Professional Documents

Culture Documents

240 PDF

240 PDF

Uploaded by

ChristianGuerreroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

240 PDF

240 PDF

Uploaded by

ChristianGuerreroCopyright:

Available Formats

contents

240 valves & fittings

econ sight glasses with BSPP threaded ends and

boro-silicate glass

with indicator

fig. 620: cast iron (Ws.no. 0.6025)

fig. 623: bronze (Ws.no. 1.1096.01)

with flap of stainless steel and

double window

with boro-silicate glass and

flanged ends to DIN PN 16

fig. 621: cast iron (Ws.no. 0.6025)

fig. 3621: stainless steel (Ws.no. 1.4436)

with soda lime glass and

flat faced flanges to DIN PN 16

fig. 633: cast iron (Ws.no. 0.6025)

fig. 634: bronze (Ws.no. 1.1096.01)

application: Of all sight glasses with flow indication, those provided with a flap are the most

simple and reliable.

They can be built-in both horizontally and vertically, with the inlet under the flap.

These sight glasses can be applied extremely well in totally filled pipes, in

particular in cooling water and lubricating oil systems.

Besides, the position of the flap gives a certain indication of the velocity (and

quantity) of the liquid.

pressure/temperature rating: fig. 620, 621and 623 : 8 * bar - 185 °C

fig. 3621 : 8 * bar - 185 °C

fig. 633 : 10 bar - 120 °C | 8 bar - 200 °C

fig. 634 : 16 bar - 120 °C | 13 bar - 200 °C

*DN ≤ 32: 10 bar

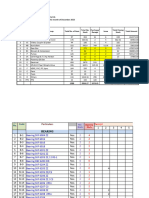

dimensions (mm): DN 15 20 25 32 40 50 65 80 100 125 150

1 3

d /2” /4” 1” 11/ 4” 1 1/2 ” 2”

fig. 620/623 L 105 105 110 120 140 160 – – – – –

fig. 633/634 L 140 140 150 165 185 185 230 240 305 310 410

fig. 621/3621 L – 135 140 150 170 170 185 210 230 – –

fig. 621/633/

634/3621 A 95 105 115 140 150 165 185 200 220 250 285

fig. 620/623 1.5 1.6 1.8 2 3.2 3.5 – – – – –

fig. 633 wt 3.4 3.9 4.1 5.5 7.2 8.1 14 17 21 35 54

(kg)

fig. 634 3.6 4.2 4.9 6.1 8.2 9.3 16 18 23 38 58

fig. 621/3621 – 3.5 4.5 5.7 6.5 8.5 11 16 20 – –

You might also like

- Filmora KeyDocument3 pagesFilmora KeyMis50% (2)

- Scoring Rubric For Speaking TestDocument2 pagesScoring Rubric For Speaking Testnur fauziyah89% (18)

- Signature AssignmentDocument11 pagesSignature AssignmentHugoNo ratings yet

- Raiseboring Drill PipesDocument16 pagesRaiseboring Drill Pipesmanuel_plfNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Science Investigatory Project: Group#3 Banana Peel As Shoe PolishDocument11 pagesScience Investigatory Project: Group#3 Banana Peel As Shoe PolishGMae Lim100% (4)

- 239 PDFDocument1 page239 PDFChristianGuerreroNo ratings yet

- Installation Components: TubingDocument31 pagesInstallation Components: TubingZahir KhiraNo ratings yet

- Features: Water WaterDocument1 pageFeatures: Water WaterajsdlkasjdklNo ratings yet

- Cim 3739 Series en - Rev 0Document20 pagesCim 3739 Series en - Rev 0BellatchaNo ratings yet

- Avk Supa Plus™ Flange Adaptor, PN 10/16 623/10: Tensile, For PE and PVC Pipes, Incl. Flange Gasket 004Document3 pagesAvk Supa Plus™ Flange Adaptor, PN 10/16 623/10: Tensile, For PE and PVC Pipes, Incl. Flange Gasket 004Ariane Joy LucasNo ratings yet

- Fig. 292 ® Gate Valve: Also Available in PN16Document2 pagesFig. 292 ® Gate Valve: Also Available in PN16TamNo ratings yet

- FT Eslabon Maestro A342Document1 pageFT Eslabon Maestro A342fernando.solarNo ratings yet

- Foam Spray Nozzle Ul ListedDocument2 pagesFoam Spray Nozzle Ul ListedAhmed ElbarbaryNo ratings yet

- Gate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesGate Cast Steel Astm A216 WCB Class 150: Pressure Temperature RatingsJavier Hinojosa Garrido LeccaNo ratings yet

- V-Cone Ficha TécnicaDocument2 pagesV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- K-823-A, SCVDocument1 pageK-823-A, SCVamir shokrNo ratings yet

- Class 125 Iron Y-StrainerDocument1 pageClass 125 Iron Y-StrainerNarendra Reddy BhumaNo ratings yet

- SKF Quiet Running Deep Groove Ball BearingsDocument4 pagesSKF Quiet Running Deep Groove Ball BearingsvietkhamNo ratings yet

- Weld Fittings.... : Stainless Steel Fittings Product CatalogDocument14 pagesWeld Fittings.... : Stainless Steel Fittings Product CatalogEliza Nightry De LargeNo ratings yet

- Wafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design DescriptionsDocument2 pagesWafer Cast Steel Check Valve150Lb/300Lb: Applicable Standards: Design Descriptionsmigaspro energiaNo ratings yet

- R/F - 150Lb Rating Light Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 150Lb Rating Light Duty 'Y'-Type Strainer: Form Number: QD/177/01NagLakshmananNo ratings yet

- Victaulic AGS Grooved End Fittings: 1.0 Product DescriptionDocument17 pagesVictaulic AGS Grooved End Fittings: 1.0 Product DescriptionDiego Francisco Ancajima CuevaNo ratings yet

- Kunkletabla Seleccion PSVDocument12 pagesKunkletabla Seleccion PSVedwinmenaNo ratings yet

- Bondstrand PDFDocument8 pagesBondstrand PDFkrisNo ratings yet

- 05263G Sample ChapterDocument1 page05263G Sample ChapterBambangIrawan48No ratings yet

- Neway Check ValvesDocument3 pagesNeway Check ValvesismaeljcoorpNo ratings yet

- ANSI B16.5 Slip-On, Raised Face Flanges - Class 150 or 300: Configuration Sheet Model Precision Tube SeriesDocument2 pagesANSI B16.5 Slip-On, Raised Face Flanges - Class 150 or 300: Configuration Sheet Model Precision Tube SeriesEdisonCorderoNo ratings yet

- 910 21 001 PDFDocument3 pages910 21 001 PDFMatt SterlingNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLDocument1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLNagLakshmananNo ratings yet

- Gate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature RatingsDocument2 pagesGate Cast Steel A216 WCB Class 150 Mod. XXXXX: Pressure Temperature Ratingsjaponesito01No ratings yet

- DW12G SSDocument1 pageDW12G SSQuyết Bạch ĐìnhNo ratings yet

- Figure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingDocument4 pagesFigure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingСергей КолесниковNo ratings yet

- 3530 3533 BrochureDocument14 pages3530 3533 Brochureganeshemmadi1987No ratings yet

- Ductile Iron Double Regulating Valve With Regulating and Isolating Functions (FODRV) - PN16Document8 pagesDuctile Iron Double Regulating Valve With Regulating and Isolating Functions (FODRV) - PN16Dan FielderNo ratings yet

- FT Accesorios PVC SCH40,80 - CantexDocument1 pageFT Accesorios PVC SCH40,80 - CantexLogística ArequipaNo ratings yet

- Avk Air & Vacuum Valve, PN 16 701/30: For Water, Ductile Iron, DN 100 and 200-300 020Document2 pagesAvk Air & Vacuum Valve, PN 16 701/30: For Water, Ductile Iron, DN 100 and 200-300 020lan bautistaNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01cmpuckNo ratings yet

- C Compression ConnectorsDocument84 pagesC Compression ConnectorsSam ANo ratings yet

- BB1-Catalogue 2015Document8 pagesBB1-Catalogue 2015nima hasanzadehNo ratings yet

- 621-41-001 - Avk130 - en 2206 - 478821Document2 pages621-41-001 - Avk130 - en 2206 - 478821bre brilianNo ratings yet

- F 908 WDocument1 pageF 908 WHaythem AhmedNo ratings yet

- A342 Alloy Master LinkDocument4 pagesA342 Alloy Master LinkKailin JuNo ratings yet

- 4403 2 PDFDocument24 pages4403 2 PDFAnonymous PIqdeNp8No ratings yet

- Valv. Comp. Ansi 150 Crane Fig. 47xuDocument2 pagesValv. Comp. Ansi 150 Crane Fig. 47xujulio sanchez camonesNo ratings yet

- 02 60 AVK Gate Valve F5 Long-BodyDocument3 pages02 60 AVK Gate Valve F5 Long-BodyArshad IqbalNo ratings yet

- Performance Curve Notes: Viking Universal Seal PumpsDocument2 pagesPerformance Curve Notes: Viking Universal Seal PumpsErick GoyesNo ratings yet

- Reductor Presiune Abur RP45 DN15-100Document2 pagesReductor Presiune Abur RP45 DN15-100vvlad34No ratings yet

- Forged Gate, Globe & Check ValvesDocument4 pagesForged Gate, Globe & Check ValvesRavi KantNo ratings yet

- Transformers and Ignitors: Engineered Solutions For Power and The EnvironmentDocument16 pagesTransformers and Ignitors: Engineered Solutions For Power and The EnvironmentDuile Blanco LopezNo ratings yet

- Stainless Steel Flexible Hose AssembliesDocument10 pagesStainless Steel Flexible Hose AssembliesDkdkkdNo ratings yet

- A New Era In: Filtration Performance and InnovationDocument6 pagesA New Era In: Filtration Performance and InnovationCARLOS SARMIENTONo ratings yet

- Check Swing Cast Steel A216 WCB Class 150: Pressure Temperature RatingsDocument2 pagesCheck Swing Cast Steel A216 WCB Class 150: Pressure Temperature Ratingsbreyca4 bcrNo ratings yet

- Bonstrand FP282BDocument20 pagesBonstrand FP282BFaisal AldyNo ratings yet

- Codo 90 8 SCH 40 Astm A234 21941Document1 pageCodo 90 8 SCH 40 Astm A234 21941antoniosofwareNo ratings yet

- Stag en MainDocument8 pagesStag en MainFederico AlarconNo ratings yet

- CI2400 BS2400 Product DataDocument6 pagesCI2400 BS2400 Product DataDaniel BrownNo ratings yet

- Fuse Link CatalogDocument14 pagesFuse Link CatalogWayan dhani Saputra100% (1)

- (S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Document3 pages(S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Bernard Bonnin CervantesNo ratings yet

- Avk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- FT - AWWA C900 - Tubería Enterrada C900Document3 pagesFT - AWWA C900 - Tubería Enterrada C900Jimmy Fernández B.No ratings yet

- Eo Weld Fitting 4100e001Document11 pagesEo Weld Fitting 4100e001sandeepNo ratings yet

- 09 Store Material Stock List 02 Deceber 2023 IMS-STR-F-06Document323 pages09 Store Material Stock List 02 Deceber 2023 IMS-STR-F-06Samruddhi DeshmukhNo ratings yet

- BAC SR8 Ball Valves Forged Steel Stainless Steel Full Bore ANSI Class 800Document1 pageBAC SR8 Ball Valves Forged Steel Stainless Steel Full Bore ANSI Class 800ChristianGuerreroNo ratings yet

- Econ Check Valves Tilting Disc Type ANSI Class 150: ApplicationDocument1 pageEcon Check Valves Tilting Disc Type ANSI Class 150: ApplicationChristianGuerreroNo ratings yet

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Document1 pageEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNo ratings yet

- Econ Y-Pattern Globe and Check Valves Forged Steel Stainless Steel TrimDocument1 pageEcon Y-Pattern Globe and Check Valves Forged Steel Stainless Steel TrimChristianGuerreroNo ratings yet

- Econ Gate Valve For Oil Tankers Cast Iron Bronze Trim Class 125 Fig. 339Document1 pageEcon Gate Valve For Oil Tankers Cast Iron Bronze Trim Class 125 Fig. 339ChristianGuerreroNo ratings yet

- Econ Globe Valves Carbon Steel Stainless Steel Trim ANSI Class 150 and 300Document1 pageEcon Globe Valves Carbon Steel Stainless Steel Trim ANSI Class 150 and 300ChristianGuerreroNo ratings yet

- Econ Globe Valves Forged Steel Stainless Steel Trim ANSI Class 800Document1 pageEcon Globe Valves Forged Steel Stainless Steel Trim ANSI Class 800ChristianGuerrero0% (1)

- Flange Dimensions and Drilling To JIS B 2210 (1984)Document1 pageFlange Dimensions and Drilling To JIS B 2210 (1984)ChristianGuerreroNo ratings yet

- Flow of Water at Several Velocities Through Pipelines DN 10 To DN 300Document1 pageFlow of Water at Several Velocities Through Pipelines DN 10 To DN 300ChristianGuerreroNo ratings yet

- Econ Check Valves Bronze Class 150 Fig. 1425: Pressure/temperature RatingDocument1 pageEcon Check Valves Bronze Class 150 Fig. 1425: Pressure/temperature RatingChristianGuerreroNo ratings yet

- Linear Conversion Table Inches - Millimetres: (1 Inch 25.4 Millimeter)Document1 pageLinear Conversion Table Inches - Millimetres: (1 Inch 25.4 Millimeter)ChristianGuerreroNo ratings yet

- Steam Table For Specific Volume of Superheated Steam From 1 To 50 Bar Absolute. (100 - 320 °C)Document1 pageSteam Table For Specific Volume of Superheated Steam From 1 To 50 Bar Absolute. (100 - 320 °C)ChristianGuerreroNo ratings yet

- Steam Table For Saturated SteamDocument1 pageSteam Table For Saturated SteamChristianGuerreroNo ratings yet

- Steam Table For Saturated Steam: (Continued)Document1 pageSteam Table For Saturated Steam: (Continued)ChristianGuerreroNo ratings yet

- Sizing of Pipelines For Saturated Steam: Section 21 Technical DataDocument1 pageSizing of Pipelines For Saturated Steam: Section 21 Technical DataChristianGuerreroNo ratings yet

- Flange Dimensions and Drilling To DIN 2501: Section 21 Technical DataDocument1 pageFlange Dimensions and Drilling To DIN 2501: Section 21 Technical DataChristianGuerreroNo ratings yet

- 239 PDFDocument1 page239 PDFChristianGuerreroNo ratings yet

- Econ Level Gauges For Steam Boilers Forged Steel Reflex/transparentDocument1 pageEcon Level Gauges For Steam Boilers Forged Steel Reflex/transparentChristianGuerreroNo ratings yet

- Econ Level Gauges Forged Brass and Steel PN 25: Safety: Max. Working PressureDocument1 pageEcon Level Gauges Forged Brass and Steel PN 25: Safety: Max. Working PressureChristianGuerreroNo ratings yet

- Econ Level Gauges Bronze: Max. Working Pressure: On Request: Dimensions (MM)Document1 pageEcon Level Gauges Bronze: Max. Working Pressure: On Request: Dimensions (MM)ChristianGuerreroNo ratings yet

- Econ Level Gauges For Chemical Applications: Fig. 577: Knee Type Arms of Stainless Steel, Ws - No. 1.4571 (AISI - 316)Document1 pageEcon Level Gauges For Chemical Applications: Fig. 577: Knee Type Arms of Stainless Steel, Ws - No. 1.4571 (AISI - 316)ChristianGuerreroNo ratings yet

- Econ Level Gauges Forged Steel PN 40: MaterialsDocument1 pageEcon Level Gauges Forged Steel PN 40: MaterialsChristianGuerreroNo ratings yet

- Automobile Tire Life Prediction Based On Image Processing and Machine Learning TechnologyDocument14 pagesAutomobile Tire Life Prediction Based On Image Processing and Machine Learning TechnologyLê Gia MinhNo ratings yet

- CRSBS BrochureDocument2 pagesCRSBS BrochureKarthik PalaniswamyNo ratings yet

- Coral Reef Restoration A Guide To EffectDocument56 pagesCoral Reef Restoration A Guide To EffectDavid Higuita RamirezNo ratings yet

- Lab #2: PI Controller Design and Second Order SystemsDocument4 pagesLab #2: PI Controller Design and Second Order SystemssamielmadssiaNo ratings yet

- Manual Efis 5.0Document448 pagesManual Efis 5.0AndresLopezMllanNo ratings yet

- DEVICE Exp 4 StudentDocument4 pagesDEVICE Exp 4 StudentTouhid AlamNo ratings yet

- Purdue Pharma-Mass. AGDocument312 pagesPurdue Pharma-Mass. AGWews WebStaff100% (1)

- U-Bolts For PolesDocument11 pagesU-Bolts For PolesMosa Elnaid ElnaidNo ratings yet

- Fairview Terminal PhaseII Expansion Project Report - Oct2012Document436 pagesFairview Terminal PhaseII Expansion Project Report - Oct2012NewsroomNo ratings yet

- Group 2I - Herman Miller Case AnalysisDocument7 pagesGroup 2I - Herman Miller Case AnalysisRishabh Kothari100% (1)

- Agricultural Revolution - Industrial RevolutionDocument2 pagesAgricultural Revolution - Industrial RevolutionJenni SilvaNo ratings yet

- Lymph Nodes.120182800Document43 pagesLymph Nodes.120182800honeyworks100% (1)

- Sep Incoming Exchange Guide PDFDocument13 pagesSep Incoming Exchange Guide PDFhmmmNo ratings yet

- GECG Curriculum - Biomedical EngineeringDocument52 pagesGECG Curriculum - Biomedical Engineeringdhruv7887No ratings yet

- Grade 7 3rd Term English Question 2078Document8 pagesGrade 7 3rd Term English Question 2078Deependra SilwalNo ratings yet

- Legal Counseling EssayDocument3 pagesLegal Counseling EssayKit UndugNo ratings yet

- Healing YogaDocument330 pagesHealing YogaVasanth TowmanNo ratings yet

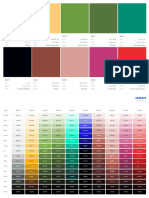

- Color 1 Color 2 Color 3 Color 4 Color 5: RGB Cmyk Name RGB Cmyk Name RGB Cmyk Name RGB Cmyk Name RGB Cmyk NameDocument4 pagesColor 1 Color 2 Color 3 Color 4 Color 5: RGB Cmyk Name RGB Cmyk Name RGB Cmyk Name RGB Cmyk Name RGB Cmyk NameValentina TorresNo ratings yet

- Iit Bombay Rankwise Branch List 2023Document1 pageIit Bombay Rankwise Branch List 2023Ratan ChoudharyNo ratings yet

- Introducing and Exchanging Personal Information: Practice 1Document11 pagesIntroducing and Exchanging Personal Information: Practice 1Riyan RiyanuartzNo ratings yet

- Notice Machine À CoudreDocument62 pagesNotice Machine À Coudreker lenoNo ratings yet

- Chapter-4 Newton - S Law of MotionDocument52 pagesChapter-4 Newton - S Law of Motionaditya sureshNo ratings yet

- Ann. Anim. Sci., Vol. 16, No. 2 (2016) 507-519 DOI: 10.1515/aoas-2015-0087Document13 pagesAnn. Anim. Sci., Vol. 16, No. 2 (2016) 507-519 DOI: 10.1515/aoas-2015-0087Cristian José CardozoNo ratings yet

- Comparing Microstrip and CPW PerformanceDocument6 pagesComparing Microstrip and CPW PerformanceA. VillaNo ratings yet

- Breath of Life Attunement (Self Attunement)Document4 pagesBreath of Life Attunement (Self Attunement)Petrea CiortanNo ratings yet

- 12th Sprint Reloaded-SolutionsDocument47 pages12th Sprint Reloaded-SolutionsMuhammad Anas BilalNo ratings yet