Professional Documents

Culture Documents

Loop Test Sheet PDF

Loop Test Sheet PDF

Uploaded by

seif0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

LOOP TEST SHEET.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageLoop Test Sheet PDF

Loop Test Sheet PDF

Uploaded by

seifCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

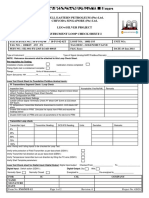

LOOP TEST SHEET

System: P&ID: Project:

Loop Number Description

Alarm Settings L= LL = H= HH =

Actual alarm values L= LL = H= HH =

Alarms needing reset

Post test statement Signed

The loop is installed as shown on the P&ID and loop YES NO

diagram

The loop will perform as designed YES NO

Field Labelling OK – N/A Instrument

Motor push buttons Air Isolation correct

Motors Accessible

Control/On-Off Valves Location correct per Loop diagram and P&ID

Instruments and cabel Input continuity check

Orifice Plates Calibration

Junction Box Range check with Control system

Marshalling Cabinet Loop direct/reverse action

DCS/PLC Panel Serial number correct

Local Panels State change OK on control system

General electrical wiring Control- On/Off valves

Other Position 0% = mA =

MCC Room Position 25% = mA =

Starters and push buttons Position 50% = mA =

Lighting suitable Position 75% = mA =

Accessibility of terminations Position 100% = mA =

Fuse/breaker lock box available Valve positioner operates correctly

Heating adequate State change OK on control system

Cooling adequate Fail position checked

Cabinet air fan acceptable?

Labels on cabinet door correct Interlock tested

Wires labeled

Cables labelled Documentation

Other Interlock data on loop and P&ID correct

DCS and or I/O Room All loop diagram data correct

DCS/PLC panels labelled Master copy red lines for final mark up

Termination panel access suitable Control room has copy until as built issued

Termination drawing suitable

Fuse in place

Motor

Megged/rating

Rotation

State change OK on control system

Signed for Instrument/Control / Electrical Date

Signed for process Date

You might also like

- Temperature MeasurementDocument33 pagesTemperature MeasurementTrí Nguyễn100% (1)

- 1.laboratory Cs3000 Eng FinalDocument142 pages1.laboratory Cs3000 Eng FinalTrí NguyễnNo ratings yet

- Loop Check Procedure PDFDocument8 pagesLoop Check Procedure PDFImran Nawaz Mehthal80% (5)

- Samples Instrumentation KKS EnglishDocument143 pagesSamples Instrumentation KKS EnglishTomuta StefanNo ratings yet

- Generator Set Installation Checklist-Open Generator SetDocument2 pagesGenerator Set Installation Checklist-Open Generator SetHaroon ZafarNo ratings yet

- Factsheet H Ergonomic Hazards-1030Document12 pagesFactsheet H Ergonomic Hazards-1030Trí NguyễnNo ratings yet

- DCS Commissioning StepsDocument14 pagesDCS Commissioning StepsElton Hove100% (1)

- 3210-8550-FS-0008 Foundation Fieldbus Functional RequrementDocument34 pages3210-8550-FS-0008 Foundation Fieldbus Functional Requrementsuhailfarhaan100% (2)

- LoopCheckProcedure E1Document3 pagesLoopCheckProcedure E1mc_prayer50% (2)

- Cold Loop CheckingDocument1 pageCold Loop CheckingZulkernain Omer TariqNo ratings yet

- Instrument Calibration ChecklistDocument11 pagesInstrument Calibration ChecklistMohd A IshakNo ratings yet

- 3.1 Fat Document BSL Tata Olp PLC SystemDocument6 pages3.1 Fat Document BSL Tata Olp PLC Systemkoushik42000No ratings yet

- PLC Panel Check ListDocument6 pagesPLC Panel Check ListPATEL AKASHNo ratings yet

- Foundation FieldbusDocument5 pagesFoundation FieldbusKarthik Selva100% (1)

- L1 Instrumentation CANDUDocument100 pagesL1 Instrumentation CANDUIonescu ViorelNo ratings yet

- Pre-Loop Check ProcedureDocument1 pagePre-Loop Check ProceduresithulibraNo ratings yet

- Loop Checking GuideDocument66 pagesLoop Checking Guidefazilpaf100% (5)

- Instrument Loop CheckDocument3 pagesInstrument Loop Checknayum100% (1)

- TroubleshootingDocument39 pagesTroubleshootingTrí NguyễnNo ratings yet

- I11c Instrument Close Loop Check PG 1Document1 pageI11c Instrument Close Loop Check PG 1Momo ItachiNo ratings yet

- 43 (Lecture - Instrumentation For P&ID's - Cookbook)Document55 pages43 (Lecture - Instrumentation For P&ID's - Cookbook)Trí NguyễnNo ratings yet

- 43 (Lecture - Instrumentation For P&ID's - Cookbook)Document55 pages43 (Lecture - Instrumentation For P&ID's - Cookbook)Trí NguyễnNo ratings yet

- CENTUM VP Fundamentals For Operation: Day 1 Training Module Code: VPOF Duration: 5 DaysDocument38 pagesCENTUM VP Fundamentals For Operation: Day 1 Training Module Code: VPOF Duration: 5 DaysJohn HowardNo ratings yet

- Yokogowa Centum VP Licence Manager Activation Step by Step PDFDocument25 pagesYokogowa Centum VP Licence Manager Activation Step by Step PDFseifNo ratings yet

- A.S. A. Ap117: (Instrument & Control Engineer) & Spi (Intools) Specialist ObjectiveDocument5 pagesA.S. A. Ap117: (Instrument & Control Engineer) & Spi (Intools) Specialist ObjectiveAkoKhalediNo ratings yet

- BESA SAT Procedure Rev 0 YokogawaDocument61 pagesBESA SAT Procedure Rev 0 YokogawaWan Mohd Fauzan bin Wan NawiNo ratings yet

- P-5000T - Loop Folder PDFDocument15 pagesP-5000T - Loop Folder PDFSrikant SuruNo ratings yet

- Instr Loop CheckDocument3 pagesInstr Loop CheckMiko Quijano100% (1)

- Specification For Cables Installation and MarkingDocument12 pagesSpecification For Cables Installation and Markingdon121don121No ratings yet

- Loop Checking and Field Instrument Testing ProcedureDocument7 pagesLoop Checking and Field Instrument Testing Procedurecharzree0% (1)

- Instrument Check ListDocument19 pagesInstrument Check ListFarhan KhanNo ratings yet

- Loop Check: Operator's GuideDocument21 pagesLoop Check: Operator's Guidemc_prayerNo ratings yet

- Loop Check Sheet Sol ValveDocument2 pagesLoop Check Sheet Sol Valveshanks263100% (1)

- DCS Commisioning StepsDocument7 pagesDCS Commisioning StepsJoven BabieraNo ratings yet

- Loop Checking Procedure IdeasDocument2 pagesLoop Checking Procedure IdeasJonatas13No ratings yet

- Instrumentation Switch ChecklistDocument5 pagesInstrumentation Switch Checklistrenjithv_4No ratings yet

- Control Loop Foundation OverviewDocument163 pagesControl Loop Foundation Overviewsubhu1981No ratings yet

- Spi FFDocument17 pagesSpi FFjose_johnNo ratings yet

- Loop Check Sheet TransmitterDocument2 pagesLoop Check Sheet Transmittershanks263100% (2)

- 9.9 Differential Pressure TransmittersDocument99 pages9.9 Differential Pressure TransmittersorazioconiglioNo ratings yet

- DCS Connector Board DetailDocument29 pagesDCS Connector Board Detailsajid789No ratings yet

- Hazira Site - Control Valve Calibration SheetDocument3 pagesHazira Site - Control Valve Calibration Sheet8103 Anshu Patil100% (1)

- Foundation Fieldbus TutorialDocument71 pagesFoundation Fieldbus Tutorialابزار دقیق100% (1)

- I-004 Control Valve Calibration RecordDocument1 pageI-004 Control Valve Calibration RecordAr RahmanNo ratings yet

- I Et 6000.67 0000 800 Pdy 001 eDocument178 pagesI Et 6000.67 0000 800 Pdy 001 epitucha_hs100% (1)

- Instrumentation CablesDocument1 pageInstrumentation Cablesrobinknit2009No ratings yet

- Loop CheckDocument9 pagesLoop Checkyangher100% (1)

- Commissioning of InstrumentationDocument16 pagesCommissioning of InstrumentationrajuNo ratings yet

- Commissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD SingaporeDocument52 pagesCommissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD Singaporesolo AdoNo ratings yet

- Loop Check and ValveDocument1 pageLoop Check and ValveMohd A IshakNo ratings yet

- Icl 009 PLC PanelDocument2 pagesIcl 009 PLC Panelsamwel kariukiNo ratings yet

- Resume of An Instrument Technician.Document5 pagesResume of An Instrument Technician.Sony John GeorgeNo ratings yet

- Analyzer Spare Part List 201216Document3 pagesAnalyzer Spare Part List 201216Jan Richardo GultomNo ratings yet

- Boiler Instrumentation and ControlsDocument23 pagesBoiler Instrumentation and Controlshayat umar bhat100% (4)

- En ACS580 Standard Control Program FW C A5Document440 pagesEn ACS580 Standard Control Program FW C A5joseNo ratings yet

- Apnedix 4 - Method Statement For Loop TestDocument11 pagesApnedix 4 - Method Statement For Loop TestShahid IqbalNo ratings yet

- PLCDocument2 pagesPLCnidhushan RNo ratings yet

- Modbus IntroDocument10 pagesModbus IntroArmando GarciaNo ratings yet

- Instruments Hookup BOQDocument2 pagesInstruments Hookup BOQSijo Joy100% (1)

- Control Loops TroubleshootingDocument3 pagesControl Loops TroubleshootingRahul ChandrawarNo ratings yet

- Deltav Scalable Process System Class I Division 2 Installation InstructionsDocument10 pagesDeltav Scalable Process System Class I Division 2 Installation InstructionsJesus Feria VillalobosNo ratings yet

- Model Work Place Check ListDocument5 pagesModel Work Place Check ListT S VirdiNo ratings yet

- Tender Synopsis (06.08.16)Document36 pagesTender Synopsis (06.08.16)Prashant MohokarNo ratings yet

- JKR Acmv Ahu PDFDocument4 pagesJKR Acmv Ahu PDFHafiz Abdullah50% (2)

- Erroor Code SamsungDocument5 pagesErroor Code SamsungZdravko PeranNo ratings yet

- MEP Systems Design RequirementsDocument1 pageMEP Systems Design Requirementssujan1980No ratings yet

- Sub-Contractor QA/QC Rep. Ak/Ihi Qa/Qc Rep. CLNG Rep.: by by by Date Date DateDocument1 pageSub-Contractor QA/QC Rep. Ak/Ihi Qa/Qc Rep. CLNG Rep.: by by by Date Date DateDeepakNo ratings yet

- Macurco CM6-FCK UserManualDocument4 pagesMacurco CM6-FCK UserManualTrí NguyễnNo ratings yet

- Appendix F: Engineering Standards Manual ISD 341-2Document3 pagesAppendix F: Engineering Standards Manual ISD 341-2Trí NguyễnNo ratings yet

- Pid Controller Design by Modified Ziegler-Nichols Method: M. Hypiusová, S. KajanDocument10 pagesPid Controller Design by Modified Ziegler-Nichols Method: M. Hypiusová, S. KajanTrí NguyễnNo ratings yet