Professional Documents

Culture Documents

EPC Execution of Borealis Ethane Tank Project TGE EN PDF

Uploaded by

JosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EPC Execution of Borealis Ethane Tank Project TGE EN PDF

Uploaded by

JosCopyright:

Available Formats

BASED ON EXPERIENCE

TGE GAS ENGINEERING

EPC EXECUTION OF BOREALIS ETHANE TANK PROJECT

www.tge-gas.com 24/10/2016 Page 1

CONTENT

Overview on the Services and Experience of TGE Gas Engineering GmbH

Project Overview and Process Description

Construction Phase

Pre-Commissioning and Commissioning

Time Schedule

www.tge-gas.com 24/10/2016 Page 2

COMPANY PROFILE

TGE Gas Engineering GmbH (TGE) is one of the LIQUEFIED GAS STORAGE

world‘s leading contractors for projects involving the CAPACITY PERFORMED (m³)

storage and handling of liquefied gases in the energy Status Sep. 2016

and petrochemical/chemical industries. 6.000.000

TGE has over 30 years of experience in this field,

providing full range of services from concept 5.000.000

/feasibility studies through to Lump Sum Turn-Key

Project execution.

4.000.000

Our target is to provide to customers the added value

based on our experience and Know-How in delivering

“millions of m³” of Liquefied Gas Storages and 3.000.000

Handling Facilities.

TGE is a technology focused company that is active 2.000.000

worldwide with main operating units throughout

Europe and Asia.

1.000.000

0

Overall LNG Ethylene / Propylene,

capacity Ethane LPG, etc.

www.tge-gas.com 24/10/2016 Page 3

SCOPE OF SERVICES BOREALIS

Consultancy Detailed Engineering

Technical and Commercial Feasibility Studies Procurement/Procurement Services

Site Selection Construction/Construction Services

Conceptual Design Supervision Services

Environmental Impact Assessment (EIA) and Pre-Commissioning and Commissioning Services

HAZOP Studies

Start-Up/Shut Down Services

Capital Cost (CAPEX) and Operating Cost

(OPEX) Estimation Selection and Training of Operators

Business Plan for Capital Investments and Operations Operation and Maintenance Services

Basic Engineering and Front End Engineering Design Life-Cycle Engineering Studies and Plant

(FEED) Life-Cycle Optimisation

www.tge-gas.com 24/10/2016 Page 4

PROJECT OVERVIEW

DESIGN BASIS

Medium Main equipment

Liquid Ethane In-tank Pumps (3 x 50% capacity)

Storage Tank Screw Compressor Package (2 x 50% Capacity)

Ground Flare System

Full Containment Storage Tank

Utilities

Working Volume 52,000 m³

Design Conditions Design Requirements

-4.5 to 300 mbarg Unloading Rate

-115°C to Ambient Sendout Rate

Level / Temperature / Pressure Measurement & Control

Systems

www.tge-gas.com 24/10/2016 Page 5

PROJECT OVERVIEW – FLOW DIAGRAM

www.tge-gas.com 24/10/2016 Page 6

PROJECT OVERVIEW

MAIN PROJECT STEPS

Tank Design Hazop Review Meeting

Full Containment Design acc. EN14620 Safety Discussions Client & Vendors

Insulation Calculations 3D Model Review

Design of Equipment 30% 3D Model Review – Lines

Type 60% 3D Model Review – Maintability and Operability

Data Sheets 90% 3D Model Review – All Layout

Noise Study Compressor Shelter Safety Review by Inspecta

Restriction of Noise Review of Project Design regarding Overall Safety

Natural Ventilation e.g. Check of Safety Valve Sizing

www.tge-gas.com 24/10/2016 Page 7

PROJECT OVERVIEW - PROCESS

SPECIAL PROCESS DESIGN

Screw Compressors

Preheating of Cold Ethane Vapour

Shell & Tube Heater

Usage of Hot Compressor Discharge

Preheating to -40°C

Compressor Inlet Temperature controlled via Bypass

Safety System

Stop Compressor at low Temperature

www.tge-gas.com 24/10/2016 Page 8

PROJECT OVERVIEW - PLOTPLAN

www.tge-gas.com 24/10/2016 Page 9

CONSTRUCTION

STATISTICS ORGANIZATION

Duration 26 months (08.14. – 09.16) Daily Site Coordination Meetings

Number of Near Misses: 303 Weekly Meetings with CLIENT and Subcontractors

Total Hours Worked: 292.506 Weekly Safety Walks

Accidents: 0 Toolbox Meetings

Lost Working Hours: 0 Involvement of CLIENT and INSPECTA from the beginning

www.tge-gas.com 24/10/2016 Page 10

CONSTRUCTION

WORKS

www.tge-gas.com 24/10/2016 Page 11

CONSTRUCTION

MECHANICAL COMPLETION / PRE-COMMISSIONING

Deviation into Systems and Subsystems and Testpacks

Inspections

Line Cleaning

System Drying & Inerting

Instrument Loop

Interlock / ESD Checks

PID Checks

Electrical Circuit / Motor / Equipment Checks

Equipment Installation

Mechanical Equipment Checks

Vendor Checks

Introduce IA and N2 – Flush & Test

Service Test FW System – Flush & Test & Drain

Follow Up Done by PIMS CMS System

www.tge-gas.com 24/10/2016 Page 12

PRE-COMMISSIONING / COMMISSIONING

PRE-COMMISSIONING / COMMISSIONING

Start Half a Year in Advance with first Commissioning Tank Purging with Nitrogen

Meetings (Scope, Interfaces, Organization)

Tank Gassing-up & Start-up Compressors

Operator Training Support

Tank Cool Down

Dedicated Commissioning Team Full Time on Site

Start of In-tank Pumps

Start of Sendout

Performance Tests

Taking Over

www.tge-gas.com 24/10/2016 Page 13

COMMISSIONING

CHALLENGES

Integration of: Support

New DCS / SM into old DCS / SM DCS programming according TGE design

Equipment into old DCS / SM Adjustment of Control for Preheater System

Manual Control for Preheaters during Cooldown

Sensible Interaction between Components of System for

Adjustment

Observation of Behavior of the Control Systems during

Manual Control

www.tge-gas.com 24/10/2016 Page 14

IMPORTANT MILESTONES

www.tge-gas.com 24/10/2016 Page 15

THANK YOU FOR YOUR ATTENTION!

Vielen Dank cпaсибо большое

Obrigado

多谢

www.tge-gas.com 24/10/2016 Page 16

CONTACT

TGE Gas Engineering GmbH

Mildred-Scheel-Str. 1

53175 Bonn

Germany

+49 228 60448 0

+49 228 60448 893

www.tge-gas.com

tge-service@tge-gas.com

www.tge-gas.com 24/10/2016 Page 17

PRODUCT LINES

Storages and Storage and Small-Mid Scale Other

Terminals Terminals Natural Gas LNG Package Plants for gas

for LNG for Petrochemical/ Liquefaction Plants treatment or elements

Chemical Gas of storage product

lines

LNG as Fuel

Storage Tank

Design Services

www.tge-gas.com 24/10/2016 Page 18

FACTS & FIGURES

STORAGES AND TERMINALS FOR LNG

17 Projects in Total (EPC & EP+CS) STORAGE TANKS

Import Terminals: 9 Storage Tanks installed 30,000 - 160,000 m³

Export Terminals: 7 Storage Tanks designed 5,000 - 260,000 m³

Import/Export Terminal: 1 Storage Tanks installed in Europe 940,000 m³

72 LNG Truck/Container Loading Stations Storage Tanks installed in Asia 1,908,000 m³

Total Regasification Capacity > 13 mio t/a

Total Production Capacity INSTALLED CAPACITY

Small-Mid Scale LNG > 3 mio t/a

21 Full Containment Tanks 2,838,000 m³

5 Single Containment Tanks 170,000 m³

Reference for all relevant International Design Codes:

TOTAL INSTALLED CAPACITY 3,008,000 m³

Tanks: EN 14620, EUROCODE

API 625, API 620, ACI 376

Facilities: EN 1473, NFPA 59a, S

www.tge-gas.com 24/10/2016 Page 19

FACTS & FIGURES

STORAGES AND TERMINALS FOR

PETROCHEMICAL GASES

36 Projects in Total (EPC & EP+CS) for

Petrochemical Products: Ethylene, Ethane,

Propylene, Butane, LPG, Ammonia.

STORAGE TANKS

Tanks installed with capacities from

3,000 - 120,000 m³

up to

Facilities installed in Europe 327,000 m³

Facilities installed in Asia 1,684,000 m³ LARGEST INSTALLED CAPACITY

LPG 120,000 m³ Full Containment

INSTALLED CAPACITY

Ethylene 80,000 m³ Full Containment

20 Full Containment Tanks

1,205,000 m³

with installed capacity Ethane 120,000 m³ Full Containment

22 Single Containment Tanks

560,000 m³ Propylene 80,000 m³ Full Containment

with installed capacity

TOTAL INSTALLED CAPACITY 1,765,000 m³ Ammonia 25,000 ton Full Containment

www.tge-gas.com 24/10/2016 Page 20

You might also like

- Magic Frequencies: Excerpted From The Mixing Engineer's HandbookDocument5 pagesMagic Frequencies: Excerpted From The Mixing Engineer's HandbookmehmetkurtulusNo ratings yet

- 近斷層調整因子研究NCREE 2014 005F PDFDocument117 pages近斷層調整因子研究NCREE 2014 005F PDFLEENo ratings yet

- 近斷層調整因子研究NCREE 2014 005F PDFDocument117 pages近斷層調整因子研究NCREE 2014 005F PDFLEENo ratings yet

- LP Africa (11th Edition)Document406 pagesLP Africa (11th Edition)TucaVieiraNo ratings yet

- 1 Aerodynamics Lecture - Viscous FlowDocument70 pages1 Aerodynamics Lecture - Viscous Flowccoyure100% (2)

- Abacus & Junior Vedic Maths SyllabusDocument2 pagesAbacus & Junior Vedic Maths SyllabusDayalan ArunachalamNo ratings yet

- History TakingDocument51 pagesHistory TakingJAMES TONNY OKINYINo ratings yet

- CTS-TANK Gert Van MeijerenDocument38 pagesCTS-TANK Gert Van MeijerenA87_navjNo ratings yet

- Data Sheet Crude Oil Tank Mixer PDFDocument3 pagesData Sheet Crude Oil Tank Mixer PDFsiska bedegul100% (1)

- Design Philosophy of A Mixed Feed Cracker Dharmendra Narang Chief Engineer Technipfmc 6825 PDFDocument25 pagesDesign Philosophy of A Mixed Feed Cracker Dharmendra Narang Chief Engineer Technipfmc 6825 PDFNAVEEN AVVARUNo ratings yet

- TCXDVN 375-2006 p2 (English)Document40 pagesTCXDVN 375-2006 p2 (English)xja1mex0% (1)

- Design and Analysis of A Small-Scale Natural Gas Liquefaction Process N2 and CO2Document8 pagesDesign and Analysis of A Small-Scale Natural Gas Liquefaction Process N2 and CO2Williams Javier Ramos VasquezNo ratings yet

- Low Pressure and Ammonia Storage Tank: Engineering Standard Specification FORDocument11 pagesLow Pressure and Ammonia Storage Tank: Engineering Standard Specification FORHamid MansouriNo ratings yet

- LNG Storage Tanks - Advancements in Weld Inspections PDFDocument3 pagesLNG Storage Tanks - Advancements in Weld Inspections PDFjperdigon9634No ratings yet

- Comm-Op Aspect Refrigerated LPG TerminalDocument11 pagesComm-Op Aspect Refrigerated LPG TerminalMikiRoniWijayaNo ratings yet

- B - Algeria Sonatrach LNG Liquefaction Facility (LNG As Bunker)Document4 pagesB - Algeria Sonatrach LNG Liquefaction Facility (LNG As Bunker)Sofia KentNo ratings yet

- PAMDocument14 pagesPAMRashed IslamNo ratings yet

- Ammonia Storage Decommissioning PDFDocument19 pagesAmmonia Storage Decommissioning PDFDAYAMOY APL100% (1)

- Ethylene StorageDocument5 pagesEthylene Storagedewiayunov100% (3)

- Floating Roof Design (Liquid Hight)Document4 pagesFloating Roof Design (Liquid Hight)Hamid MansouriNo ratings yet

- Regenerative Thermal OxidizersDocument3 pagesRegenerative Thermal OxidizersEka KusyantoNo ratings yet

- Cci LNG GuideDocument28 pagesCci LNG GuidesabinvargheseNo ratings yet

- Fluor LNGRegasificationUtilizationDocument20 pagesFluor LNGRegasificationUtilizationMahesh DivakarNo ratings yet

- Cryogenic Air Separation UnitDocument13 pagesCryogenic Air Separation UnitMehran IsgandarliNo ratings yet

- TariqLNG - Technology SelectionDocument4 pagesTariqLNG - Technology SelectionAndrey KrNo ratings yet

- Liquid Storage Tanks Chapter 7 PDFDocument104 pagesLiquid Storage Tanks Chapter 7 PDFFabio MiguelNo ratings yet

- 2015 References Terminals EDocument59 pages2015 References Terminals EAllyson JohnsonNo ratings yet

- LNG - Storage - Tank - Rollover PDFDocument7 pagesLNG - Storage - Tank - Rollover PDFchemsac20% (1)

- General LNG ProcessDocument52 pagesGeneral LNG ProcessMochamad Yusuf Al GhazaliNo ratings yet

- Quantitative Risk Assessment of LNG Above Ground TanksDocument12 pagesQuantitative Risk Assessment of LNG Above Ground TanksAhmad FauzanNo ratings yet

- Nitrogen RejectionDocument7 pagesNitrogen RejectionOmar TocmoNo ratings yet

- LNG 5 - Containment New Drawings 7.3.09-Aacomments-Aug09Document8 pagesLNG 5 - Containment New Drawings 7.3.09-Aacomments-Aug09FernandoTremariNo ratings yet

- Power Plant Design InformationDocument47 pagesPower Plant Design InformationAnonymous gr5Pr9AV100% (1)

- Design and Construction of Gravity Based LNG TankDocument29 pagesDesign and Construction of Gravity Based LNG TankthawdarNo ratings yet

- GTL TechnologyDocument24 pagesGTL Technologychaitanya_scribd100% (1)

- Stratification and Rollover in LNG TanksDocument14 pagesStratification and Rollover in LNG Tanksleak100% (2)

- Cbi LNG Storage US Rev8 LoresDocument4 pagesCbi LNG Storage US Rev8 LoresVilas AndhaleNo ratings yet

- Technical Aspect of Storage Tank Loss PDFDocument9 pagesTechnical Aspect of Storage Tank Loss PDFIlze Lorena Priego AhumadaNo ratings yet

- Electric Heaters For Safe Startup ofDocument9 pagesElectric Heaters For Safe Startup ofSteve WanNo ratings yet

- LNG Vaporization PDFDocument18 pagesLNG Vaporization PDFihllhm100% (1)

- Amine Loading To SystemDocument6 pagesAmine Loading To SystemRathinavel PerumalNo ratings yet

- Improvement of Emissivity of Furnace RefractoryDocument8 pagesImprovement of Emissivity of Furnace RefractoryRinku SingrohaNo ratings yet

- LNG Tank Base - Bottom Corner InsulationDocument6 pagesLNG Tank Base - Bottom Corner InsulationFrenky60100% (1)

- Ammonia Storage TanksDocument2 pagesAmmonia Storage TanksZeroRecoNo ratings yet

- Gas To Liquids (GTL)Document41 pagesGas To Liquids (GTL)thuythukopaiNo ratings yet

- Safety Aspects of LNGDocument10 pagesSafety Aspects of LNGNeil AlexNo ratings yet

- Propylene StorageDocument2 pagesPropylene StorageMarnel Roy Mayor0% (1)

- 2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankDocument19 pages2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankAdnan AliNo ratings yet

- Decommissioningand Inspectionof Ammonia Storage TankDocument11 pagesDecommissioningand Inspectionof Ammonia Storage TankVrbank KrabNo ratings yet

- Coke FormationDocument10 pagesCoke Formationghasem_726990287No ratings yet

- Simple Method For Calculation of Cryogenic Transfer Line Cool DownDocument8 pagesSimple Method For Calculation of Cryogenic Transfer Line Cool DownIgnacio ChaparroNo ratings yet

- Polypropylene Homopolymer Via Bulk Process - Cost Analysis PP E11ADocument54 pagesPolypropylene Homopolymer Via Bulk Process - Cost Analysis PP E11AAsad KhanNo ratings yet

- Sener Fsru EnglishDocument33 pagesSener Fsru EnglishFrancisco J RodríguezNo ratings yet

- Chemistry of Ethylene Production From NaphthaDocument2 pagesChemistry of Ethylene Production From NaphthaKimal Wasalathilake0% (1)

- DSF-1101901-0568-SPC-MEC-179 Rev 4 PDFDocument6 pagesDSF-1101901-0568-SPC-MEC-179 Rev 4 PDFanon_102608277No ratings yet

- Sustainable Ammonia ReportDocument33 pagesSustainable Ammonia ReportAnonymous oBfI1LANo ratings yet

- 9686-6130-MS-000-0002 - B2 - MS Tank Construction. - ApprovedDocument23 pages9686-6130-MS-000-0002 - B2 - MS Tank Construction. - ApprovedANIL PLAMOOTTIL100% (1)

- EthyleneDocument9 pagesEthyleneFenghua YouNo ratings yet

- PDFDocument15 pagesPDFJohansen HasugianNo ratings yet

- Sarnia Lambton Propylene Investment Opportunity Final Report EDocument38 pagesSarnia Lambton Propylene Investment Opportunity Final Report EPranav Bhat100% (1)

- Fluid Catalytic Cracking Unit (FCCU)Document1 pageFluid Catalytic Cracking Unit (FCCU)Billy BlinksNo ratings yet

- COEN 13116 Duct Burner Solutions LR WebDocument2 pagesCOEN 13116 Duct Burner Solutions LR WebscribdkhatnNo ratings yet

- Dehydration of Ethanol To EthyleneDocument10 pagesDehydration of Ethanol To EthylenewiboonwiNo ratings yet

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988From EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNo ratings yet

- Hafiz M Abubakar - OriginalDocument4 pagesHafiz M Abubakar - OriginalMuhammad ShehzadNo ratings yet

- Mubasher Javaid - OriginalDocument6 pagesMubasher Javaid - OriginalMuhammad ShehzadNo ratings yet

- Ali Huzafa Sayyar - OriginalDocument3 pagesAli Huzafa Sayyar - OriginalMuhammad ShehzadNo ratings yet

- Esr 1917 中文版Document11 pagesEsr 1917 中文版LEENo ratings yet

- CF I 750Document1 pageCF I 750LEENo ratings yet

- Astm a325 分類及材質Document2 pagesAstm a325 分類及材質LEENo ratings yet

- DSP Lab RecordDocument97 pagesDSP Lab RecordLikhita UttamNo ratings yet

- The Laws of Motion ¿ ¿ Cengage LearningDocument57 pagesThe Laws of Motion ¿ ¿ Cengage LearningNguyễn Khắc HuyNo ratings yet

- View Result - CUMS Comprehensive University Management System - M.K.Bhavnagar University Powered by AuroMeera A College Management System ProviderDocument1 pageView Result - CUMS Comprehensive University Management System - M.K.Bhavnagar University Powered by AuroMeera A College Management System ProviderKiaanNo ratings yet

- 01 TMCR Heat Balance DiagramDocument1 page01 TMCR Heat Balance DiagramPrescila PalacioNo ratings yet

- Basic Concepts of SociologyDocument4 pagesBasic Concepts of SociologyAiman HaiqarlNo ratings yet

- Outline On Dengue Fever - EDITEDDocument2 pagesOutline On Dengue Fever - EDITEDDavid Skeat0% (1)

- Cause and Effect PowerpointDocument20 pagesCause and Effect PowerpointSherly V.LizardoNo ratings yet

- Managing Housekeeping Inventory: Ihm MumbaiDocument5 pagesManaging Housekeeping Inventory: Ihm MumbaiAbhishek ChowdhuryNo ratings yet

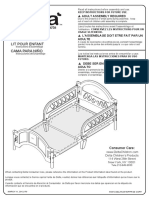

- BB204-Toddler Bed Assembly InstructionsDocument10 pagesBB204-Toddler Bed Assembly InstructionsCaloi PastorfideNo ratings yet

- Catchment CharacterisationDocument48 pagesCatchment CharacterisationSherlock BaileyNo ratings yet

- Đề Cương Giữa Kì 1 Lớp 11 (2023-2024) Ban HsDocument10 pagesĐề Cương Giữa Kì 1 Lớp 11 (2023-2024) Ban Hsmyorange9277No ratings yet

- Falsework For Concrete Structures - Guidelines: Indian StandardDocument24 pagesFalsework For Concrete Structures - Guidelines: Indian StandardLivinston JosephNo ratings yet

- Thank You For Your Order: Power & Signal Group PO BOX 856842 MINNEAPOLIS, MN 55485-6842Document1 pageThank You For Your Order: Power & Signal Group PO BOX 856842 MINNEAPOLIS, MN 55485-6842RuodNo ratings yet

- PIA Rivalry Strategy MapDocument16 pagesPIA Rivalry Strategy MapRomeo KhanNo ratings yet

- ACE Inhibitors Vs ARBsDocument3 pagesACE Inhibitors Vs ARBsKo Phyo WaiNo ratings yet

- Idioms & PhrasesDocument4 pagesIdioms & PhrasesHimadri Prosad RoyNo ratings yet

- Industrial Training Sample Report of Last YearDocument42 pagesIndustrial Training Sample Report of Last YearKetan NikamNo ratings yet

- Business, Government & Society: Pawan Kumar N K 12301005Document8 pagesBusiness, Government & Society: Pawan Kumar N K 12301005Pawan NkNo ratings yet

- Installiation of Automatic Fire Sprinkler System and Design CalculationDocument8 pagesInstalliation of Automatic Fire Sprinkler System and Design CalculationSat AungNo ratings yet

- BCA 5005 Minor Project Synopsis Format & GuidelinesDocument7 pagesBCA 5005 Minor Project Synopsis Format & GuidelinesAnu VermaNo ratings yet

- DS-7204HI-VS Net DVR - V2.0 (080909)Document88 pagesDS-7204HI-VS Net DVR - V2.0 (080909)ANTONIO PEREZNo ratings yet

- Irving Hallowell - Ojibwa Ontology, Behavior and World ViewDocument24 pagesIrving Hallowell - Ojibwa Ontology, Behavior and World ViewFa Di LaNo ratings yet

- International StandardDocument8 pagesInternational Standardnazrul islamNo ratings yet