Professional Documents

Culture Documents

Crash Cushions and Barrier End Treatments: SECTION 02843

Uploaded by

Hafiz Ibnu TufalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crash Cushions and Barrier End Treatments: SECTION 02843

Uploaded by

Hafiz Ibnu TufalCopyright:

Available Formats

SECTION 02843

CRASH CUSHIONS AND BARRIER END TREATMENTS

PART 1 GENERAL

1.1 SECTION INCLUDES

A. Furnish and install crash cushions and barrier end treatments.

B. Furnish and install crash cushion and barrier end treatment markings.

1.2 RELATED SECTION

A. Section 02056: Embankment, Borrow, and Backfill

B. Section 02890: Retroreflective Sheeting

1.3 REFERENCES

A. Energite® III Module Systems Design Manual

B. Manual for Assessing Safety Hardware (MASH)

C. NCHRP Report 350 – Recommended Procedures for the Safety

Performance Evaluation of Highway Features

D. UDOT Guidelines for Crash Cushions and Barrier End Treatments, current

edition

1.4 DEFINITIONS Not Used

1.5 SUBMITTALS

A. Installer Certification

1. Manufacturer certified installer.

2. Provide proof of certification before installation.

B. Letter of certification for each system location affirming it is installed

according to Department’s and the manufacturer’s specifications.

1. Reference project number and describe station/location indicating

median, left or right shoulder, or gore area application.

Crash Cushions and Barrier End Treatments

02843 – Page 1 of 7

January 1, 2012

PART 2 PRODUCTS

2.1 CRASH CUSHION AND BARRIER END TREATMENTS

A. Select from the current approved products list and UDOT Guidelines for

Crash Cushions and Barrier End Treatments.

1. Refer to the current UDOT Guidelines for Crash Cushions and

Barrier End Treatments, current edition for specific uses and

requirements for each approved system type. The UDOT

Guidelines for Crash Cushion and Barrier End Treatments is

maintained by the Division of Traffic and Safety and available

through the Department Web site. Refer to

http://www.udot.utah.gov/go/standardsreferences.

a. Systems tested under NCHRP Report 350 requirements and

a letter of acceptance issued by FHWA.

1) Products approved before January 1, 2011

b. Systems tested under Manual for Assessing Safety

Hardware (MASH) requirements and a letter of acceptance

issued by FHWA.

1) Products approved after January 1, 2011

c. Supply four sets of shop drawings and installation drawings

for each system type supplied.

1) Distribute drawings to Contractor, installation

contractor, Engineer or designated representative,

and local maintenance supervisor.

2. Refer to CC Series Standard Drawings for approved crash cushion

or end treatment type.

B. Crash Cushion Types

1. Type A – Protects fixed hazards greater than 3 ft wide within 15 ft of

traveled way, with less than 100 ft of longitudinal space in front of

the hazard.

a. Supply system with an adequate width according to the plan

set.

b. Supply system for the required speed according to UDOT

Guidelines for Crash Cushions and Barrier End Treatments,

current edition.

c. Galvanize all steel parts according to manufacturer’s

requirements.

d. Supply transition element for the approach of opposing traffic

when system is installed with bi-directional traffic and the

back of system is within the maximum required clear zone.

1) Two transition elements required when system is

installed with W-beam median barrier.

e. Install system on concrete pad according to manufacturer’s

requirements.

Crash Cushions and Barrier End Treatments

02843 – Page 2 of 7

January 1, 2012

f. Supply crash cushion markings. Refer to CC Series

Standard Drawings.

2. Type B – Protects fixed hazards up to 3 ft wide or less and within

15 ft of traveled way, with less than 100 ft of longitudinal space in

front of the hazard.

a. Supply system with an adequate width according to the

plans.

b. Supply systems for the required speed according to UDOT

Guidelines for Crash Cushions and Barrier End Treatments,

current edition.

c. Galvanize all steel parts according to manufacturer’s

requirements.

d. Supply transition element for the approach of opposing traffic

when system is installed with bi-directional traffic and the

system is within the maximum required clear zone.

1) Two transition elements required when system is

installed with W-beam median barrier.

e. Install system on concrete pad according to manufacturer’s

requirements.

f. Supply crash cushion markings. Refer to CC Series

Standard Drawings.

3. Type C – Protects the approach ends of median W-beam guardrail

and the longitudinal space in front of the hazard greater than 100 ft.

a. Galvanize all steel parts according to manufacturer’s

requirements.

b. Supply double-sided W-beam transition element when

system is installed in conjunction with concrete barrier or

bridge parapet. Refer to BA 4 Series Standard Drawings.

c. Supply crash cushion markings. Refer to CC Series

Standard Drawings.

4. Type D – Protects fixed hazards within 15 ft of traveled way. Use in

areas where one impact per year is anticipated or when repair

history indicates two or more impacts over a three year period.

Systems are self restoring upon initial design impact.

a. Supply system with an adequate width according to the plan

set.

b. Supply system for the required speed according to UDOT

Guidelines for Crash Cushions and Barrier End Treatments,

current edition.

c. Galvanize all steel parts according to manufacturer’s

requirements.

d. Supply transition element for the approach of opposing traffic

when system is installed with bi-directional traffic and the

back of system is within the maximum required clear zone.

1) Two transition elements required when system is

installed with W-beam median barrier.

Crash Cushions and Barrier End Treatments

02843 – Page 3 of 7

January 1, 2012

e. Install system on concrete pad according to manufacturer’s

requirements.

f. Supply crash cushion markings. Refer to CC Series

Standard Drawings.

5. Type E – Sand Barrel Arrays – Protects fixed hazards outside of 15

ft from the traveled way and there is an unlimited amount of space.

Refer to the UDOT Guidelines for Crash Cushion and Barrier End

Treatments for specific uses and requirements of sand barrel

arrays.

a. Design sand barrel array using Energite® III Module

Systems design manual.

1) Design sand barrel array to meet roadway design

speed.

b. Certify sand barrels and components meet NCHRP-350 for

non-re-directive gating crash cushions.

c. Construct sand barrels using a frangible polyethylene

material that will shatter upon impact.

1) Use yellow sand barrels.

2) Permanently apply manufactured date, month, and

year to each piece of the barrel system.

3) Use one or two piece barrel construction.

4) Interface cones with the barrel to prevent sand

leakage but allow for drainage of excess water for

sand barrel systems that use barrel and cone

configuration.

5) Provide lids for each sand barrel. Fasten lid securely

to barrel.

d. Provide sand barrels that hold the required amounts of sand

according to requirements of the typical sand barrel array.

1) 200 lb, 400 lb, 700 lb, 1,400 lb, and 2,100 lb.

2) Mark each barrel in a manner that the amount of sand

required for the nominal weight is visible for systems

that are designed using barrels for multiple sand

weight requirements.

e. Use dry sand to fill modules, 2 percent or less moisture.

f. Supply crash cushion markings and construct pad. Refer to

CC Series Standard Drawings.

C. End Treatment Types

1. Type F – Protects concrete barrier or bridge parapets with less than

150 ft of longitudinal space in front of the hazard. Used in a

unidirectional application.

a. Galvanize all steel parts according to manufacturer’s

requirements.

b. Install system on concrete pad according to manufacturer

and to the manufacturer’s specifications.

Crash Cushions and Barrier End Treatments

02843 – Page 4 of 7

January 1, 2012

c. Supply crash cushion markings. Refer to CC Series

Standard Drawings.

2. Type G – Protects the approach end of single face W-beam

guardrail or approach ends of bridge parapet and concrete barrier

with unlimited longitudinal space (greater than 125 ft) in front of the

hazard in a unidirectional application and install where a tangent

system is desired. W-beam transition element is required when

system is installed at the end of bridge parapet or the end of

concrete barrier.

a. Supply post option as described in UDOT Guidelines for

Crash Cushion and Barrier End Treatments, current edition.

b. Supply system with 12½ ft galvanized W-beam rail elements

according to manufacturer’s requirements.

c. Supply manufacturer approved impact head and hardware.

d. Galvanize all steel parts according to manufacturer’s

requirements.

e. Supply crash cushion markings. Refer to CC Series

Standard Drawings.

3. Type H – Protects the approach end of single face W-beam

guardrail or approach end of bridge parapet and concrete barrier

with unlimited longitudinal space (greater than 125 ft) in front of the

hazard in a unidirectional application and is installed where a flared

system is desired. W-beam transition element is required when

system is installed at the end of a bridge parapet or the end of

concrete barrier.

a. Supply post option as described in UDOT Guidelines for

Crash Cushion and Barrier End Treatments, current edition.

b. Supply system with 12½ ft galvanized W-beam rail elements

according to manufacturer’s requirements.

c. Supply manufacturer approved impact head or end section

and hardware.

d. Galvanize all steel parts according to manufacturer’s

requirements.

e. Supply crash cushion markings. Refer to CC Series

Standard Drawings.

2.2 CRASH CUSHION MARKINGS

A. Marker plate and self-adhesive sheeting requirements:

1. Refer to CC Series Standard Drawings.

2. Construct marker plate 18 x 18 inches using 0.032 gauge aluminum

with appropriate object marker sheeting.

a. Drill a 7/16 inch hole in each corner of plate.

b. Sheeting – Refer to Section 02890.

1) Date placement specified in Section 02890 is not

required.

Crash Cushions and Barrier End Treatments

02843 – Page 5 of 7

January 1, 2012

3. Use of self-adhesive sheeting without marker plate. Sheeting –

Refer to Section 02890.

a. Date placement specified in Section 02890 is not required.

b. Use appropriate sheeting type for the substrate that sheeting

is placed on.

c. Place a minimum of 324 in2, typically 18 x 18 inch, on the

approach end of crash cushion or barrier end treatment.

d. Use of manufacturer’s supplied object marker sheeting is

acceptable when sheet type and amount meet or exceed

requirements.

B. Marker Post – Refer to CC Series Standard Drawings.

1. Construct marker post 60 inches long and 2 inches OD using black

polyethylene material.

a. Close top of marker post.

b. Drill three 7/16 inch mounting holes.

c. Apply three 4 inch bands of yellow sheeting. Refer to

Section 02890.

PART 3 EXECUTION

3.1 INSTALLATION

A. Prepare site to finished grade before installing crash cushion or barrier

end treatment.

1. Construct approach areas and recovery areas to meet Department

Standards and system requirements before system installation.

a. Refer to CC Series Standard Drawings for system

requirements.

2. Construct concrete pad according to system requirements when

applicable.

a. Crash Cushion Types A, B, and D require concrete pad when

installed in a permanent applications.

1) End Treatment Type F QuadTrend 350 requires a

concrete pad and concrete anchor system in all

applications. Refer to manufacturer’s requirements.

2) End Treatment Type F BEAT-SSCC can be mounted

on a concrete pad with surface mounted posts. Refer

to manufacturer’s concrete mounting requirements.

b. Crash Cushion Type C and End Treatment Types F, G, and H.

1) Do not drive steel posts, wood posts, or foundation

tubes through asphalt greater than 6 inches in depth.

Crash Cushions and Barrier End Treatments

02843 – Page 6 of 7

January 1, 2012

2) Leave out hole required when installing ground

mounted system into asphalt or concrete.

a) Drill a 16 inch hole through asphalt or concrete

or cut 15 inch x 15 inch hole through asphalt or

concrete.

b) Install post face or foundation tube face to

front, traffic side, of hole.

c. Use manufacture’s specification for concrete pad

construction.

d. Refer to CC Series Standard Drawings for Type E sand

barrel detail, for pad requirements.

3. Obtain Engineer’s approval of site grading, approach and recovery

areas, and layout before system installation.

4. Compact backfill material around posts and foundation tubes to

minimum 96 percent of maximum laboratory density and dispose of

excess material. Refer to Section 02056.

B. Install according to:

1. CC Series Standard Drawings and UDOT Guidelines for Crash

Cushion and Barrier End Treatments.

2. Manufacturer’s specifications and recommendations.

3. Use manufacturer certified installer to perform the installation.

C. Complete repair or replacement of any crash cushion damaged during

construction within 24 hours of notification of damage.

1. Contractor is responsible for the cost of repair or replacement of

any permanent system damaged for any reason until final

acceptance.

a. Exception

1) Damage is caused by an errant vehicle.

2) Damage occurs after traffic has been established in

the final lane configuration with shoulders as

established in the project plans.

b. Payment will be made using a Force Account basis for the

cost of repair or replacement of the damaged system when

the Engineer determines the conditions described under the

exception in this Section, article 3.1, paragraph C1a apply.

END OF SECTION

Crash Cushions and Barrier End Treatments

02843 – Page 7 of 7

January 1, 2012

You might also like

- Fhwa Aashto 98Document8 pagesFhwa Aashto 98Efraín CórdovaNo ratings yet

- PASER Asphalt ManualDocument32 pagesPASER Asphalt ManualTin Aung Kyi100% (1)

- Bridge Inspections - Assessing Defects & Details For SafetyDocument51 pagesBridge Inspections - Assessing Defects & Details For SafetySeptinurriandianiNo ratings yet

- 84B540865AB RevCDocument34 pages84B540865AB RevCivanNo ratings yet

- Oracle EBS R12.2.6 Application Tier Cloning With Step by StepDocument10 pagesOracle EBS R12.2.6 Application Tier Cloning With Step by Stepdoyenblog100% (1)

- The Interaction of Mercury and Aluminium in Heat Exchangers in A Natural Gas PDFDocument7 pagesThe Interaction of Mercury and Aluminium in Heat Exchangers in A Natural Gas PDFToth IstvanNo ratings yet

- PDO ScopeDocument34 pagesPDO ScopeShankar Raj100% (1)

- Wfe Week 2 Worksheet KeyDocument3 pagesWfe Week 2 Worksheet KeyJean Kendal Reategui0% (1)

- Appendix D Examples Users GuideDocument205 pagesAppendix D Examples Users Guidejhocape100% (1)

- Dowel Bar Size and Spacing For Rigid Pavements PDFDocument8 pagesDowel Bar Size and Spacing For Rigid Pavements PDFTim Lin100% (1)

- Topic 8 - Rigid Pavement Stress AnalysisDocument14 pagesTopic 8 - Rigid Pavement Stress AnalysisSrieirianti Ulina Pinem100% (1)

- 15 Rigid Pave Design 2010 AASHTO UpdatedDocument72 pages15 Rigid Pave Design 2010 AASHTO UpdatedCong LuoNo ratings yet

- LTRC Final Report For Valuation of The Fatigue and Toughness of Fiber Reinforced Concrete For Use As A New Highway Pavement DesignDocument74 pagesLTRC Final Report For Valuation of The Fatigue and Toughness of Fiber Reinforced Concrete For Use As A New Highway Pavement Designwalaywan100% (1)

- Indo-US Workshop On Highway and Airport Pavement Engineering (HiPAVE) v2Document43 pagesIndo-US Workshop On Highway and Airport Pavement Engineering (HiPAVE) v2Narendra Kumar Boddeti100% (1)

- Guide For Mechanistic-Empirical Design: Appendix QQDocument93 pagesGuide For Mechanistic-Empirical Design: Appendix QQBridger WangNo ratings yet

- NCHRP RPT 500v1Document75 pagesNCHRP RPT 500v1joebriffaNo ratings yet

- Pile Driver-Xuzhou FanyaDocument15 pagesPile Driver-Xuzhou Fanyaagus saputraNo ratings yet

- Clear ZoneDocument3 pagesClear ZonejbmNo ratings yet

- Use of The AASHTO 1993 Guide MEPDG and Historical Performance Pavement Design CaelogDocument29 pagesUse of The AASHTO 1993 Guide MEPDG and Historical Performance Pavement Design Caelogs_khan1997466No ratings yet

- CPG Complete DownloadDocument188 pagesCPG Complete Downloadram100% (1)

- Guide For Curing of Portland Cement Concrete Pavements, Volume IDocument52 pagesGuide For Curing of Portland Cement Concrete Pavements, Volume Ilandsv01No ratings yet

- Evaluation AASHTO 2002Document133 pagesEvaluation AASHTO 2002Luis Fuentes Pumarejo100% (2)

- Liquefaction FachryDocument133 pagesLiquefaction FachryFachry IbrahimNo ratings yet

- Elmod Software ManualDocument2 pagesElmod Software ManualbickycivilNo ratings yet

- Annual Report CMNP 2018Document373 pagesAnnual Report CMNP 2018CharmanyaMarcheitaNo ratings yet

- Roughometer II User Manual PDFDocument60 pagesRoughometer II User Manual PDFNofran ArifinNo ratings yet

- Concrete Spec Japek 2 ElevatedDocument1 pageConcrete Spec Japek 2 ElevatedjimdabrondNo ratings yet

- DMRB hd3816 Concrete Surfacing and MaterialsDocument27 pagesDMRB hd3816 Concrete Surfacing and MaterialsLebo.emx Mathosa100% (1)

- Roadroid Quick Start - Ver 1.2.1 Nov 13Document6 pagesRoadroid Quick Start - Ver 1.2.1 Nov 133pivopijeNo ratings yet

- Microsoft PowerPoint - Admixture Untuk Inovasi Beton - Untuk PDFDocument72 pagesMicrosoft PowerPoint - Admixture Untuk Inovasi Beton - Untuk PDFRizki Muda KeulanaNo ratings yet

- WINPAS User ManualDocument105 pagesWINPAS User Manualjuan camilo chivata alvaradoNo ratings yet

- Sika Trial A1Document1 pageSika Trial A1jimdabrondNo ratings yet

- Austroads Guide Road Design Part6 AGRD06 09Document296 pagesAustroads Guide Road Design Part6 AGRD06 09kevin_au18No ratings yet

- 1 Sejarah Strukur&DesainDocument34 pages1 Sejarah Strukur&Desaininspektorat babelNo ratings yet

- Airfield Pavement1 PDFDocument8 pagesAirfield Pavement1 PDFvinay rode100% (1)

- Backcalculation of Pave Layer ModuliDocument73 pagesBackcalculation of Pave Layer ModulibloomdidoNo ratings yet

- Uji Tarik Coupler Mechanical Joint Type-M Ex FujiboltDocument6 pagesUji Tarik Coupler Mechanical Joint Type-M Ex FujiboltjimdabrondNo ratings yet

- AASHTO Rigid Design IDocument11 pagesAASHTO Rigid Design Ietikaf100% (1)

- Schedule Setting Launcher & Erection PCI Girder AdhimixDocument1 pageSchedule Setting Launcher & Erection PCI Girder AdhimixAchsan IrvanNo ratings yet

- Calculating Mass Transit "Line Capacity", ITE Handbook, 1992Document12 pagesCalculating Mass Transit "Line Capacity", ITE Handbook, 1992Bob DiamondNo ratings yet

- Teknologi Peralatan Konstruksi.: Peralatan Dan Pelaksanaan Pondasi Bor PileDocument45 pagesTeknologi Peralatan Konstruksi.: Peralatan Dan Pelaksanaan Pondasi Bor PileMustofaNo ratings yet

- Mapping HotmixDocument4 pagesMapping Hotmiximmanuel lumbantobingNo ratings yet

- Elmod 5 To 6 GuideDocument28 pagesElmod 5 To 6 GuideGonzalo Alejo MitaNo ratings yet

- Pavement Deisgn 2012Document59 pagesPavement Deisgn 2012WillowcrestNo ratings yet

- Long-Life Asphalt Pavements - Technical2007Document24 pagesLong-Life Asphalt Pavements - Technical2007Sen HuNo ratings yet

- 2001 Lake Mead Sedimentation SurveyDocument212 pages2001 Lake Mead Sedimentation SurveyAlexander Gilang Samudra RajasaNo ratings yet

- Updates On Mechanistic Empirical Pavement Design Guide MEPDGDocument44 pagesUpdates On Mechanistic Empirical Pavement Design Guide MEPDGsupasart100% (1)

- Perilaku Beton Geopolymer Dibanding Beton Normal Ditinjau Dari Perawatan, Absorpsi Dan Kuat TekanDocument8 pagesPerilaku Beton Geopolymer Dibanding Beton Normal Ditinjau Dari Perawatan, Absorpsi Dan Kuat TekanJimianta S.S.TNo ratings yet

- Procurement of Works For Above 6 Million Rupees NCB July 2010Document100 pagesProcurement of Works For Above 6 Million Rupees NCB July 2010jhoward2012npNo ratings yet

- Challenges in PavementsDocument23 pagesChallenges in PavementsSomeshwar Rao ThakkallapallyNo ratings yet

- Project Assessment ManualDocument119 pagesProject Assessment ManualRobeam Solomon100% (1)

- SJ-5112 1011 3B Horizontal AlignmentDocument103 pagesSJ-5112 1011 3B Horizontal AlignmentWelly Pradipta bin Maryulis100% (1)

- ASTM D6373 16 Especificacion PGDocument6 pagesASTM D6373 16 Especificacion PGPedro AlvelaisNo ratings yet

- Geofaom Supplier - StyrofillGeofoam - Geofoam Manufacture and SupplierDocument11 pagesGeofaom Supplier - StyrofillGeofoam - Geofoam Manufacture and SupplierMohamed Ismail ShehabNo ratings yet

- (1a) Soil Improvement Stabilisasi Tanah Secara Mekanis Dan KimiawiDocument44 pages(1a) Soil Improvement Stabilisasi Tanah Secara Mekanis Dan KimiawijoNo ratings yet

- Topic 7 - AASHTO Flexible Pavement DesignDocument16 pagesTopic 7 - AASHTO Flexible Pavement DesignJose Juan PeñalbaNo ratings yet

- Advances in Backcalculating The Mechanical Properties of Exible PavementsDocument11 pagesAdvances in Backcalculating The Mechanical Properties of Exible PavementsArthur Nnang100% (1)

- Perhitungan Baja II CremonaDocument27 pagesPerhitungan Baja II CremonaAdi Indra BrugmanNo ratings yet

- 5.FDR BookletDocument80 pages5.FDR BookletSourabh PalNo ratings yet

- fc40 + Barchip Fiber (6 kg/m3)Document15 pagesfc40 + Barchip Fiber (6 kg/m3)jimdabrondNo ratings yet

- CIRCLY 7.0 Workshop - Brisbane - 24 October 2019 - 1 Page Per Slide PDFDocument310 pagesCIRCLY 7.0 Workshop - Brisbane - 24 October 2019 - 1 Page Per Slide PDFLewis HamiltonNo ratings yet

- Project Name Fall Protection Devices Construction Documents - Date PAGE 1 of 3Document3 pagesProject Name Fall Protection Devices Construction Documents - Date PAGE 1 of 3issaNo ratings yet

- EscalatorsDocument8 pagesEscalatorsFeroz HameedNo ratings yet

- Maintenance EquipmentDocument7 pagesMaintenance Equipmentwalid abou kachfeNo ratings yet

- 07 92 16 Rigid Joint Sealants Spal Pro RS65 2020Document4 pages07 92 16 Rigid Joint Sealants Spal Pro RS65 2020crowNo ratings yet

- Pendahuluan: Kerja (K3) Pembangunan Infrastruktur Jalan Dan Jalan Layang"Document2 pagesPendahuluan: Kerja (K3) Pembangunan Infrastruktur Jalan Dan Jalan Layang"Hafiz Ibnu TufalNo ratings yet

- HW2 1Document3 pagesHW2 1Hafiz Ibnu TufalNo ratings yet

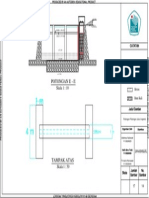

- Potongan E - E: Skala 1: 10Document1 pagePotongan E - E: Skala 1: 10Hafiz Ibnu TufalNo ratings yet

- 14 9 200Document26 pages14 9 200Hafiz Ibnu TufalNo ratings yet

- Federal Highway AdministrationDocument18 pagesFederal Highway AdministrationHafiz Ibnu TufalNo ratings yet

- Alat Pemecah BatuDocument4 pagesAlat Pemecah BatuHafiz Ibnu TufalNo ratings yet

- Perhitungan FastaDocument30 pagesPerhitungan FastaHafiz Ibnu TufalNo ratings yet

- Catatan Catatan Catatan: Hulu Sungai Hilir SungaiDocument1 pageCatatan Catatan Catatan: Hulu Sungai Hilir SungaiHafiz Ibnu TufalNo ratings yet

- Tugas DrainaseDocument24 pagesTugas DrainaseHafiz Ibnu TufalNo ratings yet

- 11111111111111111111Document4 pages11111111111111111111Hafiz Ibnu TufalNo ratings yet

- Reference ConcreteDocument1 pageReference ConcreteHafiz Ibnu TufalNo ratings yet

- 2 Sipil 1 PagiDocument3 pages2 Sipil 1 PagiHafiz Ibnu TufalNo ratings yet

- ACC 5 Supported 3rd Party Cameras & Encoders PDFDocument8 pagesACC 5 Supported 3rd Party Cameras & Encoders PDFDanilo Moreira CisternaNo ratings yet

- Ansi - Ahri Standard 420-2008Document30 pagesAnsi - Ahri Standard 420-2008Walter MNo ratings yet

- REPORT OF SUPPLIES AND MATERIALS ISSUED From Jan. To Dec. 2014Document5 pagesREPORT OF SUPPLIES AND MATERIALS ISSUED From Jan. To Dec. 2014Jonelyn Capalad100% (2)

- Measurements of Static and Dynamic Displacement From Visual Monitoring of The Humber Bridge 1993Document12 pagesMeasurements of Static and Dynamic Displacement From Visual Monitoring of The Humber Bridge 1993ciscoNo ratings yet

- Saumen ResumeDocument1 pageSaumen Resumeapi-261430347No ratings yet

- Storage Foundation 7.3 LinuxDocument891 pagesStorage Foundation 7.3 LinuxPopescu AndreiNo ratings yet

- Gn001 Application Guide: Design With Gan Enhancement Mode HemtDocument44 pagesGn001 Application Guide: Design With Gan Enhancement Mode HemtTuan TranNo ratings yet

- GBH 36 VF Li Professional Manual 148897Document249 pagesGBH 36 VF Li Professional Manual 148897Gomez GomezNo ratings yet

- IT AssignmentDocument3 pagesIT AssignmentKanthi Rekha VardhiNo ratings yet

- SDK-Python Interface ENG V1.0Document32 pagesSDK-Python Interface ENG V1.0Chandru ChristurajNo ratings yet

- Destruction and Disposal of Sensitive DataDocument15 pagesDestruction and Disposal of Sensitive DataHelenNo ratings yet

- 3P SampleDocument7 pages3P SampleparagpunjabiNo ratings yet

- West Bengal Pollution Control Board ContactDocument18 pagesWest Bengal Pollution Control Board ContactAvik PattanayakNo ratings yet

- ME 361 Unit 6Document53 pagesME 361 Unit 6Dennis ArhinNo ratings yet

- The Art of Public SpeakingDocument12 pagesThe Art of Public SpeakingagahNo ratings yet

- Combination Waste and Vent: Plumbing Systems InteractiveDocument39 pagesCombination Waste and Vent: Plumbing Systems InteractiveKevin PagayamanNo ratings yet

- 2004 Viking-Excalibur ManualDocument45 pages2004 Viking-Excalibur ManualjackNo ratings yet

- Submersible Sewage Ejector Pump: Pump Installation and Service ManualDocument8 pagesSubmersible Sewage Ejector Pump: Pump Installation and Service Manualallen_worstNo ratings yet

- Industrial Control 11)Document33 pagesIndustrial Control 11)Arindam LayekNo ratings yet

- RAN Working Paper No.2Document19 pagesRAN Working Paper No.2Rex TyrannosaurNo ratings yet

- Short-Term Scheduling of Battery in A Grid-Connected PV-Battery SystemDocument9 pagesShort-Term Scheduling of Battery in A Grid-Connected PV-Battery SystemEric GalvánNo ratings yet

- IFTF Future of Persuasion ReportDocument59 pagesIFTF Future of Persuasion ReportSean NessNo ratings yet

- Section 22 - Sulfur RecoveryDocument145 pagesSection 22 - Sulfur RecoveryCHANADAS100% (1)

- Approximations and ErrorsDocument13 pagesApproximations and ErrorsBishesh Acharya100% (1)

- Brian's Toys Product Catalog #82Document32 pagesBrian's Toys Product Catalog #82Brian's Toys, Inc.No ratings yet