Professional Documents

Culture Documents

Study of D If 636518233805217029

Study of D If 636518233805217029

Uploaded by

Prem Ranjan Mehta0 ratings0% found this document useful (0 votes)

24 views4 pagesLarge Cardamom

Original Title

Study of d if 636518233805217029

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLarge Cardamom

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views4 pagesStudy of D If 636518233805217029

Study of D If 636518233805217029

Uploaded by

Prem Ranjan MehtaLarge Cardamom

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

VOL.

VII, ISSUE XXV, JAN 2018 MULTILOGIC IN SCIENCE ISSN 2277-7601

An International Refereed, Peer Reviewed & Indexed Quarterly Journal in Science, Agriculture & Engineering

STUDY OF DIFFERENT DRYING METHODS EFFECT ON QUALITY OF LARGE-CARDAMOM (AMOMUM SUBULATUM

ROXB.) CAPSULES

1

Prem Ranjan, 2Jitson Achom, 3Manjeet Prem, 4Sajesh Chettri, 5Pema T. Lepcha, 6Thameridus B. Marak

Department of Processing and Food Engineering, College of Agricultural Engineering and Post-Harvest Technology (CAU),

Ranipool, East Sikkim, India-737135.

(Received: 01.10.17; Revised: 08.11.2017; Accepted: 09.11.2017)

(RESEARCH PAPER IN PROCESSING AND FOOD ENGINEERING)

Abstract

The large cardamom is one of the most important spice crops grown in the Himalayan region of Sikkim, India. India is the second largest

producer of large-cardamom in the world next to Nepal. The dried fruits of large cardamom (Amomum subulatum Roxb.), a high-value spice

crop. It is used in foods, beverages, perfumes, and medicines. Production is currently declining, and the improved postharvest process would

be one way to help ensure the sustainability of this position crop. The drying by the traditional system have reduces the quality of cardamom

capsules (colour, flavor and oil content etc.) and as well as cost. This article reviews the crop's drying by a different system (traditional,

improved, electric and diesel operated, and solar drying). In this article, we see that the good quality of the product is found in improved

dryers. Also, the solar dryer system has a good quality product and it was reported that solar dryer system saves about 50% of drying time

for the solar dryer in comparison to the open sun drying of large cardamom capsules.

Key words: Bhatti’s, capsules, curing, dryer, flavor,

Introduction troubles, congestion of lungs, inflammation of eyelids, digestive

Large cardamom (Amomum subulatum Roxb.) is one of the popular disorders and in the treatment of lung tuberculosis.

spices that comes under the family Zingiberaceae. Eastern Himalayas Materials and Methods

region as its origin where wild species are still located (Sharma et al., Varieties of large cardamom

2000). Cardamom is the world's third-most expensive spice, exceeded The local varieties of large cardamom found in Himalayan regions

in price per weight only by vanilla and saffron. It is an ancient spice- are Ramsey, Golsey, Chibesey, Dambersey, Sawney and Kantidar.

cummedicinal herb. India is the largest producer and exporter of The most important varieties found in Sikkim include Ramsey,

large-cardamom (Amomum subulatum Roxb). The other major Golsey, Sawney, Kopringery, Madhusay and Rhangbhang. In this

producers of large-cardamom are Nepal and Bhutan. Its cultivation is variety, only Ramsey, Golsey and Sawney are considered for

confined in Eastern Himalaya covering Sikkim, West Bengal commercial production as these cultivars are well suited to high

(Darjeeling hills) and Arunachal Pradesh. It is one of the most altitudes and can be cultivated even in steep slopes (Harktkamp,

important livelihood sources for mountain people in the Himalayan 1993). Some of the varieties of cultivars grown in Sikkim are given

region. It is a low volume high-value crop (Avasthe et al. 2011). It in table 1.

has been considered important since many centuries in Ayurvedic Beneficial uses of large cardamom

preparation and Unani system of medicines (Madhusoodanan and The seeds of large cardamom have been used to flavor food,

Rao 2001). It is known by various names such as Bhadr (Sanskrit), confections, beverages and liquids (Singh et al., 2008). Furthermore,

Bari elaichi (Hindi), Greater or Nepal cardamom(English), it has been used as an insecticide as well (Satyal et al., 2012). Its

Cardamom(French), Ts’ ao-k’ ou (Chinese). usage in Ayurvedic is well known from prehistoric time. It is used as

India is the second largest producer and exporter in the world. Total flavoring and preservative to different types of coffee, liquors,

area under cultivation of large cardamom in India is 30,000 ha. and confections, beverages and tobacco. Volatile oil (2-4%) is the

production is 5,000 MT. At the national level, Sikkim contributes 89 principal aroma-giving compound in large cardamom and 1,8-

% large cardamom area and 86 % production. A farmer can earn of cineole is the major active compound after compound, in an extent 60

Rs. 25,000 to 30,000 from one-hectare plantations. The crop grows to 80% of the total volatile oil. Alcohol and aqueous extract of large

well in the shade of forest trees at altitudes ranging from 6002000 m. cardamom have been reported to contain allopathic, analgesic, anti-

with a rainfall of 20003500 mm per annum at temperature 530 0C. inflammatory, antimicrobial, antioxidant, antiulcer, cardio-

Deep and well-drained soils with a loamy texture are best suited for apoptogenic and hypolipidemic activities. Large cardamom and its

cardamom. The soil in Sikkim is generally rich in organic matter and powder, oleoresin and essential oils have many culinary and

nitrogen, medium in available phosphorus and medium to high in therapeutic uses (Gautam et al. 2016).

available potash. The soils have a pH range from 4.5 to 6.0. Even Large cardamom (Amomum subulatum Roxb.) has been used for the

though the crop can be grown in undulating and steep terrains, land treatment of various diseases and disorders like gastric, ulcer. Hence,

with a more moderate slope is preferred. It is a tall, perennial, the antimicrobial activity of petroleum ether, methanol and aqueous

evergreen, herbaceous monocot plant (Gopal et al., 2012). The height extracts from leaves and roots, essential oil and isolated vasicine from

of cardamom plant ranges from 1.5-3.0 m and leaves are found at the A. vasica were tested against various microorganisms. Antimicrobial

upper portion of the stem (Bisht et al., 2011). activity was done by disc diffusion method. The zone of inhibition

Large cardamom has a pleasant aromatic odour, due to which it is observed was compared with that of standard drugs, ciprofloxacin

extensively used for flavouring vegetables and many food and fluconazole. Minimum inhibitory concentration was determined

preparations in India. It is also used as an essential ingredient in against microorganisms. The methanol extract of fruits of large

mixed spices preparation. The large cardamom capsule contains 23 % cardamom shows notable antimicrobial activity against Escherichia

of essential oil. Apart from the aroma, large cardamom also has high coli whereas in case of other microorganisms used it was found

medicinal value. The decoction of seeds is used as a mouthwash in inferior to the standard drug used. The methanol extract of rind

infection of teeth and gums. Large cardamom also possesses curative presented good antimicrobial activity against Staphylococcus aureus.

properties and be one of the major spices which are mentioned in It was found that the essential oil isolated was effective against the

Ayurveda and Unani medicine (Chempakam and Sindhu, 2008). majority of microorganisms used viz. Bacillus pumilus,

Large cardamom seeds are considered as an antidote to either snake Staphylococcus aureus, Staphylococcus epidermidis, Pseudomonas

venom or scorpion venom. It is also reported that large cardamom aeruginosa, Saccharomyces cerevisiae (Agnihotri and Wakode,

seeds are used as preventive as well as a medicinal measure for throat 2010).

Results and Discussion

VOL. VII, ISSUE XXV, JAN 2018 MULTILOGIC IN SCIENCE ISSN 2277-7601

An International Refereed, Peer Reviewed & Indexed Quarterly Journal in Science, Agriculture & Engineering

Drying of large cardamom use it due to poverty as they cannot invest that the huge amount of

After harvesting of the cardamom, capsules are dried either in fuel money in the construction of modern dryer. About, 32.9 % of

Kiln or electrical drier or in the sun drying. Soaking freshly harvested households used traditional bhattis due to both lacks the idea and

green cardamom capsules in 2 % washing soda solution for 10 mins. economic cause. Also, 6.3 % of households did not answer the

previous to drying helps to retain original green colour during drying. question as they were not involved in cardamom cultivation and some

Under flue pipe dryer, it should be dried at 4550 °C for 14 to 18 didn’t respond, as their cardamom had not come into production stage

hours, while over-night drying at 5060°C is required in an electric (Yadav, 2013).

dryer. The cardamom capsules are spread thinly and stirred frequently The traditional Bhatti's is developed by farmers and used for curing

to ensure uniform drying. The dried cardamom capsules are rubbed fresh large cardamom capsules (Sharma et al. 2000) ; it is a direct

with hands or agitated to confirm uniform drying. After drying, they heating system, and drying time is required 25–40 hours (Mande et.

are winnowed to remove any foreign matter. Then capsules are sorted al. 1999). The fuel efficiency of this system is very poor (Rao et al.

according to size and colour and stored in black polythene lined 2001) ; it requires 2.5 kg of fuelwood to produce 1 kg of dried

gunny bags to retain the green colour during storage (Anonymous, capsules (Sharma et al. 2009). The quality of cardamom capsules

2015). cured in traditional Bhatti's is poor. They are dark brown colour and

Traditional Bhatti’s have a smoky flavour; the quantity of charred and cracked capsules is

high, as is the loss of volatile oil. But, the cost of building and

maintenance of a bhatti’s is low. A traditional bhatti’s can easily

make using locally available materials and requires no scientific

knowledge.

Farmers have practised traditional method of processing cardamom.

The cardamom capsules are dried in traditional bhattis. The fuel

(wood) is consumed in the ratio of 4:1 for cured cardamom; about

Figure.1. Traditional Bhatti (Source: Sharma et al. 2000) 800 kg/ha of wood are required to cure 200 kg/ha of the finished

Drying of cardamom capsules is mostly achieved by traditional product. Recently, some institutions have developed improved

wood-fired dryers, which are built in the orchard. However, this Bhatti's and gasifiers for curing as well as capsule tail cutting and

traditional processing method causes blackening of the capsules and polishing machines for added value; but farmers have not been

gives smoky flavor (Oli, 2011). Cardamom capsules are spread adopting these technologies (Sharma et al. 2000).

uniformly in a thick layer of 25-30cm on a bamboo mat placed over Gasifier based curing system

the frames of wood firing pit. Capsules are then dried by the The Tata Research Institute (TERI) developed and introduced a

combined effect of heat and smoke generated by the burning of wood. gasifier based curing system constituting of an updraft biomass

Drying process takes about 24 to 28 hours and frequent racking is gasifier connected from the gasifier is connected to a traditional

made to get uniform drying. After uniform drying, the capsules are Bhatti (TERI, 2012). In this system producer gas obtained from the

rubbed against the rough surface in order to remove the tail (Tamang, gasifier was used for heating of the capsules. Since the producer gas

2000; Oli, 2011). The quality of cardamom capsules dried in does not produce smoke, the quality of the cured capsules reported

traditional bhattis is poor and they have a dark brown colour with a having been better than that of the traditional Bhatti. Singh and

smoky flavor. There is a production of large quantity of burned, Pothula, (2013) have mentioned that the better quality of dried

cracked capsules having less volatile oil in traditionally dried capsules was produced by improved dryer than that of capsules dried

capsules. However, no scientific knowledge is required to build this in traditional Bhatti.

kind of traditional bhattis. In the villages of producing areas, The advantages of the gasifier based curing system over traditional

building, operation and management cost of bhattis is cheap and they Bhatti are better in energy conversion efficiency, controlled

are mostly constructed from locally available materials (Singh et al., combustion, and production of the flue gases (Rao et al.2001). The

1989). gasifier based curing system has more than 70%heatconversion

For the long-duration storage of cardamom capsules and in order to efficiencies. Fuelwood saving was reported up to 60-65% (Rao et

bring out its aroma, the fresh cardamom capsules (with 80-85% al.2001). it also produces capsules of attractive colour and greater

moisture) has to be dried immediately after harvesting to bring down volatile oil content. However, this curing system is not usually used

its moisture content to less than 10% (w. b.) through a curing (drying) by farmers. Chipping of fuel woods and the additional cost of

process. Still, a primitive and inefficient (operating efficiency level of installing the gasifier might be the reason for unacceptability by the

about 5-15%) smoking method (using traditional Bhatti's) is being large cardamom farmers. The cost of this curing system ₹12,000.00

used for drying of large-cardamom resulting in huge (estimated (Deka et al., 2003).

20,000 MT/yr.) wastage of fuel wood and poor (charred and ICRI improved Bhatti curing system

blackened) quality product (Rao et al., 2001). The various Indian Cardamom Research Institute (ICRI) also developed improved

inadequacies of this system make traditional bhatti’s less than Bhatti for curing of large cardamom which is shown in figure no.2.

desirable for producing a marketable end product. Drawbacks include This system is an indirect heating dryer. The capacity of this Bhatti

uneven heating and drying; loss of volatile oils in the dried capsules varies from 200–400 kg fresh capsules. Heated air is used for curing

(Zala, 2002); loss of the characteristic rich, dark red colour; charring; the capsules which are supplied by flue gas pipes.

and an infusion of smokiness from the wood fire below (Rao et al.,

2001).

All, more or less the households of producing area used traditional

bhattis for drying cardamom. These traditional techniques consume

much more firewood than the modern dryer, and the quality of the

cardamom also degrades when the traditional dryer is used. In this

system, the cardamom capsules come in direct contact with the

smoke and turn the capsule to a dark brown-black colour with a

smoky smell. About, 53.2 % of households had not used modern Figure 2: ICRI improved Bhatti for curing of large cardamom

dryer due to lack of information. Also, 7.6 % of households did not (Source: Vijayan et al. 2013)

VOL. VII, ISSUE XXV, JAN 2018 MULTILOGIC IN SCIENCE ISSN 2277-7601

An International Refereed, Peer Reviewed & Indexed Quarterly Journal in Science, Agriculture & Engineering

Deka et al. (2003) reported that curing time of capsules in this system University), Ranipool (27° 20′ N, 88° 40′ E), Gangtok, Sikkim. It was

is 17–24 hr. and it gives excellent product quality with volatile oil observed that on an average 55.7% of higher temperature was

content in the range of 2%-4% and the colour of the capsules is obtained in the solar dryer over the ambient temperature. A total

maroon. The cost of one ICRI improved Bhatti is ₹5,000 (Deka et al., drying time of 24 hr. (3 sunny days) was required for large cardamom

2003). The ICRI improved Bhatti(s) are being used by few farmers in drying in the solar dryer to reduce the moisture content from 75.6%

Arunachal Pradesh, India (Singh et al., 2013). It is also introduced in (w.b.) to 10.1% (w.b.) compared to that of 48 h for the open sun

the Sikkim, India by Spices Board of India but farmers are reluctant drying to obtain the same level of moisture contents resulting in a net

to adopt it due to some specific reasons (Anonymous, 2007). Stoep saving of about 50% of drying time for the solar dryer in comparison

(2010) reported that use of similar kind of curing system is also found to the open sun drying (Seveda & Jhajharia 2012).

in Nepal. Solar-biomass hybrid dryer

Improved Bhatti’s

Traditional bhatti’s are improved for more efficient and effective

drying of large cardamom capsules, where heating is performed

indirectly through hot air and smoke is released outwards. Hence, use

of heat in the absence of smoke in improved dryers, they give more

natural colour and better-quality product than traditional method (Oli,

2011). Department of food technology and quality control (DFTQC),

Nepal has developed six drum dryers containing two sections- firing

and drying sections for more efficient and effective drying of

cardamom capsules. These sections are enclosed in a wall made of

stone and mud and the whole assembly is kept under the enclosed

covered structure. The capacity of this dryer varies from 360 kg to

400 kg of fresh cardamom and the drying time is reported to have 24

hr (Oli, 2011). Gurudutt and Naik, (2000) reported that in the

improved method, cured capsules are dried into two stages, at 60ºC Figure 4. Solar-biomass hybrid dryer (Source: Sankar, V. A.,

and 55ºC respectively to get the desired moisture content (approx. 10- 2017)

12%). The content is then cooled, cleaned, tails are removed and The developed solar-biomass hybrid dryer was fabricated and tested

capsules are graded according to their size. Those capsules are at College of Agricultural Engineering and Post Harvest Technology,

packed in jute bags (waterproof lined with polythene) and stored in Central Agricultural University, Ranipool, Gangtok, Sikkim. The

dry places (Oli, 2011). developed solar-biomass hybrid dryer was used for drying of large

Singh and Pothula, (2013) stated that another dryer containing cardamom to use solar energy as the main heat source and biomass

mechanical trolley system operated by diesel or electricity. This gasifier was used only when solar energy was not available during

curing system consisting of a blower, a heating unit, and a multi-tray early morning, late evening, cloudy weather conditions and at night.

curing chamber, similar to a mechanical cabinet tray dryer. This The average gasifier efficiency and combustion efficiency of the

system works effectively and produces high-quality dried capsules. solar-biomass hybrid dryer for drying of large cardamom were

Its capacity is 600 kg and curing time is 12 hrs. Another dryer having 71.57% and 55.36% respectively. The study also revealed that about

indirect heat curing system. They also stated and is called the rocket 6 kg of biomass was sufficient for operating of gasifier and drying of

stove dryer, which has been introduced as part of a Netherlands 20 kg of large cardamom in the solar-biomass hybrid dryer. The

Development Organization initiative in Nepal. This flue-gas-based temperature attained in the drying chamber of solar biomass hybrid

system produces less smoke and is reported to produce high-quality dryer system was up to 70°C in the gasifier mode and 66.6°C in the

capsules (Stoep, 2010). There are several reports of curing systems solar mode of operation.

developed in India by the research institute, G.B. Pant Institute of 6. Miscellaneous curing systems

Himalayan Environment and the Development and Central Food G.B. Pant Institute of Himalayan Environment and Development

Technological Research Institute in Mysore (Singh and Pothula, (GBPIHED) and Central Food Technological Research Institute,

2013) , but none are in use by farmers so far. These dryers are not Mysore (CFTRI) have also developed curing systems for large

cost effective as compared to traditional cured capsules dryers. cardamom but none is in use by the farmers so far (Madhusoodanan

Hence, use of modified dryer by farmers are very rare. et al., 2001; Deka et al., 2003).

An indirect heating system, called ‘rocket stove dryer’ has recently

Solar dryer

been introduced in Nepal by the Netherlands Development

Organization (Stoep, 2010). It is a flue gas heating type of curing

system with less amount of smoke. This system is reported to have

produced quality large cardamom capsules.

The Spices Board of India has also developed a modified bhatti with

a 200 kg or 400 kg capacity. This modified bhatti uses heat that is

more evenly distributed to cure the cardamom and generate a higher

quality product and is accessible at a subsidized rate by the Spices

Board under the scheme of ‘Export Oriented Production and Post-

Harvest Improvement of Spices (Spices Board 2011).

Conclusion

Large cardamom capsules have great demand in the international

Figure 3. Solar dryer for large cardamom (Source : Seveda & market due to his pleasant aromatic odour, and flavor. It is a

Jhajharia 2012)). medicinal measure for throat troubles, congestion of lungs,

A solar dryer was designed, fabricated, and evaluated for drying of inflammation of eyelids, digestive disorders and in the treatment of

large cardamom (Amomum Subulatum) at College of Agricultural lung tuberculosis. Drying of capsules is generally done by the

Engineering and Post-Harvest Technology, (Central Agricultural traditional bhattis. Which greatly affect the quality (colour and oil

VOL. VII, ISSUE XXV, JAN 2018 MULTILOGIC IN SCIENCE ISSN 2277-7601

An International Refereed, Peer Reviewed & Indexed Quarterly Journal in Science, Agriculture & Engineering

content etc.) of capsules. These traditional Bhatti's are made of Oli, P. (2011). Post-Harvest Technology of Tea, Coffee and Spices,

locally available material. Now, many improved Bhatti's, gasifier, First Ed. Lalitpur Valley College, Nepal.

electric or diesel operated and solar dryer are designed by the Rao, V. G., Mande, S., & Kishore, V. V. N. (2001). Study of drying

research institutes. These dryers produce dried capsules that have a characteristics of large-cardamom. Biomass and Bioenergy, 20(1),

more attractive colour and larger volatile oil content. These improved 37-43.

dryers cost is more than the traditional bhatti’s, it is not being Sankar, V. A., (2017) Design and Development of Solar - Biomass

afforded by the small farmers. Also, due to lack of knowledge, the Hybrid Dryer for Large Cardamom Drying. [M.Tech thesis, Advisor-

farmers not used these improved dryers. Seveda, M.S.]. Sikkim, India: College of Agricultural Engineering

References and Post Harvest Technology, Ranipool.

Agnihotri, S., and Wakode, S. (2010). Antimicrobial Activity of Satyal, P., Dosoky, N. S., Kincer, B. L., & Setzer, W. N. (2012).

Essential Oil and Various Extracts of Fruits of Greater Cardamom. Chemical compositions and biological activities of Amomum

Indian Journal of Pharmaceutical Sciences, 72 (5): 655-657. subulatum essential oils from Nepal. Natural product

Anonymous, (2007). Proceedings of the Group Meeting Held on 06- communications, 7(9), 1233-1236.

112007. Tadong, Sikkim, India: Indian Cardamom Research Institute, Seveda, M. S., and Jhajharia, D., (2012) Design and performance

Regional Research Station. evaluation of solar dryer for drying of large cardamom (Amomum

Anonymous, (2015). Processing of Cardamom. My agriculture subulatum). Journal of Renewable and Sustainable Energy, 4(6),

information bank (Production Technology of Spices), 063129.

Avasthe, R.K., Singh, K.K., Tomar, J.M.S. (2001). Large Sharma, E., Sharma, R., Singh., K. K., and Sharma, G. (2000). A

cardamom (Amomum subulatum Roxb.) based agroforestry system for Boon of Mountains population: Large Cardamom Farming in the

production, resources conservation and livelihood security in Sikkim Sikkim Himalaya. Mountain Research and Development, 20(2):108-

Himalaya. Indian Journal of Soil Conservation. 39(2):155-160. 111.

Bisht, V.K., Negi, J.S., Bhandari, A.K. and Sundriyal, R.C. Sharma, G., Sharma, R., Sharma, E., (2009). Traditional

(2011). Amomum subulatum Roxb: Traditional, phytochemical and knowledge systems in large cardamom farming: Biophysical and

biological activities-An overview. African J Agric Res, 6(24): 5386- management diversity in Indian mountainous regions. Indian Journal

5390, of Traditional Knowledge 8(1):17–22.

Chempakam, B., and Sindhu, S. (2008). Large Cardamom. In: Singh, A. I., & Pothula, A. K., (2013). Postharvest processing of

Parthasarathy VA, Vhempakam B and Zachariah TJ (Eds.), large cardamom in the eastern Himalaya. Mountain Research and

Chemistry of Spices. CAB International, pp. 59-69. Development, 33(4), 453-462.

Deka, T. N., Biswas, A. K., Gopakumar, B., and Potty, S. N., Singh, K. A., Rai, R. N., & Bhutia, D. T. (1989). Large cardamom

(2003) Large cardamom curing through ICRI improved bhati. (Amomum subulatum Roxb.) plantation—An age-old agroforestry

Journal of Hill Research 16(1):57–60. system in Eastern Himalayas. Agroforestry systems, 9(3), 241-257.

Gautam, N., Bhattarai, R. R., Khanal, B. K. S., & Oli, P. (2016). Spices Board, (2011). Annual report 2009–2010. Cochin: Ministry of

Technology, chemistry and bioactive properties of large cardamom Commerce and Industry, Government of India.

(Amomum subulatum Roxb.): An overview. International Journal of http://www.indianspices.com/pdf/Spice-AR-2009-10-English.pdf.

Applied Sciences and Biotechnology, 4(2), 139-149, Stoep G. A. V., (2010). Enhancing Competitiveness of Nepal's Large

Gopal, K., Baby, C., & Mohammed, A. (2012). Amomum Cardamom Value Chain. Kathmandu, Nepal: SNV Netherlands

Subulatum Roxb: An overview in all aspects. International Research Development Organization.

Journal Pharmacy, 3(7), 96-99. Tamang, P. R. (2000). Theoretical design of an appropriate large

Gurudutt, K. N., Naik, J. P., Balasubrahmanyam, N., & cardamom (Amomum Subulatum Roxb.) drier at farm level in Nepal.

Dhanaraj, S. (2000) Packaging and storage studies on flue-cured Dissertation, B.Tech. (Food), Central Campus of Technology,

large cardamom (Amomum subulatum Roxb. Journal of Food Hattisar, Dharan.

Science and Technology, 37(6), 577-581. TERI [Tata Energy Research Institute], (2012). A New Curing

Hartkamp, A. D., (1993). Black Gold- A study on large cardamom Chamber for Large Cardamom. New Delhi, India: TERI.

in the Eastern Hills of Nepal. Report on a practical training, www.teriin.org/index.php? option = com case study& task =

Department of Agronomy, Department of Plant Taxonomy, details& sid=2.

Wageningen Agricultural University, Nederland, Vijayan, A. K., Chhetri, P., Gudade, B. A., and Parthasarathy, U.

Kapoor, I. P. S., Singh, B., Singh, G., Isidorov, V., & Szczepaniak, (2013). Scientific cultivation of large cardamom changing lifestyle -A

L. (2008). Chemistry, antifungal and antioxidant activities of success story. (Success story of Mr Augustine Lepcha, farmer from

cardamom (Amomum subulatum) essential oil and Kalimpong, Darjeeling district of West Bengal).

oleoresins. International Journal of Essential Oil Therapeutics, 2(1), Yadav, S., (2013). Cardamom cultivation, its effect in rural

29-40. livelihoods and its importance in international market. (M.Sc. thesis).

Madhusoodanan, K. J., and Rao, Y. S. (2001). Cardamom (large). Zala, K.V., (2002). Quality improvement of large cardamom using

In: Peter, K.V., editor. Handbook of Herbs and Spices, vol. 1. an advanced gasifier based dryer [Powerpoint].

Cambridge, United Kingdom: Woodhead, pp. 139. http://intranet.daiict.ac.in/~ranjan/rer/presentation/200231007.pdf.

Mande, S., Kumar, A., & Kishore, V. V. N., (1999). A study of

large-cardamom curing chambers in Sikkim. Biomass and

Bioenergy, 16(6), 463-473.

www.ycjournal.net NAAS Rating- 5.20 Impact factor-1.137 186

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Ordering Code ABB REF615Document4 pagesOrdering Code ABB REF615talaporri100% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 3512C Parts ManualDocument0 pages3512C Parts ManualGomez Gallardo Andres100% (1)

- Microsoft CEO Satya Nadella's Master Plan - Business Insider PDFDocument4 pagesMicrosoft CEO Satya Nadella's Master Plan - Business Insider PDFLove JainNo ratings yet

- Anton Ber Ce PresentationDocument24 pagesAnton Ber Ce Presentationarcher183No ratings yet

- VDA 4530 Disposable Small Load CarrierDocument32 pagesVDA 4530 Disposable Small Load CarrierEd RiNo ratings yet

- Esat - Review MatzDocument13 pagesEsat - Review Matzazakura_2000No ratings yet

- The Romancing of BastilaDocument3 pagesThe Romancing of BastilaBrandiNo ratings yet

- Tutorial Sheet - 1 On Design of Spring': Department of Mechanical EngineeringDocument2 pagesTutorial Sheet - 1 On Design of Spring': Department of Mechanical EngineeringSrimanthula SrikanthNo ratings yet

- Control of OSBF at Highveld SteelDocument6 pagesControl of OSBF at Highveld SteelAlina StoroshchukNo ratings yet

- ChE ReviewerDocument82 pagesChE ReviewerMichael Robert Gatdula SamarNo ratings yet

- Management of HondaDocument8 pagesManagement of HondafarhansufiyanNo ratings yet

- AnswerDocument35 pagesAnswerAmit JainNo ratings yet

- Moasa But 2 2017Document8 pagesMoasa But 2 2017BeatriceGhitaNo ratings yet

- PSV Presentation PDFDocument43 pagesPSV Presentation PDFmani2cronyNo ratings yet

- Solutions To In-Class Assignments (Chapter 1)Document3 pagesSolutions To In-Class Assignments (Chapter 1)smk1983No ratings yet

- DC Machines QuizDocument9 pagesDC Machines QuizDanny MartinNo ratings yet

- D 2511Document2 pagesD 2511Asep TheaNo ratings yet

- Lesson 7 - Power System Analysis and ControlDocument46 pagesLesson 7 - Power System Analysis and ControlBarun GhoraiNo ratings yet

- Virtual Reality (VR)Document7 pagesVirtual Reality (VR)Shynycia R.No ratings yet

- Chemical Epcon C8 Spit Bars Tec TD en 01Document4 pagesChemical Epcon C8 Spit Bars Tec TD en 01osama aNo ratings yet

- Cassandra Interview Questions AnswersDocument10 pagesCassandra Interview Questions AnswersAnonymous gqSpNAmlWNo ratings yet

- Container Cargo NotesDocument8 pagesContainer Cargo NotesdhaneshbhorNo ratings yet

- Globalisation and Education (Role and Skills of 21st Century Teacher)Document19 pagesGlobalisation and Education (Role and Skills of 21st Century Teacher)jrbajaoNo ratings yet

- User Manual User ManualDocument13 pagesUser Manual User ManualNeath MaroonNo ratings yet

- Excel FN SQRT SQRT (Number) Round ROUND (Number, Num - Digits)Document12 pagesExcel FN SQRT SQRT (Number) Round ROUND (Number, Num - Digits)sitti.aNo ratings yet

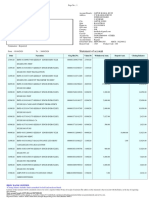

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument8 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceKeshav SinghNo ratings yet

- As 4600 Rel NoteDocument14 pagesAs 4600 Rel NoteDiana Ho WyNo ratings yet

- Lab 01 Brushed DC Motor (Permanent Magnet & Wound) : Prepared byDocument4 pagesLab 01 Brushed DC Motor (Permanent Magnet & Wound) : Prepared bychongzhenkhai8966No ratings yet

- South Africa's Economic DiplomacyDocument11 pagesSouth Africa's Economic DiplomacyVuyani LingelaNo ratings yet

- Creating Data Tables: Skills IntroductionDocument4 pagesCreating Data Tables: Skills Introductionjane deeNo ratings yet