Professional Documents

Culture Documents

TSP Arc Rated Flash Suits 2 PDF

TSP Arc Rated Flash Suits 2 PDF

Uploaded by

letaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSP Arc Rated Flash Suits 2 PDF

TSP Arc Rated Flash Suits 2 PDF

Uploaded by

letaCopyright:

Available Formats

DuPont™ Protera® Arc Rated Flash Suits

Standard Hood

ATPV 55 Arc Visor

Cooling Hood

ATPV 55 Arc Visor

Jacket

Gloves

Multi layer construction

Storage Bag

Trousers

Test Report K-418230-R01

ASTM F 1959/F 1959M-12

Standard Test Method for Determining the

Arc Rating of Materials for Clothing

Fabric Arc Rating, ATPV 55Cal/cm²

Fabric Heat Attenuation Factor, HAF 99%

TECHNICAL SERVICES & PROJECTS cc

P.O. BOX 2676 KRUGERSDORP 1740 GAUTENG SOUTH AFRICA

TEL: +27 (0)11 954 2505 FAX: +27 (0)11 954 0165

E-mail: info@tspsa.co.za Website: www.tspsa.co.za

DuPont™ Protera® Arc Rated Flash Suits

Standard Hood

Cooling Hood

Jacket

Gloves

Multi layer construction

Storage Bag

Trousers

Test Report K-418648-03-R00

ASTM F 1959/F 1959M-12

Standard Test Method for Determining the

Arc Rating of Materials for Clothing

Fabric Arc Rating, ATPV 100Cal/cm²

Fabric Heat Attenuation Factor, HAF 99%

TECHNICAL SERVICES & PROJECTS cc

P.O. BOX 2676 KRUGERSDORP 1740 GAUTENG SOUTH AFRICA

TEL: +27 (0)11 954 2505 FAX: +27 (0)11 954 0165

E-mail: info@tspsa.co.za Website: www.tspsa.co.za

WARNING – READ BEFORE USING GARMENTS AND PRODUCTS

Arc flash garments and products are intended to provide protection from the thermal hazards of an electric arc

flash. The garments and products comply with the standards that are intended to protect users against arc

flash in most situations that arise from normal use. There may be exceptional circumstances, in which even

the best protection may not be sufficient to prevent injuries, or related effects, caused by an electric arc flash

and the mechanical effects of the arc blast. The use of the garments and products does not guarantee that

complete protection will be provided in those exceptional circumstances. It is the responsibility of the user to

determine if the garments and products are appropriate for the intended use and that it complies with all the

laws and regulatory standards. If in doubt or if you do not fully understand these limitations, please contact us

for additional information and assistance.

Face Shields

v Do not leave face shields in direct sunlight for long periods of time.

v Do not place or store face shields near a heat source.

v Do not use cracked or broken face shields.

v Do not use face shields that have been exposed to an arc flash.

Ageing caused by radiation from direct sun and ambient light:

For face shields using absorption technology, easily recognisable by the green or yellow tinted visors, almost

all the harmful radiation is absorbed by the visor and not transmitted through the visor. It is this absorption of

radiation that will protect users during an electric arc flash event. However, the visor will also absorb radiation

from the daily exposure to sun and ambient light, which will accelerated the ageing and change the optical

characteristics of the visor. This ageing process will require periodic inspection and replacement of the face

shields.

For face shields using reflection technology (BSD ErgoS Face Shield family and BSD Arc Protection Hoods),

only a small part of the harmful radiation will be absorbed and the majority of the radiation will be reflected. This

reflection technology will not only protect the user during an arc flash but will also protect the visor from the

radiation that it’s exposed to during daily use. The lifespan of the polycarbonate visor is therefore extended

well beyond the estimated lifespan of the face shield.

The BSD ErgoS-2Plus and ErgoS-Power face shields, with clear visors, have no restriction on lifetime and

durability when used in accordance with the instruction for use. Classification criteria for defects are all defects

and damages that are identified by the user during the visual inspection of the product.

Definitions:

v Arc Thermal Performance Value (ATPV): Numerical value of incident energy attributed to a material that

describes its thermal properties of attenuating (reducing) a heat flux generated by an electric arc. The

ATPV is the value of incident energy which results in a 50% probability that sufficient heat transfer through

the test specimen is predicted to cause the onset of a second degree skin burn injury based on the Stoll

curve.

v Heat Attenuation Factor (HAF): Percentage of the incident energy which is blocked by a material at an

incident energy level equal to ATPV.

v Break open threshold energy (EBT): Numerical value of incident energy attributed to a material that

describes its break open properties when exposed to heat flux of electric arc. The EBT is the value of

incident energy with a 50% probability that break open of the test specimen will occur.

TECHNICAL SERVICES & PROJECTS cc

P.O. BOX 2676 KRUGERSDORP 1740 GAUTENG SOUTH AFRICA

TEL: +27 (0)11 954 2505 FAX: +27 (0)11 954 0165

E-mail: info@tspsa.co.za Website: www.tspsa.co.za

You might also like

- NFPA70E ARC CalculatorDocument46 pagesNFPA70E ARC CalculatorRPantel100% (2)

- Procedure For IEEE 1584 Based Arc Flash CalculationsDocument6 pagesProcedure For IEEE 1584 Based Arc Flash CalculationsWilber LucasNo ratings yet

- Optical Con Field Assembly - Technical Info v1.0Document14 pagesOptical Con Field Assembly - Technical Info v1.0Mariano AcostaNo ratings yet

- Arc Flash Guide v2Document4 pagesArc Flash Guide v2tatacpsNo ratings yet

- Arc Flash PPE CatalogueDocument16 pagesArc Flash PPE Cataloguejmarrero488307No ratings yet

- Bulwark FRDocument76 pagesBulwark FRuniformguy1155No ratings yet

- DC Arc FlashDocument11 pagesDC Arc Flashgerrzen64No ratings yet

- Ieee 1584 and Nfpa 70eDocument5 pagesIeee 1584 and Nfpa 70ejesusbarajasNo ratings yet

- Catalog 27-512 Base Station AntennasDocument99 pagesCatalog 27-512 Base Station AntennasJocelyn DervainNo ratings yet

- CCI - RU and BU CablesDocument32 pagesCCI - RU and BU CablesBob JohnsonNo ratings yet

- EVA Powered Air-Purifying Respirator Technical SpecificationsDocument2 pagesEVA Powered Air-Purifying Respirator Technical SpecificationsRianAidilNo ratings yet

- Corona Performance of KaptonDocument4 pagesCorona Performance of KaptonAlfChenNo ratings yet

- Catalog EN Arc Flash PPE 2023Document49 pagesCatalog EN Arc Flash PPE 2023raúl lara aravenaNo ratings yet

- Arc FlashDocument16 pagesArc FlashMidfiild Cosmin100% (1)

- 3 KTA DesignguideDocument32 pages3 KTA Designguideodin_auerNo ratings yet

- Lighting Lighting: Philips UV-C Batten, The Power To ProtectDocument6 pagesLighting Lighting: Philips UV-C Batten, The Power To ProtectLOI HONo ratings yet

- Tecsun PV PV1 FDocument8 pagesTecsun PV PV1 FDaniel GnanaselvamNo ratings yet

- Specifications: Type SCRN Film-Paper/Extended Foil Commutating CapacitorDocument4 pagesSpecifications: Type SCRN Film-Paper/Extended Foil Commutating CapacitorCheranjeevi ChiruNo ratings yet

- PC75 123 ManualDocument72 pagesPC75 123 ManualAndreasNo ratings yet

- Calculo Nfpa 70 e en Una Caja de 20x20Document24 pagesCalculo Nfpa 70 e en Una Caja de 20x20Adolfo EcheverriaNo ratings yet

- CPA-Arc Flash Protection-ASTM 1506-NFPA 70EDocument16 pagesCPA-Arc Flash Protection-ASTM 1506-NFPA 70EJOSE LUIS FALCON CHAVEZNo ratings yet

- Report - Arc Flash27112020Document47 pagesReport - Arc Flash27112020ramesh cuppu100% (1)

- 9361824d 741516Document2 pages9361824d 741516alexteixeira1No ratings yet

- Arc Flash PPE-ATPV HRC 3 - 2020 PDFDocument9 pagesArc Flash PPE-ATPV HRC 3 - 2020 PDFRenán SuárezNo ratings yet

- Offshore CablesDocument68 pagesOffshore CablesAmet koko Taro100% (1)

- Surge Voltage ProtectionDocument22 pagesSurge Voltage Protectionrajpre1213No ratings yet

- Av-20-02 (Plan-08)Document66 pagesAv-20-02 (Plan-08)Ulugh BaigNo ratings yet

- Kathrein Anten Catalog 021006Document229 pagesKathrein Anten Catalog 021006Gaby Linda JacomeNo ratings yet

- Cat-CMP Cable GlandDocument64 pagesCat-CMP Cable GlandSyahirul Alim100% (1)

- Pulsar GBDocument4 pagesPulsar GBEkarat NareepangsriNo ratings yet

- 739 634Document2 pages739 634slymnNo ratings yet

- Solar Energy - Lightning and Overvoltage Protection - 1TXH 000 118 B0202Document8 pagesSolar Energy - Lightning and Overvoltage Protection - 1TXH 000 118 B0202Roberto McVerickNo ratings yet

- 730368Document2 pages730368AnnBliss100% (1)

- Tindo Panel Data SheetDocument2 pagesTindo Panel Data SheetJoshHumphreyNo ratings yet

- UPC-85 ML Instruction Manual Rev.01Document24 pagesUPC-85 ML Instruction Manual Rev.01Chris TeohNo ratings yet

- MCCB CatalogueDocument6 pagesMCCB Cataloguewawa ishakNo ratings yet

- Arc Flash Ppe Requirements FRDocument6 pagesArc Flash Ppe Requirements FRariesyihaNo ratings yet

- Arc Flash Protection LV HV Switching Suits For Racking in & OutDocument2 pagesArc Flash Protection LV HV Switching Suits For Racking in & OutSourav BhuniaNo ratings yet

- 742266V01Document4 pages742266V01DAVIDNo ratings yet

- Radox 4 Gkw-Ax 1800V MM S Traction Cable: Product DescriptionDocument5 pagesRadox 4 Gkw-Ax 1800V MM S Traction Cable: Product DescriptionRudy IndrawanNo ratings yet

- Guía de SoldaduraDocument44 pagesGuía de SoldaduraJuan Novillo RamosNo ratings yet

- AS332 Film Cooled TailpipeDocument2 pagesAS332 Film Cooled Tailpipehiscoke69No ratings yet

- Built To Run, Built To Last: Cambium Point-To-Point RadiosDocument4 pagesBuilt To Run, Built To Last: Cambium Point-To-Point RadiosAdvantec SrlNo ratings yet

- ComPact NSX - LV429540Document3 pagesComPact NSX - LV429540Sara TariqNo ratings yet

- Kathrein 730691Document2 pagesKathrein 730691Roberto EmmeNo ratings yet

- Arc Flass CoverallDocument16 pagesArc Flass CoverallIMAM MAHMUDANo ratings yet

- s010 Usa OPGW Standard PDFDocument2 pagess010 Usa OPGW Standard PDFAlberto GarcíaNo ratings yet

- What Is An Arc FlashDocument5 pagesWhat Is An Arc FlashJemark LapinigNo ratings yet

- Arc Flash and NFPA 70E: Safe Work PracticesDocument22 pagesArc Flash and NFPA 70E: Safe Work PracticesWaleed ElzanatiNo ratings yet

- CMP IECEx ATEX 01Document10 pagesCMP IECEx ATEX 01rocket-vtNo ratings yet

- Ex Cable GlandsDocument18 pagesEx Cable GlandsAntonis BafatakisNo ratings yet

- Product:: Fieldbus, 1 PR #18 STR TC, PP Ins, OS, PVC JKT, Flexible SUN RES OIL RES, PLTC-ER, ITC-ER, CMX-Outdoor, CMDocument2 pagesProduct:: Fieldbus, 1 PR #18 STR TC, PP Ins, OS, PVC JKT, Flexible SUN RES OIL RES, PLTC-ER, ITC-ER, CMX-Outdoor, CMflavioNo ratings yet

- BrightPhoton - VCSEL - LD0940-B130-0014CC-1035 Spec V.01Document4 pagesBrightPhoton - VCSEL - LD0940-B130-0014CC-1035 Spec V.01黄孙峰No ratings yet

- Cabling Products and Solutions: CATALOGUE 2010/2011Document196 pagesCabling Products and Solutions: CATALOGUE 2010/2011Georgi PanayotovNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Underwater Technology: Offshore PetroleumFrom EverandUnderwater Technology: Offshore PetroleumL. AtteraasNo ratings yet

- HP BIOS Serial Console User Guide: July 2004 (First Edition) Part Number 372432-001Document33 pagesHP BIOS Serial Console User Guide: July 2004 (First Edition) Part Number 372432-001MaríaHaNo ratings yet

- It Manuals 20180510162751791Document68 pagesIt Manuals 20180510162751791Gayatri AtishNo ratings yet

- Lesson Plan - The Science of Light and ImpressionismDocument10 pagesLesson Plan - The Science of Light and Impressionismapi-317030373No ratings yet

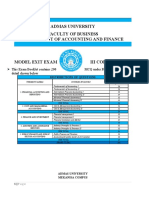

- Business Exam: Name: . Number: . Year: . Date: .. / .. /2021 Time 90 Minutes MarkDocument8 pagesBusiness Exam: Name: . Number: . Year: . Date: .. / .. /2021 Time 90 Minutes MarkSylwia SdiriNo ratings yet

- What Is Pneumonia?: Patient EducationDocument2 pagesWhat Is Pneumonia?: Patient EducationDian Putri NingsihNo ratings yet

- Chapter 2 - Principles of Electromechanical Energy ConversionDocument22 pagesChapter 2 - Principles of Electromechanical Energy Conversionchibssa alemayehuNo ratings yet

- South Yarra Cable Tram Engine House and Tram ShedDocument18 pagesSouth Yarra Cable Tram Engine House and Tram ShedGary VinesNo ratings yet

- HersheysfailureDocument3 pagesHersheysfailureirenesarange6No ratings yet

- SBI द्वारा सुप्रीम कोर्ट में दाखिल किया गया Compliance AffidavitDocument7 pagesSBI द्वारा सुप्रीम कोर्ट में दाखिल किया गया Compliance Affidavitvrastogi100% (1)

- Civil Law MTDocument28 pagesCivil Law MTKaira Marie CarlosNo ratings yet

- Tugas Bahasa Inggris "Roleplay Ambulation": OlehDocument3 pagesTugas Bahasa Inggris "Roleplay Ambulation": Olehnono NonoNo ratings yet

- (123doc) - A-Qualitative-Study-Of-Project-Based-Learning-In-MainstreamDocument12 pages(123doc) - A-Qualitative-Study-Of-Project-Based-Learning-In-MainstreamThai ThuyNo ratings yet

- Confidence IntervalsDocument18 pagesConfidence IntervalsDeniseJade LeguardaNo ratings yet

- Ra 7560Document3 pagesRa 7560Joseph Santos GacayanNo ratings yet

- Evaluation Studyof MPLSNetwork Potencyin Yemen NetDocument13 pagesEvaluation Studyof MPLSNetwork Potencyin Yemen NetAdham AliNo ratings yet

- PFI - Panelist Information BookletDocument8 pagesPFI - Panelist Information BookletHayley OleksiakNo ratings yet

- YDS 2016 İlkbahar Deneme - 2Document15 pagesYDS 2016 İlkbahar Deneme - 2Zeynal Abidin ŞabaşNo ratings yet

- Bliss Manufacturing Company Internal Lab Scope: Laboratory PersonnelDocument2 pagesBliss Manufacturing Company Internal Lab Scope: Laboratory PersonnelsachNo ratings yet

- Ice Cream Cones Manufacturing and Production Project ReportDocument22 pagesIce Cream Cones Manufacturing and Production Project Reportwww.projecreportinfo.comNo ratings yet

- Colonial MentalityDocument2 pagesColonial MentalityInnaNo ratings yet

- Schneider Acti9 Control CatalogueDocument36 pagesSchneider Acti9 Control CatalogueChaouki AbdallahNo ratings yet

- FM 23-24 Dragon Medium Antitank/Assault Weapon System M47Document24 pagesFM 23-24 Dragon Medium Antitank/Assault Weapon System M47VincenzoNo ratings yet

- 20 Rules of Closing A Deal PDFDocument21 pages20 Rules of Closing A Deal PDFbioarquitectura100% (9)

- Casio px-130 Ver.4 SMDocument60 pagesCasio px-130 Ver.4 SMPoon Electronic Training CentreNo ratings yet

- All QuestionDocument37 pagesAll QuestionOUSMAN SEIDNo ratings yet

- Group 2 CONTEMPORARY ARTDocument47 pagesGroup 2 CONTEMPORARY ARTShiella Marie Alvindia GanibanNo ratings yet

- Nadim Kanaan Seminar FinalDocument146 pagesNadim Kanaan Seminar Finalamo3330100% (1)

- Technology Assessment RubricDocument2 pagesTechnology Assessment Rubricapi-554368239No ratings yet

- Web-Based Procurement SystemDocument29 pagesWeb-Based Procurement SystemMish Lei Franxh100% (1)

- OIG Compliance Program For Third-Party Medical Billing CompaniesDocument15 pagesOIG Compliance Program For Third-Party Medical Billing CompaniesaaronborosNo ratings yet