Professional Documents

Culture Documents

Polymer Science and Technology 1 PDF

Polymer Science and Technology 1 PDF

Uploaded by

coppernitrate0 ratings0% found this document useful (0 votes)

10 views6 pagesOriginal Title

POLYMER SCIENCE AND TECHNOLOGY 1.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views6 pagesPolymer Science and Technology 1 PDF

Polymer Science and Technology 1 PDF

Uploaded by

coppernitrateCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

POLYMER SCIENCE AND TECHNOLOGY b.

Intermolecular – forces between two chains,

(impt. for crystalline)

I. Introduction and Basic Concepts Secondary bonding: (inter)

vdW

Polymers- long chain molecules, Dipole forces

Polymer properties- cheap, corrosion resistant, H-bonding*

lightweight, good formability Induction forces

c. Entanglements (impt. for amorphous)

By Origin:

a. synthetic organic polymers – mostly from Functionality:

petrochemicals Number of reactive groups, number of

b. biopolymers – proteins, natural rubber reactive sites

c. semi-synthetic – chemically modified Basic functionality required is two

biopolymers, easy to degrade bonding sites (linear chain)

d. inorganic- carbon replaced by Si Higher functionality -> crosslink or

branched

Important notes:

Elastomers are polymers that are II. Polymer Nomenclature

capable of high extension under

ambient ( ex. Rubber, tire, nitrile butyl A. Common Names

rubber) - some are named from the place of origin,

Nylon and polyester are example of some are named from the discoverer, some are

polymers that are suitable into long named after the number of carbons

fibers B. Source-based Names

Plastics, another kind of synthetic -from the name of the reactant monomer + the

polymer, often with additives and fillers word ‘poly’

Monomer – repeating unit -copolymer: poly(A-co-B), types: block,

N, degree of polymerization (DP) - # o alternating, graft, and random

repeating units (ex. A-block-B-block-C)

Oligomer – fewer than 10 repeating C. Structure-based Names

units -IUPAC system

Homopolymer – one king of repeating -Linkage-based names

unit D. Chemical abstracts-based polymer

Copolymer – more than one kind of nomenclature

repeating units -IUPAC and CAS: based on structural repeating

Terpolymer- three different repeating unit, IUPAC-poly(constitutional repeat unit),

units CAS-poly(structural repeating unit)

MW(poly) = MW(rep) X DP Seniority: heterocylic rings>

greatest # of most preferred acyclic

Molecular forces: heteroatoms>

a. Intramolecular – forces between atoms in carbocyclic rings>

one chain (impt. for amorphous) greatest # of multiple bonds >

Primary bonding: (intra) lowest locant>

Ionic bond only C chains

Covalent bond* O>S>Se>Te>N>P>As>Sb>Bi>Si>Ge>Sn>Pb>B>Hg

Coordinate bond E. Trade Names, Brand Names and Abv.

Metallic bond

III. Polymer Classification B. Physical Properties (thermal response)

A. Origin Thermoplastics

Natural -heat softened

Semi-synthetic -no crosslinks

Synthetic -weak attractive forces

B. Physical Properties (thermal response)

Thermoplastics Thermosets

Thermosets -chains are chemically linked by

C. Polymerization Mechanism or Mode of covalent bonds

Formation -crosslinked networls resist heat , creep

Addition and solvent attack

Condensation

D. Polymer Structure C. Polymerization Mechanism or Mode of

Based on backbone Formation

Homochain Addition

Heterochain -from unsaturated monomers (double

Arrangement of monomer bond) or closed rings (ring-opening

Homopolymer polymerization)

Copolymer (random, alternating, block, -most are chain growth

graft) Condensation

Type of Molecular structure/ Line structure -from random reaction of two

Linear –two ends molecules having complementary

Branched – have side chains functional end units

Cross-linked - networked -with liberation of a small molecule in

Type of functional group the form of a gas, water or salt

Alcohol, ester, etc. -most are step-growth

E. Tacticity

Isotactic D. Polymer Structure

Syndiotactic Based on backbone

Atactic Homochain – one atom

F. Crystallinity Heterochain – more than one atom

Amorphous (non-crystalline) grouped according to the types of

Semi- crystalline atoms and chemical groups

Crystalline

G. Application and Physical properties Arrangement of monomer

Rubbers/Elastomers Homopolymer

Plastics Copolymer (random, alternating, block,

Fibers graft)

Paint and Adhesives *The actual squence of monomer units

A. Origin is determined by their relative

Natural – available in nature reactivities

Semi-synthetic- chemically modified *Long block monomers , AB-block

natural polymers (hydrogenated, copolymers ot triblock copolymers

halogenated) *Graft copolymers can be prepared by

Synthetic – man-made poymerizing a monomer in a presence

of a fully formed polymer or another

monomer.

Type of Molecular structure/ Line Head to tail configuration:

structure Isotactic – R on the same side of the

Linear – with two ends planar, (stereoregular)

-soluble, fusible Syndiotactic – R on alternate sides of

Branched – have side chains the planar, (stereoregular)

-side chains are results of Atactic – R are randomly distributed

uncontrolled side rxns or by *stereoregular- high strength and stiffness,

design heat resistant, low solubility, high density

-more soluble, fusible than

linear F. Crystallinity

Cross-linked – networked Amorphous (non-crystalline) – lack of

-insoluble, infusible positional order on the molecular scale

-shows order of swelling Semi- crystalline - both

Crystalline

Type of functional group *0 to 90% crytallinity

Polyester *affected by structure, temperature, MW,

PET (or PETE) – thermoplastic, used in stereochemistry, processing conditions

synthetic fibers containers,

thermoforming apps, often in G. Application and Physical properties

combination with glass fiber Rubbers/Elastomers

Polyolefin Long-range elasticity

From simple olefin (alkene), polyalkene, Rather weak and unstable

petrochemical industry, ex. Cross-linked (vulcanization)

polypropylene Plastics

Polyamide Usually stronger than rubbers

Amides joined by peptide bonds, Some are hard and stiff, some are soft

commonly used in textiles, carpet, and flexible

sportswear durable and strong Fibers

Polyether Strongest among the three

Polyurethane Plant or animal origin

Widely used in high resiliency flexible High mechanical strength, thermal

foam seating, rigid foam insulation insulation, soft, flexible

panels, microcellular foam seals and Paint and Adhesives

gaskets, high perormance adhesivesm

surface coatings Important notes on Crystallanity:

Polyacrylic Crystalline- stronger but less flexible

Crystalline polymers, the denser areas

E. Tacticity have higher refreactive index thus,

-relative streochemistry (configuration, diff opaque or translucent, isotactic,

from conformation) syndiotactic

-effect on physical properties High-impact polystyrene – individually

-regularity of macromolecule structure affects amporphous and transparent but

the degree of crystallinity different refractive indexes thus,

-head to head, head to tail and random appears white and translucent

Property-structure relationships GLASS TRANSITION T (Amorphous phase)

Glass Transition T 1. Heating from low T – increased kinetic energy

- Increases w/ bulky pendant of molecules, increase motion only short range

groups i.e. vibrations, rotation

- Decreases w/ additives 2. Glass Transition T , Tg– from brittle crytalline

Solubility (lower length) to rubbery

- Increase amorphous 3. At Higher T, Tm – lose elastomeric properties,

- Low interchain force flow as liquid

- Disorder Factors affecting Tg:

- Temp -chain interaction -> chain polarity,

- Compatible solvent dipole force

Crystallinity (high interchain force) -MW, low # of chain ends, low free vol.

- Regularity, symmetry -flexibility (rigid-> high)

- Decrease volume -steric effect - bulky groups – less

- Increased stress freedom

- Slow cooling -stiffness

- Homogeneous lengths *high volume of pendant – increase

*flexibilty of pendant – decrease (plasticizing)

CRYSTALLINITY *length of pendant – increase

-highly stereoregular, little/no (entanglement/side-chain polymerization)

branching *flexible substituents – increase free vol.

- highly polar, strong dipole-dipole or H- *branching of pendant – increases

bonding *polarity of pendant – increases

METHODS *cross-linking – restricts rotational motion

1. Cooling of molten polymer raises Tg

2. evaporation of polymer soln’s

3. heating of polymer under vacuum Tg is influenced by 5 factors:

4. stretching = drawing 1. free volume

2. attractive forces

Glass Transition (amprophous region) (glassy 3. internal mobility

state to rubbery state) 4 stiffness

-Below Tg – disordered w/ immobile molecules 5. chain length

-Above Tg – disordered w/ portion where

molecules can wiggle around

-Second order transition POLYMER PROPERTIES

Melting ( crystalline region) (solid to melt) 1. Molecular weight

- Below Tm – ordered solid 2. Conformation – arrangement of chains in

- Above Tm – disordered melt space

- First order transition 3. Configuration – arrangement of atoms along

the chain

Effects of Crystallinity

1. Mechanical Property

Stronger and stifer

2. More Opaque

Scattering of light

3. Higher Density

4. More solvent resistant

IV. MOLECULAR WEIGHT 4. ultracentrifuge techniques

1. Number- Average MW 5. viscosity measurements

(total mass/ total no. of moles)

Three methods (Polymer Fractionation):

1. fractional precipitation

2. Weight- Average MW -Good solvent to produce solution

(/ total W) -Slowly adding non-solvent/precipitant then

filter

-High MW precipitate first

*constant T- adding precipitant

Important notes: *solvent – slowly decreasing T

Mn are determined by Raout’s

techniques and dependent on 2. elution fractionation

colligative properties such has -solid polymer then use increasing solvent

ebulliometry, cryometry, osmometry, power

and end-group analysis -Low MW will dissolve first ( collect high MW)

Mw are determined by expermients -use thin film polymers to enhance separation

and more dependent on the number of (increase contact area)

heavier molecules than the ave weight,

affects the bulk properties such as 3. gel permeation chromatography

viscosities and toughness -principle of size-exclusion chromatography

(SEC)

Polydisperty index = Mw/Mn – measures the -molecular sieving

range of molecular sizes or the breadth of the -using a column filled w/ swollen crosslink

molecular weight distribution polystyrene gel resulted in voids in the polymer

gel

3. Viscosity Average MW -High MW pass first

-bigger molecules makes a more viscous -Low MW stay longer , passes the voids

solution, molecules flow slowly

-bigger hydrodynamic volume, the volume that Five methods (MW determination):

the coiled up polymer takes up in a solution 1. end-group analysis

-slows down the solvent molecules by blocking No. of end group = no. of chains (linear)

their motion

2. colligative properties

V. Fractionation Boiling point, freesing point and osmotic

-targeted manipulation of the MW distribution pressure

of a polymer by separating and grouping short

and/or long chain materual 3. light scattering measurement

Information about motion

Three methods (Polymer Fractionation): Higher MW scatter light more

1. fractional precipitation

2. elution fractionation 4. ultracentrifuge techniques

3. gel permeation chromatography To determine the sizes and MW of colloidal and

other small particles

Five methods (MW determination): Sedimentation coefficients is a function of size,

1. end-group analysis shape and density

2. colligative properties Larger particles will sediment at lower speed

3. light scattering measurement

LIMITATIONS: chain not spherical, size of p. and

solvent, complicated and expensive equip.

5. viscosity measurements

Viscosity dependpends on nature of solvent,

type of P, MW of P, solution conc., T

Gives relative MW

You might also like

- Handout 1Document24 pagesHandout 1coppernitrateNo ratings yet

- Balcombe Et Al 2004 PDFDocument246 pagesBalcombe Et Al 2004 PDFChristian HarijantoNo ratings yet

- WINSEM2018-19 - CHY1701 - ETH - SJT304 - VL2018195004125 - Reference Material I - Module 7Document39 pagesWINSEM2018-19 - CHY1701 - ETH - SJT304 - VL2018195004125 - Reference Material I - Module 7kumarklNo ratings yet

- Polymer Lecure 1 PDFDocument78 pagesPolymer Lecure 1 PDFHadeed IlyasNo ratings yet

- Unit 4 - Polymer Chemitry 1Document20 pagesUnit 4 - Polymer Chemitry 1lokeshgundluru28No ratings yet

- Unit Vi. Polymeric Materials: Topic OutlineDocument13 pagesUnit Vi. Polymeric Materials: Topic OutlineIvyy Joyce BuanNo ratings yet

- Introduction To Polymerphysic: Che - Untirta.ac - IdDocument32 pagesIntroduction To Polymerphysic: Che - Untirta.ac - IdIlham Kiki ShahilaNo ratings yet

- Ref ChaptersDocument30 pagesRef ChaptersARULNo ratings yet

- Polymers: What Is A Polymer?Document3 pagesPolymers: What Is A Polymer?Theresa TuliaoNo ratings yet

- Polymer Structure: D. Jagan MohanDocument34 pagesPolymer Structure: D. Jagan MohanEllana NabilahNo ratings yet

- Introduction To Polymer Chemistry LecturDocument27 pagesIntroduction To Polymer Chemistry LecturBlack IrisNo ratings yet

- CHE3172 Nanotechnology and Materials I: Prof Huanting Wang Email: Huanting - Wang@monash - EduDocument13 pagesCHE3172 Nanotechnology and Materials I: Prof Huanting Wang Email: Huanting - Wang@monash - EduDivya KariaNo ratings yet

- Polymers NEWDocument70 pagesPolymers NEWHisham TaherNo ratings yet

- Introduction To Polymer Chemistry.Document25 pagesIntroduction To Polymer Chemistry.TobennaNo ratings yet

- Introduction and Basic Concepts: Essentials of Polymer Science and Engineering Che 297Document40 pagesIntroduction and Basic Concepts: Essentials of Polymer Science and Engineering Che 297Nino FelicesNo ratings yet

- Lecture 09Document42 pagesLecture 09winnieNo ratings yet

- Basic Concept of PolymerDocument19 pagesBasic Concept of PolymerSakib ZamanNo ratings yet

- Synthetic & Natural Polymers Module-6-3Document9 pagesSynthetic & Natural Polymers Module-6-3Raju SinghNo ratings yet

- Lecture 1 by Madam Shagufta PolymerDocument32 pagesLecture 1 by Madam Shagufta PolymerAhmad Shah 8999No ratings yet

- Lecture-1 Basic Terms and Classification 240723Document54 pagesLecture-1 Basic Terms and Classification 240723Tirth PrajapatiNo ratings yet

- Topik PolimerDocument43 pagesTopik PolimerZindarud Muhammad HaqNo ratings yet

- Polymer NotesDocument25 pagesPolymer NotesSwara BhideNo ratings yet

- Chemistryy Is NiceDocument16 pagesChemistryy Is NiceMark HibionadaNo ratings yet

- Lecture By: Dr. Harminder KaurDocument173 pagesLecture By: Dr. Harminder KaurNaman JollyNo ratings yet

- Polymer: Structure and Properties: Anshul GautampurkarDocument66 pagesPolymer: Structure and Properties: Anshul GautampurkarAnshul GautampurkarNo ratings yet

- 12CHEM18 Polymers 1Document42 pages12CHEM18 Polymers 1Arjun PasrichaNo ratings yet

- Polymers PDFDocument10 pagesPolymers PDFKrishna limNo ratings yet

- Polymer Science For PharmaceuticalsDocument17 pagesPolymer Science For PharmaceuticalsShoaib AhmedNo ratings yet

- SA Unit 5 POLYMER AND ORGANOMETALLIC COMPOUNDSDocument34 pagesSA Unit 5 POLYMER AND ORGANOMETALLIC COMPOUNDSguptaneha8700003783No ratings yet

- Genchem LESSON 13 READING MATERIALSDocument5 pagesGenchem LESSON 13 READING MATERIALSk4htn0No ratings yet

- Polymers Group 3Document43 pagesPolymers Group 3Theodore JohnFer Buensuceso LicuananNo ratings yet

- DR - Dhoke-Unit 3-Lecture 1-Speciality Polymers-Biodegradable PolymersDocument25 pagesDR - Dhoke-Unit 3-Lecture 1-Speciality Polymers-Biodegradable PolymersLadliNo ratings yet

- PolymersDocument38 pagesPolymersGarima UppadhyayNo ratings yet

- Polymer Lect1 EditedDocument27 pagesPolymer Lect1 EditedfahadfiazNo ratings yet

- Clase 7 - Propiedades FisicoquimicasDocument43 pagesClase 7 - Propiedades FisicoquimicasLaura HernandezNo ratings yet

- 2012 Wiley India Pvt. Ltd. All Rights Reserved.: Engineering ChemistryDocument75 pages2012 Wiley India Pvt. Ltd. All Rights Reserved.: Engineering ChemistrySarfaraz KhanNo ratings yet

- Subtopic 6.1: Polymers: MaterialsDocument32 pagesSubtopic 6.1: Polymers: MaterialschiggsNo ratings yet

- GROUP-10:, N Erl Ie JoDocument41 pagesGROUP-10:, N Erl Ie JoChelle Galleros TorremochaNo ratings yet

- Unit-1 Macromolecules With Problems - CompressedDocument42 pagesUnit-1 Macromolecules With Problems - CompressedcoolinkenanatamNo ratings yet

- High PolymersDocument22 pagesHigh PolymersRamalingam Chandra SekarNo ratings yet

- PolymersDocument72 pagesPolymersThe Private DetectiveNo ratings yet

- Introduction To Plastics, Polymers, and Their Properties. The Effect of Temperature and Other Factors On Plastics and ElastomersDocument45 pagesIntroduction To Plastics, Polymers, and Their Properties. The Effect of Temperature and Other Factors On Plastics and ElastomersDuong Doan100% (1)

- Introduction To The Physical Chemistry of PolymerDocument172 pagesIntroduction To The Physical Chemistry of PolymerAmr Gamal100% (1)

- Mse 470 S20 L2-1 PDFDocument32 pagesMse 470 S20 L2-1 PDFAndre VictorNo ratings yet

- 4.1. PolymersDocument79 pages4.1. Polymersbroadbazaar3819845No ratings yet

- General Introduction and Its ScopeDocument19 pagesGeneral Introduction and Its ScopeAnonymous OfZCqCNo ratings yet

- ChE17 PolymerTypesStructuresDocument8 pagesChE17 PolymerTypesStructuresZAIRA JOY UDANG SOTARIDONANo ratings yet

- Unit 5.2. POLYMERDocument12 pagesUnit 5.2. POLYMERAnusha PanchumarthiNo ratings yet

- History of PolymerDocument9 pagesHistory of PolymerelyakachanNo ratings yet

- ch1 Introduction To Polymer PDFDocument60 pagesch1 Introduction To Polymer PDF임성민No ratings yet

- Polymer IntroductionDocument11 pagesPolymer IntroductionmansourotaibiNo ratings yet

- Lecture - Engineeirng Materilas - Week 45678Document51 pagesLecture - Engineeirng Materilas - Week 45678Salar KhanNo ratings yet

- Lecture No. (1) Introduction of PolymersDocument21 pagesLecture No. (1) Introduction of PolymersKhalid AbeedNo ratings yet

- Introduction of Polymers: PolymerDocument7 pagesIntroduction of Polymers: PolymerTee bagNo ratings yet

- NEET UG Chemistry PolymerDocument11 pagesNEET UG Chemistry PolymerVeer SinghNo ratings yet

- Material 2 1Document76 pagesMaterial 2 1jeneneabebe458No ratings yet

- Classification of PolymersDocument14 pagesClassification of PolymersMuzzamilNo ratings yet

- Polymers: 1. Polymers 1.1 General Introduction and Its ScopeDocument7 pagesPolymers: 1. Polymers 1.1 General Introduction and Its ScopeJayvee MendozaNo ratings yet

- Lecture 5 - Polymers and RubbersDocument56 pagesLecture 5 - Polymers and RubbersRUGERO KeslyneNo ratings yet

- Module 1 PolymerDocument95 pagesModule 1 PolymerHardik JindalNo ratings yet

- PolymersDocument12 pagesPolymersmohsinsaeed45b1No ratings yet

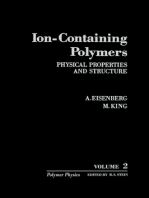

- Ion-Containing Polymers: Physical Properties and StructureFrom EverandIon-Containing Polymers: Physical Properties and StructureA. EisenbergNo ratings yet

- Equipment & Utility Costing2Document6 pagesEquipment & Utility Costing2coppernitrateNo ratings yet

- Handout 4Document26 pagesHandout 4coppernitrateNo ratings yet

- Health HazardsDocument2 pagesHealth HazardscoppernitrateNo ratings yet

- Handout 6Document21 pagesHandout 6coppernitrateNo ratings yet

- Handout 5Document14 pagesHandout 5coppernitrateNo ratings yet

- Polymer Science and Technology 2Document8 pagesPolymer Science and Technology 2coppernitrateNo ratings yet

- Fuels and CombustionDocument3 pagesFuels and CombustioncoppernitrateNo ratings yet

- Handout 2Document32 pagesHandout 2coppernitrateNo ratings yet

- Chap5 - Conditional Statements in MATLABDocument12 pagesChap5 - Conditional Statements in MATLABcoppernitrateNo ratings yet

- Chapter 3 Machine ExercisesDocument2 pagesChapter 3 Machine ExercisescoppernitrateNo ratings yet

- Review of CalculationsDocument8 pagesReview of CalculationscoppernitrateNo ratings yet

- Problem SetDocument1 pageProblem SetcoppernitrateNo ratings yet

- Worksheet: The Matlab® EnvironmentDocument8 pagesWorksheet: The Matlab® EnvironmentcoppernitrateNo ratings yet

- Appendices A. Sample Calculations: 3+ - 1 1 2 2 2 1 1 2 3+ 3+ Init - InitDocument2 pagesAppendices A. Sample Calculations: 3+ - 1 1 2 2 2 1 1 2 3+ 3+ Init - InitcoppernitrateNo ratings yet

- Chapter 20 PetrucciDocument67 pagesChapter 20 PetruccicoppernitrateNo ratings yet

- Introduction To CavitationDocument13 pagesIntroduction To CavitationMadhav ReddyNo ratings yet

- Marlin Studios: Tropical Trees & Foliage Alpha MapsDocument3 pagesMarlin Studios: Tropical Trees & Foliage Alpha MapsKALFERNo ratings yet

- Lab Weir Exp 3Document15 pagesLab Weir Exp 3Amy FarhanaNo ratings yet

- ENS RS Siremobil CompactDocument10 pagesENS RS Siremobil CompactdoraveteNo ratings yet

- Analysis of Helical Coil Heat Exchangers: by V.Swapna Priya Guide R S MauryaDocument23 pagesAnalysis of Helical Coil Heat Exchangers: by V.Swapna Priya Guide R S MauryaSwapna Priya VattemNo ratings yet

- TarguardDocument4 pagesTarguardMariela Tabata Calizaya ChipanaNo ratings yet

- Fujitsu Siemens Amilo l7310 Mitac 8650 Rev R0a SCHDocument34 pagesFujitsu Siemens Amilo l7310 Mitac 8650 Rev R0a SCH1cvbnmNo ratings yet

- Force Transducers Pb2 1 - 600knDocument7 pagesForce Transducers Pb2 1 - 600knMIGUEL LOPEZNo ratings yet

- Safeguard Performance of ABAP CDS Views CDS View ComplexityDocument4 pagesSafeguard Performance of ABAP CDS Views CDS View ComplexityPhan Nho VươngNo ratings yet

- Introduction Machine ToolsDocument28 pagesIntroduction Machine ToolsMobassher Al HasanNo ratings yet

- 3.4 Viewing FTE Status Auxiliary Display of Remote FTE NodeDocument1 page3.4 Viewing FTE Status Auxiliary Display of Remote FTE NodeAnonymous OYLvnCxNo ratings yet

- Questions: National Building Code of The PhilippinesDocument2 pagesQuestions: National Building Code of The PhilippinesFrancis TolentinoNo ratings yet

- Service Manual: Washing Machine Frontloader AWG 329Document9 pagesService Manual: Washing Machine Frontloader AWG 329cavmroNo ratings yet

- Helicopter Dynamic Stability-1Document7 pagesHelicopter Dynamic Stability-1KaradiasNo ratings yet

- PowToonQuickReference PDFDocument6 pagesPowToonQuickReference PDFWaka KaNo ratings yet

- UK Guidance-Use of Anchor Bolts in ConcreteDocument4 pagesUK Guidance-Use of Anchor Bolts in ConcreteswabrightNo ratings yet

- Supercritical Fluid Extraction From Vegetable Materials - SovovaDocument78 pagesSupercritical Fluid Extraction From Vegetable Materials - SovovaAlysson MendesNo ratings yet

- STC 9200Document6 pagesSTC 9200agustinpizzioNo ratings yet

- National Air and Space Museum Exterior Cladding Information PresentationDocument2 pagesNational Air and Space Museum Exterior Cladding Information PresentationEaterNo ratings yet

- Logic - Working With VideoDocument1 pageLogic - Working With VideoAlican ÇamcıNo ratings yet

- Programming Java NC III CGDocument29 pagesProgramming Java NC III CGJenny ANo ratings yet

- Progrid ® Compo GB: Glass Fibre Asphalt GeocompositeDocument1 pageProgrid ® Compo GB: Glass Fibre Asphalt Geocompositesukhoi474614No ratings yet

- Javelin ATGM Manual, CDNDocument113 pagesJavelin ATGM Manual, CDNGasMaskBob100% (1)

- User Manual stm32Document26 pagesUser Manual stm32SkvkNo ratings yet

- 06185747Document5 pages06185747nguyenductuyenNo ratings yet

- How To Build A Generic Air CannonDocument11 pagesHow To Build A Generic Air CannonJuan David Cardenas NavasNo ratings yet

- Astm C476Document2 pagesAstm C476Артем Титов100% (1)

- Magnet 40x15x8Document1 pageMagnet 40x15x8George PaulNo ratings yet

- Electronic Troubleshooting Manual RR-P38 EngDocument579 pagesElectronic Troubleshooting Manual RR-P38 EngIvo Dielen100% (12)