Professional Documents

Culture Documents

QuickGuide Roundtest PDF

Uploaded by

Arvin BabuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QuickGuide Roundtest PDF

Uploaded by

Arvin BabuCopyright:

Available Formats

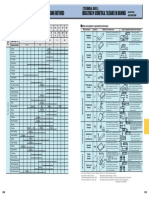

Quick Guide to Precision Measuring Instruments

Roundtest (Roundform Measuring Instruments)

■ JIS B 7451-1997: Roundness measuring instruments

■ JIS B 0621-1984: Definition and notation of geometric deviations

■ JIS B 0021-1998: Geometric property specifications (GPS) of products – Geometric tolerance

Roundness Straightness Flatness Cylindricity

Any circumferential line must be contained within Any line on the surface must lie within the The surface must be contained within the The surface must be contained within the

the tolerance zone formed between two coplanar tolerance zone formed between two parallel straight tolerance zone formed between two parallel tolerance zone formed between two coaxial

circles with a difference in radii of t lines a distance t apart and in the direction specified planes a distance t apart cylinders with a difference in radii of t

0.1 0.1

0.1

0.1

t

Notation example Notation example Notation example

t

t

Notation example

t

Tolerance zone

Tolerance zone

Tolerance zone

Inspection example Tolerance zone

Inspection example Inspection example

Inspection example

Concentricity Coaxiality Perpendicularity

The center point must be contained within the The axis must be contained within the tolerance The line or surface must be contained within the tolerance zone formed between two planes a

tolerance zone formed by a circle of diameter t zone formed by a cylinder of diameter t distance t apart and perpendicular to the datum

concentric with the datum concentric with the datum

A ø0.08 A

A 0.08 A

ø0.08 A A

A Notation Notation example Notation example

ø0.08 A

example

øt øt

Notation example øt

Datum A

Datum

center

t

Datum axis

Datum axis Tolerance zone

Tolerance zone Inspection example Inspection example Tolerance zone

Inspection example Tolerance zone

Inspection example

Circular Runout Total Runout

The line must be contained within the tolerance zone formed between two coplanar and/or concentric The surface must be contained within the tolerance zone formed between two coaxial cylinders with a

circles a distance t apart concentric with or perpendicular to the datum difference in radii of t, or planes a distance t apart, concentric with or perpendicular to the datum

Radial Runout 0.1 A Axial Runout 0.1 A

A

Total Radial Runout 0.1 A Total Axial Runout 0.1 A

A

A A

Notation example Notation Notation example

Notation

example example

t t

Datum axis Datum axis

t

t

Datum axis Datum axis

Inspection example Tolerance zone Inspection example Tolerance zone Inspection example Tolerance zone

Inspection example Tolerance zone

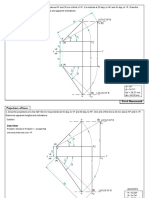

■ Adjustment prior to Measurement

Centering Leveling

A displacement offset (eccentricity) between the Roundtest's rotary table axis and that of the workpiece Any inclination of the axis of a workpiece with respect to the rotational axis of the measuring

results in distortion of the measured form (limaçon error) and consequentially produces an error in the instrument will cause an elliptic error. Leveling must be performed so that these axes are sufficiently

calculated roundness value. The larger the eccentricity, the larger is the error in calculated roundness. parallel.

Therefore the workpiece should be centered (axes made coincident) before measurement.

Some roundness testers support accurate measurement with a limaçon error correction function.

The effectiveness of this function can be seen in the graph below. 100

Effect of eccentricity compensation function

ø1mm

1000 ø200mm

ø2mm 10

θ ø100mm

ø5mm

ø50mm

Workpiece

Error due to inclination (µm)

ø10mm

100

ø20mm ø20mm

Workpiece

Dimeter D 1 ø10mm

Dimeter

ø50mm

Roundness error (µm)

ø100mm ø5mm

10

ø200mm ø2mm

0.1 ø1mm

1

0.01

0.1

Eccentricity 0.001

0.01 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

1 10 100 1000 D e

Eccentricity (µm) Inclination (degrees)

Figure: Eccentricity versus roundness error Figure: Inclination versus elliptic error

Quick Guide to Precision Measuring Instruments 42

Roundness Testing

■ Effect of Filter Settings on the Measured Profile ■ Undulations Per Revolution (UPR) data in

Roundness values as measured are greatly affected by variation of filter cutoff value.

It is necessary to set the filter appropriately for the evaluation required. the roundness graphs

Measurement result graphs

90

No filter ΔZq=22.14µm

Amplitude

180 0 0

0 90 180 270 360

270 Angle

A 1 UPR condition indicates eccentricity of the workpiece relative to the rotational

axis of the measuring instrument. The amplitude of undulation components

Low-pass ΔZq=12.35µm ΔZq=16.60µm ΔZq=20.72µm ΔZq=22.04µm

depends on the leveling adjustment.

filter

90

Amplitude

180 0 0

0 90 180 270 360

15 upr 50 upr 150 upr 500 upr

Band-pass ΔZq=17.61µm ΔZq=18.76µm ΔZq=14.50µm

270 Angle

filter

A 2 UPR condition may indicate: (1) insufficient leveling adjustment on the

measuring instrument; (2) circular runout due to incorrect mounting of the

workpiece on the machine tool that created its shape; (3) the form of the workpiece

is elliptical by design as in, for example, an IC-engine piston.

90

15-150 upr 15-500 upr 50-500 upr

Amplitude

180 0 0

■ Evaluating the Measured Profile Roundness

0 90 180 270 360

Roundness testers use the measurement data to generate reference circles whose dimensions define the roundness

value. There are four methods of generating these circles, as shown below, and each method has individual 270

Angle

characteristics so the method that best matches the function of the workpiece should be chosen.

A 3 to 5 UPR condition may indicate: (1) Deformation due to over-tightening of the

Least Square Circle Minimum Zone Circles Minimum Circumscribed Maximum inscribed holding chuck on the measuring instrument; (2) Relaxation deformation due to

(LSC) Method (MZC) Method Circle (MCC) Method Circle (MIC) Method stress release after unloading from the holding chuck on the machine tool that

A circle is fitted to the measured Two concentric circles are The smallest circle that can enclose The largest circle that can be created its shape.

profile such that the sum of the positioned to enclose the the measured profile is created. enclosed by the profile data is

squares of the departure of the measured profile such that their The roundness figure is then created. The roundness figure is

profile data from this circle is a radial difference is a minimum. defined as the maximum then defined as the maximum 90

minimum. The roundness figure is The roundness figure is then departure of the profile from this departure of the profile from this

then defined as the difference defined as the radial separation of circle. This circle is sometimes circle. This circle is sometimes

between the maximum departures these two circles. referred to as the ‘ring gage’ referred to as the `plug gage'

Amplitude

of the profile from this circle circle. circle.

(highest peak to the lowest 180 0 0

valley). 0 90 180 270 360

270

Angle

ΔZ ΔZ ΔZ ΔZ 90

q z c i

Rmin Rmin Rmin Rmin

Rmax Rmax Rmax Rmax

Amplitude

180 0

0

0 90 180 270 360

ΔZq = Rmax-Rmin ΔZz = Rmax-Rmin ΔZc = Rmax-Rmin ΔZi = Rmax-Rmin 270 Angle

A 5 to 15 UPR condition often indicates unbalance factors in the machining method

or processes used to produce the workpiece.

90

■ Traceability System for Roundform Measuring Instruments

(Traceability to PTB*)

Amplitude

180 0 0

0 90 180 270 360

PTB Calibration

Straightness PTB Calibration PTB Calibration PTB Calibration NMI

Master (600mm) Optical Flat Reference Hemisphere Cylindrical Square PTB mutual Accreditation

270 Angle

Mitutoyo Corporation 90

Miyazaki Plant NKO K107

Amplitude

180 0 0

Reference Calibration 0 90 180 270 360

Sphere Gauge Block

Measuring

Instrument

Calibration Tester 270 Angle

A 15 (or more) UPR condition is usually caused by tool chatter, machine vibration,

coolant delivery effects, material non-homogeneity, etc., and is generally more

<Z-axis/R-axis straightness> <Column parallelism> important to the function than to the fit of a workpiece.

90

<Rotational accuracy>

<Detector>

Axial direction Radial direction

Amplitude

Roundness/Cylindrical Geometry Measuring Instrument Reference Hemisphere Magnification Calibration Kit 180 0 0

0 90 180 270 360

*PTB: Physikalisch-Technische Bundesanstalt (Germany)

270 Angle

■ Stylus Tip 90

Ball type Cylinder type Axe type Egg type Tip shape: Ball, axe, cylinder,

Amplitude

R and egg

Tip radius : 0.25mm, 0.8mm, 180 0 0

R

R

r

2.5mm, 8mm, 25mm

r

r

0 90 180 270 360

r

r (tolerance: 30%

r

of the nominal value)

Measuring force: 250mN or less 270 Angle

43 Quick Guide to Precision Measuring Instruments

You might also like

- Surface Roughness by Different Processing MethodsDocument1 pageSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- Surface RoughnessDocument17 pagesSurface RoughnessShanmugi VinayagamNo ratings yet

- Metrology 1CDocument44 pagesMetrology 1CRadhaMadhavNo ratings yet

- New GD&TDocument3 pagesNew GD&TvasantNo ratings yet

- Geometric Dimensioning and TolerancingDocument7 pagesGeometric Dimensioning and TolerancingRamprasad T N100% (15)

- Geometric Dimensioning and TolerancingDocument6 pagesGeometric Dimensioning and TolerancingPedro LeosNo ratings yet

- Geometric Dimensioning and Tolerancing Visual GlossaryDocument23 pagesGeometric Dimensioning and Tolerancing Visual GlossarypdmnbraoNo ratings yet

- Geometric Dimensioning & Tolerancing (GD&T)Document43 pagesGeometric Dimensioning & Tolerancing (GD&T)Victor Manuel Estrada0% (1)

- Latest Report 2Document13 pagesLatest Report 2Piyush BariNo ratings yet

- Geometric Tolerance Class NotesDocument6 pagesGeometric Tolerance Class NotesEngineernadeemshahidNo ratings yet

- GD&TDocument5 pagesGD&TkbhattacNo ratings yet

- Bonus Tolerance - Formula & ExamplesDocument2 pagesBonus Tolerance - Formula & ExamplesSelvaraj Balasundram100% (1)

- F 5 Geo TolerancesDocument23 pagesF 5 Geo TolerancesRodrigo RomeroNo ratings yet

- GD&T Glossary and Resource - GD&T Symbols and TermsDocument4 pagesGD&T Glossary and Resource - GD&T Symbols and TermsMohammed Adil100% (1)

- Dimensional Engineering Seminar: Geometric Dimensioning and Tolerancing Variation Simulation ModelingDocument71 pagesDimensional Engineering Seminar: Geometric Dimensioning and Tolerancing Variation Simulation Modelingprasungovindan100% (1)

- GD&TDocument10 pagesGD&TShahed FacebookNo ratings yet

- Geometric Dimensioning and TolerancingDocument3 pagesGeometric Dimensioning and Tolerancingdesign12No ratings yet

- CHAP (35) 35 Engr Metrology & InstrumentationDocument4 pagesCHAP (35) 35 Engr Metrology & InstrumentationfarizanNo ratings yet

- GD&TDocument5 pagesGD&Travindra_2011No ratings yet

- Tolerance Stack Up Analysis What Is Stack Up Analysis?Document25 pagesTolerance Stack Up Analysis What Is Stack Up Analysis?Venkadakrishnan ThiagarajanNo ratings yet

- GD&T: Theory To Reality: Mission StatementDocument67 pagesGD&T: Theory To Reality: Mission StatementCharlie Tej100% (1)

- Engineering Metrology and Measurements N.V. Raghavendra L. KrishnamurthyDocument54 pagesEngineering Metrology and Measurements N.V. Raghavendra L. KrishnamurthyRandøm TalkìêsNo ratings yet

- Unit 1 - Metrology Basics, Elements in Measurements & Line and End StandardsDocument80 pagesUnit 1 - Metrology Basics, Elements in Measurements & Line and End StandardsShayan ChowdaryNo ratings yet

- Introduction To GDDocument8 pagesIntroduction To GDCatalin FinkelsteinNo ratings yet

- IIGDT - Tolerancing Optimization Examples With $ SignsDocument9 pagesIIGDT - Tolerancing Optimization Examples With $ Signsநளின் கான்No ratings yet

- Bias and Accuracy Definition PDFDocument7 pagesBias and Accuracy Definition PDFVallik TadNo ratings yet

- GD&T 1Document41 pagesGD&T 1Sai CharanNo ratings yet

- IATF1 6949- 2016 英文版 main std PDFDocument62 pagesIATF1 6949- 2016 英文版 main std PDFpunitg_2No ratings yet

- Fundamentals of Geometric Dimensioning & TolerancingDocument109 pagesFundamentals of Geometric Dimensioning & Tolerancingkiran.katsNo ratings yet

- To Study and Design A Helical Spring.Document6 pagesTo Study and Design A Helical Spring.Kartik BadalNo ratings yet

- Tolerances of Form (Form Errors) For A Hydraulic ValveDocument10 pagesTolerances of Form (Form Errors) For A Hydraulic ValveHycom Engineering India Pvt LtdNo ratings yet

- Geometrical Dimensioning and TolerenceDocument61 pagesGeometrical Dimensioning and TolerenceAd Man GeTigNo ratings yet

- Uncertainty Budget TemplateDocument4 pagesUncertainty Budget TemplateshahazadNo ratings yet

- Engineering Metrology and Measurements N.V. Raghavendra L. KrishnamurthyDocument26 pagesEngineering Metrology and Measurements N.V. Raghavendra L. KrishnamurthyRandøm TalkìêsNo ratings yet

- GD&T 1Document69 pagesGD&T 1JayanthiANo ratings yet

- Metrology: ME3190 Machine Tools and MetrologyDocument64 pagesMetrology: ME3190 Machine Tools and MetrologySujit MuleNo ratings yet

- The New Y14.5: We've Improved The Gold StandardDocument9 pagesThe New Y14.5: We've Improved The Gold StandardVignesh PanneerselvamNo ratings yet

- Orientation (GD&T)Document39 pagesOrientation (GD&T)Kishor kumar BhatiaNo ratings yet

- GD&T Position TolDocument204 pagesGD&T Position Toldramilt100% (2)

- First and Third Angle in Engineering DrawingDocument20 pagesFirst and Third Angle in Engineering DrawingChampionip4p100% (4)

- Lecture 5 - Form TolerancesDocument34 pagesLecture 5 - Form TolerancesSUNILNo ratings yet

- Surface Roughness Significance and SymboDocument18 pagesSurface Roughness Significance and SymboStefan NikolićNo ratings yet

- Statistical Constants FileDocument12 pagesStatistical Constants FileAnandhi ChidambaramNo ratings yet

- Selection of Cutting Tool Materials: CBN & PCDDocument24 pagesSelection of Cutting Tool Materials: CBN & PCDKarthick NNo ratings yet

- Flat Ness: Our Comprehensive List of GD&T SymbolsDocument29 pagesFlat Ness: Our Comprehensive List of GD&T SymbolsMidhilesh RavikindiNo ratings yet

- Geometrical Tolerances: Geometrical Tolerances On Drawing Precision Measurement of Geometrical TolerancesDocument30 pagesGeometrical Tolerances: Geometrical Tolerances On Drawing Precision Measurement of Geometrical Tolerancessohkimfai6340100% (3)

- GDT TutorialDocument76 pagesGDT TutorialSrk ChowdaryNo ratings yet

- ISO#TS 15530-1 2013 (E) - Character PDF DocumentDocument4 pagesISO#TS 15530-1 2013 (E) - Character PDF DocumentCamila QuidorneNo ratings yet

- Statistical Quality ControlDocument18 pagesStatistical Quality ControluzaimyNo ratings yet

- Grain SizeDocument12 pagesGrain SizeTejwinder S ChauhanNo ratings yet

- Roundtest (Roundform Measuring Instruments)Document1 pageRoundtest (Roundform Measuring Instruments)Durai NaiduNo ratings yet

- Form-Und Lagetoleranzen e PDFDocument1 pageForm-Und Lagetoleranzen e PDFnangkarak8201No ratings yet

- Form-Und Lagetoleranzen e PDFDocument1 pageForm-Und Lagetoleranzen e PDFirwanNo ratings yet

- Din Iso 1101 PDFDocument1 pageDin Iso 1101 PDFRafi deenNo ratings yet

- Form and Location Tolerances According To DIN ISO 1101Document1 pageForm and Location Tolerances According To DIN ISO 1101dullecncNo ratings yet

- Form and Location Tolerances According To DIN ISO 1101Document1 pageForm and Location Tolerances According To DIN ISO 1101quenmallory100% (1)

- pr1169 1170 PDFDocument1 pagepr1169 1170 PDFrahulmuleNo ratings yet

- Design Data BookDocument1 pageDesign Data BookVASIM MANSURINo ratings yet

- Isentropic Nozzles: - Apply Equations For Isentropic Flow With Area Change To NozzlesDocument3 pagesIsentropic Nozzles: - Apply Equations For Isentropic Flow With Area Change To Nozzlesengr_n_n_malikNo ratings yet

- IATF - International Automotive Task Force: IATF 16949:2016 - Frequently Asked Question (FAQ)Document19 pagesIATF - International Automotive Task Force: IATF 16949:2016 - Frequently Asked Question (FAQ)Arvin BabuNo ratings yet

- Microtec Technology en WebDocument1 pageMicrotec Technology en WebArvin BabuNo ratings yet

- Common Mistakes Commirtted in Statistical Process ControlDocument6 pagesCommon Mistakes Commirtted in Statistical Process ControlArvin BabuNo ratings yet

- Aiag Training Selection Tool 2017-05-26Document2 pagesAiag Training Selection Tool 2017-05-26Arvin BabuNo ratings yet

- Caterpillar Inc.: BackgroundDocument1 pageCaterpillar Inc.: BackgroundArvin BabuNo ratings yet

- Control of The Grinding Process Using In-Process Gage FeedbackDocument14 pagesControl of The Grinding Process Using In-Process Gage FeedbackArvin BabuNo ratings yet

- Sterling Gun Drills, Inc.: Gundrilling Guidelines: Gun Drilling On A CNC or Manual Lathe or MillDocument1 pageSterling Gun Drills, Inc.: Gundrilling Guidelines: Gun Drilling On A CNC or Manual Lathe or MillArvin BabuNo ratings yet

- Product Data Sheet Silicon Carbide Grinding Paper CA enDocument3 pagesProduct Data Sheet Silicon Carbide Grinding Paper CA enArvin BabuNo ratings yet

- Efficient Manufacturing India Surface Treatment TechDocument2 pagesEfficient Manufacturing India Surface Treatment TechArvin BabuNo ratings yet

- Self and Datum Referenced Form Measurements: George Schuetz, Mahr Federal IncDocument2 pagesSelf and Datum Referenced Form Measurements: George Schuetz, Mahr Federal IncArvin BabuNo ratings yet

- Comparison Chart US-Mesh vs. FEPADocument1 pageComparison Chart US-Mesh vs. FEPAArvin BabuNo ratings yet

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocument14 pagesMachining Processes Used To Produce Round Shapes: Turning and Hole MakingArvin BabuNo ratings yet

- Meister Top 10 Problems SolutionsDocument1 pageMeister Top 10 Problems SolutionsArvin BabuNo ratings yet

- Status of Standards 2013-09-05 FEPApublicDocument1 pageStatus of Standards 2013-09-05 FEPApublicArvin BabuNo ratings yet

- 35735Document1 page35735Arvin BabuNo ratings yet

- PerturbationsDocument7 pagesPerturbationsdeardestiny0% (1)

- ConcreteDocument14 pagesConcretevasudeva yasasNo ratings yet

- Sat CommDocument13 pagesSat CommKirstie Alley San JoseNo ratings yet

- Chapter 3 - Satellite - 20192020Document100 pagesChapter 3 - Satellite - 20192020Dhamirah MirahNo ratings yet

- GNAV Questions by LessonDocument83 pagesGNAV Questions by LessonLucasNo ratings yet

- Orbital MechanicsDocument47 pagesOrbital Mechanicsrvanande21No ratings yet

- Maintenance Manual Maintenance Manual Maintenance Manual Maintenance ManualDocument102 pagesMaintenance Manual Maintenance Manual Maintenance Manual Maintenance ManualЮрий. Б0% (1)

- Test Bank For Astronomy at Play in The Cosmos Preliminary EditionDocument14 pagesTest Bank For Astronomy at Play in The Cosmos Preliminary Editionloandung51cvzp100% (22)

- Kidder S. Q. & Haar T. H. - Satellite Meteorology (1995)Document465 pagesKidder S. Q. & Haar T. H. - Satellite Meteorology (1995)celso QueteNo ratings yet

- Un It V - Part2-Satellite, Multiple Access, Satellite Acccess (Spade, Tdme), Spread SpectrumDocument67 pagesUn It V - Part2-Satellite, Multiple Access, Satellite Acccess (Spade, Tdme), Spread Spectrumsivagami nithyaNo ratings yet

- Projection of LinesDocument10 pagesProjection of Linesmd musaib aliNo ratings yet

- EG TutorialDocument20 pagesEG TutorialSubramanian ManivelNo ratings yet

- Lecture 6 - Projection of Lines Inclined To HP and VP and Traces - Students PDFDocument55 pagesLecture 6 - Projection of Lines Inclined To HP and VP and Traces - Students PDFSivapriya M ANo ratings yet

- Interplanetary MFDDocument22 pagesInterplanetary MFDDasangNo ratings yet

- Science: SeasonsDocument24 pagesScience: SeasonsJan JanNo ratings yet

- Problems On Engineering Drawing 1st YearDocument30 pagesProblems On Engineering Drawing 1st YearKrishna AsharNo ratings yet

- Aryabhat Astronomy Quiz: The SunDocument16 pagesAryabhat Astronomy Quiz: The SunSamyak GuptaNo ratings yet

- Projectile On An Inclined PlaneDocument75 pagesProjectile On An Inclined PlaneBholu WhoopNo ratings yet

- Boomer l2d With ExplaneDocument130 pagesBoomer l2d With ExplaneAhmad83% (6)

- Orbiter ConfigDocument40 pagesOrbiter ConfigVirtual EntitiesNo ratings yet

- Wireless Communications Systems (DCS Unit-4)Document18 pagesWireless Communications Systems (DCS Unit-4)Mukesh100% (2)

- 06 Auxiliary ProjectionDocument16 pages06 Auxiliary Projectionamar BaroniaNo ratings yet

- Introduction To The Earth Tides: Michel Van CampDocument54 pagesIntroduction To The Earth Tides: Michel Van CampJahankeer MzmNo ratings yet

- Continuous Azimuth Measurement Fluctuation When Drilling North-South - 5675177 - 01Document11 pagesContinuous Azimuth Measurement Fluctuation When Drilling North-South - 5675177 - 01beicabNo ratings yet

- MCQs - Satellite CommunicationDocument26 pagesMCQs - Satellite Communicationshamsundar kulkarniNo ratings yet

- 1.5 Seasons 3D SEDocument6 pages1.5 Seasons 3D SEWyatt KesterNo ratings yet

- Stargazing 101 - Whirlwind Tour of Night SkyDocument36 pagesStargazing 101 - Whirlwind Tour of Night Skygeoholub100% (1)

- Projetion of Straight Line ProblemDocument3 pagesProjetion of Straight Line ProblemRajesh JunghareNo ratings yet

- Remote Sensing Satellites, Sensors and Their CharacteristicsDocument50 pagesRemote Sensing Satellites, Sensors and Their CharacteristicsMD Mostain BillahNo ratings yet