0 ratings0% found this document useful (0 votes)

681 views301 pagesHma Book

water tanks

Uploaded by

Sundareswaran KVCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

681 views301 pagesHma Book

water tanks

Uploaded by

Sundareswaran KVCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

RETAINING WALLS 585

suit this bending moment may now be computed. The slab is

‘usually built of the same thickness. The main reinforcement require-

ment may now be calculated. This steel runs horizontally, its

Tequirement being away from the earth side at sections mid-way

between the cou .terforts and near the earth side at the sections on

the counterforts.

Fig. 362 Upright s ab subjected to lateral loading.

The slab shall also be provided with distribution steel at not

Yess than 0°15% of the gross area of the section. The distribution

-ateel is placed vertically near both the faces, since the upright slab

fs considerably thick. These bars should form a mesh with the

horizontal bars. Hence these bars will have to be supported by

additional horizontal bars at certain places where main horizontal

bars are not forming a mesh with them.

(ii) The base slab. The width of the base slab may be made

06 H to 0'7 H where H is the overall height of the retaining wall.

The base slab consists of the toe slab and the heel slab. The toe

projection is usually one-fourth of the total width of the base slab.

i Heel slab, The heel slab should be designed as a continuous

horizontal slab with the counterforts as the supports. The slab is

designed a8 8 continuous slab consisting of cont:nuous strips parallel

to the wall.

Each strip is uniformly loaded ; but the loading on the various

oe from a maximum at the heel edge to a minimum near

ll.

: The loading on a strip of beel slab will consist of the follow-

iB :

(a) Dead load of the strip

306 DEMON Of REINFORCED CONCRSTS SERUCTURED

) Weight of earth above the strip

(©) Vertical component of lateral pressare in the casq uc carth

eurcharged at ifthe is

= an angie. | surcharge angie is «, then the intensity

=C> wh' sin « tan «

A’ pheight of earth above the strip e

$=angle of repose.

(d@) Superioad intensity acting on the retained soil if any

(e) Upward soil pressure.

It will be seen that the net load on the heel slab will be a down~

ward load. If the net load be Q per unit area near the heel end, thea

consider a one metre wide strip near the heelend. The maximum

bending mcment for the stipa tS The moment will be a sag-

ging moment at sections midway between the counterforts and will be

a hogging moment at the sections over the supports.

Fig. 363

‘Thicknear of the nase slab. The author suggests that this may

‘be taken not less than the following, in order ‘it may not be found

- unsafe from B.M. anc S.F. considerations.

D=4ll ly H

De-21H

where De-=thickness of the base slab in cm.

I==spacing of counterforts in metres

Heoverall height of wall in metres.

W the soil is surcharged at angle «, increase H by 0°7 m.

RETAWENG WALLS se

If the sol ia s.perionded increase H by SEPS® Wed ntersiy

Of the soil

Counterforts are spaced from 3 metres

to 3°50 metres. This spacing may also be taken from one third the

height of the wail to half the height of the wall.

The spacing may also be computed as the for which

the maximum bending moment for the upright requires an

overall thickness of 30 cm.

7 Let the spacing be | metres. Let the height of upright slab be

metre.

In M.K.S. units, to satisfy t_¢ above condition,

oo metre for M 150 concrete.

wi

In SL units,

an 143825

Vv wh

Toe slab. The design of the toe slab ‘depends upon whether’

the toe slab is allowed to remain a cantilever, or it is made to act as

& continuous slab by providiog front counterforts. When the front

counterforts are not provided the toe slab should be designed asa

cantilever slab subjected to upward soil reaction, But if a front

counterfort be provided then, the toe slab shall be designed as a con~

tinuous slab with the front counterforts as the supports. In such @

case at section midway between the front counterforts the bending

moment for the toe slab vill be of a hogging type, while at the seo-

tion on the supports, th bending moment for the toe slab will be

of the sagging type.

(iti) Counterforts. As mentioned already the retaining wall

yaay have main counterforts or main couaterforts and front counter-

-orts.

I metre for M 15 concrete.

couaterforts. These are designed as vertical cantilevers

held in‘position by the base slab. The loading on these counterforts

is due to the lateral earth pressure acting on the upright slab.

Let h be the height of cantilever above the base.

spacing of counterforts

a@=su:charge angle

Total horizontal force transferred to one counterfort

Pim Gy | cos « acting ata height of

+ above the base

588 DESIGN OF REIN! ORCED CONCRETE STRUCTURES

.". Max. bending moment for the counterfort

=M=P. 4

Macy 08 «

The reinforcement required to resist this bending moment can

be easily calculated.

ant sec 8

where B=inclination of the reinforcement with the normal to

the horizontal section of counterfort (i.c., inclination of the rein-

forcement with the vertical).

Curtailment of steel

We know Ara Ma M a Mu approximately

ae

“ Aca he”

If At and Ave are the areas of steel required at depths Ay and hs

Aa _ ht

we have da he

But A: is proportional to the number of bars.

Let n be the number of bars at the depth A

) depth hi

fers depth hy

mM ono oom Gepth hs

Then we have

ae Al)

ee ied (2)

matt 3)

and so on.

Hence at what depth a certain number of bars can be curtailed,

can be determined. :

Front cowsterforts, These are designed as horizontal cantilevers.

The loadieg on these will be due to the upward soil reaction on the

toe slab. It is quite likely that the front counterfort will be subjected

to considerable sear force. Hence shear stirrups of two or four legs

be provided.

RETAINING WALLS

Fig. 364. Retaining wail witbfrant aodmain counterfort,

The main reinforcement of the main counterfort and also that

Of the fromt counterfort should be embedded into the base slab for

sufficient length to develop the necessary bond strength. The bars of

the main Counterfort should be securely anchored at the bottom by

bending them back into the base slab,

In the case of a wall provided with main as well as front

counterforts the critical section for the max. bending moment for the

main counterforts shall be taken at a level Corresponding to the top

level of the front counterfort. :

Horizontal ties Connecting the main counterforts aad uy;

stab. Horizontal links of two legs are provided Connecting the main

i

Sectional Plan Stow Moin Reinfor of the Counter Fort

and the Horsontor ih be coontor ford on grea,

Pig. 365

. DENGN OF REINFORCED CONCRETE STRUCTURES

HORIZONTAL 118KS

O° Fw LEGS

counterfort and the upright slab to tic the wall to the

and also to resist diagonal tension in the counterfort. stone teas

mast be looped around the Q

main reinforcement of the (MAIN REIMFORCEMEN

‘counterfort. Fig. 364 shows OF COUNTER FORT

the horizontal links and Figs.

365 and 366 show two alter-

native ways in which the hori-

zontal links may be provided.

ting

and the Heel slab.

We know that the bee! slab

will transfer its load to the

counterforts which are suppor-

‘ting them. In order that the

heel ne tay transfer its load

to the counterfort, it is neces- i:

fury’ t9 provide vertical tes" ”"coammrfor and the Hel ath.

which are in the form of vertical links of two legs. i

Design 89 (S.L). De:

follow etcaior: | sign a counterfort type retaining wall to th

(i) Height of wall above G.L.=5'50 metre

(ii) Safe bearing capacity of the soil= 160 kN/metre®

(iit) Angle of repase= 30°

(tv, Weight of soils 16000 N/metre*

OQ Spacing of counterforts=3 metres centres

(vf) Weight of R.C.C.=25000 Nimetre?

(vit) Use M 15 concrete.

BETAL-ING WALLS, E]

Seletien. Wepth of foundation

~#L3 es]

1+sin ¢

= sean om (yar 11m.

Let us provide a foundation depth of 1°20 metre.

Overall height of wall

=5'50+1" 20=6" ‘70 metre

Thickwess of the base slab

This shall be nearly

(417 1-V FB em.=417x3 V E7328 cm.

(i) 21H cm.=2* 3X67 = 40°20 cm,

Let us provide 40 cm. overall for the base slab

.", Actual height of the upright slab

=6°70—0'40 = 6°30 metre

Pressure intensity at the bottom of the upright slab

wh Tae G 16000 %63x +

=33600 Nimetre?

Maximum bending moment for the upright slab for\the bottom

1 metre strip

== 336003, x 100 N om.

=2,520,000 N cm.

Adopting c~5 N/mm2=500 Nicm* ; tad Nimm2

= 14000 Nicm.' ; and m=18, and equating the moment of resi:

to_the bending moment

85 bd*=85 x 100 d*=2520000

Py d=17 cm.

Effective cover =4cem.

=17+4=2) cm.

2 ‘the thickness of the upright slab will be kept uniformly at

1 ems.

Base width. This will be kept from 0°6 H to 0°7 H

06X67—=4'02 n.

07 x6°7—4'59 m.

Let us provide a base width of 4°50 metre

Toe projection. This will be kept at about one-fourth of the

width of base

592 DESIGN OF REINFORCED CONCRETE STRUCTURES

In our case the toe projection

=Se11 metre

= 4 etre

Let us provide a toe projection of 1 metre.

2lem

121994 107906

N/me Nome

Fig. 368

Stability calculations. Stability calculations for 1 metre run of

the wall are shown in the table on page 593.

*. Distance of the point of application of the resultant from o

1026420

== fo5707 7250 ™

~. Eccentricity | bn 20x m.

base 6b

But, E76 =0'75m e kg. m.

= 66679°2 kg. metres.

Overajl width of the counter-

fort at the base

=3°50 metres=350 cms.

Eff. depth available

=350—6 =344 ems.

Inclination of the main steel

with the vertical is given by

tan P5390 /}— 450m 4

p=26° 3’ Fig. 371

6,667,920 4

4*ja00x0 610x344 %5C- 26° 3

=18 cm?

Provide & bars of 18 mm. dia. (Area provided = 20°36 cm.2).

Curtailment of bars. Let i be the depth at which 2 bars can

be curtailed, then

8-2_ he

8 63?

“ hy=5'S metres from the top.

Let he be the depth at which 2 more bars can be curtailed, then

84 ha?

8 638

fe hy =4'4 metres from the top.

RETAINING WALLS 603

Let hg be the depth at which 2 more bars can be curtailed, then

8-6 _ hat

8 63

it hs=3'1 metres from the top.

Connection between counterfort and the upright slab.

Consider the bottom | metre height of the upright slab. The

Pressure on this strip

3360 kg./m2

heigh Lateral earth pressure transferred to the counterfort for 1 metre

it

=3360 (3—0°42) kg. = 8670 kg.

Steel required per metre height

8670

1400

Spacing of 8 mm. dia. bars

=6°2 cm?

0° X 100 _

62 =S cms.

Since this reinforcement is provided in the form of horizontal

links of two legs each, the spacing of such links will be at 16 cms.

rentre.

Connection between the counterfort and the heel slab.

‘Tension transferred in 1 metre width of the counterfor. near the

heel end

=5010 (3—0°42) kg.=12926 kg.

Steel required in 1 metre width

Provide 8 mm. dia. two-legged links at 10 cms. centres.

Design 91 (S.f.). Design a counterfort type retaining wall to the

following particulars :

(i) Spacing of councrforts

(ii) Surcharge angle

(iif) Angle of repose =35°

(iv) Weight of soil = 16000 Nimetre®

(v) Overall height of wall =7 metres

(yi) Toe slab to be supported by front counterforts

Adont the following working siresses :

e=5 Nimm.’, t= 140 Nimm2, m= 18.

DESIGN OF REINFORCED CONCRETE STRUCTURES

Solution.

Lateral pressure intensity at any depth is given by

P==Cp wh acting parallel tothe top surface

of the retained soil

cos a— VV’ cos* a—cos*

cos a+ -V/ cos? a—-cos? ¢

In our case «=15° and a=35°

.cos 15° -V/ cos? 1

cos 15°+ ~/ cos? 15°—cos® 35°

where Ceo=cos «

7 Cocos 15)

C+=0°297.

Thickness of base slab

This may not be less than the following :

GD) 217 DEO T m. = 417 & 3 4/ 707 cm. = 3.47 cm,

(ti) 2 4-0°7) cm. ==2X3X(7'7) cm. =46°2 cm.

Let us provide a thickness of 50 em.

Horizonta! pressure intensity at a depth h metres is given by

Pa==Cp wh cos &

=0°297 x 16000 xh cos 15° N/metre*

== 4590 h N/metre*

Height of upright slab

= 71-—0S=65 m.

Hence ite burizonta) pressure intensity on the upright slab at

iis bottom

= 4590 x 6529835 N/m.2

Since (he apright slab will be designed as a continuvus slab,

tle maximum bending moment for this slab for a one metre deep

strizt

1006 N cm.

29835 x 3?

12

= 2237625 N cm,

ting the moment of resistance to the maximum bending

es Wave,

12% BS x 100 d2== 2237625

RETAINING WALLS 605

d=16 cm.

Providing an effective cover of 4 cm.

Overall depth =16+4=20 cm.

Width of the base=0°6 H to 0°7 H.

In our case, 0°6 H=0°6x7=4'2 m.

07 H=07X7=49 m.

Let us provide a base width of 4°5 m.

Toe projection about > base width

45...

=7 =lim.

Let us provide a toe projection of 1 m.

y=3°3 tan 15° 0°88 m.

Total lateral pressure on the wall per

metre run

Pac,"

20°297 X 16000 x

=147536 N

Horizontal component of P

=Pa=147536 cos 15°= 1425’

Vertical component of P

=Ps= 147536 sin 15° = 38185 27

*. Distance of the point of applicatin of the resultant from

1203222

N

the end a I= 493367 =2'439 m

Eccentricity =e=z ’ ==2'439—2'250=U'189 m.

Bo 450 9-750 m.

6

.", The maximum and minimum pressures a{ the base are given

| ee L 14 6X0189_ sxe ise vine tre

131256 Nimetre®

by

66 DESIGN OF REINFORCEM CONCRF™& STRUCTURES

Stability Calcuiations for Ome Metre Run of the Wall

| Magnitude of | Distance

i load

Load due to froma

(N) (my

W, 0°2x6'50x 25000 32500 | 340

W, 4°50X.0°50 x 25000 3620 | 22s

Backing 3°30 6'50x 16000 343200 165

: lo

3130x288 x 16000 a2} SB iyo

i

Pe 38s;

Moment of Pa

142sosx 738 374324

Total 493364 1203222

493-67 [ ,__6x0189

45 4>

=82008 N/metre.”

Design of the uprigtt siab

Maximum bending moment

= 2237625 N cm.

= 2231625 __ ag, 2

A= Faq0d x0'8T x16 N48 em:

Spacing of 16 mm. ¢ bars

and Pmin= Nimetre®

Provide 16 mm. bars @ 17 em. ele

Distribution steel = 43. x20x100—3 om?

Spacing of 8 ram. bars

052100 5,

= 93% 109 13 om.

Since the distribution steel will be provided near both the faces,

the spacing of these bars will be at 26 cm. cle near each face

RETAINING WALLS 07

Design of the toe slab

Since a front counterfort is provided, the toe slab should be

designed asa continuous slab continuous over the front counter-

forts.

Loading on @ one-metre wide strip of the toe slab will consist

of the following :

(i) Upward pressure = 137266 Nfmetre®

(ii) Dead load of slab =250 X 5012500 N/metre®

Net upward pressure 124766 N/metre®

Maximuta bending moment |

2

Sel x 100 N em.

=9357450 N cm.

Equating the moment of resistance to the maximum bending

moment

We have 85 bd® = 85 ». 100 d2—= 9357450

ioe d=33 20 em.

If an effective cover of 6 cm. be provided to the reinforcement

effective depth available =50—6—44 cm.

2357650

14000 x0'87 x44. ™

=17'46 em?

Spacing of 16 mm. ¢ bars

: 1201 x100_

= pag Lem.

Design of the heel slab. Consider a one metre wide strip of

the heel slab near the hee! end. This strip is subjected to the

following loads.

A=

Ni/metre®

(i) Weight of the soil= 16000 (6 50-+0°88)= 118080

(ii) D.L. of base slab=0°5 x 1 x 25000 = 12500

(iii) Vertical component of lateral pressure

—C> wh’ sina tan @

=0°297 x 16060 (6°5+-0°88) sin 15° tan 15°= 2430

133010

(iv) Deduct for upward pressure = 82008

-. Net downward load = 51002 Nimetre®

608 DESIGN OF REINFORCED CONCRETE STRUCTURES.

: Maximum bending moment for this strip

= NO «100 N cm.

=3825150 N cm.

Ae

=714 cm?

.". Spacing of 12 mm. ¢ bars

1:13 100__ |,

= 714 =158 cm.

Provide 12 mm. ¢ bars @ 15 cm. c/c.

Distribution steel = = oe x 50x 100=7'50 cm?

Spacing of 8 mm. ¢ bars

05 x 100

75

Since the distribution steel will be provided near both the faces,

the spacing of the bars near each face will be 13 cm. c/c.

Design of front counterfort

Total upward soil pressure transmitted to the front counter-

=67 cm. say 65 cm.

fort

(137266+124986)

2

=393378 N

This acts at a distance of

124986+2 x 137266 1

="124986+137266 <3

=0°51 metre from c.

Moment of upward pressure

= 393378 X0'S1 Nm.

=200623 N m.

Moment due to dead load of slab

=1x0°5X3x 25000 X4 Nm.

=18750 Nm.

Net bending moment for front counterfort

= 200623 — 18750= 181873 Nm.

= 18187300 N cm.

Let the width of the counterfort be 45 cm.

Equating the moment of resistance to the bending moment,

We have, 85 bd?=85X45 d?=18187300

“ d=68'9 cm.

*x3xKIN

m.

QBTAINING WALLS 609

Effective cover

Cover to centre of toe slab bars 60cm,

Half diameter of toe slab bars - U8 cm.

Liameter of distribution bars - DR om.

Ficlf diameter of counterfort bars (22 mm )--1! cr.

eT om

. Overall depth required

~=68°9+23°7 = 776 om

Provide an v,crall depth of 80 cm.

Actual effective depth = 8&6 --2°7 --71°3 cn.

3187300 :

ao 1318730 2 vm*

[14000 x 0°87 x 71 3

Provide 6 bars of 22 mm. $ (228i cm2)

Maximum shear force

= S= 393378 —1 X05 x 5 x 25000

=~ 393378 ~ 37500 = 385878 N

Nominal shear stress

S 355878, ers

Gem ys ycqy THO? Siem

=<11l N/mm?

Percentage of steel provided

22.81< 100°

pea Seca 3 tee

Vor 07% steel, 40°33 N/mm #=33 Niem?

.. Shear resistance of concrete -~4 bd

= 33x45 .x 71 3= 108880 N

. Shear to be resisted by stirrups = Vs = 3558

= 249998 N

Spacing of 4-legged 10 mm. » stirrups

Awted

7 OY

4X0 79% 146608 713

a 249998 .

=126 cm.

Provide 4-legged 10 mm. ¢ stirrups @ 12 cm c'c

mar

-- FOS8R80

Ucsign of main counterforts

The critical section for the main counterfort at *lns) she

610 DISIGN OF REINFORCED CONCRETE STRUCTURES

bending moment should be determined is at the section XX (just at

the level of the top of the front counterfort).

Width of the counterfort of the critical section XX,

=3'50— 3.507040 yg»

‘3°50: 65 x0°3 m.

=3°36 m.=336 cm.

Total horizontal pressure transferred to the counterfort above

the critical section XX

= 4590 x

=264660 N

B.M. at the critical section

=264660x 2 100 N cm.

5 9°3)2

6593 x3N

== 54,696,400 N cm.

Effective depth available = 336 —6= 330 cm.

Let B be the inclination of the main reinforcement with the

vertical

tanga 4A. Beas 30"

Aux 54696400 sec 25° 30°

*= "14000 x 0°87 x 330

Provide 5 bars of 20 mm. ¢.

Out of theso 5 bars, let two of them be curtailed at a depth of

x metres from top

15 cm?

3

Ano Mi a_i?

‘At2 Ma ha®~ ha?

a2

se

3 “(65-03%

Hence two of the five bars may be curtailed at 62—4'8=1'4 m.

above the base slab.

Connection between the upright slab and the counterfort

_ Horizontal soil pressure intensity at the level of the critical

section XX

.'. x=48 metres from the top.

= 4590 X 6'2= 28468 N/metre®

(Width of counterfort=45 cm)

RETAINING WALLS

611

-. Tension transmitted to the counterfort per metre height

at this level

omit

rane @ recuse]

Nee persue

res 20cm j

to ~aane

« as

pemngginc sms

iaeren enn ge nang wom ce

ah a

= 28458(3—0°45)=72568 N

aot 23

sorrel cours

Fe

Ws

aaiaiaeana

\

T

hsaaes-roane

| Bieas a

|eartencncn J needed nbsonce

a —

ee

Fig. 373 (a)

k

fin)

ra 30aRs-20mme omno

LINKS ar

acm cj

ammo

LINKS 47.

1OCMKe

gon,

on jpn’

“ann e@ 196m

Bers eg SSSI

ataiso yen a @ sem“;

eBAKs-22mme

ECTION AB

Fig. 373 (5)

3m. --

om,

Jenn o@urcatf

sr Z)1

“best +756

SECTION CE

612 DESIGN OF REINFUXCED CONCRETE §“RUCTURES

o enh me

seer0m e+

Fig. 373 (e)

.’. Horizontal steel required per metre height

T2568 = 5.1 cm?

“1 518 cm

Spacing of 8 mn. ¢ bars

05x 100

518

Since this reinforcement is provided in the form uf horizontat

dinks of two legs, the spacing of the links will be 10 cm. Jc.

Connection between the base slab and the counterfort

Consider a one metre wide strip of the heel slab near the heel.

=96 cm., say 9om

end.

Nex 1oaa un the surip=51002 N/metre?

Tension transmitted to the coubterfort in one metre width

= 51002 (3—0'45)=- 130055 N

«". Steel required per metre width

130055

14000

Spacing of 8 mm. diameter bars

Sens cn ays ca

929

Since this reinforcement will be provided in the form of vertical

links of two legs, the spacing of the links will be 10 cm. cle.

Design 92. Design a counterfort retaining wall to the following

Particulars :

{i) Spacing of counterforts =3 metres

(A) Surcharge angle = IS

=9°29 cm.*

RETAINING WALLS 613

(tii) Angle of repose =i

iy) Weight of soi! = 1600 kg/metre®

(v) Overall height of wall =7 metres

(vi) Toe slab to be supported by front counterforts

Adopt the following working stresse:

c= 50 kg.lem:

1400 k, 2, m=

ae g [om.2, m= 18,

Lateral pressure intensity at any depth is given by

p= Cp wh acting pataliel to the top surface

of the retained scil

cos x~ V'con

where Crmcos «

cos

Tn or: case = 15" and $= 35°

Cy cos 18° =

i cos IS +

Cy 0297.

Thicaness of basc slab

This may not be less than the following :

(i) FIT IV A407 cm. 4 17 x3 /14-0'T om. --34°7 cm.

Gi) ZKATOT) cm, =2KIXxT ‘Tem. = 462 cm.

Let us provide a thickness of 50 crs

Horizontal pressure intensity at 2 depth h metres is given by

Pa= Cy wh COs o

=0°297 X 1600 x AX cos 15° kg./metre™

= 459 A kg./en®

Height of upright slab

=27-5=6 5 m.

Hence the lateral ure intensity on the upright slab at its

bottom

=459%6'S kg/m?

27984 kg./m?.

Since the upright slab will be designes as a continuous slab,

e maximum bending moment for this slab for a one metre deep

strip

2

~ BEE 100 kg. em.

= 223800 kg. cm.

614 DESIGN OF REINFORCED CONCRETE STRUCTURES

Equating the moment of resistance to the maximum bending

moment, we have,

8°50 x 100 d?= 223800

aa d=16 cm.

Providing an effective cover of 4 cm.

Overall depth =16+4=20 cm.

Width of the base = =0°6 H to 0°7 H

In our case, 06 H=0'6x7=42 m.

07 H=0'7X7=4'9 m.

13712 12491

kgim? — kglm?

Fig. 374

Let us provide a vase width of 4°5 m.

Toe projectior =about + base width

Let us prdvice a toe projection of 1 m.

» ses tan 15°=0°88 m.

RETAINING WALLS 613

Total lateral pressure on the wall per metre run

wh?

P=C, aoe

07297 «1600x738 ke

= 14750 ke.

Horizontal component of P

=Pr=14750 cos 15° kg.

= 14250 kg.

Vertical component of P

=Po=14750 sin 15° kg. -

=3820 kg.

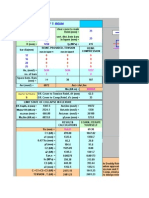

Stability Calculations for one metre run of the Wall

Load due to Magnitude of | | Distance from a Moment about a

load (kg.) (ke. m.)

ee = |

i '

w, i

i

0'2x6'5x 2500 | 3250 1 34 i 11050

: |

Ry | | H

4'5x0'S x 2500 5625 | 235 12656

Backing

i

B x65% 600 | 34320 | 165 56628 |

sax SS «1600 | 333 assy

'

Pe | a 0 0 |

Moment of Ph | l |

785 '

14250% - 1 37430 }

120319

. Distance of the point of application of the resultant from

the heel end a

oo 120319

49338

metre

O16 DBSIGN OF REINFORCED CONCRETE STRUCTURES

=2'438 metre

Ecceniricity e=z— 3

=2°438 —2°250=0°188 m

b 45_,,,

But, 6-6 = 0°75 m.

6b

en

-. The maximum and minimum pressures at the base aro

given by

Ae eer + 20188 agin?

=13712 kg.[m2

wi Pann S287 1-- S291 J bgt

= 8216 kg./m.2

Design of apright stab

Maxinum B.M. = 223800 kg. cm.

Overall depth = 20 em

Effective cover to ceinforcement

= dom.

Effective depth =20 -4-16 cm.

223800

4 va50 x08T x16

= 148 cm?

Spacing of 16 mm. diameter bars

201 x 100

14g

175 em. say 17 om. efe

Distribution steel =X 20 100 em?

Soacing of 8 num. diameter bars

= 95X10, 1g a

Since the distribution steel will be provided near both the faccs,

she spevg of these bars will be at 26 cm. ¢/c near each face.

RETAINING WALLS 617

Design of the toe slab. Since a front counterfort is provided,

the toc slab should be designed as a continuous slab continuous over

the front counterforts.

Loading on a one-metre strip of the toe slab will consist of the

following :

(i) Upward pressure =13712 kg./m2

(ii) Self-weight of slab 2550 = 1250 kg./m2

©. Net upward pressure =12462 kg./m.2

“. Max. BM. ee ® 100 kg. em.

=934650 kg. cm.

Equating the moment of resistance to the imaximum bending

moment, we have,

8°50 X 100 d?==934650

: d=332 cm.

If an effective cover of 6 cm. be provided to the reinforcement

effective depth available=50--6=44 cm.

=17 40 cm?

~. Spacing of 16 mm. diameter bars

_ 201 100

om.=11 cm.

17 40

Design of the heci slab. Consider a one metre wide strip of the

heel slab near the heel end. This strip is subjected to the following

load: :

kg.jm2

(i) Weight of soil=1600 x (6 5+-0°88) 11808

(it) Self weight of base slab=0°5 x 1 X 2500 == 1250

(iii) Vertical component of lateral pressure

=Cy wh' sine tan «

=-0 297 x 1600 (654-0 88) sin 15° tan 15° = 243

13301

(iv) Upward pressure =: 8216

Net downward load = 5085 kg./m.*

Maximum bending moment for this strip

5085 x 32

12 x 100 kg. cm.

618 DESIGN OF REINFORCED CONCRETE STRUCTURES

=381,375 kg. cm.

381,375

1400 X ("87 x 44

=712 cm?

Spacing of 12 mm. diameter bars

1:13 x 100

= 44207

=15'8 cm. say 15 cm. e/c.

Distribution steel 9) 50% 100 em.

=750 cm?

Spacing of 8 mm. diameter bars

__ 03x 100 on

a) :

=67 cm. say 6'5 cm.

A= cm.é

Since the distribution steel will be provided near both the faces,

the spacing of the bars near each face will be 13 cm. ¢/c.

Design of front counterforts. Total upward soil pressure trans-

ferred to the front counterfort

= 13712 12894 x3xL kg.

=: 39304 kg.

This acts at a distance of

12491 +2. 13712

7124914 13712

=051 m. from c

xdm.

Moment of upward pressure

= 39304 x0°51 kg. m.

Moment due to seli:

=1x05x3x2500 x3 kg. m.

= 1875 kg. m.

Nec B.M. for front counterfort

=20045— 1875 kg. m.

=18170 kg. m.

=1,817,000 kg. cm.

Let the width of the counterfort be 45 cm.

Equating the moment of resistance to the maximum bending

moment, we have

RETAINING WA .LS 619

89x45 d= 1,817,000

d=68'°9 cm.

Fffective cover

Cover to the centre of toe slab bars

Half diameter of toe slab bars

Dia. of distribution steel =0'8 cm.

Half dia. of counterfort bars

(22 mm. dia.)=1'1 cm.

87 cm.

Overall depth required

=68°9+8'7 cm.

=776 cm. say 80 cm.

Hence actual effective depth

=80—8°7 cm.

=71°3 cm.

_ 1,817,000

1400 x0 87 X71'3

=21 cm?

Let us provide 6 bars of 22 mm. diameter (22°81 em.*)

Maximum shear force

= 39304—- 1 x 0°50 X 3 x 2500 kg.

A=

em?

35554 kg.

Nominal she2~ stress

_ S 35554 :

Gm 7 = 45xTi3 Keo

=11°08 kg.jom2

Percentage of steel provided

22°81 x 100

SS

For 0'7% steel, ge 3°30 kg./cm.?

Shear resistance of concrete

Gebd = 3°3 x 45 x 71°3= 10588 kg.

Shear to be resisted by stirrups

=V,=35554—10588=24966 kg.

Spacing of 4-legged 10 mm. ¢ stirrups

Avted — 40°79 1400x713

Vase 24966

=12 em.

Design of main counterforts

The critical section for tue main counterfort at which the bend-

620 DESIGN OF RFINFORCED CONCRETE STRUCTURES

ing moment should be determined is at the section YX Gust at the

top of the front counterfort). See Fig. 374.

Width of the counterfort at the er“cal section XX.

=3°50— 3'50— 0°40) xO3m,

=336 m.

= 336 cm.

Total horizontal pressure transferred to the counterfort above

the critical section YX

(6 5— pa

=4sox' x3 kg.

= 26460 kg.

B.M. at the critical section.

=26460x ©? x 100 kg, om.

=5,470,000 ke. cm

Effective depth available

=336—6 =330 cm.

Let 6 be the inclination of the main reinforcement with the

vertical

tan B= --—— =

B=25° 30’

“dune 5s870,000 ee 25° 30" a

w=" 1400 x 0°87 x 330

=15 cm?,

Let us provide 5 bars of 20 mm diameter. Out of these 5 bars,

Iet two of them be curtailed at a depth of x metres from top

As

Ag _Mi_ a hy?

‘Ag Maha “hy?

i x=4°8 metres from the top

Hence two of the 5 bars may be curtailed at 6°2—4'8

=1'4 m. above the section XX

or 1°4+0°3=1°7 metres above the base slab.

RETAINING WALLS 621

Connection between the upright slab and the counterfort

Horizontal soil pressure at the level of critical section YX

=459 X62 kg./metre2

2846 kg./metre?

(width of counterfort=45 cm).

.. Tension transferred to the counterfort per metre height at

this level = 2846 [3—0°45] kg.

=7256 kg.

Steel required per metre height

7256

= 1400 cm2

518 em?

Spacing of 8 mm. diameter bars

05x 100

S18

=9'6 cm. say 9 om

Since the reinforcement is provided in the form of horlzontal

dinks of two legs the spacing of the links will be at 18 cm. centres.

Connection between the base slab and the counterfort. Consider

A one metre wide strip of the heel slab near the heel end.

Fig. 375 (a)

Net load on wwe str.p= 5085 kg/m.

DESIGN OF REINFORCED CONCRETE STRUCTURES

| omm 0@ remy '

2mm o@ 96m i, aaa

eS 7

SBAKS Femme

SeCTiOnw 48 see rion 6b

Fig. 375 (6)

.. Tension transferred to the counterfort in one metre width?

=50%5 (3—0°45) kg.

= 12967 kg.

seerion 6+

_ Fig. 375 (0)

+ Steel required per metre width

12967 2

1400

=9°26 cm?

.. Spacing or 8 mm. diameter bars

05 x 100

9°26

‘cm. =5'4 cm. say 5 cm.

RETAINING WALLS 623,

Since this reinforcement will be provided in the form of vertical

links of two legs, the spacing of the lints

=10 cm. cle.

§155. Buttressed Retaining Wulls

Sometimes buttresses are used instead of counterforts to streng-

then the upright slab of the

retaining wall. Fig. 376

shows a general layout of

buttressed wall. Such a wall

is designed similar to the

counterfort wall but the

following points must be

noted :

(i) The buttresses

should be designed as verti-

cal cantilevers, but canti-

Jevering from the toe slab.

(ii) Heavy reinforce-

ment in the form of vertical

links or U-stirrups should

be provided connecting the

buttre-ses and the toe slab

But only nominal horizontal

reinfercement connecting

the buttresses and the up-

right slab will be provided.

(iii) The toe slab should aig, 376, Burtressed Wall.

be designed as a continuous slab spanning between the buttresses.

(iv) The heel slab should be designed as a cantilever as the

hee] slab of a cantilever retaining wall.

Wall witk tie rods. If the height to which the soil is to be

retained is large 11 may be con-

venient to anchor the wall back

to the earth itself by means of tie WISI

rods. The tie rods may be encased

inconcrete The tie rods pass

tirough the centroid of the lateral

earth pressure Hence, if the

height of the stem be f, the tie =

rods may be provided at a height 1 ee BLOR

of 4 above the base slab. One = __ }

end of the tie rod is properly se- as

cured or fixed to the stem while Fig. 377

its other end is embedded into a concrete block. The lateral move-

ment of the block is resisted by friction between the block and the.

soil above and below it.

624 DESIGN OF RBINFORCED CONCRETE STRUCTURES

If the tie rods be provided at a spacing of x metres the tension

in each+tie rod.

2

-T= os kg.

Hence the sectional area of each rod

pee

= 1400 ©

Size of tne concrete block. Let the area of the block be 4

metres*. Hence effective avea of the block in contact with the soil

equals 2 A metre? (since the depth of the block is small only the

area of ‘he top and bottom faces of the block are considercd).

Suppose the block be y metres below the retained surface (y

will be § 4).

Vertical pressure intensity on the block

=w y kg./m?.

.. Frictiona! resistance

=lXwy aXe

Equating the frictional resistance to the tension in the rod, we

ave,

co ewy Au

2

From the above relation the area 4 of the bl.ck can be

determined.

Sometimes, at the end of the tie rod a vertical stecl plafe is

provided. This adds to the resistance to horizouta) movement

considerably.

Connection between the tie rods and the stem. Cotrespénding

to the level of ties a horizontal beam may be cast monolithically

with the stem, The stem can now be designed as cantilevering on

either side of the horizontal beam. “Thee beam wan be designd as

a continuous beam, the ties serving as the suppoits.

Alternatively vertical-beams (cantilevers) are SuiJt monolithi-

cally with the stem and to these beams the horizontal ties way be

connected. In such a case, the stem shoald be designed as a “conti-

nuous slab spanning horizontally “over the vertical beams... The

vertical beams serve as counterfoyts. The vertical beam should be

designed as two cantilevers cantilevering 2n zither side of the point

at which the tie rod is connected to it.

Sometimes retaining walls may

be provided on both sides of a high

embankment (Fig. 378).

In such cases the tie rods will

simply connect the two retaining

walls. The lateral pressure on one

wall provides the necessary anchoring

force.

RETAINING WALLS. 625

In this connegtion Taylor Thompson and Smulski in their

work Concrete, Plain and Reinfurced Vol 1 have mentioned about

an interesting wall designed by Gustave kindenthal fof New York

connecting rail road In this case, there are two walls 20 metres

high enclosing a rail r ad fil! which is nearly 18 metres wide. The

rl road fill carries four lanes of traffic (subjected to £ 60 ioading

and designed for 10%, impact). The longitudinal walls are con-

nected by transverse walls at intervals of iGme res The lateral

earth pressure acting on the Jonguzadinal walls 1s resisted by tie

toss of 60 mm diameter 931 is of 3 metres apert

vertically and horivontally js arr theated:

vi nuts are provided over + be pressure is ra ferred to

concrete by longitudins! us si ax vertical chanceis plored

ire the outside face of the wal. Th, Gots at tne eae ol ae

ne rods bear against the arch reantis the See 8

syraanded by concrete to forn aers Ya “aS

tone only for protecuion again

"186. Sheet Pited Retaining Wait

mana tee

gates Gavy De

ene Bier

she pile

wn gad RFOOWE

avy Me fase Or apy

Fig 309 wm of key cmvy be pro-

{ Sud rraming walls may

ay be diven wie by che side of

may also be driven at iv'ervals the

led with slabs spano horizontally,

-t the soit and he pressure

id be taken for sufficient depth below

Le hilt i many vay

The athe cominuousty

3

a

SLAB Stadt

Pig. 10

the lower sround level so as to prevent the movement of the cetained

earth under them.

When the piles are driven contiouously their tops will suto-

matically form the top of the retaining wall. ‘They are generally

surmounted by a continuous capping

Sometimes it is found economical to design the piles having

626 DESIGN OF REINFORCED CONCRE{& STRUCHERES

a T-shape which increases their width without considerable increase

of weight or area.

Though it is usual to form the point of a sheet pile with a

rake so that it is induced to close up to its neighbouring pile,

generally a little opening exists between adjacent piles. Often this

1s an advantage since it prevents the accuculatio. of water bebind

the piles.

Cie IE

TEE SHAPED PLE

Fig. 381

But, in case it is necessary to provide watertight ee

perfectly make it cartbtight, grooves may be provided ‘on bot

of each pile, and after the ‘wiles

PE One are driven, the tube or the cavity

formed can be cleared out and

i filled with cement grout or fine

concrete.

Amcherage of walls. It 4s

a necessary to provide means to

oareseae oes prevent the forward movement of

‘i piled retaining walls. This is done

Fig. 382 by providing anchor-ties at inter-

vals near the tops of the piles. The anchor-ties are secured to a

horizontal walling which connects all the piles. The walling trans-

saffs the thrust of the earth to the ties. The walling is designed as

beam. Generally a b

ne Tener sends Of a. 0 | 2 EARTH FILLING

matically retained ?

hy driving them, 1

for sufficient depth :

yato the ground. Y

However, if found foe

necessary. the

Tower ends of the i

piles may alto be

secured by a second Fig. 383

series of anchor ties. The anchor tie may cocsist of one or more steel

hars of requisite sectional area. In order to protect them from corro-

sion particularly in damp porous soils, it is advisable to surround the

ties with dense concrete. Alternatively, the ties may be wrapped

with canvas soaked in bitumen. If this is not possible, the ties may

atleast be coated with hot tar.

14

Stair Cases

Stairs consist of steps arranged in a series for purpose of giving

access to different floois of a building. Since a stair is often the

Only means of communication between the various floors of a

building, the locatvon of the stair requires good and careful consider-

ation. In a residential house the stair case may be provided near

the maip entrance In a public building, the stairs must be from the

main entrance itself and located centrally, to provide quick accessibi-

lity to the principal apartments. All stair cases should be adequately

lighted and properly ventilated.

$187. Techpical Terms used in Connection with Stnir Case

(7) Tread. Tread means the horizontal upper portion of a

step.

(it) Riser. This is the vertical portion of a step.

Rise means the vertical distance between the horizontal surfaces

of two consecutive steps.

‘iii) Winders. These are steps used for changing the direction

of the siair. These are usually triangular in plan. -

(i) Landing. This is a horizontal platform provided at the

head of a series of steps. A landing extending right across a stair

case is called a Aaif space landing If a lancing extends only half

across a stair case. st is called quarier space landing

(+) Nosimg. This is the outer projecting edge of a tread.

(i) Flight. This consists of a series of steps provided hetween

landiogs

(s17; Liwe ef Nosing. This is straight line touching the nosings

of the vart us steps and parallel to the slope of toe stair.

Classification of stairs

{7} Strasgbt Stairs. This consists of steps leading in the same

direction "+, 1S provided in a long narrow stair case. This often

conausts of one flight: but in some circumstances it mav consist of

two flights with an intermediate landing

(5: Dog legged stair, 1n this type the succeeding flights rise in

opposite directions. The two flights, in plan, are not separated by a

well, A landing is provided corresponding to the level at which the

direction of flight changes.

627

628 DESIGN OF REINFORCED CONCRETE STRUCIURIS:

'fi.) Opem newel stair. In this type a rectangular well or

ovening 1s Jeft between forward and backward tights. Tnis type of

slats fh a very comfortable form — The well assists as a means for

Rood by hti The forward and the backwaru flights may be con-

mectect by a landing platform Buta space allows, a short flight is

a tataduced sounectag fhe fooward apd the backward Aights with

& quarter space Landis on each side of the snort flight.

ir) Geometrical stait. In this type of stairs the well between

the forward and te backward fk is curved, Winders

bothese vende in whith ev the

tof hile Stair ved soar the

hig over ube

be above Depes OU SUT H,

i

thea Js

BLOM: Trea, 5 aes

Focmsy. an”

Tread vad ris i

ad & may be to satsfy the following

the rise be & canis

relations +

i) TR= 400 to 410

(ii) 2R+T= 60

In dweliing houses the tread may be 25 err and the Tise nay be

16cm, in public buildings the tread may be 27 cm to 30 en. and

the rise may he 1S. cm Sn factories a tread of 25 em and rise of

19 cm may be adopted. In cinema theatres the tread may & 27 cre.

and the rise may be 15 cm.

STAIR CASES 629

The :inimum width of a stair shall be 85 cm. In residentiai

buildings :he minimum width is preferably LOS cm.

Heac room over a stair ~The head roum over a stair shall be at

least 2°10 metres.

- Numher of steps in a flight’ The number of sieps ut one stretch

in a flight may not preferably be more than (2. If more ure provid-

ed than the ad we limit, it becomes difficult and tiresome to ascead

znd descend the stairs.

Live loads on stairs The live loads 10 considered on staiz<

bave been stipulated by 7S 875 Revived) Cok uf Practice for

Structura! Safety of Buildings : Loading Standards

As per this code th

may be take 30

¢ live load on stairs, laadings and balcenies

Non ome Ob ke por sq metrel in

ferthaps, bere there are tee possi af svguedmg Bat ia

the case of public burddings aad warehouses, bere evercr awd

Tkely, the live load may be taken at SuGu N pet dc ire® (SUD kg.

sq. metre )

§158. Design of Stairs

Based on the direction along wt ’.t a stair lab spans, the stairs

may be classified into the following two types +

(#) Stairs spanning horizontally,

UD Stairs spanning longitudinally

59 Stairs Spanning Horizontally

These starrs

or atone

are supported at each side by walls, stringer bess.

by wall and af the other side by a beam = When tue

span of the starr does not cceed 1 50 metres one bur of 10 mm dia.

pers ibe found suticient. A distributi el of 6 mm dia.

bar. at heme centres may ve provided.

Gach step will be designed as spanning horizontally. For

purposes of design each step will be taken as equivalent to a

rectungular beam of width 6 and effective depth D/2. For specifica-

w

Fig. 385. Stairs spanning horizontally.

"DISTON OF REINFORCED CONCRETE STRUCTURES

tions of b and D see Fig. 386. A waist of about 8 cm, may be

Provided.

Fig. 386

Each step may be designed as an equivalent rectangular beam

ine a bresdth /- and effective depihd= Die

havi

Design 93(S1). 4 light of stairs to be Provided in an office

building is to be supported by a stringer keam on one edge anda brick

wall on the other The effective horizontal Span of the stairs may be

taken as 1°50 metre. The risers are 5 cm. and the treads are 27 cm.

Design the steps allowing a live load of 3000 Nimeires?. Use M 15

concrete.

Solation. Fig. 387 shows the. °

Steps.

Let the thickness of the Waist be

Sem,

ba VIFF

=30°89 cm.

27x15

Da BH ag =21 LL em.

Load per metre run of step Fig. 387

DL. of step =4X027X0°15x 25000 — 506 N/metre

DL. of waist=0°3089 x 0°08 x 25000= 618 N/metre

13 mm. thick granolithic finish on tread

0013 x0°27x24000— 34 Nimeire

Total dead load = 1208 Ni/meire

LL. at 3000 N/metre?=0:27 x 3000 = 810 Nimetre

Total load/metre run 2018 N/metre:

BAIR CASED 63

Maximum bending moment

wt _2018 x19

z 8 %100 N em.

= 56756 N cm.

Equating the moment of resistance to the bending moment,

85 bd? = 85 x 30°89 d? — 56756

“ d=465 cm.

But effective depth available

toe 2 at = 10°56 cm.

56756

= =0. a

4&1 gou0 x 0°87 x 10°56 0 44

Provide one bar of 8 mm. ¢ (0 50 cm.*)

Provide also a distribution stee! of 6 mm. ¢ @ 30 cm, cle.

Design 94. A flight of stairs to be provided in an office building

is to be supported by a stringer beam on one edge anda brick wall on

the other. The effective horizontal span of the stairs may be taken as

ISO metres. The risers are 15 cm and the treads are 27 em. Design

the steps allowing a live load of 300 ke./metre*. Use M 150 concrete.

Solution.

Fig. 388 shows the steps.

Let the thickness of the waist be

8 em.

b= V 272+153=30'89 cm.

27x15 :

D=8+ 30 g9 CM =2UIL cm,

Load per metre run of step

Fig. 388

Dead Ioad of step

eye Ue =

> rae ria * 2500 kg.= 50°6 kg /m.

3089, 8

Waist 100° * 100 x 2500 = 618 kg./m.

13 mm thick granolithic finish

ee oe

on tread= 1000 “00 * 2400. 84 kg./m.

Tota! dead load =1208 kg Jm.

Live load at 300 kg./mctre®

Top x x 300 = 81 kg./m.

Total load/metre run =201'8 kg./m. say 202 kg./m.

632 DESIGN OF REINFORCED CONCRETE STRUCTURES

-. Maximum bending momeat

awe

8

POETS" 100 kg. cm. +5681 kg. om.

Adopting ¢=50 kg./em2, ¢=:1400 kg.fom? and m.=18 and

equatirg the moment of resistance to the maximum bending moment,

we have,

8°5 X 30°89 u2= 5681 « d=46 cm.

But effective depth available

J 10°56 cm?

S63)

i400 x.0°87 x 10 56 “™

=0°44 com?

Provide one bar of 8 mm. diameter (0 5 em.2)

Provide also a distribution steel of 6 mm. diameter bars at 30 cm.

centics

Stairs spanning horizontally, with # newel wall provided between

the two flights Fig 339 shows a usual arrangement of stairs

spanning horizontally. Each

stair is supposted at one end bv

a side waii and at the other end

bythe pewe! wall into whichit is

chased for 12 cm. The stairs

should be designed as in the

Previous case A sinall beam

may also be provided to span

trom end wall to the newel wall. ie (TION

The landing slab can now he © PAN OF

designed as a continuons slab = ‘76 1-4

supported on the side walls and Fig. 389

the intermediate beam.

§160. Stairs Spanniug Longitudinally

Stairs of this category span between supports at the bottom

and top of the flight and remain unsupported at the sides In

-— @ case the beadirg moment per unit width may be taken as

‘ai, where w is the load per unit horizontal area and I's the effective

horizontal span Sometimes beams ate avoided to support the stairs

and the flight will be cast along with the landings which may be

supported on walls. Iu such a case the effective horizontal span may

be taken as the horizontal distance between the centres of bearings.

The maximum bending mecnent may be taken as wn

‘STAIR CASES 633

In this connection I.S. : 456 (Revised) Code of Practice for Plane

and Reinforced Concrete has stipulated the following :

Effective span of stairs. The effective span «f stairs without

Mringer beams shall be taken as the following horizontal distances.

(a) Where suppories at top and bottom rise

by beums spanning

parallel to the risers: Disian ¢ between centres of }

ms

(6) Where spon. he nat

parallel with the eso

the stairs

anetns whi

spans

hie the pou of

landing er une

matt abot aia das tlh

en well, th

oo Gixet

fis se aiyty

on ebay

oof keoding on stairs

He soa. parlly

ton toad Ca aren common to

mV two such spony may be

nel am each

ion as shown in Fig.

for a length of aor less than

110 mm and are designed to

span in the direction of the

flight, a 150 mm strip may

be deducted froin the loaded

area, and the effective breadth

of the section increased by

75 mm, for purposes of desiga.

See Fig. 391 (a). tg. 295

634 DESIGN OF REINFORCED CO.iCREIE STRUCTURES

15mm !

__Etfective breadth

Fig. 391 (a)

rot:

vite Te

ie

Depth of section. The depth of section shall be taken as the

Minimum thickness per sendicular to the soffit of the stair case.

Estimation of weight

Let the »uist te 15 em. thick measured at right angles to the

slope. Its werzist per s@. m. on slope

= 250 X 15=3750 N/metre?

To obtain the corresponding load per sq. metre of horizontal

area, this value should be multiplied by

VR =

where R=Rise and T=Tread

Vr yee

tinny thy

rites pupte Suppose R=15 cm.

Willie Hh and T=27 em.

oe in REG Ti_ 4/19 pak

er then ¥® ak ~ vasa

N at

a , =1i4

i ©. Weight on plan=weight on

remtsd Slopex 114,

OF ast The weight of the steps per sq.

metre of horizontal area can be estima

Fig. 392 ted by treating all the steps as equi-

valent to a horizontal slab of thickness 4.

Design 95‘S.L.) The main stair of an office building has to be

located in @ stair measuring 35 m.X5'5 m. The vertical distance

STAIR CASES 632

between the floors is 3°75 m. Design the stairs. Allow a L.L, of 3000

Nimetre®. Use M 15 concrete.

Solution. It is proposed to provide two flights for the stairway.

Hence, the height ofeach fight=" 75 m,

=1°875 metres

=187'5 cm.

Assuming 15 cms. risers,

2 i 187°5

number of risers required =!87. 12

i “S

Hence the actual rise of each riser = !®

Number of treads in each flight =number of risers—1

=12—1=11 treads,

Let the width of the stairs be 160 cms.

Let the tread of the steps be 27 cms.

Fig. 393 shows the arrangement of the stairs in plan.

Design of the flight AB. Let the bearing for the ‘ight’ be

15 cms,

Effective horizontal span

gee

29741 60+ “2 = 4645 metres

Let the thickness of the waist be 22 cms. (This can be assumed

at 4 to 5 cm. per metre run of horizontal span).

iret

we

t

a

636 DESIGN OF REINFORCED CONCRETP STRUCTURES

Loads

D.L. of 22 cm. waist = 250 x 22 = 5500 N/metre?

Ceiling finish (1°25 cm)=240X1'25= 300 N/metre®

5800 Nimetre®

Corresponding load per sq metre on plan

2 "622 4.272

= X580= on FOP saci 6 700 Nimetre®

Hence, the actual load per sg metre of plan area wil consist

of the following :

Waist and ceiling finish = 6100 Nimetee®

DL of step ( sen ern, vrage )

“BEX 260 1952 Nimeire®

Top finish (1°28 cm )=4°25 240: - 3110 N/merre®

Live Load 3000 WV, enctre®

Total = J

Maximum bending moweat per metre width

08) 4 EAS: #

eee “100 N em

8

=32234-0 Nom.

Adopting car 8 Nimm2%= 800 Nom? , 5 Noon

SISELACE.

14000 Nem? s m= 182 and equating the munmeat ot

to the bending moment, we have,

BS bd2~¥#5 x 100 d= 3223460

d= 19'S en.

Providing 14 mm. bars at a clear cover uf 13 sm.

Effective cover =-154-7==22 mm.~ 22cm.

Effective depth = 22--22=19 8 em

fee 22ND

14:00 x 0 87», 19°8

Spacing of 14 mm. # bars

154% 100

= pe WS em.

Provide 14 mm. $ @ 11 cm. cle.

Destribution steel = 97°. x 22x 100=3'3 cm?

= 1337 cm?

Provide 8 mm. ¢ @ Il cm

STAIR CASBB 637

1200 01a Baws

AT CR CENTRES

ae EOS ee ate eee nO + cise}

1 he locaied

re vorticul distince between

the nay aitwing ab lise foud of

30 hey . “concrete

od weed te vide ve tupsts fer the slaw

was

Loot each fight

1D EERIE metre INT Sunn

Tras esers, nucl er UF Msers FeGueree:

=

ate — $3 som--

iis a ae

Big. 95

638 DESIGN OF ReINFURCED CONCREFL STRUCTURES

Hence the actual rise of each riser= '97° = 15°62 ems.

Number of treads in each flignt =number of risers—1

=12—1=I1 treads.

Let the width of the stair be 160 cms.

Let the tread of the steps be 27 . ms.

Fig. 395 shows the arrangement of the stairs in plan

Design of the fight AB. Let the bearing for the flight be

15 ems.

Effective horizontal span

=2974+1°60+ a =4°645 metres

Let the thickness of the waist be 2? cms. (This can be assumed

at 449 5 em. per metre run of horizontal span).

‘wads. Dead load of 22 cms. waist=25 x 22—550 kg./metre®

Ceiling finish (1°25 cm ) thick 24 x 1°25— 30 kg./metre®

= $80 kg./metre®

Corresponding load per sq. metre on plan

eV R47? _ Vi15 624272

TF x557= aay eatae

=670 kg /m2.

Hence the actual load per sq. metre of plan area will consist of

he following :

x 580 kg. /metre®

Waist and ceiling finish= 670 kg /m.?

1562

a.

Dead load of steps ( cm. average )

=781 x25 = 195 kg /m2

Top finish (1°25 cm. thick)

=1°25% 24 = 2 kg./m2

Live Load= 300 kg /m?

= 1195 kg/m?

Max. bending moment per metre width of staus

(4°645)2

: = go X 100 kg. cm.

: 322290 kg. em.

Adopting c=350 kg/cm? 1= 1400 kg Jem?

and m=18, we have 9 a=0°87d

and

STAM CASES 639

8°50 x 100 d? = 322,290

d=19'5 cms.

Providing 14 mm. # bars at a clear cover of 15 mm.

Rffectve cover =15-+7=22 mm.=2°2 cm.

Rffective depth ~22--2°2= 9% cm.

RH

A= Tiooxoerxiee

13°36 cm?

Spacing of 14 mm. dia. bars (area 1°54 cm.*y

1 54x 100

shone

Provide 14 mm. 4 @ 11 em. cle.

Distribution steel == ©! Tg 24x 100 ~Fa em?

Provide 8 mm. $ @ II cm cle.

ce

ame a a

4 17 Gua BAR at 5

Cm CEM Tere S t

21m Osa. BARS AT

0 (@ EMTRES

{

|

ie

pa

Fig. 396

Design 97 (S.1.). Fig. 397 shows an arrangement jor a stair case

(0 be Ponte’ for ofa building. Design the stair case, The risers

em. and the treads are 25cm. The walls are 40 cm. thick and

the ae slab has full bearing on the masonry walls. The supporting

beam is 40 cm. wide. Use M 15 concrete.

Solution. Let us provide a waist of 20 cm.

Loads

DL of waist =20x 250 == 5000 N/metre®

Ceiling uaish = 200 Nimetre?

= 9300 Mimetret

640 DESIGN OF REINFORCED C INCRETE STRUCTURES

400m

as Ce

a

4

Dond pur sq eet sea phe

261 Nfinen

Waist go" cull we at

Vel 25 me KTS Nengoe &

vetah fF

PLel og

se UR Nypmiesre*

s MI0G Nimeres®

pha

me

. Load

‘Total wd 1d

Since the ‘andiay sinh is og two way slaby the ioud on fhe

landing slab mas be taken 1s

5677 5 Nimetre®

STAIR CASES 641

Flight AB

Effective span=centre to centre distance between the

supporting walls.

+1°70 = U504+1°70—= 4°90 metre

5677-5 N/m 11355 N/m 5677-5 N/m

eaareeeee 90m

Fig 398

Consider a one metre wide strip of the flight.

Reaction at each support

NBSSXIS4S6TTS%3° ggg,

Maximum bending moment

_l8t68 x49

2 —(5677°5 x 17 1'6)

075?

-( 11355x z )

=44511°6— 15442'8—3193'6 N m.

=25875°2 Nom.

Fquating the moment of resistance to the maximum bending

moment,

85 bd?=85 x 100 d¥=25875'2 x 100

ae d=17'4 em.

Providing a clear cover of 15 mm. and using 12 mm. ¢ bars,

Effective cover =15+6—21 mm.==2°1 om.

Effective depth available

=20—2'1—17°9 cm.

25875°2 x 100

14000 x 0°87 x 17°9

Provide 12 mm. ¢ @ 10 cm. cle.

hlight DA

I:nective span=Centre of beam to centre of bearing on wall

=2+1°5+0°20+0'20=3'90 metre

Consider a one metre wide strip of the flight. Fig. 399 shows.

the loading on the strip.

A =11'87 cm?

642 DESIGN OF REINFORCED CONCRETE STRUCTURES

41355 N/m 5677-5N/m

0

Ma

Kens 399

T:.king moments about D,

Vo x 3°9 = (11355 % 2°2X 1°1)+ 5677'S x 1°7 (2°2+0°85)

Vom 1459409 N,

Vo =(11355 x 2°2) +(5677'5 x 1°7)— 1459409

= 20038°66 N

Let the shear force be zero at a distance of x metres from D.

For this condition,

20038°66— 11355 x=0

2003866

x=- 11355 1°76 m.

Maximum bending moment

“162

= 20038'661'76—11355x I wm,

= 1TES1°40 Nm.

= 1768140 N cm.

stam CASES

1768140, :

40 fago0 x0'87x179 B10 om

Spacing of 12 mm. ¢ bars

113X100

810

Provide 12 mm. $ @ 14 cm. cle.

Fig. 400 shows details of reinforcements.

Design 98. Fig. 40! shows an arrangement for a stair case to

be provided for an office building. Design the Stcir ease. The risers

are 15 cm. and the treads are 25cm. The walls wre 40 cm. thick and

the stair slab has fuli bearing on the masonry walis. The supporting

beam i3 40 cm. wide.

=14 cm.

, som

150M te 650m be p50m- m4

Fig. 401

Solution. Let us provide a waist of 20 cm.

onda. Dead load of waist =20X25 = 500 kg./m.®

Ceiling finish = Whkg/m!

530 kg./m?

644 DESIGN OF REINFORCED CONCRETE STRUCTURI

Corresponding load ~-:r sq. mctre on plan

=530 { v. — } ketm2=530 {viists2S Veims

=618 kg./m2

Load per sq. metre on plan

Waist and ceiling finish = 618 kg./m2

D.L. of step’ (= cm, average = 187 kg./m.2

Top finish = 30 kg./m2

Live load = 300 kg./m2

Total = 1135 kg.fm2

Since the landing slab is a two way slab, the load on the land-

ing slab may be taken at 567°5 kg /m.?

Flight AB

Effective span =Centre to centre distance between the

supporting walls

“70+1°50+4-1°70 m

=49 m.

SE7Skg/m IBS kg/m 567-5 kg/m

(7m 15m '7m

Fig. 402

Consider a@ one metre wide strip of the flight.

Each vertical reaction

1135 x 1°5+567'5 x 3'4

= NBS X 1S 456715 X34 kg.

= 1816 kg.

Maximum bending moment

= E1649 _(567°5x1°7 x 16)— — (1135 «278 ke. m

= 2586'4 kg. m.=258640 kg. em.

Adopting c=50 kg./em4, t=1400 kg./em? and m=18 and

sauating the moment of resistance to the maximum bending moment,

we have,

8'5X100 d?=258640

“ d=174 cm.

STAIR CASES 645

Providing a clear cover of 15 mm. and using 12 mm. ¢ bars.

Effective cover =15+6=21 mm.=2°10 cm.

Effective depth available =20—2°1=17°9 cm.

=. 258640

1400 x 0°87 x 179

Provide 12 mm. ¢ @ 10 cm. c/e

Flight DA. Effective span=Centre of beam to centre of bearing on

wall

=24+-1'5+0 20+02 m,

=3'9 m.

Consider a one metre wide strip of the flight. Fig 403 shows

the loading on the strip.

Taking moments about D, we have,

ae At em.2=11'87 cm.*

N35 kg/m 567 5 kg/m

o 22m Wm A

Vd

Va

Fig. 403,

Va X 3°9=(1135 x 2'2 x 1°1)4+567°5 x 1°7 (2°2+0°85)

Vu=1458°76 kg.

Ve (1435 X 2°2)-+(567'5 x 1°7)— 1458°76

= 200299 kg.

Let the shear force be zero at distance of x metres from D. For

this condition.

1135x= 2002'99

x 76 m.

B.M. at x= 1°76 m.

7 1:76?

200299 x 176-1135 x—>— kg. m.

=1767 kg. m.

1767 X 100

~ 1400 0°87 x 18 07"

=8'10 cm?

ME DESIGN OF REINFORCED CONCRETE STRUCTURES

.. Spacing of 12 mm. diameter bars

113x100

ey om. 14 em.

Fig. 400 shows details of reinforcements.

Design 99. Fig. 404 shows the general layout cine

balcony. Design the balcony. Allow a live load rede sn

tread and rise of the steps are respectively 80 em. and I.

fulcrum girder is 50 cm.x100 cm. Take weight of R.C.C. oe

kg.Im?. Use M 150 concrete.

Soletiea.

Design of the decking slab. The decking slab is supported on

the rakers and is designed as a continuous slab.

Loads

Dead load of waist slab (10 cm. thick)

=24x 10 —

fo V PTT 245 bgt

Dead load of steps 4 (12) 24 =144 kg./m®

Live load 450 kg./m3

Tota) =837 kg.jm®

Consider 1 m wide strip of the slab

Maximum bending moment

aM Eas? te x 100 kg. em.

pn keg. em.

Equating the M R. to the B.M.

85x 100d? = 52310 . d=T84 em

Effective depth available

=10—2=8 cm.

: $2310 :

. A Tao x 08T XE 537 emt

Spacing of 10 mm. bers

079x100

S77 167 cm.

Provide 10 mm. ¢ bars @ 14 cm. centres.

STAT Cases on

Fig. 404

Design of rakers

Consider one intermediate raker. The raker is a T-beam.

Let the depth of the rib be 30 cm. Let the width of the rib be

also 30 cm.

Load from decking slab =:837 2° 2093 kg./m.

Dead load of rib =03x03%2400 = 216 kg/m.

=2009 kg/m.

‘Tes loading on the gangway will also be taken as 2309 kg./me.

648 DISIGN OF REINFORCED CONCRETE STRUCTURES

Load due to 10 cm. balustrade=0°10X0°80%2'5 x 2400

= 480 kg.

This ‘cad acts as a concentrated load at the free end of the

Provide a‘ bearing of 50cm. for the raker. Since the width

of the fulcrum girder is also 50 cm., the effective span of the raker

beam between the fulcrum girder and the supporting wall

=4°80+0'50=5'30 m.

Fig. 405 shows the raker beam and the loading on it.

Let Ve and Vo be the reactions at the supports A and B. Taking

moments about 4,

653

Vo x 5302309 x "+ 480 x6'65

7 Vo=10235 kg.

: Ve= (2309 x 6°65)+480—10235=5599'85, kee

Fig 423 shows the S.F. diagram for the raker beam.

Let the section of zero shear dex metre from A.

Equating the shear force to zero

5599°85—2309 x=0 -. x=2'43 m,

B.M. calculations

Moa=M.=0

b= — 2309 x 132" — 480 x 1°35

2M Dlegrom a72kgm

Fle. 405

STAIR CASES 649

B.M. at 2°43 m. from A

243%

= 5599°85 X 2 43—2309 x ae

= +6790 kg. m.

Fig. 405 shows the B.M. diagram for the raker beam.

In the region of sagging bending moment, the beam will be

considered as a T-beam. In the region of hogging bending moment,

the beam will be considered as a rectangular beam.

Consider the region of hogging bending moment.

Maximum hogging bending moment

=2752 kg. m.

= 275,200 kg. cm.

Equating the moment of resistance to the bending moment,

8°50 x 30 d?=275200 .. d=-32'85 cm.

Overall depth of the beam

=30+10=40 cm..

Available effective depth (with an effective cover of 6 cm.)

=40--6=34 em.

ated eee

i= Fa00 x 0°87 x 34 7°84 Om

Provide 3 bars of 20 mm. diameter (3 x 3°14=9°42 cm.?)

Maximum shear force near the support B

=6637°85 kg.

Nominat shear stress=%e ~- = oe kg.fom*

65 kg./om?

Percentage of tensile steel

myo? x10020'92%

30x34 ‘ :

For 0°92% steel %0==3°6 kg./cm.®

Shear resistance of concrete =4 bd

~~ 36 x30 x 343672 kg.

.'. Shear to be resisted by stirrups

= Ve 663785 —3672=2965°85 kg.

Spacing of 4-legged 10 mm. ¢ stirrups

Acted (4x0'7!

eee “Z

1400 X34 50 om.

Provide a spacing of 30 cm. elec.

650 DESIGN OF REINFORCED CONCRETE STRUCTURES

Now let us consider the region of sagging beading moment.

As mentioned earlier the region of sagging beading moment will be

designed as a T-beam.

Maximum sagging bending moment

=6790 kg. m.

=679,000 kg. cm.

Flange width of the T-beam

Flange width amt +be+6 de

530+ 304-(6x 10)=178'3 em, say 178 om.

Effective depth d= 40—6=34 cm.

Approximate lever arm=a=d— $

= e =29 cm.

Approximate steel required

_- 679,000 :

Bape 71672 em:

Provide 6 bars of 20 mm. diameter(18°84 em.*)

Position of Neutral Axis

Assuming the neutral axis to lie within the flange and taking

moments about the neutral axis,

178 X08 18x 18°84 (34—n)

Solving, we get n=9'64 cm.

Actual lever amma=d— >

=34—-24 30°79 om.

. 679000

Actual stress in steel i994 36°79 kg.jem?

=1170 kglem®

Corresponding compressive stress in concrete

70 964

“Te 34-964

=25°7 kg.fom*

Shear analysts

S.F. at A and at the point of coatrafiexure

= 559985 ky.

STAIR CASES 651

.. Nominal shear stress

— 5 _5599°85

ied "30x34 5°49 kg.jcm.*

Percentage of tensile steel

a fX314 ee

Sorga *100=1'23%

For 1°23% steel %0"*4 kg. /em.*

Shear resistance of concrete

= Ge brd== 4 x 30 x 34=4080 kg.

Shear to be resisted by stirrups

= Vom 5599'85—4080 = 1519°85 kg.

Spacing of 4-legged 10 mm. ¢ stirrups

= 4 X0°79 X 1400 34 _ og

1519°85 ie

Provide 4-legged 10 mm. ¢ @ 20 em. c/c.

Design of the fulcrum girder

The fulcrum girder supports the raker beams. Hence the

on the raker beam consists of (i) a number of concentrated

loads transmitted by the raker beams and (ii) its own weight.

Concentrated load transmitted by each raker beam=10235 kg.

Depth of the fulcrum girder = 100 cm.

.. Dead load of the fulcrum girder

=0'S x 1 x 2400=1200 kg./m.

Providing a bearing of 60 em. for the fulcrum girder effective

span of the girder= 15+0'60 = 15°60 m.

Total load on the fulcrum girder

=(5X 10235) + 1200 x 156 69895 kg.

Reaction at each support

S885 anes ke.

Fig. 406 shows the — and B.M. diagram for the falcrum

Max. BM. at the centre

=34947'$ x 780—1200x te

—10235 x S— 10235 x 2s.

199,320 kg.

652 DESIGN OF REINFORCED CONCRETE STRUCTURES

ae eee Mzitg — 10235kg esky 102 35g

£60m 250M "250M —ohe— 2 50h

Hasensap EP ch spc 0218-60 —

36967 549

35675

i $6 omswam 9°75 BFF i

i iansa5 7

: i

i IS9320kgm 5

14278pkgm Sgr 5

7142 780tgm 778 HIS

ssisorgr

8M. DIAGRAM

Fig. 405

Equating the M.R. to the maximum B M.

8°50 x 50 d? 159320 x 100 uv. d=194 cm,

The overall depth of the fulcrum girder is only 100 cm.

The fulcrum girder will therefore be designed as a doubly

reinforced beam.

Providing an effective cover of 8°5 cm. to the compression as

well as tension reinforcement.

Distance between the centres of the top and bottom steel

100-2 x 85 = 83 cm.

—159320x100 __.,.. 2

Ac At 1400 x83 =137 1 em,

Providing 40 mm. ¢ bars number of bars at top or bottom

Number of bars =Bo =I11 bars

Let us provide 12 bars of 40 mm. diameter arranged in two

layers with 6 bars per layer.

Check for shear

Maximum S.F. =S=34947'S kg.

S 349475 _g. 2

Shear stress= 75 = 93 5¢5,) 8°42 kg.fem.

Spacing of 4-legged 12 mm. diameter stirrups

_Avtea_ 4x 1°13 x 14000 x 83 15

Ss 604TS ee

.. Provide 4-legged 12 mm. diameter stirrups at 15 cm. cfc.

653

STAIR CASES

Loy “S14

yI0HID WhAIING

wood

ae wae

DSS

ie saruzs pr0b71% —guwor-9 sult OD-9 nee

ta

as es pata >

usez om

me

G

1 /

3 puuor-9 pawor-9

F208 te 08» ar

aps wn sang Yo uD

puu zs

p2563;% Y%ur068

euaogs pabdarr

i PuuoZ-2 @ uu Oe-b

/ Jf daa extra |

7 Murer d

oud £26600 9

euuzs-e

aye

x 0s109 WI wazt sie

654 DESIGN OF REINFORCED CONCRETE STRUCTURES

These stirrups will be provided for a distance of 2°50 m. from

each support. In the remaining region provide nominal 4-legged

12 mm. diameter stirrups at a spacing of 30 cm. centres,

Curtailment of steel

Perimeter of bottom bars required from local bond stress

consideration, near the supports

i S _349475_

a5 7 83 x 10742 10 em.

Perimeter of | bar =nx4=12'S6 em.

42°10

12°56

Let the lower 6 bars of the bottom bars be present for this

whole span. The other 6 bars of the upper layer will be curtailed

“. Number of bars= 4

at J of the span fe, at 4 (156)=223 m. say 225 m. from the

support. Similarly the bars may be curtailed in the compression

zone also.

15

Design of Water Tanks

A reinforced concrete tank (is a very useful structure which is

meant for the storage of water, for swimming baths, sewage sedimen-

tation and for such simular purposes. The usual types of water tanks

are the following :

(i) Tanks situated on the ground.

(i) Tonks sttuated under ground,

(iii) Lauks situated above ground level.

The tanks may be either open or roofed cver and they may be

either circular or rectanguiar ia plan.

Concrete used has to be watertight. This can be achieved by

Proper mixing and placiog and curing of concrete. Well graded

cement in richer proportion shall be used. The mix usually adopted

is M 20 in S.1. designs and M 200 in M.K.S. designs (nearly 1 : 1}: 3).

The impermeability can be appreciably increesed by asphalt lining or

puddle backing.

$161. Stresses tu Steel

In order to reduce any possible tensile cracking of concrete of

the tank wall, it is usual to assume a working stress of 100 N/mm.®

(1000 kg jem) in steel reinforcement situated near the water face.

The stress in the stee) reinforcement situated away from the water face

will be taken at 125 N/mm. (1250 kg./em®.)

§162. Basis of Design

There are two important factors .o be noted in the design of

an R.C. tank. It is not enough if the structure is designed so as to

ne a desited strength. What is required in addition is water-

tightness.

It is necessary to prevent shrinkage cracks in the tank walls.

‘This is possible by adopting a distribution reinforeement amounting

to at least 0°3 pergent of the gross area of the wal!. Further, slabs

should be eonereted in lengths rot greater than 7°S metres. It is

also necessary to proyide contraction joints hetween adjacent slab

units, In order to accommodate any additional thermal displace-

ments. exparision joints shall also be provided at intervals of 30 m.

For ficors it is necessary that tbe ground should be first covered with

a 8 cm. 1HCk lever of pisin concrete.

655

656 DESIGN OF REINFORCED CONCRETE STRUCTURES

Figs. 408 to 411 show the common forms of joints used in

tanks.

3163. Jciats w Tanks

Rigid Jaints These are joints provided to serve a continuity

between a firs? cast concrete and a second cast concrete. When a

gocd bond is required, it is usual that the

whole fave of the joint is completely removed

for a depth of 3 mm. by jetting or bush

hammering and a layer of 1} sand cement See Maree Ba

mortar is spread on the face which is cast

first immediately before the new concrete is

placed. A typical detail of such a joint is

shown in Fig. 4ux. A galvanised steel-water

bar is also cast into the concrete work to

prevent the passage of water across the line

of the joint.

Flexible Joint. For larger structures 16/0 Jom

flexible joints are preferred. Fig. 408. Rigid Joint.

These joints are meant to provide a free movement. The joint

faces should not be allowed to remain rough. They shall be finished

evenly. The second-cast concrete should be worked into a layer of

14: 1 sand cement mortar which should be spread on to the first cast

concrete face.

Fig. 409 (a) shows a flexible horizontal construction joint in the

wall of a structure. Such joints are required for the sake of con-

venience in setting the form work and also to afford proper access

for compaction of concreting.

SEAL

SAL WATER FACE

~PREPARED.

JOINT SURFACE

(b) VERTICAL CONTRACTION

JOINT OF A WALL

(B) HORIZONTAL CONS TRUC TION

JOINT OF a Walt Al

FLEXIBLE FUER SEAL WATER FACE

fC) VERTICAL EXPANSION JOINT

Fig. 409. Wall joint.

Fig. 409 (b) shows a vertical contraction joint in a wall. Such

are to be provided at intervals of 7°5 metres at places of zero

DESIGN OF WATEE TKS 637

shear. The first placed concrete surface should be left smooth and

unkeyed so that the joint is allowed to open as the concrete on either

eide cools or shrinks. Thus, all movements are localised or collected

at pre-determined pcsitions. A poly-vinyl chloride (PVC) water stop

is found satisfactory. It is also necessary to provide a triangular fillet

seal on the water face

Fig 409 (c) shows vertical expansi@h ‘joint io ¥ Nall. Such

joints are necessery ag-intervals of 30 metres at a place df zerd shear.

A flexible filler of 2 cm. thickness is provided in the joint. This

allows the joint @o partially close when the concrete on either side.

should expand. A suitable’ filler consists of cellular cane fibres

11 CEMENT SAND

(upede LAvER REINFORCED SLAR

” BOTTOM LAYER ik PLAIN CONCRETE Si AB

BUILDING PAPER

(@) CONTRACTION JOINT iN UPPER SLAB

WATER FACE

UPPER LAYER REINFORCED SLAB

BOTTOM LAYER ‘SEAL PLAIN CONCRETE

BUILDING PAPER ¢) guty JOINT IN THE whose AB

Fig. 410. Tank floor joints.

Sia

(@) CONTRACTION JOINT

FLEXIBLE FULLER™

BUILDING ebee

(by) EXPANSION JOWT

Fig. 411, Roof stab joints.

gs DESIGN OF REINFORCED CONCRETE STRUCTURES