Professional Documents

Culture Documents

Th-130 Universal Hardness Tester

Uploaded by

Juan CarlosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Th-130 Universal Hardness Tester

Uploaded by

Juan CarlosCopyright:

Available Formats

UNIVERSAL HARDNESS TESTER TH-130 “IMPACT-D” TM

Handheld dynamic metal hardness tester TH-130

Dynamic rapid hardness test procedure

Impact device D integrated: no cables!

Wide measuring range

Direct display of hardness scales Rockwell HRB, HRC,

Vickers HV, Brinell HB, Shore HS, Leebs HLD

For all metallic materials

Provides testing at any angle, even upside down

Simple handling and low test expenditure

High accuracy ±0.5%

Clear LCD display showing all functions and parameters

Conforms to ASTM A 956

Data output RS-232 (Dataview software DV130 optional)

Optional printer TA-220 available

Material HLD HRC HRB HRA HB HV HS

Steel and cast steel 300-900 20-68 39-100 59-86 81-654 81-955 32-100

Cold work tool steel 300-840 20-67 - - - 80-898 -

Stainless steel 300-800 20-62 46-101 - 85-655 85-802 -

Grey cast iron 360-650 - - - 93-334 - -

Nodular cast iron 400-660 - - - 131-387 - -

Cast aluminium alloys 200-570 - 24-34 - 27-164 - -

Brass 200-550 - 13-95 - 40-173 - -

Bronze 300-700 - - - 60-290 - -

Copper 200-690 - - - 45-315 - -

The ranges are stipulated by the application limits of the relevant static procedure

Technical specifications Standard delivery

Main unit with integrated

Hardness parameter HLD, HRC, HRB, HRA, HV, HB, HS impact device type D

Measuring range/metallic materials See table above Test block with HLD-value

Charger

Accuracy Within ±6HLD Cleaning brush

Statistics Average (max. 99) Coupling paste

Output RS-232 (Dataview software optional) Pocket protection case

Min. Surface roughness of workpiece 1.6µm (Ra) Data cable

Impact device D (standard) integrated Certificate

Manual

Workpiece max. hardness value 900HLD Plastic carrying case

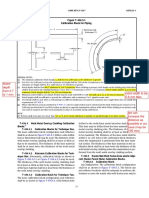

Workpiece radius (convex/concave) Rmin = 50mm (with support ring Rmin= 10mm)

Workpiece minimum weight 2kg-5kg on solid support Optional accessories

(0.05kg-2kg with couplant paste) Test blocks UKAS certified with any

Workpiece min. thickness coupled 5mm hardness parameter

Workpiece min. case hardened depth 0.8mm Support rings for convex and

Indentation depth See page: Impact devices data concave surfaces

Dataview software

Power Rechargeable battery NiMH 3.6V, 70mAh Printer TA-220

Charger 9V, 200mA (1.8VA) See page accessories for

Charging time 8 hours IMPACT-series

Operating temperature 0°C to 40°C

Overall dimensions 155mm x 24mm x 55mm

Weight 180gr

WWW.CVI-EUROPE.COM © 2008 CV INSTRUMENTS EUROPE BV

ACCESSORIES FOR IMPACT SERIES TM

TEST BLOCK D

TA-510

For performance tests of IMPACT series a test block D is available

(HLD hardness value). Tolerance allowed is ±6 units HLD.

Values too low: impact device dirty.

Value too high: spherical test tip flattened, or test block impacted all over.

Optional : similar test block D but UKAS certified according to any

hardness scale such as HRC or HV for traceable reference.

MINI-PRINTER TA-220 COUPLANT

Reliable and fast mini-printer with quality EPSON print head and clear Light parts can be coupled to a solid base plate using a thin layer

LCD display, RS-232 interface. Optional data cable TA-510 to IMPACT of coupling paste.

series available. Prints all numerical IMPACT hardness test data direct Both contact surfaces must be perfectly flat.

real-time or per batch after testing.

SUPPORT RINGS DATAVIEW FOR IMPACT TH-130

On curved surfaces having a radius of under 30mm, effective positioning User friendly Windows software for IMPACT TH-130 version 2.0.

on the component is facilitated by the use of support rings. For hardness data processing, graphical representation, real time limit

This ring can be screwed on front of the impact device. exceeding alarm, statistical data, database.

Direct display on computer in any available hardness scale in IMPACT

We offer a set of 7 rings: TH-130. Connection of IMPACT TH-130 to computer with data cable.

convex model 10mm-15mm / 14.5mm-30mm / 25mm-50mm,

concave model 11mm-13mm / 12.5mm-17mm / 16.5mm-30mm,

universal model.

WWW.CVI-EUROPE.COM © 2008 CV INSTRUMENTS EUROPE BV

You might also like

- Bs en 12668 3 2000 NDT Ut Equipment PT 3 Combined Equipment CompressDocument14 pagesBs en 12668 3 2000 NDT Ut Equipment PT 3 Combined Equipment CompressSalvador AguileraNo ratings yet

- EN 1043-2 Micro Hardness TestDocument13 pagesEN 1043-2 Micro Hardness TestMadley RockNo ratings yet

- BS EN 1559 - 2 (Founding Steel, 2000)Document27 pagesBS EN 1559 - 2 (Founding Steel, 2000)John BoranNo ratings yet

- Metal matrix composites: Processing and InterfacesFrom EverandMetal matrix composites: Processing and InterfacesR EverettNo ratings yet

- Amorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryFrom EverandAmorphous and Nano Alloys Electroless Depositions: Technology, Composition, Structure and TheoryNo ratings yet

- Curso Eddy Current PDFDocument300 pagesCurso Eddy Current PDFsgsdgsdNo ratings yet

- ASTM E 1065-1999 (R 2003) - Standard Guide For Evaluating Characteristics of Ultrasonic Search UnitDocument23 pagesASTM E 1065-1999 (R 2003) - Standard Guide For Evaluating Characteristics of Ultrasonic Search UnitKhemaraj PathmalingamNo ratings yet

- Piping TCG Caliberation BlockDocument1 pagePiping TCG Caliberation BlockAhmed Abd ElmegeedNo ratings yet

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- Non-Oriented Fully Process Electrical Steel - ASTMDocument28 pagesNon-Oriented Fully Process Electrical Steel - ASTMhpham2005No ratings yet

- American Society For Nondestructive Testing: RECOMMENDED PRACTICE No. SNT-TC-1A (1968 Edition)Document5 pagesAmerican Society For Nondestructive Testing: RECOMMENDED PRACTICE No. SNT-TC-1A (1968 Edition)ibnu.asad984No ratings yet

- Sherwin Mat GuideDocument2 pagesSherwin Mat GuideMiguel AngelNo ratings yet

- Failure Analysis of A Machinable Brass Connector in A Boiler Unit InstallationDocument6 pagesFailure Analysis of A Machinable Brass Connector in A Boiler Unit InstallationAnnisa RakhmawatiNo ratings yet

- SMS-603-UT-003 Ultrasonic - API 1104 - B31.8 - Rev 3 PDFDocument20 pagesSMS-603-UT-003 Ultrasonic - API 1104 - B31.8 - Rev 3 PDFDewAngga YudistiraNo ratings yet

- Electromagnetic (Eddy Current) Examination of Seamless and Welded Tubular Products, Titanium, Austenitic Stainless Steel and Similar AlloysDocument4 pagesElectromagnetic (Eddy Current) Examination of Seamless and Welded Tubular Products, Titanium, Austenitic Stainless Steel and Similar Alloysfredy lopezNo ratings yet

- The ABC's of Nondestructive Weld ExaminationDocument10 pagesThe ABC's of Nondestructive Weld Examinationlethanhhai0306No ratings yet

- E164-97 UT Contact Examination of WeldmentsDocument23 pagesE164-97 UT Contact Examination of WeldmentsALP69No ratings yet

- TB10 Download Datablad Eng PDFDocument2 pagesTB10 Download Datablad Eng PDFDanny Milton Silva VasquezNo ratings yet

- NiCr Test Panels - Product Data Sheet - English PDFDocument1 pageNiCr Test Panels - Product Data Sheet - English PDFஅன்புடன் அஸ்வின்No ratings yet

- Astm E165-NdtDocument20 pagesAstm E165-NdtbaladiroyaNo ratings yet

- Vallen AE AccesoriesDocument11 pagesVallen AE AccesoriesSebastian RozoNo ratings yet

- Mil STD 1501bDocument12 pagesMil STD 1501bJuan Pablo ToroNo ratings yet

- AISI Type 430Document3 pagesAISI Type 430Agus MulyadiNo ratings yet

- Ultrasonic Comparison SNR PDFDocument78 pagesUltrasonic Comparison SNR PDFsoledenseNo ratings yet

- RepairDocument0 pagesRepairPatricio TamayoNo ratings yet

- PW3Document49 pagesPW3Mujaffar ShaikhNo ratings yet

- Test Methods For Textile Fibres With Textile LabDocument5 pagesTest Methods For Textile Fibres With Textile LabRezaul Karim TutulNo ratings yet

- Acceptance Criteria For Weld Defects - Welding & NDTDocument11 pagesAcceptance Criteria For Weld Defects - Welding & NDTKevin ThomasNo ratings yet

- E545-99 Neutron Image QualityDocument4 pagesE545-99 Neutron Image QualityaboutdestinyNo ratings yet

- Radiograph Interpretation - CastingsDocument7 pagesRadiograph Interpretation - Castingshumayun mdNo ratings yet

- Identification of Weld DiscountinuitiesDocument42 pagesIdentification of Weld DiscountinuitiesAhmed shabanNo ratings yet

- CH-24-Stainless Steel Notes PDFDocument7 pagesCH-24-Stainless Steel Notes PDFArvind RaguNo ratings yet

- Steel Plates For Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)Document10 pagesSteel Plates For Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)Sama UmateNo ratings yet

- CVD 1 PDFDocument11 pagesCVD 1 PDFpichonsisimoNo ratings yet

- Tool Life and MachinabilityDocument23 pagesTool Life and MachinabilitySairamRamakrishnanNo ratings yet

- Ferrit Tartalom A Hegesztesi VarratbanDocument1 pageFerrit Tartalom A Hegesztesi Varratbanmkh1985No ratings yet

- Angle Gloss MeterDocument4 pagesAngle Gloss Meterlisun008No ratings yet

- E 310 - 99 - Rtmxma - PDFDocument4 pagesE 310 - 99 - Rtmxma - PDFUpul Eranda AbeyrathnaNo ratings yet

- E127 15 PDFDocument9 pagesE127 15 PDFDaniel Mauricio Prieto ValderramaNo ratings yet

- UOP952Document12 pagesUOP952goodcharacter1No ratings yet

- B703 Standard Test For Apparent Density by Arnold MeterDocument3 pagesB703 Standard Test For Apparent Density by Arnold MeterakjeevananthamNo ratings yet

- B343 92a Reapproved 2014 PDFDocument3 pagesB343 92a Reapproved 2014 PDFNinad PawarNo ratings yet

- Tool Wear MechanismDocument8 pagesTool Wear Mechanismnduvu1050% (2)

- Section 05505 METAL FABRICATIONS PDFDocument13 pagesSection 05505 METAL FABRICATIONS PDFIm ChinithNo ratings yet

- Astm E2491 06Document13 pagesAstm E2491 06phanthanhhungNo ratings yet

- Relationship Between Tool Flank Wear Area and Component Forces in Single Point TurningDocument6 pagesRelationship Between Tool Flank Wear Area and Component Forces in Single Point TurningAniruddha GuptaNo ratings yet

- Selection of Leak Testing Method PDFDocument3 pagesSelection of Leak Testing Method PDFdcsamaraweeraNo ratings yet

- Knoop and Vickers Hardness of Materials: Standard Test Method ForDocument43 pagesKnoop and Vickers Hardness of Materials: Standard Test Method ForDiana Gaviria MurilloNo ratings yet

- Standard Test Method For Coefficient of Linear Thermal Expansion of Plastics Between 30°C and 30°C With A Vitreous Silica Dilatometer 1Document6 pagesStandard Test Method For Coefficient of Linear Thermal Expansion of Plastics Between 30°C and 30°C With A Vitreous Silica Dilatometer 1Gaurav KumarNo ratings yet

- Surface Roughness TesterDocument6 pagesSurface Roughness TesterLingga SetiawanNo ratings yet

- E2014-Metallographic Laboratory SafetyDocument8 pagesE2014-Metallographic Laboratory SafetyGeorgon MontoyaNo ratings yet

- Sales Presentation - OmniScan SX-R1Document41 pagesSales Presentation - OmniScan SX-R1M. R. Shahnawaz KhanNo ratings yet

- BS en 10258-1997Document12 pagesBS en 10258-1997david13andreiNo ratings yet

- Evaluation of Welding Properties of Construction Materials Using The SEP 1390 TestsDocument7 pagesEvaluation of Welding Properties of Construction Materials Using The SEP 1390 TestsRoman BugajNo ratings yet

- Metz Lab Presentation: First Floor, Thangavel Nagar, Walajabad Main Road, Mannivakkam-600048Document20 pagesMetz Lab Presentation: First Floor, Thangavel Nagar, Walajabad Main Road, Mannivakkam-600048sevugarajanNo ratings yet

- E1418 10Document6 pagesE1418 10Enrique AntonioNo ratings yet

- L02a Radiation ContrastDocument7 pagesL02a Radiation ContrastDebendra Dev KhanalNo ratings yet

- Hardness TesterDocument2 pagesHardness TesterAgus RasidNo ratings yet

- HLN 11Document2 pagesHLN 11umamNo ratings yet

- SaluTron HardyTest D600 EnglishDocument2 pagesSaluTron HardyTest D600 Englishprevrtljivac100% (1)

- Present Simple: Form Statement NegativeDocument1 pagePresent Simple: Form Statement NegativeJuan CarlosNo ratings yet

- RadeyeDocument4 pagesRadeyeJuan CarlosNo ratings yet

- Positive Material Identification Report: PMI - Just in CaseDocument1 pagePositive Material Identification Report: PMI - Just in CaseJuan CarlosNo ratings yet

- Positive Material Identification Report: PMI - Just in CaseDocument1 pagePositive Material Identification Report: PMI - Just in CaseJuan CarlosNo ratings yet

- Iec TR 62343-6-8-2011Document14 pagesIec TR 62343-6-8-2011Amer AmeryNo ratings yet

- UNDP NP Dhangadhi SWM TOR FinalDocument4 pagesUNDP NP Dhangadhi SWM TOR FinalNirmal K.c.No ratings yet

- National Railway Museum Annual Review 04-05Document40 pagesNational Railway Museum Annual Review 04-05sol.loredo1705530No ratings yet

- BSO 04cDocument267 pagesBSO 04cSamikshya BNo ratings yet

- Edrolo ch3Document42 pagesEdrolo ch3YvonneNo ratings yet

- Chapter 4 TurbineDocument56 pagesChapter 4 TurbineHabtamu Tkubet EbuyNo ratings yet

- Ddrive Transmission ReportDocument43 pagesDdrive Transmission Reportelah150% (2)

- HandbikeDocument10 pagesHandbikeLely JuniariNo ratings yet

- Materi Asking and Offering For HelpDocument9 pagesMateri Asking and Offering For HelpFranky ArdanaNo ratings yet

- Modern Residential Housing in UAEDocument15 pagesModern Residential Housing in UAEBee Dan BudhachettriNo ratings yet

- Long Quiz 1 Eim Tools, MaterialsDocument1 pageLong Quiz 1 Eim Tools, MaterialsLea Ann PalaciosNo ratings yet

- Air Cooler With Checking DoorDocument2 pagesAir Cooler With Checking DoorSuraj KumarNo ratings yet

- Iare Ece Aec012 DSP QB 0Document20 pagesIare Ece Aec012 DSP QB 0projects allNo ratings yet

- Elements, Compounds, MixturesDocument35 pagesElements, Compounds, MixturesNorvieNo ratings yet

- Analisis Keterampilan Berpikir Kritis Mahasiswa Pada Materi KinematikaDocument11 pagesAnalisis Keterampilan Berpikir Kritis Mahasiswa Pada Materi KinematikaTrisnaNo ratings yet

- JCB R135 & R155-HD Skid Steer-New BrochureDocument8 pagesJCB R135 & R155-HD Skid Steer-New BrochureAshraf KadabaNo ratings yet

- Ar ExportsDocument1 pageAr ExportsRais AlamNo ratings yet

- Electrical BOQ 07.12.2021 New Boq R4 05-01-2022 Final 16.02.2022Document92 pagesElectrical BOQ 07.12.2021 New Boq R4 05-01-2022 Final 16.02.2022Upendra ChariNo ratings yet

- Saberon StratMan2Document3 pagesSaberon StratMan2paredesladyheart18No ratings yet

- Smart Dust Technology Seminar ReportDocument32 pagesSmart Dust Technology Seminar ReportSushan Upadhyay67% (3)

- Concrete ON MALDIVESDocument55 pagesConcrete ON MALDIVESKãrthìçk JkrNo ratings yet

- P eDocument22 pagesP eKiks AshNo ratings yet

- Electron Withdrawing and Electron Donating GroupsDocument2 pagesElectron Withdrawing and Electron Donating GroupsOmar Abd ElsalamNo ratings yet

- Explaining Zambian Poverty: A History of Economic Policy Since IndependenceDocument37 pagesExplaining Zambian Poverty: A History of Economic Policy Since IndependenceChola Mukanga100% (3)

- Service Manual: RP-6000 MK6 LTD RP-6000 MK6 BDocument44 pagesService Manual: RP-6000 MK6 LTD RP-6000 MK6 BFivor EdwardsNo ratings yet

- Research Papers On Climate Change Global WarmingDocument4 pagesResearch Papers On Climate Change Global Warminggw1nm9nbNo ratings yet

- Free Non Veg Nutrition Plan YSF PDFDocument8 pagesFree Non Veg Nutrition Plan YSF PDFAbhilash Wasekar100% (1)

- Toda People in IndiaDocument9 pagesToda People in IndiaAmoona KopiKoNo ratings yet

- F3 FDCS 1Document3 pagesF3 FDCS 1Lucian LuciNo ratings yet

- Green Engine 2 PDFDocument7 pagesGreen Engine 2 PDFharivardhanNo ratings yet