Professional Documents

Culture Documents

Pipe Bending Methods, Tolerances, Process and Material Requirements

Pipe Bending Methods, Tolerances, Process and Material Requirements

Uploaded by

Денис ПекшуевOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Bending Methods, Tolerances, Process and Material Requirements

Pipe Bending Methods, Tolerances, Process and Material Requirements

Uploaded by

Денис ПекшуевCopyright:

Available Formats

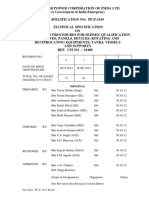

PFI Standard ES-24

(Reaffirmed- September 2010)

PIPE BENDING METHODS,

TOLERANCES,

PROCESS AND MATERIAL

REQUIREMENTS

Prepared by

Pipe Fabrication Institute Engineering Committee

All PFI Standards are advisory only. There is no

agreement to adhere to any PFI Standard and their

use by anyone is entirely voluntary.

Copyright by

PIPE FABRICATION INSTITUTE

Dedicated to Technical Advancements and Standardization in

the Pipe Fabrication Industry

Since 1913

USA CANADA

511 Avenue of America 's, #. 601 655, 32"d Avenue, # 201

New York, NY 10011 Lachine, QC H8T 3G6

WEBSITE

www.pfl- ins I itute. org

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Sold to:HHI , 01968263

No reproduction or networking permitted without license from IHS 2013!7/17 7:49:34 GMT

PFI Standard ES-24

(Reaffirmed - September 201 0)

Pipe Bending Methods, Tolerances,

Process and Material Requirement

(

METRIC CONVERSIONS

The conversion of quantities between systems of units involves a determination of the number of significant digits to be retained.

All conversions depend upon the intended precision of the original quantity and are rounded to the appropriate accuracy.

Pipe sizes together with applicable wall thicknesses are not shown with metric equivalents.

The SI (metric) values where included with the customary U.S. values in this Standard are the rounded equivalents of the U.S .

values and are for reference only.

Metric units were derived utilizing the following conversion factor:

Conversion Factor Conversion Factor

Inches to 25.4 Deg. Fahr. to 5/9 (Deg. F.- 32)

Mitlimeters Deg. Cent.

Lb/in 2 to 0.0703

2

Kg/cm

1. Scope Dn Nominal outside diameter of pipe.

tn Nominal wall thickness of pipes.

1.1 This standard covers methods, process tm Minimum calculated wall thickness

requirements, tolerances and acceptance criteria for required by the applicable code.

shop fabricated pipe bends. T Pipe wall thickness (measured or

1.2 The bending methods described in this standard are

minimum, in accordance with purchase (

specification).

a partial representation of commonly used R Center line radius of bend.

processes and do not preclude the use of other

methods.

3. Bending Methods

2. Terminology 3 .l This standard covers bends formed by both hot and

cold bending methods. For this standard, a

2.1 The symbols and terms defined below are used temperature 100 degrees F below the lower critical

throughout this standard: temperature of the material is defmed as being the

boundary between hot and cold bending.

CENTER TO END J

TANGENT I 3.2 Unless otherwise specified by the governing code,

the bending procedure, including the

... heating/cooling cycle and post bend heat treatment,

.

On is determined by the pipe material, diameter, wall

thickness, bend radius and the required properties

after bendirig. Because of the many variables

involved, the bending procedure should be

BENDINTRADOS

determined by the fabricator.

FIGURE 2.1

D Nominal pipe size. (

Copyrig ht Pipe Fabrication Institute

Provided by IHS under license with PF I Sold to: HHI. 01 968263

No reproduction or networking permitted without license from IHS 2013nl17 7:49:34 GMT

PFI Standard ES-24

(Reaffirmed - September 20 10)

3.3 While the bending equipment used in many of the ~ HEATING DEVICE

( methods is generically the same, there may be

differences in bending procedures, material

D

---f.---

allowances, hold and pull legs, wall thickness,

etc., between bending fabricators .

D

3.4 Hot bending methods

t ANCHOR BOX

3.4.1 FURNACE BENDING:

In this method, the pipe is firmly packed

with sand and then heated in a furnace to a

temperature in the range of 2000 degrees F.

After removing from the furnace, one end of FIGURE 3.4.2

INCREMENTAL BENDING

the pipe is retained in a holding device and a

bending moment is applied at the other end.

3.4.3 'INDUCTION BENDING:

The radius of the bend is controlled by dies,

The induction bending equipment is

stops or templates as the pipe is bent. For

composed of three basic components

long radius bends and/or heavy wall pipe,

consisting of a bed, a radial arm, which is

the sand filling operation may not be

set at the required radius, and an induction

necessary.

heating system. The pipe is placed in the

bed and the front tangent is clamped to the

radial arm. The induction heating system

heats a narrow circumferential band around

the pipe to the appropriate bending

temperature. When this temperature is

reached, the pipe is continuously moved

through the heating coil while a bending

moment is applied to the heated area. After

passing through the coil, the pipe may be

RADIUS STOPS either forced or naturally cooled as required

(OPTIONAL) by the appropriate qualified bending

PULLING DEVICE

procedure.

FIGURE 3.4.1

FURNACE BENDING

3.4.2 INCREMENTAL BENDING:

The incremental bending equipment is

composed of an anchor box, a hydraulic

cylinder, and a moveable heating device.

The pipe is clamped in the anchor box and BED)

the front tangent is connected to the

RADIAL

hydraulic cylinder. The heating device heats ARM

a narrow circumferential band on the arc to

the proper bending temperature. A force is

then applied by the hydraulic cylinder to

bend the small increment a predetermined FIGURE 3.4.3

amount. The heating device is then moved INDUCTION BENDING

to successive segments where the process is

repeated until the required arc is attained.

After bending each increment, the heated

area is cooled as required by the appropriate

bending procedure.

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Sold to:HHI , 01968263

No reproduction or networking permitted without license from IHS 2013nt17 7:49:34 GMT

PFI Standard ES-24

(Reaffirmed - September 201 0)

3.5 Cold bending methods

(

3.5 .1 ROTARYDRAWBENDING:

In this method, the pipe is secured to a

bending die by a clamping die. As the

bending die rotates , it draws the pipe against

the pressure die and, if necessary to prevent

wall collapse, over an internal mandrel. The

pressure die may remain fixed or move with

the pipe.

PRESSURE DIE

FIGURE 3.5.3

ROLL BENDING

4. Welds in Bends

4.1 In some instances it is not practical to utilize pipe

ROTATING BEND DIE of sufficient length to satisfy the required arc

length of the bend. When it becomes necessary to

join lengths of pipe resulting in a circumferential

FIGURE 3.5.1

butt weld in the arc of a pipe bend, the following

ROTARY DRAW BENDING

practices should be considered:

3.5 .2 RAM BENDING:

In ram bending, the pipe is held by two 4.1.1 Pipes to be welded should be selected to ·

supporting dies and a force is applied by provide the best uniformity possible at the

means of a hydraulic ram to a forming shoe mating ends. Pipe wall thickness shall not be

located at the center of the workpiece. The less than the design minimum plus bend

thinning allowance (see section 7.0).

(

supporting dies rotate on their mounting

pins so that they follow the pipe and 4.1.2 End preparation for welding shall be in

maintain external support throughout the accordance with the qualified welding

operation. procedure to be used. Internal counterboring

should be avoided wherever possible. During

fit-up of the joint, the pipes should be rotated

HYDRAULIC RAM

or aligned as necessary to provide the least

amount ofl.D. and/or O.D . mismatch and the

best transition across the weld.

4.1.3 The welding procedure must be qualified in

accordance with the governing Code for the

FORMING SHOE thermal exposures, (if any) excepted in

bending and heat treatment.

4.1.4 After completion of the circumferential butt

FIGURE 3.5.2 weld, but before bending, the O.D. and I.D.

RAM BENDING (where accessible) of the weld should be

ground to remove excess weld reinforcement

3.5.3 ROLL BENDING : and blended smoothly into the base metal.

In roll bending, three forming rolls of

approximately the same diameter arranged in 4.1.5 It is good practice to examine the

a pyramid are used. The two fixed rolls circumferential butt weld by radiography

oppose the adjustable center roll. The pipe is prior to and after bending, whether or not

passed through the rolls with the position of such radiography is required by the

the adjustable roll controlling the bend applicable Code.

radius. (

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Sold lo :HHI , 01968263

No reproduction or networking pennitted without license from IHS 201317/17 7:49 :34 GMT

PFI Standard ES-24

(Reaffirmed- September 2010)

( 5. Linear and Angular Tolerances

5.1 Bends shall be provided with a total angularity

tolerance of± .5 degrees as determined by the

intersection of the tangent centerlines measured

by appropriate equipment.

5.2 When the fabricator is required to provide bends

cut to a specified center-to-end dimension it shall

be to the tolerances specified in PFI ES-3.

5.3 If intermediate portions ofthe bend profile are FIGURE6.2

essential, their tolerances shall be a matter of APPLICATION OF PIPE WALL BUCKLING

agreement between the purchaser and the TOLERANCES

fabricator.

Note 1- Depth of average crest to valley is the sum of the

outside diameters of the two adjoining crests divided by two,

5.4 See fig . 9.3 for an explanation of terminology

minus the outside diameter of the valley.

regarding bend tolerances.

6. Form Tolerances Depth= (OD), + (ODh - (ODh

2

6.1 The ovality of a pipe bend shall not exceed the Note 2- Ratio of distance between crests to depth is:

ovality required by the governing code. If there is

A 12

no governing code, the difference between the - ------ >-

maximum and minimum diameters shall not Depth (per Note 1) - 1

exceed 8% of the average measured outside

diameter of the straight portion of the pipe unless 6.3 Buckles which exceed the above tolerances will

by mutual agreement between the purchaser and be subjected to corrective action to bring them

the fabricator. Where operating conditions require within tolerance.

less ovality it may be necessary to use larger

radii, heavier pipe walls or a specific bending

6.4 If operating conditions require tighter tolerances

method that will provide a closer control of

on buckles, it may be necessary to use larger

ovality.

radii, heavier pipe walls or a specific bending

process.

6.2 Since there are occasions when buckles cannot be

avoided, the following restrictions should apply:

6.5 To determine what bends can be produced with a

satisfactory degree of quality, the Pipe

(a) All wave shapes shall blend into the pipe Fabrication Institute has conducted studies on

surface in a gradual manner. carbon steel and low alloy steel hot bends to

(b) The maximum vertical height of any wave, determine minimum recommended bend radii for

measured from the average height of two various ratios of outside diameters to wall

adjoining crests to the valley, shall not thickness. The resulting bending range

exceed 3% of the nominal pipe size. (See determined by these studies for each of the

Figure 6.2, Note 1) bending processes is shown in Figure 6.5 .1 and

6.5.2.

(c) The minimum ratio of the distance between

crests as compared to the height between

crests and the included valley should be 12

to I. (See Figure 6.2, Note 2)

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Sold to:HHI, 01968263

No reproduction or networking permitted without license from IHS 201317/17 7:49:34 GMT

PFI Standard ES-24

(Reaffirmed - September 201 0)

(2) Enter 29.1 on the Dn!T axis of Figure 6.5.1

BENDS IN THIS AREA ARE SUBJECT

TO SPECIAL CONSIDERATION and move vertically to the intersection with (

7

I ~

7 the bending range boundary.

6 (3) Then move horizontally to determine the

BENDING RANGE _/ minimum recommended radius to diameter

5

1-- / ratio which equals approximately 4.5. For

c5

!;

(/)

:::>

4

3

L._......-- /: I

practical purposes, bending radii are seldom

expressed in terms of fractional numbers,

but rather in terms of whole integers

0 2 I multiplied by the nominal pipe size. Hence,

~ I the recommended bending radius would be

0 I

z 5x12=60".

w I

CO Q I

Example B: Determine the minimum

0 10 20 30 40 50 60 70

permissible wall thickness required

DIAMETER TO WALL THICKNESS RATIO (Dn/T)

for induction bending 22" O.D.

FIGURE 6.5.1 carbon steel pipe per ASTM A 53-

FURNACE BENDING RANGE Grade B at a 3D bend radius.

(1) Enter 3 on the R/Dn axis of figure 6.5.2 and

7 move horizontally to the intersection with

the bending range boundary.

6

BENDING RANGE (2) Then move verticality to determine the

5 ------~

minimum recommended diameter to wall

thickness ratio which equals approximately

4 -~----

45. i.e. Dn/tn = 45 or tn = Dn/45 = 22/45 =

"2 .489".

0

ii: 3

6.7 Figure 6.5.1 is based on extensive experience in (

(J)

::J I furnace bending carbon and low alloy steel pipe.

Ci 2 t- Since stainless and non-ferrous materials have

~ I higher coefficients of expansion than carbon and

0

z -~- --~--

1 ~~

low alloy steels, a greater reduction in the density

LU

CD

of the sand fill occurs as these materials are being

0 -

heated to the bending temperature. As a result,

0 25 50 75 100 125 150 the sand fill does not provide the same rigidity

DIAMETER TO WALL THICKNESS RATIO (Dnltn) against flattening and buckling as it does when

carbon or low alloy steel pipe is being bent.

FIGURE 6.5.2

INDUCTION AND INCREMENTAL BENDING RANGE Because of this fundamental difference, special

consideration must be given to the selection of

6.6 Two examples are given for the determination of the minimum bending radius by the design

minimum recommended wall thickness and engineer.

bending radius combinations for a given pipe

size. 6.8 Cold bending ranges can vary significantly with

the process and degree of specialized tool used.

Example A: Determine minimum permissible Figure 6.8 .1 can be used to select the type of bend

bending radius required for furnace or the process required.

bending 12"-Extra Strong carbon

steel pipe per ASTM A 106-Grade

B.

( 1) Determine the diameter to wall thickness

ratio. 12" X-Stg. is 12.75" O.D. with a .500"

nominal wall. Under ASTM A 106, the

minimum wall is .438". Therefore Dn/T =

12.75/.438 = 29.1.

(

:opyright Pipe Fabrication Institute

:~rovided by IHS under license with PFI Sold to:HHI , 01968263

'lo reproduction or networking pennitted without license from lHS 2013!7/17 7:49 :34 GMT

. PFI Standard ES-24

(Reaffurned- September 2010)

( 12 The formula used to calculate the third column is:

11 t

10 (2nd column value)- ( 1 - ...!!!.. ),

9 t

8 where t =Nominal pipe wall thickness minus

"2

Cl 7 manufacturing tolerance, and t111 is derived from

~ 6 equation (3) of B31 .1, par. 104.1.2. The most

::> 5

(f)

conservative values over that range of pipe sizes

0 4

~ 3 and wall thicknesses where used.

Cl

z 2

w 1 TABLE 7.2.1

Ill

0 FURNACE BENDING

0 25 50 75 100 125 150

DIAMETER TO WALL THICKNESS RATIO (Dn/tn) Bend Minimum Thickness Factored

FIGURE 6.8.1 Radius Prior to Bending Thickness

COLD BENDING RANGE

6D 1.06 tm 1.03 tm

7. Material Allowances 5D 1.08 tm 1.04 tm

4D 1.14tm l.09tm

7.1 The following recommendations for material 3D 1.25 tm 1.19 tm

allowances will vary with the bending method,

material, pipe size, bend radius and the bend TABLE 7.2.2

fabricator's equipment. It is suggested that the INDUCTION AND INCREMENTAL BENDING

purchaser contact the fabricator for specific

information. Bend Minimum Thickness Factored

Radius Prior to Bending Thickness

7.2 Tb compensate for wall thinning from bending, the

sbcond column, ("Minimum Thickness Prior to 6Dn 1.06 tm 1.03tm

Bending"), in Tables 7.2.1, 7.2.2, 7.2.3, and 7.2.4 can 5Dn 1.08 tm 1.04 tm

be used as a guide for ordering pipe for the appropriate 4Dn 1.10 tm 1.05 tm

process. ASME B31 .1 Power Piping, equations 3Dn 1.14tm 1.08 tm

102.4.5(3B, 3C & 3E), and B31.3 Process Piping, 2Dn 1.22 tm 1.13 tm

equation 304.2.1(3c & 3e) defme a minimum thickness 1.5Dn 1.30tm 1.19 tm

at the extrados of the bend that is less than the

minimum thickness required for straight pipe. TABLE 7.2.3

Conversely, the minimum thickness for the intrados of ROTARY DRAW BENDING

the bend needs to be proportionally thicker than that

required for straight pipe. The third column, ("Factored Bend Minimum Thickness Factored

Thickness"), of these tables lists the minimum required Radius Prior to Bending Thickness

thickness prior to bending factored for the allowable

thinning at the extrados of the bend. Experience 6Dn 1.09 tm 1.06 tm

indicates that a minimum thickness of straight pipe 5Dn 1.14tm l.lOtm

shown in tables should be sufficient to meet the 4Dn 1.20 tm 1.15 tm

minimum thickness requirements after bending. 3Dn 1.28 tm 1.22 tm

Interpolation is permissible for bending to intermediate

radii. TABLE 7.2.4

RAM AND ROLL BENDING

The code formula for calculating the minimum

thickness required for the bend extrados, as defined in Bend Minimum Thickness Factored

B31.1 2007 is: Radius Prior to Bending Thickness

6Dn 1.08 tm 1.05 tm

5Dn l.lOtm 1.06tm

4Dn 1.13 tm 1.08tm

3Dn 1.17 tril 1.11tm

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Sold to :HHI , 01968263

No reproduction or networking permitted without license from IHS 201317/17 7:49:34 GMT

PFI Standard ES-24

(Reaffirmed - September 2010)

7.4 Because induction heated bends are produced

7.3 Since the start of the bend is somewhat dependent on under pressure, a compression of the material takes (

factors not completely within the control of the bender, place which results in more footage of straight pipe

some additional length must be added to insure that being required than that determined from the

overall center-to-end dimensions can be met. To developed length. To provide for this compression

compensate for this factor, the purchaser should add 6 the purchaser of induction bends should add 5% to

inches to the total of the required straight tangent the theoretical arc length. The compression of the

lengths. matefial may leave a hump, or bump, at the

beginning of the bend on the inside radius which is

not detrimental to the bend.

Nominal pipe size 1" thru 2" 2 Yz" thru 3 Yz" 4" thru 48"

Pulling End 6" 8" 2D (10" min)

Holding End 6" 8" 1.5D (10" min)

Tangent Between Bends (Tm) 6" 9" 1D (12" min)*

*Note: 9" mrn for 4" ptpe. 10" mm for 5" ptpe.

TABLE 7.5.1

MINIMUM TANGENT LENGTHS FOR FURNACE BENDS

7.5 In order to produce a bend properly, minimum

straight tangents are required on both ends of the

arc for holding and/or pulling purposes.

Characteristic minimum tangent lengths for the

(

various processes are given in Tables 7.5 .1, 7.5 .2,

and 7.5.3 . Defmition of these tangent lengths can

be seen in Figure 7.5.4. Minimum tangent lengths

required for incremental bending should be

obtained from the fabricator. Longer tangents

should be utilized wherever possible and should

be considered in the piping des ign. In cases

where tangents must be kept short, it should be FIGURE 7.5.4

realized that an out-of-round condition may exist TANGENT LENGTHS

at the pipe ends.

8. Material Requirements for Hot Bending

Nominal Pipe Size 2" thru 24" 26" thru 66"

8. 1 Pipe to be bent should be protected from the

Front Tangent OD+6" OD+ 6"

72" 132"

contamination of harmful materials such as the

Rear Tangent

Tangent Between Bends (Tm) 24" 60" low melting temperature alloys of copper, brass

and lead.

TABLE 7.5.2 8.2 Stainless steel pipe suspected of being

MINIMUM TANGENT LENGTHS contaminated with ferrous metals or other

FOR INDUCTION BENDING harmful materials should be cleaned prior to

bending to remove the contaminants.

Nominal Pipe Size 1" thru 10"

Front Tangent 2XD 8.3 Stainless steel pipe should be furnished in the

Rear Tangent 3XD solution annealed condition.

Tangent Between Bends (Tm) 2XD

TABLE 7.5.3

MINIMUM TANGENT LENGTHS FOR COLD BENDING

Copyrig ht Pipe Fabrication Institute

Provided by IHS under license with PFI S old to: HHI , 01968263

No reproduction or networking permitted without license from IHS 201317/17 7:49:34 GMT

PFI Standard ES-24

(Reaffirmed- September 2010)

9. Ordering Information 9.3 Suggested Bending Tolerances:

( 9.1 The Pipe Bend Order Form, (Form 9.1), provides Radius of Bend --------------- 1% of Dim "C"

the recommended information required for the Degree of Bend--------------- 0.5 Degree

purchase pipe bends. Plane of Bend----------------- 1.0 Degree

9.2 The applicability and acceptance criteria of each Flat Plane ofBend------------1% of Dim "C"

field, as defmed by the Pipe Bend Order Form, Linear Dimensions -----------118", 12" & under

shall be determined by the applicable codes, 3/16", over 12"

specifications and fabrication requirements. Ovality in Bent Area --------- 8% of Diameter

after Bend

Ovality at End Prep.----------ASME B 16.9

9.4 The miscellaneous remarks area and the space

provided at the bottom of the pipe bend order

form can be used to address additional

requirements such as, Piece Marking, Centerline

Scribing, Bend Heat Treatment, Butt Welds in

._______ Lineal Bends Area, etc .

Dimension

14---- - Lineal Tangent

Dimension ~ Length

-----------7

Radius of I

Bend (Dim C) Plane of Bend

I

I (Angle between

Two Bend Planes)

I

(

_t_ _______________ [

Plan View End View

--- -]--- ---------

---

- Ovality Tolerence :

The difference

between the major

and minor axis (percen

1

Flat Plane

Major

of Bend

Dia.

I

y

Ovality

(2 x size)

Elevation

Figure 9.3

Tolerences

Copyright Pipe Fabrication Institute

Provided by IHS under license with PFI Sold to: HHI , 01968263

No reproduction or networking permitted without license from IHS 201317/17 7:49:34 GMT

z-o o

o a o

~ ~~-

g_~~

~- ~ i

~en ,

;~~

~=-~

~ ~- g

~r iil :;-

~i~

3 CD

""

:!:!!

:::T

Pipe Bend Order Form

•~ Pipe Fabrication institute

s

Pipe Bend Tag: Completed By Vendor

[

~W~G~G>C

Spool No. Actual Dimensions

~

""'

Material Spec:

Pipe Diameter:

Fab Code:

Design Press:

Design Temp:

Y'' E'

Ull

,

~G

PREP "A"

Dimension A

Dimension B

Dimension C

AngleD

n-"f_

Corr. AIIow: UT 2

Calc'd Min Wall: Min Thick as Measured

Required Dimensions UT Point 1:

"A" Tang Length

"B" Tang Length

Dimension C

~ngle D

Dimension A

Dimension B

Dimension E

""

"

0.00

0.00

0.00

.•. I

~r· :·

--

' '

.

:

~·~~

\_ END PREP "B'

"B' TANG l ENGTH

L~

UT Point2 :

UT Point 3:

End "A":

End "B":

End Prep OD as Measured

Major Minor

Actual Heat Treatment ..

I

End Preparation Tolerances [Time:

616.25 Sketch Controi"C" Radius of Bend: 1% of Dim "C" Temperature:

"A" End: n/a Degree of Bend(D) 0.5 degrees Remarks

"B" End: n/a Plane of Bend (POB) 1.0 degrees Actual Bending temp (P1 maU > 3/4" thk only)

Req. Heat Treatment Flat Plane of Bend 1% of Dim "C"

tnme Per ASME B31.1 (129) Linear Dimensions 1/8"12" and under Remarks

r-emperatura PerASME B31 .1 (129) 3/16" over 12" Mat'l Heat No.

Non Destructive Testing Ovallity in Bent Area 8% of dia after Bending

MT/PT : n/a Ovallity at End Prep ASME B16.9 I Date I Vendor Sign Off

Hardness Tests: n/a Mise Remarks ..

Other: Circ welds shall not be located within pipe bend

Bend shall be normalized and tempered after

forming.

Bend shall be permanently die stamped and painted with Pipe Bend Tag No.

Pipe Bend Tag:

~

Pl

Bend must have the Centerlines of each run scribed in the pipe wall. 8l

§

FORM 9.1 (1)

0."0

PIPE BEND ORDE R FORM l '"rj

[/)-

(1) [/)

'"0 ....

.... Pl

(1) ;::3

8cr-P>0.

(1) .....

..... 0.

N t"Ii

0 [/)

~ /'\

...

-I

/""""""'\ oN

'-'

You might also like

- Reintjes Marine Reduction Gear Operating ManualDocument72 pagesReintjes Marine Reduction Gear Operating Manualbigcee6496% (24)

- Tamd 63Document2 pagesTamd 63Cristiano NunesNo ratings yet

- What Pipeliners Need To Know About Induction Bends PDFDocument20 pagesWhat Pipeliners Need To Know About Induction Bends PDFmarcos2dami2o2de2azeNo ratings yet

- PIP PNE00002 Piping Material Specification Selection, Development, and Application GuidelinesDocument17 pagesPIP PNE00002 Piping Material Specification Selection, Development, and Application Guidelinespreemee100% (3)

- Miter Bend CalculationDocument4 pagesMiter Bend CalculationRavindra S. Jivani100% (3)

- Astm A694Document3 pagesAstm A694Muhammad Awais0% (1)

- 1.4301 Austenite Stainless SteelDocument3 pages1.4301 Austenite Stainless SteelSM Waqas ImamNo ratings yet

- Astm A358Document8 pagesAstm A358Dyna Mafikasari100% (2)

- Astm A234 PDFDocument9 pagesAstm A234 PDFJuan Hernández Hernández100% (1)

- High Frequency Induction Bending PDFDocument22 pagesHigh Frequency Induction Bending PDFMohd AshrafNo ratings yet

- SecVIII Div1 UW40Document2 pagesSecVIII Div1 UW40arianaseriNo ratings yet

- Water in Air Calculator - Version 3Document7 pagesWater in Air Calculator - Version 3Neelakandan DNo ratings yet

- Project x19 - PbsDocument54 pagesProject x19 - Pbsbdlovin75% (4)

- PFI ES 24 Pipe BendingDocument24 pagesPFI ES 24 Pipe BendingSrinivas Jasti100% (1)

- Electric-Fusion-Welded Steel Pipe For Atmospheric and Lower TemperaturesDocument7 pagesElectric-Fusion-Welded Steel Pipe For Atmospheric and Lower Temperaturesrgi178No ratings yet

- Pfi-Es-22 (1999)Document4 pagesPfi-Es-22 (1999)jothish100% (5)

- Astm GradesDocument3 pagesAstm GradeszackjipangNo ratings yet

- CladtekPresentation16 02 2011Document30 pagesCladtekPresentation16 02 2011Chee Hong LeeNo ratings yet

- Ra 1 020 Ep242 11001 Piping Material Specification 1Document363 pagesRa 1 020 Ep242 11001 Piping Material Specification 1Hugo RuizNo ratings yet

- F2620 PDFDocument19 pagesF2620 PDFAhmad Zubair RasulyNo ratings yet

- ASTM A672 Welded Pipe Standard PDFDocument7 pagesASTM A672 Welded Pipe Standard PDFumeshNo ratings yet

- PFI ES-2-2000 Method of Dimension Ing Piping AssembliesDocument4 pagesPFI ES-2-2000 Method of Dimension Ing Piping Assembliessekharsappa2100% (3)

- ASME PCC-1 - PresentationDocument15 pagesASME PCC-1 - PresentationAjmi Hmida100% (1)

- Problems With B16.5 and B16.47 Flange StandardsDocument1 pageProblems With B16.5 and B16.47 Flange StandardsManohar SeetharamNo ratings yet

- Lad and Lined Pipe SpecificationDocument65 pagesLad and Lined Pipe SpecificationYehia Hassan100% (2)

- Din en Iso 16135Document26 pagesDin en Iso 16135Ahmed HassanNo ratings yet

- Engieering Standard - Piping SpecificationDocument10 pagesEngieering Standard - Piping SpecificationDinesh MohanNo ratings yet

- P9127 - Piping Pressure Testing - Rev 0 - GENERICDocument20 pagesP9127 - Piping Pressure Testing - Rev 0 - GENERICmengelito almonte100% (1)

- Proposed New ASMEB31P Standard On Preheat & PWHT PDFDocument34 pagesProposed New ASMEB31P Standard On Preheat & PWHT PDFWitchfinder General100% (1)

- API 6A Flange ChartsDocument6 pagesAPI 6A Flange ChartsDanDeMarcoNo ratings yet

- Steps of Making WPSDocument51 pagesSteps of Making WPSDavid Macatangay100% (7)

- Steel Pipes For Pipelines For The Transmission of Hydrocarbon Gases and LiquidsDocument20 pagesSteel Pipes For Pipelines For The Transmission of Hydrocarbon Gases and Liquidshalim_kaNo ratings yet

- Pfi Es-24Document10 pagesPfi Es-24kingstonNo ratings yet

- Asme B 16.34 InterpretacionDocument21 pagesAsme B 16.34 InterpretacionJuan Manuel Montoya G.No ratings yet

- Insulating JointDocument17 pagesInsulating Jointreza329329100% (1)

- Arcelormittal Pressure Vessel PDFDocument10 pagesArcelormittal Pressure Vessel PDFImmanuel SNo ratings yet

- MSS SP 6Document6 pagesMSS SP 6d1a9v8i3d100% (1)

- Global Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelDocument33 pagesGlobal Projects Organisation: Material Specification For 316/316L and 6mo Austenitic Stainless SteelThiyagarajan JayaramenNo ratings yet

- Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalDocument7 pagesFerritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalSameh AminNo ratings yet

- Asme Ix Welder Qualification InterpretationDocument95 pagesAsme Ix Welder Qualification Interpretationvangie3339515100% (3)

- ASTM F1545 Plastic Lined Pipe 0803 PDFDocument6 pagesASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesNo ratings yet

- Piping Inspector's Handbook (Rev 2)Document10 pagesPiping Inspector's Handbook (Rev 2)praveentien100% (1)

- CSWIP 3.2-2010 WIS10 Senior Welding InspectionDocument302 pagesCSWIP 3.2-2010 WIS10 Senior Welding Inspectionapply19842371100% (9)

- Astm A671 2020Document7 pagesAstm A671 2020امينNo ratings yet

- PFI-ES-05 (1999) - Cleaning PDFDocument4 pagesPFI-ES-05 (1999) - Cleaning PDFRamesh Kumar Ramisetti100% (1)

- Material Selection and SpecificationDocument50 pagesMaterial Selection and SpecificationbashirNo ratings yet

- MSS-SP-25 (2013) PDFDocument31 pagesMSS-SP-25 (2013) PDFPubcrawl67% (3)

- Astm A312Document12 pagesAstm A312Ruth Sarai YañezNo ratings yet

- Golden WeldDocument4 pagesGolden Weldenels77No ratings yet

- Corporate Piping SpecDocument56 pagesCorporate Piping Specamanojp100% (2)

- p91 WeldingDocument5 pagesp91 Weldingsaji_t1984100% (1)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- ES 49BranchConnectionsDocument7 pagesES 49BranchConnectionsrodofgodNo ratings yet

- 1 ErrrrffDocument11 pages1 ErrrrffAllswell ElleNo ratings yet

- 00-Contract 4C.4 Specifications For Pipeline WorksDocument9 pages00-Contract 4C.4 Specifications For Pipeline WorksALINo ratings yet

- Induction BendingDocument20 pagesInduction BendingAnoop N Kutty100% (4)

- GHGGFHJDocument13 pagesGHGGFHJAllswell ElleNo ratings yet

- Tech. Spec - Tubular PoleDocument8 pagesTech. Spec - Tubular PoleVarun SharmaNo ratings yet

- 24 Loomis Welding Procedures 9.10.14Document22 pages24 Loomis Welding Procedures 9.10.14viswamanojNo ratings yet

- Wms Acmv Duct WorksDocument8 pagesWms Acmv Duct Worksfahmi_majid_2No ratings yet

- Specification For HDPE MANHOLES PDFDocument4 pagesSpecification For HDPE MANHOLES PDFPipeline EngineerNo ratings yet

- Is 3589 - 2001Document21 pagesIs 3589 - 2001Aara MeghNo ratings yet

- Tube To T Joints The Many Choices BJ SandersDocument38 pagesTube To T Joints The Many Choices BJ Sandersscbd83No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- 0488a0vvgc001 06Document73 pages0488a0vvgc001 06AlienshowNo ratings yet

- Welding Discontinuities X-Ray Films PDFDocument12 pagesWelding Discontinuities X-Ray Films PDFAlienshowNo ratings yet

- 20160811033138-Certificate 2014-68-EU DH Material Producer PEDDocument1 page20160811033138-Certificate 2014-68-EU DH Material Producer PEDAlienshowNo ratings yet

- Holiday Detector DJ SeriesDocument1 pageHoliday Detector DJ SeriesAlienshowNo ratings yet

- 2014 68 Eu PDFDocument96 pages2014 68 Eu PDFAlienshow100% (1)

- Fail-Safe System: Torque 20 50 100 140 180 210 Closing Time 1 Sec 1 Sec 1 Sec 1 Sec 1 Sec 1 SecDocument1 pageFail-Safe System: Torque 20 50 100 140 180 210 Closing Time 1 Sec 1 Sec 1 Sec 1 Sec 1 Sec 1 SecAlienshowNo ratings yet

- ASME-Section I Power Boilers Checklist: Department of Safety and Professional Services, Division of Industry ServicesDocument2 pagesASME-Section I Power Boilers Checklist: Department of Safety and Professional Services, Division of Industry ServicesAlienshowNo ratings yet

- Ibexu 04 Atex 1125 XDocument6 pagesIbexu 04 Atex 1125 XAlienshowNo ratings yet

- Power Plant OperationDocument199 pagesPower Plant OperationVijay Bhargav Badam83% (6)

- CHAPTER 3 Giancoli: Physics Study Guide Dr. Lee: y V T - GTDocument3 pagesCHAPTER 3 Giancoli: Physics Study Guide Dr. Lee: y V T - GTheypartygirlNo ratings yet

- Fike Pressure Relief Product GuideDocument5 pagesFike Pressure Relief Product GuideEason NgNo ratings yet

- Bimetal Dial ThermometerDocument2 pagesBimetal Dial ThermometerAnonymous edvYngNo ratings yet

- " " Reach: Ordering InformationDocument8 pages" " Reach: Ordering InformationTrong TranNo ratings yet

- Liquid Filling Section MachineryDocument18 pagesLiquid Filling Section MachinerySANJAY100% (1)

- 01 Kinematics Formula SheetDocument6 pages01 Kinematics Formula SheetDhiva roman reignsNo ratings yet

- BDA30603Document8 pagesBDA30603Nik JaffNo ratings yet

- Deep Hole Drilling: CAE DS - Mould Parts MachiningDocument6 pagesDeep Hole Drilling: CAE DS - Mould Parts MachiningAlex Kiko VillalobosNo ratings yet

- Kepodang BP Muriah - Spec For Welding WMSS LinepipeDocument15 pagesKepodang BP Muriah - Spec For Welding WMSS LinepipeAdvisNo ratings yet

- 05-02 Boltec S - Operators Menu and Drilling ParametersDocument29 pages05-02 Boltec S - Operators Menu and Drilling ParametersALVARO ANTONIO SILVA DELGADONo ratings yet

- Fault Isolation Manual: Print Date: 2021-05-27Document12 pagesFault Isolation Manual: Print Date: 2021-05-27Mahbub RahmanNo ratings yet

- Polaris Spa Blower Repair ManualDocument16 pagesPolaris Spa Blower Repair ManualPool Supply SalesNo ratings yet

- S TATICDocument2 pagesS TATICAnnshun KiatNo ratings yet

- Original: File Name: PP - P - 1819 - R1Document61 pagesOriginal: File Name: PP - P - 1819 - R1Harish SGNo ratings yet

- TDS - G-Profi - SGE 40 NAB - All Lubricating Oil For Type 2, 3, 4 and 6 Jenbacher Gas EnginesDocument1 pageTDS - G-Profi - SGE 40 NAB - All Lubricating Oil For Type 2, 3, 4 and 6 Jenbacher Gas EnginesDavid PomaNo ratings yet

- Rotalock™: Quick Opening ClosureDocument2 pagesRotalock™: Quick Opening Closureagung wijayaNo ratings yet

- Par G: ManualDocument68 pagesPar G: ManualDany TremblayNo ratings yet

- 2 Unit 1 Impact of JetDocument16 pages2 Unit 1 Impact of Jetmohit sonawaneNo ratings yet

- Manual de Enrutamiento 16M - R9HDocument76 pagesManual de Enrutamiento 16M - R9HMARVIN JOSE MELENDEZ VANEGASNo ratings yet

- Technical Manual Ribbed Belt Drives: OptibeltDocument68 pagesTechnical Manual Ribbed Belt Drives: Optibeltvictor perdomoNo ratings yet

- DC Fan DatasheetDocument2 pagesDC Fan DatasheetTalha NasrNo ratings yet

- Understanding Centrifugal Compressor Capacity ControlsDocument5 pagesUnderstanding Centrifugal Compressor Capacity Controlsjuancgr77100% (1)

- Ventilation SystemDocument56 pagesVentilation SystemFranklinNo ratings yet

- Proheat 35: Air-Cooled Induction SystemDocument4 pagesProheat 35: Air-Cooled Induction SystemAlberto LobonesNo ratings yet

- Siva Raj Mechanical TechnicianDocument4 pagesSiva Raj Mechanical Technicianjohn MNo ratings yet