Professional Documents

Culture Documents

TA & TL Details

Uploaded by

Thamaraiselvan Ramadoss0 ratings0% found this document useful (0 votes)

975 views7 pagesReinforcement Tension Anchorage (TA) and Tension Lap (TL) details

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentReinforcement Tension Anchorage (TA) and Tension Lap (TL) details

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

975 views7 pagesTA & TL Details

Uploaded by

Thamaraiselvan RamadossReinforcement Tension Anchorage (TA) and Tension Lap (TL) details

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

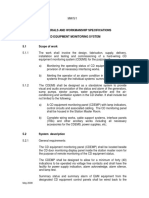

Appendix 3B Anchorage and lap lengths

(BS 8110, clause 3.12.8)

‘Table B1 Equivalent straight anchorage lengths of standard hooks & bends, mm

anchorage f bar size, mm

pe vatue_|Ninm?| 8 wy) 2 | wy % ) 3) wR)

tm 162 | 20 | 128 | 160 | 12 | 256 | 320 | 400 | siz | 610

24@ | 460 | 192 | 240 | 288 | 384 | 490 | co | 768 | 960

so | 20 | 6 | 9 | 96 | 128 | 160 | 200 | 256 | 320

re | 40 | 96 | 10 | 14 | 92 | 240 | 300 | 388 | 480

‘Table B2 Minimum overall depth of various U-bars, mm

shape code Bl rls bar size, mm

Nim? 8 10 2 16, 20 25 32 40,

eee, [| 250 | so | oo | 7 | 1 | 1 | iso | 195 | 240

TE 80 30 | 460 6 80 | oo | 130 [io | - | - [ -

. 109| 4 | 460 = = = = = 250 320 400

aia

aan 1o@[ 20 [250 [so | 100 | 120 | 10 | 20 | 250 | x0 | 400

fal a 120[ 3@| 400 | 100 | 120 | 14s | 195 [ 240 | - -

t wal ao] ao | - ~ f= 1 - | - 7 30 [450 [00

Tension laps (BS 8110, clause 3.12.8.13)

Tension laps should be at least equal in length to the anchorage

length necessary to develop the design stress in the bars. If the

lapped bars are of unequal size, then the lap length is based on the

size of the smaller bat. Furthermore:

() The tap lengths mnereased to 1.4 % anchorage length (see

” abies BA to BP) rien

() the minimum cover to lapped bars in the top ofa section

as cast is less than 2 % bar size, of

Ht \

Lapped bars

(i) the minimum cover to lapped corner bars (notin top) of

fa section is less than 2% bar size, or

<28.

<2 L joo

(i) the clear distance between adjacent laps is less than 75

‘mm or 6 % bar size. whichever Is greater

Struct Detailing Manual

<20:

<75 or <6

(b) “The lap length is increased to 2.0 x anchorage length (sce

©) Tabet wo BS) tfeonditions (a) () and (i) above apply

Compression laps (BS 8110. clause 3.12.8.15)

‘The length of the compression lap should be 1.25 x the

compression anchorage length necessary to develop the design

strexs in the bars (see Tables B4 (0 B7)

Lapping of bundled bars

(BS 8110, clause 3.12.4.1)

‘At laps no more than four bars may be in contact.

T T

top | top | tap

For bundles of three bars, laps should be staggered

‘Where bundles of two barss are lapped but not staggered, then the

lap length will be based on the equivalent diameter of the two

‘bars. Otherwise the lap length is based on the value of the single

bar.

IstructE Detailing Manual

a

Anchorage and lap lengths (BS 8110, clause 3.12.8)

(For lap lengths in accordance with BS 8007: 1987, see Section 9).

Grade 250 (mild-steel plain bar to BS 4449)

Design ultimate stress in tension or compressio

Design ultimate anchorage bond stress fy

eu. Nim 25 30 35 40

tension 4 | 153 | 166 | 7

compression fee) 1) ame) | ay || ret

0.87f, = 217.5 Ninn?

‘Table B3

size of bar, eam 8 10 2 16 2 25 32 40

tension anchorage = 0.87f, x D/fy., mm

25 310 390 465 620 715 975 ras 1555

fa | 285 355 25 570 70 885 1135 1420

fe a5 | 265 330 395 525 655 20 1050 BIS

0 245 310 370 490 65 770 ges | 1230

‘compression anchorage = 0.87f, x Di4fyy,. mm

25 250 310 375 500 20 75 995 Las

fa 25 285 340 455 565 70 10 135

fo 35, | 210 265 315 420 525 655 340 1030,

0 19s 24s 295 395 490 61s 785 985

tension lap = tension anchorage, 190 or 300 mm, whichever 1s greatest

25 310 390 465 620 ms 970 1245 1355

fa 0 300 355 25 570 710 885 1135 1420

f= 35 | 300 330 395 525 655 20 1050 BIS

0 300 305 370 490 615 70 985 1230

tension lap X 1.4 (BS 8110, clause 3.12.8.13)

2] 45 545 650 870 1085 1360 1740 2075

30 | 395 495 595 795 995 1240 1590 1985,

Son 35 370 460 550 735 920 1150 1870 1840

4o | 34s 430 515 60 860 1075 375-1 170

tension lap X 2.0 (BS 8110, clause 3.12.8.13)

25 20 7380 930 1240 1550 1940 2490 3110

fa 0 | 520 n0 850 1140 1420 170 270 2840

fos 35 530 660 790 1050 1310 1610 2100 2630

401 490 20 740 980 1230 1540 1970 2460

‘compression lap = compression anchorage x 1.25, 15 or 300 mm, whichever is the greatest

2 310 390 465 620 ms 970 1245 1555

30 | 300 355 25 570 710 885 1135 1420

fa 5 300 0 305 505 655 520 1050 131s

401 300 305 370 490 61s 770 985 1230

[Struc Detailing Manual

Anchorage and lap lengths (BS 8110, clause 3.12.8)

(For lap lengths in accordance with BS 8007: 1987, see Section 9).

Grade 460 (high yield deformed bar type 2 to BS 4449 and BS 4461)

Design ultimate stress in tension or compression = 0.87, = 400.2 N/mm?

Design ultimate anchorage bond stress fo,

Nims 30 35

tension 25, | 274 | 296 | 316

‘compression xis | 34s | 273 | 308

Table Ba

size of bar, men 8 10 2 16 20 25 22 0

tension anchorage = O.87f, x O/fn,, mm

25 | 320 400 480 40 800 1000 1280 1600

ae 290 365 440 585 730 91s 1170 1460

ioe 3s! 20 | 340 405 540 65 Bs 1080, 1385

0 25 | us 380 505 635 790 1010 12685

compression anchorage = 0.87f, x Gif, mm

25 255 320 380 50 @s 5 101s 1270

30 230 200 350 465 580 ns 930 1160

fu 35 210 270 320 430 335 670 860 1075

0 200 250 300 400 500 630 805 1005

tension lap = tension anchorage, 150 or 300 mm, whichever is greatest

25 320 400 40 | 640 800 1000 1280 1600

30 00 365 440 585 730 os 1170 1460

fou 35 300 340 40s 540 ers 845 1080, 1355

0 300 315 380 505 635 790 1010 1270

tension lap x 1.4 (BS 8110, clause 3.12.8.13)

25 450 CT 120 | 1400 1795 240

fa | 10 510 ols 20 12s | 1280 1635 208s

By 380 475 3 760 945 118s 155 1s9s

40 355 445 530 70 885 nos | 1770

tension lap x 2.0 (BS 8110, clause 3.12.8.13)

21 60 800 960 1280 1600 2000 2560 3200

fa | 585 730 875 1170 1460 1825 2340 22s

ee Sele 40) 675 810 1080 1355 1690 2165 20s

aol 505 635, 760 1010 1265 1580 2025 2530,

‘compression lap = compression anchorage X 1.25, 15 or 300 mm, whichever is the greatest

2% 320 300 475 as 795 995 1270 1500

30 300 360 435 580 75 905 1160 1430.

fo as, 300 335 405 535 670 40 1075 1340

40 | 300 315 375 ‘00 630 785 1005 1235

[struc Detailing Manual

Anchorage and lap lengths (BS 8110, clause 3.12.8)

(For lap lengths in accordance with BS 8007: 1987, see Section 9).

Grade 460 (plain wire to BS 4482)

Design ultimate stress in tension or compressio

Design ultimate anchorage bond stress fo

0.87f, = 400.2 Nima?

Table BS

size of bar, mm 5 6 i 8 9 10 R

tension anchorage = 0.87fy X Di4fiy. mm

25 355 80 500 570 os | 7s 860

fa 325 320 455, 585 650 785

fa 35 300 360 225 485 Sas 605 ns

0 230 340 395 450 S10 sos | gx

compression anchorage = 0.87, X ify. mm

25 285 345 400 455 sis 370 685

i. 2 260 315, 365 420 470 520 625

33 240 290 340 385, 435 485, 580

0 225 270 315 360 405 450 540

tension lap = tension anchorage, 150 or 300 mm whichever is greatest

2 355 480 500 370 os nis 860

a 325 390 435, 520 585 650 785

fn 35 300 360 425 485 545 605 25

40 300 340 395 450 510 565 680

tension lap x 1.4 (BS 8110, clause 3.12.8.13)

25 500 0 70 500 900 1000 1200

fe ® 455 350 640 730 1820 191s 095,

fw 35 25 505 590 615 760 4s 101s

40 395, 415 555, 635 7110 m | 950

tension lap x 2.0 (BS 8110, clause 3.12.8.13)

25 ns 860 1000 1145, 1285 | 1430 wis

fa 2 650 785 ois 1045 1175 1305 1565

fou 35, 605 ns 845 965 1085 | 1210 1450,

40 565 680 790 505 1015 1130 1355

compression lap = compression anchorage x 1.25, 150 or 300 mm. whichever is the greatest

28 385 430 soo sm | is ns 860

30 325 390 455, 520 585 650 785

fan 35 300 360 25 485, | 545 605 ns

” 300 340 385 450 510 565 680

Fd [truce Detailing Manual

Anchorage and Jap lengths (BS 8110, clause 3.12.8)

(For lap lengthsin accordance with BS 8007: 1987, see Section 9)

Grade 460 (deformed type 2 wire to BS 4482)

Design ultimate stress in tension or compression = 0.87, = 400.2 Nimm?

Design ultimate anchorage bond stress fx,

w | os | o

2m | 296 | S16

compression gas | 375 | 396

Table BS

size of bar, mm s 6 7 8 9 10 2

tension anchorage = O.87f, X fy, mm

25 200 | 240 280, 320 360 400 480,

30 185 20 255 230 330 363, Pr)

fu 35 170 205 } 25 270 305 340 405

a0 160 90 x0 a5 288 Ef 380

compression anchorage = O.87f, x Dif, im

25 10 | 1% 220 255, 285 x20 380

Fy us} 75 2os 0 280 0 350

fu 35 135 160, 190 215 240 20 320

0 mg de 5 200 2s 280 300

tension lap = tension anchorage, 152 or 300 mm whichever is greatest

25 300 | 300 300 320 360 400 480

fe | som 300 300 300 330 345, 40

je 35 | 300 300 300 300 30s 40 405

40 300 300 300 240 300, a5 380

tension lap x 1.4 (BS 6120, clause 3.12.8.13)

| 3m |S 390 450 50s 00 «0

x0 | 30 505 3a 410 460 510 as

Peale 35 ee 0) 300 330 380 425 495 370

ao! 30 | xo 310 aS 400 45 530

tension lap x 2.0 (BS 8110, cause 3.128.13)

2s | 400 480 seo 640 7 300 960

so | 365 a0 510 585 60 730 ws

fou 38 340 40s 475 540. 610 675 810

aol is 380 us Sus 570 a5 760

compression lap = compression anchorage X 1.25, 182 or 300 mm, whichever isthe greatest

3) 30 | aw 300 320 355 385 as

x0 | 300 30 x0 300 3 “00 455

fu 35 300 300 300 300 300 335 405

40 300 I 300 300 300 300 315 378

Struct Detailing Manual

Anchorage and lap lengths (BS 8110, clause 3.12.8)

(For lap lengths in accordance with BS 8007: 1987, see Section 9).

Grade 460 (welded wire fabric to BS 4483)

Design ultimate stress in tension or compression = 0.87f, = 400.2 Nimm?

Design ultimate anchorage bond ste fox

foxy Nit 25 30 35

tension 325 | 356 | 389 | aan

compression 405 | aad | 499 | Sin

Table B7

size of bar, mm 3 6 1 8 9 10 2

tension anchorage = 0.87f, x Zidfyy, mm

2 155 185 213 245 25 310 370

30 140 110 195 25 255 280 335

fu 35 130 155 180 210 25 260 310

0 20 145 470 195 20 245 290

‘compression anchorage = 0.87f, x D/4fy., mm

25 2s 150 115 200 20 245 295

30 ns 135 160, 180 205 25 270

fu 35 105 25 145 165 190 210 250

0 100 m> 185 bs 1s 195 235

tension lap = tension anchorage, but not less than 250 mm

25 250 250 250 250 25 310 370

fe ¥ 250 250 250 250 255 280 335

fu 35 250 250 250 250 250 260 310

0 250 250 250 250 250 250 230

tension lap X 1.4 (BS 8110, clause 3.12.8.13) but not less than 250 mm,

25 250 eo | 00 45 390 $30 sis

30 250 250 215 315 355 395 470

fa 35 250 250 255 290 30 365 435

40 250 250 250 25 305 340 410

tension lap x 2.0 (BS 8110, clause 3.12.8.13) but not less than 250 mm

25 310 370 430 495 555 ois 7140

30 280 335 395 450 505 360 615

fu 35 260 310 365 415 470 520 625

0 250 200 340 390 440 485 585

compression lap = compression anchorage * 1.25, but not less than 250 mm

25 250 250 20 | 250 380 310 370

30 250 250 250 250 2ss 220 340

fa 35, 250, 280 230 | 280 250 260 315

0 250 250 250 250 250 250 295

IstruetE Detailing Manual

You might also like

- CD M&W 2008 Ed - Sect 5 - CD Equipment Monitoring SystemDocument5 pagesCD M&W 2008 Ed - Sect 5 - CD Equipment Monitoring SystemThamaraiselvan RamadossNo ratings yet

- CD M&W 2008 Ed - Sect 7 - Sealing Devices - MCTsDocument25 pagesCD M&W 2008 Ed - Sect 7 - Sealing Devices - MCTsThamaraiselvan RamadossNo ratings yet

- CD M&W 2008 Ed - Sect 6 - CD Door Monitoring SystemDocument8 pagesCD M&W 2008 Ed - Sect 6 - CD Door Monitoring SystemThamaraiselvan RamadossNo ratings yet

- CD M&W 2008 Ed - Sect 4 - Dedicated CD ECS ComponentsDocument13 pagesCD M&W 2008 Ed - Sect 4 - Dedicated CD ECS ComponentsThamaraiselvan RamadossNo ratings yet

- CD M&W 2008 Ed - Sect 2 - CD Valves and PrefiltersDocument12 pagesCD M&W 2008 Ed - Sect 2 - CD Valves and PrefiltersThamaraiselvan RamadossNo ratings yet

- Shop Drawing For Catladder 50A, 50B, 51, 52 and Roof Access Hatch Details - W S2Document12 pagesShop Drawing For Catladder 50A, 50B, 51, 52 and Roof Access Hatch Details - W S2Thamaraiselvan RamadossNo ratings yet

- Shop Drawing Submission For CATLADDER 50A, 50B, 51 & 52 & Roof Access Hatch DetailADocument17 pagesShop Drawing Submission For CATLADDER 50A, 50B, 51 & 52 & Roof Access Hatch DetailAThamaraiselvan RamadossNo ratings yet

- Initiating Planning Executing Closing: Develop Project CharterDocument5 pagesInitiating Planning Executing Closing: Develop Project CharterThamaraiselvan Ramadoss100% (1)

- Reinforcing Detailing of RCCDocument40 pagesReinforcing Detailing of RCCThamaraiselvan Ramadoss100% (1)

- ScrewDocument1 pageScrewThamaraiselvan RamadossNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)