hilux (Cont. Next Page) : Power Source Combination Meter (From Jun. 2011 Production)Document4 pages50 Hilux (Cont. Next Page) : Power Source Combination Meter (From Jun. 2011 Production)Ichsan KurniawanNo ratings yet

- k00589850100 1ac3fd4Document25 pagesk00589850100 1ac3fd4Wąski3DNo ratings yet

- 21 6 23Document16 pages21 6 23Noor AmeyraNo ratings yet

- Belarus 2022/2022В 2022.3/2022В.3: Catalogue Of Parts And Assembly UnitsDocument257 pagesBelarus 2022/2022В 2022.3/2022В.3: Catalogue Of Parts And Assembly UnitsPaval PetrutNo ratings yet

- Renault, Mazda and Chevrolet models guideDocument281 pagesRenault, Mazda and Chevrolet models guideAlejandro Arr0% (1)

- Stall Test en PPSDocument18 pagesStall Test en PPSOscar Matus CarrilloNo ratings yet

- Straightforward EfficiencyDocument19 pagesStraightforward EfficiencyJukiuzNo ratings yet

- VI.a) List of The Spare Parts & Accessorries For Toyota Hilux, 4x4 Turbo, (TH) KUN-25R, For The Year 2019-20Document16 pagesVI.a) List of The Spare Parts & Accessorries For Toyota Hilux, 4x4 Turbo, (TH) KUN-25R, For The Year 2019-20tobi oduniyiNo ratings yet

- Scissors Lift Checklist GS-3384RTDocument2 pagesScissors Lift Checklist GS-3384RTChris OpubaNo ratings yet

- Roland Berger Truck Industry 2020 20110215dfbfhDocument44 pagesRoland Berger Truck Industry 2020 20110215dfbfhShashikant MishraNo ratings yet

- Alfa Romeo GT - Bertone ManualDocument159 pagesAlfa Romeo GT - Bertone ManualOgnjenLazarevic100% (2)

- Caravan World - Trakkaway 770 Legends WinnerDocument4 pagesCaravan World - Trakkaway 770 Legends WinnerAlex TrakkaNo ratings yet

- BL271713 MidibusDocument2 pagesBL271713 MidibusmichaeltibocheNo ratings yet

- Wiring Diagram HFM-SFI Sequential Multiport Fuel Injection - Ignition SystemDocument5 pagesWiring Diagram HFM-SFI Sequential Multiport Fuel Injection - Ignition SystemKanishka Prasade0% (1)

- MG Astor 2024 BrochureDocument43 pagesMG Astor 2024 Brochurerohitpatidar1256No ratings yet

- Catalogo Spazzole Tergi BoschDocument32 pagesCatalogo Spazzole Tergi Boschlucaravarotto03No ratings yet

- Echlin Part No RefDocument85 pagesEchlin Part No Refpilveni100% (1)

- Lectric II-C MDF Flush Ceiling Mount Screen for Large VenuesDocument1 pageLectric II-C MDF Flush Ceiling Mount Screen for Large VenuesCamilo Alejandro PalaciosNo ratings yet