Professional Documents

Culture Documents

Celluveyor Flyer Eng 511765

Uploaded by

Tuan Anh Le CongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Celluveyor Flyer Eng 511765

Uploaded by

Tuan Anh Le CongCopyright:

Available Formats

What is the celluveyor? What are the benefits of celluveyor?

The Cellular Conveyor, abbreviated celluveyor, is The cellular design, the partly-distributed control,

a unique modular conveying and positioning and the unique omnidirectional capabilities bring a

system. It consists of several small hexagonal number of advantages:

conveying cells, each with three individually

• Outstanding layout flexibility: The cells

driven omnidirectional wheels. Through

can be combined to any layout. They can

individual control of the wheels, objects can be

be quickly added or removed.

freely conveyed in all directions and

• High process flexibility: The functionality

orientations.

of the system can be changed at any time

Due to its modular design, the cells can be easily by means of a simple software update.

combined into conveying surfaces with any • Reduction of maintenance costs: The cells

dimensions and shapes. Complex material flow can be replaced within minutes. The spare

applications can be performed on the celluveyor parts stock is reduced to a single item.

on minimal space. • High investment security: The system can

be adapted to the current order load. A

complete reuse of the cells for new tasks is

also possible.

• Reduction of the footprint: In comparable

applications, the celluveyor uses up to 80%

less footprint.

Which objects can be conveyed?

The celluveyor can convey objects of any size and

The intelligent control system automatically shape as long as the surface is flat.

recognizes the layout of the system and

• Object size: from 15 cm x 15 cm.

configures itself. A change in the layout is

• Maximum weight: depending on object size

automatically detected by the control software.

It self-reconfigures accordingly, which minimizes (e.g. package 20 cm x 30 cm approx. 90 kg).

downtime.

Can the celluveyor do more than Can I purchase the celluveyor today?

conventional conveyor technology?

The celluveyor is the result of research and

Due to the unique omnidirectional capabilities and development work at the BIBA - Bremen Institute

the individual control of the wheels, the celluveyor for Production and Logistics at the University of

can parallelize and even reverse conveying Bremen. The celluveyor is in the final phase of the

processes. This makes it a multifunctional system. development and is currently being extensively

For example, you can: tested with logistic partners. After completion of

this pilot phase, it will be available as a product.

Perform infeeding and descrambling for

palletizing and depalletizing applications

with only a single machine.

Do you have an application where traditional

Transform the inbound department into

systems come to their limits, or do you need

outbound department by running the

conveyor system backwards with a press of

more flexibility?

a button. We are looking for challenging applications in which

Enable novel sorting concepts. the advantages and the unique capabilities of the

Perform complex sequencing tasks. celluveyor come into play.

Rapid setup of material handling systems

If you are interested in using the celluveyor or

(for e.g. seasonal tasks).

would like to know more about this innovative

Design highly flexible manual workstations

technology, please do not hesitate to contact us!

and infeeding for commissioning stations.

And many others.

c/o BIBA – Bremer Institut für Produktion und Logistik GmbH

Hochschulring 20, 28359 Bremen | +49 421 218-50160 | hello@celluveyor.com

www.celluveyor.com

You might also like

- Microrobot StationDocument25 pagesMicrorobot StationXuân MạnhNo ratings yet

- Flexible and Agile Manufacturing SystemDocument49 pagesFlexible and Agile Manufacturing SystemSakshi SinghNo ratings yet

- Batching Job Shop BuffersDocument2 pagesBatching Job Shop BuffersSaad AliKhanNo ratings yet

- BMN Automation 2023 enDocument40 pagesBMN Automation 2023 enВладимирNo ratings yet

- Transfer Line Manufacturing SystemDocument5 pagesTransfer Line Manufacturing SystemSaad AliKhanNo ratings yet

- Hawe Medikal FloorlockDocument8 pagesHawe Medikal FloorlockHahaha HahahaNo ratings yet

- Agv Vs SDV Otto MotorsDocument6 pagesAgv Vs SDV Otto Motorsjornada660No ratings yet

- TQM Chapt 6Document4 pagesTQM Chapt 6Renz AlconeraNo ratings yet

- Types of LayoutDocument11 pagesTypes of LayoutArden OrpillaNo ratings yet

- Vidmar Vertical LiftDocument6 pagesVidmar Vertical LiftHartono ExcaNo ratings yet

- SimpfliedMachineDesign 05 30 FINAL White PaperDocument8 pagesSimpfliedMachineDesign 05 30 FINAL White PaperIgor FernandesNo ratings yet

- 2018 Applications Industry4Document123 pages2018 Applications Industry4Ridwan MerduNo ratings yet

- Facade Design Pattern Simplifies Complex InterfacesDocument32 pagesFacade Design Pattern Simplifies Complex InterfacesSathiya MoorthyNo ratings yet

- Determining The Best Split-Case Automated Order Fulfillment SystemDocument5 pagesDetermining The Best Split-Case Automated Order Fulfillment Systemyi jingNo ratings yet

- TYPES OF MANUFACTURING LAYOUTS AND THEIR FEATURESDocument9 pagesTYPES OF MANUFACTURING LAYOUTS AND THEIR FEATURESVivek ShaNo ratings yet

- Industrial Control and Automation AssignmentDocument3 pagesIndustrial Control and Automation AssignmentJoao CarvalhoNo ratings yet

- Sorting Transfer Vehicle: Automated Handling SolutionsDocument2 pagesSorting Transfer Vehicle: Automated Handling Solutionshi ahiNo ratings yet

- Progressive Bundle SystemDocument4 pagesProgressive Bundle SystemMeeta Arora100% (1)

- Manufacturing Types Comparison: Job Shop vs Cells vs Transfer LinesDocument574 pagesManufacturing Types Comparison: Job Shop vs Cells vs Transfer LinesSennheiserNo ratings yet

- Unit 1 - Elements of AutomationDocument20 pagesUnit 1 - Elements of AutomationGautham BVNo ratings yet

- Advanced Robotics in Fucture PDFDocument15 pagesAdvanced Robotics in Fucture PDFNPMYS23No ratings yet

- Cellular manufacturing: a lean system for grouping similar machinesDocument4 pagesCellular manufacturing: a lean system for grouping similar machinesPrashant AroraNo ratings yet

- Best of Mia Khalifa HDDocument5 pagesBest of Mia Khalifa HDWayne Ü TadiqueNo ratings yet

- JJJJJJLDocument3 pagesJJJJJJLcloui sjNo ratings yet

- Decentralized Control of Automatic Guided VehiclesDocument13 pagesDecentralized Control of Automatic Guided VehiclesAlanNo ratings yet

- iCUBE-Brochure-Electric-Carrier-yellow-2022-Digital-web-final-v1Document14 pagesiCUBE-Brochure-Electric-Carrier-yellow-2022-Digital-web-final-v1Mario ArrondoNo ratings yet

- Manufacturing Process: Job Shops / Intermittent ManufacturingDocument8 pagesManufacturing Process: Job Shops / Intermittent Manufacturingrahul rajNo ratings yet

- Browne - Clasification of FMSDocument4 pagesBrowne - Clasification of FMSRoberto ReyesNo ratings yet

- Flexible Manufacturing SystemsDocument12 pagesFlexible Manufacturing Systemssanketsavaliya7605No ratings yet

- Types of Production Systems A Production Manager Will Have To Choose TheDocument10 pagesTypes of Production Systems A Production Manager Will Have To Choose TheAfad KhanNo ratings yet

- Pref Ace: 1. Gain Scheduling: in This Method, Typically, The Full OperatingDocument6 pagesPref Ace: 1. Gain Scheduling: in This Method, Typically, The Full OperatingBiplab SatpatiNo ratings yet

- Engelsmann Vibration Sieves: Universal, Economic, Compact ScreeningDocument16 pagesEngelsmann Vibration Sieves: Universal, Economic, Compact ScreeningBagi84No ratings yet

- Dewatalks 64 - Introduction To Powerful Cloud Platform For Developers and DevOps From Dewacloud by Dewaweb PDFDocument25 pagesDewatalks 64 - Introduction To Powerful Cloud Platform For Developers and DevOps From Dewacloud by Dewaweb PDFDans LittNo ratings yet

- Screenranger SaDocument2 pagesScreenranger Saelsieazcuna024No ratings yet

- Logforum: Automatic Simulation Modelling of WarehousesDocument11 pagesLogforum: Automatic Simulation Modelling of WarehousesGabriela Jara RamosNo ratings yet

- Microsoft Word - Chapter3F-FmCellDocument5 pagesMicrosoft Word - Chapter3F-FmCellDrMohamed MansourNo ratings yet

- Unit 5Document61 pagesUnit 5mbatechindoreNo ratings yet

- MNE 3046 Part 1Document68 pagesMNE 3046 Part 1ChunMan SitNo ratings yet

- FlexSim TPDocument72 pagesFlexSim TPrajasekharjvNo ratings yet

- CC Unit-4Document16 pagesCC Unit-4vivek74543No ratings yet

- Unit 2Document64 pagesUnit 2piyush.foruppoNo ratings yet

- Modular Production SystemDocument2 pagesModular Production SystemamitnaskarNo ratings yet

- IESLCoE Robotics-Assignment - 2Document11 pagesIESLCoE Robotics-Assignment - 2kavish malakaNo ratings yet

- Robotic Systems: Flexible Parts Management - Fully IntegratedDocument20 pagesRobotic Systems: Flexible Parts Management - Fully IntegratedEduardo SilvaNo ratings yet

- ME3013 Chap 6Document9 pagesME3013 Chap 6pavetran raviNo ratings yet

- Automation Notes 1Document18 pagesAutomation Notes 1Harsh DwivediNo ratings yet

- Computer Integrated Manufacturing NotesDocument9 pagesComputer Integrated Manufacturing NotesRoshan RamnaniNo ratings yet

- Deadlock Avoidance For Multiple Tasks in A Self Organizing Production CellDocument10 pagesDeadlock Avoidance For Multiple Tasks in A Self Organizing Production CellsoniathalavoorNo ratings yet

- Automation Doc 1Document13 pagesAutomation Doc 1Shah Sajjan KumarNo ratings yet

- Robotics Unit-5 Question BankDocument6 pagesRobotics Unit-5 Question BankveerapandianNo ratings yet

- Chapter 2 Flexible Manufacturing CellDocument20 pagesChapter 2 Flexible Manufacturing CellDo Thi My LeNo ratings yet

- 3 ChenDocument13 pages3 ChenAnonymous PsEz5kGVaeNo ratings yet

- Operator Training Simulator BrochureDocument5 pagesOperator Training Simulator Brochuremaximusala83No ratings yet

- AA V2 I4 Multibody DynamicsDocument3 pagesAA V2 I4 Multibody DynamicsArnab DuttaNo ratings yet

- Automatic Conveyor SystemDocument24 pagesAutomatic Conveyor SystemMukeshpanigrahyNo ratings yet

- Engelsmann Folder-Vibrationssiebe E 140606 WEBDocument16 pagesEngelsmann Folder-Vibrationssiebe E 140606 WEBmaulanimeli89No ratings yet

- No Absen 25Document7 pagesNo Absen 25AliJunkoNo ratings yet

- 5886 EN Palletizing CellDocument2 pages5886 EN Palletizing Cellbernardo95No ratings yet

- Digital Control Engineering: Analysis and DesignFrom EverandDigital Control Engineering: Analysis and DesignRating: 3 out of 5 stars3/5 (1)

- Sicam Q80 V3.0 enDocument30 pagesSicam Q80 V3.0 enTuan Anh Le CongNo ratings yet

- FLIR Ex5Document2 pagesFLIR Ex5Agustin A.No ratings yet

- Clearer and Longer Operating Making Your Work Easier Tool-Like Thermal CameraDocument2 pagesClearer and Longer Operating Making Your Work Easier Tool-Like Thermal CameraTuan Anh Le CongNo ratings yet

- Battery: Test SolutionsDocument16 pagesBattery: Test SolutionsTuan Anh Le CongNo ratings yet

- TN, TT, ItDocument14 pagesTN, TT, ItTuan Anh Le CongNo ratings yet

- Dewesoft Product Catalog en LatestDocument148 pagesDewesoft Product Catalog en LatestTuan Anh Le CongNo ratings yet

- A 1632 Emobility Analyser: Other Instruments / Adapters / AccessoriesDocument2 pagesA 1632 Emobility Analyser: Other Instruments / Adapters / AccessoriesTuan Anh Le CongNo ratings yet

- Cat Catgen2021web En1-00xlDocument94 pagesCat Catgen2021web En1-00xlTuan Anh Le CongNo ratings yet

- Operating Instructions: Winding AnalyserDocument226 pagesOperating Instructions: Winding AnalyserTuan Anh Le CongNo ratings yet

- Power Clamp Meter MD 9240: Delivery Package Delivery PackageDocument2 pagesPower Clamp Meter MD 9240: Delivery Package Delivery PackageTuan Anh Le CongNo ratings yet

- Track 202 Antenna PlacementDocument72 pagesTrack 202 Antenna PlacementbinhmaixuanNo ratings yet

- Power Analyzer: Welcome To The Dewesoft Experience. One Software, One Hardware, One SolutionDocument28 pagesPower Analyzer: Welcome To The Dewesoft Experience. One Software, One Hardware, One SolutionTuan Anh Le CongNo ratings yet

- MD 9016 Digital Multimeter 40-Function Field Service ToolDocument2 pagesMD 9016 Digital Multimeter 40-Function Field Service ToolTuan Anh Le CongNo ratings yet

- Bite 3: Instruction ManualDocument42 pagesBite 3: Instruction ManualTuan Anh Le CongNo ratings yet

- MD 9250 Industrial TRMS AC/DC CAT IV 1000 V: Curr Ent ClampDocument2 pagesMD 9250 Industrial TRMS AC/DC CAT IV 1000 V: Curr Ent ClampTuan Anh Le CongNo ratings yet

- Single 2016 MD 9231 Current Clamp AngDocument2 pagesSingle 2016 MD 9231 Current Clamp AngTuan Anh Le CongNo ratings yet

- Bite 3: Instruction ManualDocument46 pagesBite 3: Instruction ManualTuan Anh Le CongNo ratings yet

- Ficha Técnica Ducter MedicionesDocument2 pagesFicha Técnica Ducter MedicionesYAIRNo ratings yet

- CAT IV 1000V TRMS Digital Multimeter MD 9040Document2 pagesCAT IV 1000V TRMS Digital Multimeter MD 9040Tuan Anh Le CongNo ratings yet

- Mi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsDocument2 pagesMi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsTuan Anh Le CongNo ratings yet

- Digital Multimeters/Clamp Meters/Voltage and Continuity TestersDocument1 pageDigital Multimeters/Clamp Meters/Voltage and Continuity TestersTuan Anh Le CongNo ratings yet

- Hy Automation Drs L Operation Manual 1 en DataDocument45 pagesHy Automation Drs L Operation Manual 1 en DataArmoos OsmoarNo ratings yet

- MI 3201 - TeraOhm 5 kV Plus Insulation TesterDocument2 pagesMI 3201 - TeraOhm 5 kV Plus Insulation TesterCitlali GordilloNo ratings yet

- GLG Profile - Sep 2019 (REV) PDFDocument15 pagesGLG Profile - Sep 2019 (REV) PDFTuan Anh Le CongNo ratings yet

- Single 2011 MI 3200 TeraOhm 10 KV AngDocument2 pagesSingle 2011 MI 3200 TeraOhm 10 KV AngTuan Anh Le CongNo ratings yet

- MI 2893 - Power Master XT ANG Ver 1.2.3 20752835Document226 pagesMI 2893 - Power Master XT ANG Ver 1.2.3 20752835Tuan Anh Le CongNo ratings yet

- Autonomous Maintenance Standards & ChecklistDocument4 pagesAutonomous Maintenance Standards & ChecklistPanch BNo ratings yet

- Apollo 11 Lunar Sample Information CatalogueDocument478 pagesApollo 11 Lunar Sample Information CatalogueBob AndrepontNo ratings yet

- 320B 322B 325B Excavator Hydraulic SystemDocument2 pages320B 322B 325B Excavator Hydraulic Systemwtn201390% (21)

- Chemistry Form 4 Chapter 9Document6 pagesChemistry Form 4 Chapter 9Suriati Bt A Rashid100% (1)

- Hot Vs ColdDocument3 pagesHot Vs ColdHarisma Nugraha100% (1)

- Em MCQ SDocument5 pagesEm MCQ SmNo ratings yet

- Ventilation: MDM Nurul Aini/Qus 3206Document22 pagesVentilation: MDM Nurul Aini/Qus 3206Anisha NaiduNo ratings yet

- Febco DCD and DC 850 856 870 and 876Document12 pagesFebco DCD and DC 850 856 870 and 876Brandon TrocNo ratings yet

- NTN Bearing en AllDocument411 pagesNTN Bearing en Allbhupinder85No ratings yet

- Make No Entries Where Font Is Bold. These Are Formulas: Enter Numbers Under Yellow Cells OnlyDocument3 pagesMake No Entries Where Font Is Bold. These Are Formulas: Enter Numbers Under Yellow Cells Onlyerwin sarmientoNo ratings yet

- Helwig-Effect of Spring Pressure On Brush Wear Rate - Nov 08Document8 pagesHelwig-Effect of Spring Pressure On Brush Wear Rate - Nov 08Rohan KallaNo ratings yet

- Presentation Bio PlastDocument53 pagesPresentation Bio PlastbabuNo ratings yet

- Port of GeorgetownDocument10 pagesPort of GeorgetownTajae HarripersadNo ratings yet

- Em306 User ManualDocument2 pagesEm306 User ManualMohammed Ibrahim100% (1)

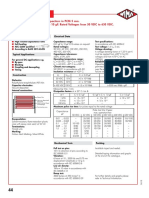

- E WIMA MKS 2Document9 pagesE WIMA MKS 2Guntara WigunaNo ratings yet

- MST Ped Overview UsDocument4 pagesMST Ped Overview UsedgarNo ratings yet

- Bolt On Turbo Kit for Honda Fit GD3Document4 pagesBolt On Turbo Kit for Honda Fit GD3GHow LeeNo ratings yet

- Shaft diameter and critical speed analysis of a Pelton turbineDocument58 pagesShaft diameter and critical speed analysis of a Pelton turbineBryan NanaNo ratings yet

- PC400LC 7eoDocument312 pagesPC400LC 7eoMichael Tiboche100% (1)

- IM Direct and Smelting Reduction Process PDFDocument10 pagesIM Direct and Smelting Reduction Process PDFRezki AshidiqiNo ratings yet

- MG586 Carry Deck Cranes System Set Up Manual W458206Document28 pagesMG586 Carry Deck Cranes System Set Up Manual W458206Juan SalvatierraNo ratings yet

- Rencana Anggaran Biaya (Rab) : Pekerjaan Musholla, Kanopi Curah Dari Finish Bin, Paving Block Dan Sumur TradisionalDocument10 pagesRencana Anggaran Biaya (Rab) : Pekerjaan Musholla, Kanopi Curah Dari Finish Bin, Paving Block Dan Sumur TradisionalWillie SudhantaNo ratings yet

- RoB Cost Estimates For Alt - 1, 63m Bowstringer GirderDocument10 pagesRoB Cost Estimates For Alt - 1, 63m Bowstringer GirderHegdeVenugopal100% (1)

- Sunica Ni-Cd Battery Technical ManualDocument29 pagesSunica Ni-Cd Battery Technical ManualKHAYAM1982No ratings yet

- Effect of The Use of Ceramic Filters in Steel CastingDocument6 pagesEffect of The Use of Ceramic Filters in Steel CastingJavier Escalante VillanuevaNo ratings yet

- Deadman Block Design for Guided WiresDocument8 pagesDeadman Block Design for Guided WiresgiovanniNo ratings yet

- Geothermal Energy PowerpointDocument19 pagesGeothermal Energy PowerpointgilangNo ratings yet

- Beta Analytic Presentation About Biogenic CO2Document26 pagesBeta Analytic Presentation About Biogenic CO2Beta AnalyticNo ratings yet

- RWPR 900 Pellet Mill BrochureDocument4 pagesRWPR 900 Pellet Mill Brochuregrupa2904No ratings yet

- Setup guide for Oneal Audio amplifiersDocument11 pagesSetup guide for Oneal Audio amplifiersGuto LiberatoNo ratings yet