Professional Documents

Culture Documents

CH 11

Uploaded by

Nitin Gandhare0 ratings0% found this document useful (0 votes)

8 views5 pagesch11

Original Title

ch11

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentch11

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views5 pagesCH 11

Uploaded by

Nitin Gandharech11

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

11

Galvanised M.S. Wire

PRODUCT CODE : N.A.

QUALITY AND STANDARDS : (i) IS 280 : 1977

(ii) IS 2629 : 1985

(iii) IS 2633 : 1986

(iv) IS 6745 : 1972

PRODUCTION CAPACITY : 1160 Ton (per year)

MONTH AND YEAR : February, 2003

OF PREPARATION

PREPARED BY : Small Industries Service Institute

22 Godown, Indl. Estate,

Jaipur - 302006 (Raj.)

INTRODUCTION With the availability of appropriate

technology, the activity is highly feasible

Galvanized M.S. Wire has versatile in the small scale sector and marketing

use in producing different Engineering is generally not a problem.

items such as Building Hardwares,

barbed wires, Screens rivets etc. BASIS AND PRESUMPTIONS

Special quality of wire is also required

for producing special purpose The profile is drawn on the basis of

fastners, reinforcement wire etc. the following presumptions:

The Galvanized M.S. Wire is a Mild (1) Working hours/shift : 8 hr. per day

Wire which is coated with a steel layer (2) No. of Shifts per day : One

of Zinc. The coating of Zinc provides (3) No. of working day/year : 300

cathodic protection to underneath Steel (4) Total no. of working hours : 2400 hrs.

surface. The Galvanised M.S. Wire offers (5) Working efficiency : 75%

better surface protection at lower cost

(6) Time period for achieving : 3 years from

in humid atmosphere. maximum capacity the date on

utilization which production

MARKET POTENTIAL will be started

(7) Labour charges : As per minimum

The Galvanized M.S. Wire has very wages Act.

good demand for its versatile use in (8) Rate of Bank Interest : 18% per annum

different applications. There is a large

The value of machinery and

demand for this item from the down

equipment is estimated on the basis of

stream industries.

54 GALVANISED M.S. WIRE

prevailing market rates. It is expected ↓

that it may take about 8 to 9 months to Annealing of wire if required

complete all activities of the project, till ↓

commercial production is achieved. If The final drawing in continuous wire

the project is available with the drawing machine

promoter, a period of 8/9 months will ↓

be needed for site selection, Registration

Pre treatment of M.S. Wire cleaning

with DIC as SSI unit, Building construction,

and degreasing by special solvent like

selection and purchase of plant and

Sodium hydroxide solution and followed

machinery, Loan sanction from financial

by pickling

Institution, Erection and commissioning

↓

of Project for trial run etc.

Galvanizing of M.S. Wire by immersing

Quality Control and Standards of M.S. wire in the molten bath of Zinc

followed by water quenching

Standardizations parameters are as

↓

follows:

Inspection of Galvanized M.S. Wire

1. IS:280-1977 specification for Mild

↓

Steel wire for general purposes.

Binding of wire coil, packing etc.

2. IS:2629-1985, IS:2633-1986,

IS:6745-1972 to test the quality

of galvanization.

FINANCIAL ASPECTS

A. Fixed Capital

Production Capacity (per year)

(i) Land and Building (Rented)

The production target of Galvanised Rent payable per month Rs. 5,000

M.S. Wire 1160 MT per year.

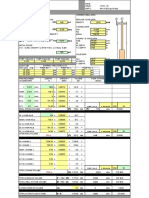

(ii) Machinery and Equipments

Quantity : 1160 MT

Sl. Name of Machinery Qty. Amount

Value : Rs. 293.20 Lakhs. No. and Equipment (In Rs.)

1. Heavy Duty Wire Drawing 1 No. 2,60,000

TECHNICAL ASPECTS Bull Block intake capacity

upto 10 mm of M.S. Wire

Process of Manufacture rod with 660 mm Capstan

and 40 HP motor complete

The production process of Galvanized with reduction gear box etc.

M.S. Wire is as follows: 2. Electric Motor 40 HP Sliping 1 set 1,30,000

type for the above complete

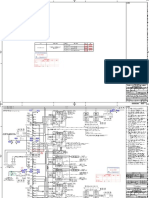

Pickling/Cleaning of the wire rod to with Switch gear Control

remove surface oxides and impurities panel, etc.

↓ 3. Set of continuous Wire 4 sets 6,50,000

Mechanical Scraping of the wire rod Drawing Machine Intake

capacity for 6 mm of M.S.

surface Wire with 550 mm Capstan

↓ and 25 H.P. Motor complete

with reduction gear Box etc.

Painting/Welding of Wire Rod

4. Set of Electric Motor of 25 4 sets 2,60,000

↓ HP for the above complete

Drawing of wire at various stages with Control Panel etc.

GALVANISED M.S. WIRE 55

5. Mechanical Desealer cap. 1 No. 32,500 2. Unskilled Workers 8 1,500 12,000

Up to 10 mm of Wire rod

3. Helper 5 1,500 7,500

complete with reduction

gears Take off Drum Salary and Wages 61,500

and 10 HP motor and

Add perquisites 12,300

Electrical

@ 20% per annum

6. Wire pointing Machine with 1 No. 18,000

Total 73,800

electric motor of 3 HP

7. Wire Butt Welding Machine 1 No. 15,000 (ii) Raw Material

suitable to weld M.S. Wire

Sl. Particulars Qty. Rate Amount

up to 10 mm

No. (In Rs.) (In Rs.)

8. Electric Furnace Bell type 1 No. 1,30,000

1. Mild Steel Wire 100 15,000 15,00,000

for Annealing of Wire Coil

rod of 8, 9 and ton per ton

rating 20 KW

10 mm Dia.

9. Hot Diping galvanizing unit L.S. 4,00,000

2. Zinc Ingot 5 65,000 3,25,000

consist of Pickling, Washing

ton ton

Flux Tank, Diesel Furnace,

Zinc Bath, Extraction unit 3. Acid Fluxes L.S. - 50,000

and Pot and other

additives

10 Electric Hoist of 1 ton capacity - 95,000

Total 18,75,000

Testing Equipment

11. Wire Testing Machine L.S. 75,000 (iii) Utilities (Rs.)

cap. 2 ton

1) Power L.S. 18,000

12. Equipment for coating test L.S. 20,000

2) Water L.S. 1,000

13. Gauges for Dimensional L.S. 15,000

measurement of wire 3) Fuel L.S. 30,000

14. Electrification and - 2,10,050 Total 49,000

Installation @ 10% of

cost of Machinery and equipment

15. Cost of Dies of various sizes - 50,000 (iv) Other Contingent Expenses (Rs.)

16. Office equipment and furniture - 30,000 1. Rent 5,000

17. Pre-operative Expenses - 1,00,000 2. Postage and Stationery 1,000

Total 24,90,550 3. Telephone 800

4. Consumable Store 15,000

B. Working Capital (per month)

(i) Staff and Labour 5. Repair and Maintenance 8,000

Administrative 6. Transport charges 10,000

Sl. Administrative No. Salary Amount 7. Advertisement and Publicity 3,000

No. Staff (In Rs.) (In Rs.)

1. Manager 1 5,000 5,000 8. Insurance 1,000

2. Supervisor 2 4,000 8,000 9. Miscellaneous Expenses 1,000

3. Clerk 2 3,000 6,000 Total 44,800

4. Accountant 1 4,000 4,000

5. Peon/Watchman 2 1,500 3,000 (v) Working Capital (In Rs.)

Workshop Staff 1. Raw material 18,75,000

1. Skilled Workers 8 2,000 16,000 2. Salary and Wages 73,800

56 GALVANISED M.S. WIRE

3. Utilities 49,000 (5) Rate of Return

4. Other Contingent Expenses 44,800 Net Profit per year × 100

Rate of Return = —————————————

Total 20,42,600

Total Investment

Working Capital (for 3 months) Rs. 61,27,800

3004947 × 100

= ———————————

C. Total Capital Investment 8618350

(i) Fixed Capital Rs. 24,90,550 = 34.8%

(ii) Working Capital Rs. 61,27,800 (6)Break-even Point (Rs.)

Total Rs. 86,18,350 1) Total Depreciation 2,52,550

2) Rent and Insurance 72,000

FINANCIAL ANALYSIS

3) Interest on total Capital 15,51,303

(1) Cost of Production (per year) (Rs.) Investment

(1) Total Recurring Cost 245,11,200 4) 40% of Salary and Wages 3,54,240

(2) Depreciation on Machinery 1,86,050 5) 40% of other contingent 1,86,240

and Equipment @ 10% expenses

(3) Depreciation on furnace and 48,000 Total 24,16,333

Testing Equipment @ 20%

Fixed Cost × 100

(4) Depreciation on office 6,000 B.E.P = ———————————

equipment @ 20% Fixed Cost + Profit

(5) Depreciation on Dies @ 25% 12,500 2416333 × 100

(6) Interest on total capital 15,51,303 = ———————————

investment @ 18% 2416333 + 3004947

Total 263,15,053 2416333 × 100

= ———————————

(2) Turnover (per year) 5421280

Sl. Items Qty. Rate Amount = 44.5%

No. (In Rs.) (In Rs.)

Addresses of Machinery and

1. Galvanised M.S. 1160 25,000 290,00,000

Wire ton per ton

Equipment Suppliers

2. Scrap Wire 40 8000 3,20,000

1. M/s. Associated Machinery Mfg.

ton per ton Pvt. Ltd.

Bulandshahar Road, Industrial

Total 293,20,000

Area, Ghaziabad.

2. M/s. C.S. Wire Pvt. Ltd.

(3) Net Profit (per year)

90-B, IDA., Jeedi Matha,

Rs. 29320000 – 26315053 = Rs. 3004947

Hyderabad.

(4) Net Profit Ratio 3. M/s. Wire Machinery Mfg.

Net Profit per year × 100

Corporation

= ———————————— 7 A, Ventinard Road,

Turnover per year Kolkata.

3004947 × 100 4. M/s. Refrigeration and Machinery

= ——————————

29320000

Corporation

Rajendra Prasad Road,

= 10.2%

Mumbai - 400080.

GALVANISED M.S. WIRE 57

5. M/s. Design Engineering Co. 8. M/s. United Agro Engineering Co.

Wadala, R.P. Road,

Mumbai - 400431. Secunderabad.

6. M/s. Wesman Engineering Co. Pvt.

Addresses of Raw Material

Ltd.

Suppliers

346, Pantheen Road,

Chennai. (i) M/s. Steel Authority of India Ltd.

7. M/s. Batliboi and Co.

(ii) M/s. Tata Iron and Steel Co. Ltd.

R.P. Road,

Secunderabad. (iii) M/s. Hindustan Zinc Ltd.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SAE hydraulic hose standards overviewDocument4 pagesSAE hydraulic hose standards overvieweqt slhl100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- RIGGING SAFETY TrainingDocument43 pagesRIGGING SAFETY TrainingBG REDDYNo ratings yet

- Air Modeller 44 PDFDocument68 pagesAir Modeller 44 PDFdushanero100% (7)

- Jis C 3410 2010 PDFDocument75 pagesJis C 3410 2010 PDFThanh Dang100% (1)

- ( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Document5 pages( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Nitin GandhareNo ratings yet

- ( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Document5 pages( (C) - CURR. DENSITY) X SHOE T.V.D. X 0.052 X 3.281Nitin GandhareNo ratings yet

- Types of CableDocument12 pagesTypes of CableIndraNo ratings yet

- Zolotukhin Reservoir Engineering 002Document217 pagesZolotukhin Reservoir Engineering 002Anttonio Gómez86% (14)

- Pitampur - Indore Industrial Company ListDocument13 pagesPitampur - Indore Industrial Company Listanon_769009642100% (5)

- Well Description: Lead Slurry 999 2276 10 550 Tail Slurry 212 1038 550 650Document8 pagesWell Description: Lead Slurry 999 2276 10 550 Tail Slurry 212 1038 550 650Nitin GandhareNo ratings yet

- Earthing Calculation, Rev-5, (AS BUILT)Document7 pagesEarthing Calculation, Rev-5, (AS BUILT)Mayank SharmaNo ratings yet

- Qcs 2014 - Sec21 p10 - Wiring Accessories and General PowerDocument9 pagesQcs 2014 - Sec21 p10 - Wiring Accessories and General PowerchandraNo ratings yet

- Production Engg - Herriot Watt Series 1. Performance of Flowing WellsDocument7 pagesProduction Engg - Herriot Watt Series 1. Performance of Flowing WellsNitin GandhareNo ratings yet

- Qty Particulars Bill Rate Amount Quoted Rate Amount Rate AmountDocument1 pageQty Particulars Bill Rate Amount Quoted Rate Amount Rate AmountNitin GandhareNo ratings yet

- TallyDocument6 pagesTallyNitin GandhareNo ratings yet

- Production Engg - Herriot Watt Series 1. Performance of Flowing WellsDocument7 pagesProduction Engg - Herriot Watt Series 1. Performance of Flowing WellsNitin GandhareNo ratings yet

- Qty Particulars Bill Rate Amount Quoted Rate Amount Rate AmountDocument1 pageQty Particulars Bill Rate Amount Quoted Rate Amount Rate AmountNitin GandhareNo ratings yet

- Brand 180 Ml. 90 Ml. 60 Ml. 30 ML.: Old Monk / MDXXX / Oc RumDocument3 pagesBrand 180 Ml. 90 Ml. 60 Ml. 30 ML.: Old Monk / MDXXX / Oc RumNitin GandhareNo ratings yet

- Elec2 PDFDocument1 pageElec2 PDFNitin GandhareNo ratings yet

- Decline CurvesDocument11 pagesDecline CurveskittyiiiNo ratings yet

- Formulas & Rules for Limits, Derivatives & Higher Order DerivativesDocument2 pagesFormulas & Rules for Limits, Derivatives & Higher Order DerivativesSwapnil GuptaNo ratings yet

- Low Cost DripDocument17 pagesLow Cost Dripসপ্তক মন্ডলNo ratings yet

- Comparis I OnDocument2 pagesComparis I OnNitin GandhareNo ratings yet

- Introduction to Rock Types and ClassificationsDocument12 pagesIntroduction to Rock Types and ClassificationsRajat WadhwaniNo ratings yet

- Integral CH - 7 06.11.06Document72 pagesIntegral CH - 7 06.11.06Anamitaa SharmaNo ratings yet

- Fluids - IIIDocument29 pagesFluids - IIINitin GandhareNo ratings yet

- Centre Pivot Irrigation SystemsDocument26 pagesCentre Pivot Irrigation SystemsNestorov IvanNo ratings yet

- Production Engg - Herriot Watt Series 1. Performance of Flowing WellsDocument7 pagesProduction Engg - Herriot Watt Series 1. Performance of Flowing WellsNitin GandhareNo ratings yet

- Gate in Petroleum EngineeringDocument3 pagesGate in Petroleum EngineeringSushil RiyarNo ratings yet

- Case StudyDocument5 pagesCase StudyNitin GandhareNo ratings yet

- O 6Document9 pagesO 6Nitin GandhareNo ratings yet

- ##Petroleum Formation Evaluation##: All The BestDocument1 page##Petroleum Formation Evaluation##: All The BestNitin GandhareNo ratings yet

- Geosteering ToolsDocument4 pagesGeosteering ToolsNitin GandhareNo ratings yet

- General Checklist RigDocument1 pageGeneral Checklist RigNitin GandhareNo ratings yet

- PoultryDocument48 pagesPoultryNitin GandhareNo ratings yet

- All The Best : ##Reservoir Engineering##Document1 pageAll The Best : ##Reservoir Engineering##Madhukar ScribdNo ratings yet

- Offshore Drilling and Production Practices NotesDocument1 pageOffshore Drilling and Production Practices NotesNitin GandhareNo ratings yet

- Duraflex Wires and Cables Duraflex Wires and CablesDocument1 pageDuraflex Wires and Cables Duraflex Wires and CablesRamled RerrefNo ratings yet

- Wire CoatingDocument11 pagesWire Coatinglalalola12345No ratings yet

- Fuse Gma 2.5aDocument5 pagesFuse Gma 2.5aJuan Felipe Garza GNo ratings yet

- ELS ONE39 EL+Retarder-Prover 208-60 US1 GIACDocument11 pagesELS ONE39 EL+Retarder-Prover 208-60 US1 GIACFreddy MayorgaNo ratings yet

- Airframe Wire Cable Guide 2016Document24 pagesAirframe Wire Cable Guide 2016sdhrtwrNo ratings yet

- Cable Design ParametersDocument6 pagesCable Design ParametersDan HawkNo ratings yet

- PT KMI Wire and Cable TBK 2Document4 pagesPT KMI Wire and Cable TBK 2angelineNo ratings yet

- MACCAFERRI - Rockfall Netting BrosurDocument32 pagesMACCAFERRI - Rockfall Netting BrosurRizki KresnaNo ratings yet

- Republic of The Philippines: Mhar CuetoDocument28 pagesRepublic of The Philippines: Mhar CuetoNelshane JohnNo ratings yet

- 01 Disintegration Test For Tablets and CapsulesDocument30 pages01 Disintegration Test For Tablets and CapsulesmefroNo ratings yet

- LT Loss CalculationDocument55 pagesLT Loss Calculationshivakumar hiremathNo ratings yet

- Saudi Arabian Oil Company: 521 P BA-169229 FS1 00Document4 pagesSaudi Arabian Oil Company: 521 P BA-169229 FS1 00Sara thNo ratings yet

- Arduino Control Draft BOMDocument4 pagesArduino Control Draft BOMabhijitNo ratings yet

- L4-Cable Rating-UpdateDocument29 pagesL4-Cable Rating-UpdateboyNo ratings yet

- Icea Nema S-61-402 Parte 7Document11 pagesIcea Nema S-61-402 Parte 7DamiánNo ratings yet

- Uen R 24200001Document4 pagesUen R 24200001Williams ArayaNo ratings yet

- Strip Heaters 375 StripDocument6 pagesStrip Heaters 375 StripEliasNo ratings yet

- Strutfast Cable Trays - LRDocument11 pagesStrutfast Cable Trays - LRzimtonyNo ratings yet

- FSAI Journal Jan-Feb 2023 Released On 21st Feb'23Document88 pagesFSAI Journal Jan-Feb 2023 Released On 21st Feb'23Sujal ShahNo ratings yet

- Perfect Finish Viking KnitDocument6 pagesPerfect Finish Viking KnitMisa BijouxNo ratings yet

- Marine Cable GuideDocument32 pagesMarine Cable GuideGabriel GalmariniNo ratings yet

- Cla 604aDocument28 pagesCla 604aChiesa Nuova Pentecoste TarantoNo ratings yet