Professional Documents

Culture Documents

Rotalock™: Quick Opening Closure

Uploaded by

agung wijayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotalock™: Quick Opening Closure

Uploaded by

agung wijayaCopyright:

Available Formats

Rotalock™

Quick Opening Closure

Innovative Design Features

While our Bandlock™ 2 is the benchmark design for

global high-pressure applications, GD Rotalock™ has

been developed to provide an inherently safe, low cost

solution for small diameter, low pressure applications.

Designed and priced to offer a superior alternative to

screwed closures and blind flanges, Rotalock™ handles

lower pressures to ANSI 300 and diameters from 4” to

14”. It provides quick and frequent access to a range of

vessels in petrochemical, pharmaceutical and chemical

process technologies, at temperatures from -30°C to

+200°C.

Typical applications include:

• Filters

• Separators

• Meter Provers

• Pig/Scraper Traps

• Blowdowns

• Strainers

• Coalescers

• Waste Disposal vessel

Pressure Warning Screw (PWS)

A key feature of our Rotalock™ design is the Pressure Warning Screw incorporating an integral screw which penetrates

through both locking elements in the hub and the cap. When the PWS is unscrewed it will warn the operator of internal

vessel pressure before the cap is rotated. Complete withdrawal of the PWS and integral locking pin is required before

the cap can be rotated and the closure opened. The PWS is fitted to all sizes but is not designed to function as a

blowdown valve.

Field Weldable Hubs Code Compliance

The Rotalock™ Closure Hub is SA350-LF2 forged The Rotalock™ Closure is designed in accordance

carbon steel and no special field welding techniques with ASME VIII Div. 1. ASME Code Stamp with U-2A

or procedures are required. Connecting thickness partial data report can be furnished as an option. Code

is for standard wall in accordance with BSI600/API. stamping verifies shop inspection of the closure and

Terminations to match thin wall or extra strong pipe are materials by an ASME Authorised Inspector.

available at extra cost.

CE Marking for European applications is available as an

option.

Durable Seal

The fully moulded lip seal is available in Nitrile (NBR) NACE Standard MR-01-75 / ISO 15156 materials are

and fluorelastomer material (Viton). It is located in the available.

cap to prevent operational damage. The use of a lip

design prevents metal-to-metal binding which is often Hydrotest

experienced when using ‘O’ rings in quick-opening Rotalock™ Closures can be hydrotested as an option.

threaded closures.

Easy Operation

The PWS with its integral locking pin is unscrewed and

completely removed. This enables the cap to be partially

rotated which separates the seal surfaces giving the

operator a secondary warning if pressure is still present

in the vessel. A further turn of the cap allows it to be

withdrawn from the hub and swung fully clear using

the hinge or davit. The whole operation can be carried

out by one person without the need for special tools or

wrenches. Total closing of the cap is also guaranteed

since the locking mechanism must be fully engaged

before the integral pin is relocated and this enables the

PWS to be finally screwed into its seating.

Secure Cap

Manufactured in cast carbon steel SA352-LCB material.

The head is drilled with a M16 metric thread into which

the PWS is located. The exposed hole is considerably

larger than that provided on other designs to ensure that

the risk of blockage is minimized.

Dual Hinging

All of our standard horizontal closures have jib arms

which allow the cap to swing to either side after opening

to give greater installation flexibility. Vertical opening

uses a screwed davit to lift the cap clear of the hub.

Your local contact:

PFM ENGINEERING PTE LTD

21 BUKIT BATOK CRESCENT

#20-79 WCEGA TOWER

SINGAPORE 658065

TEL: 62789700, FAX: 62789671

EMAIL: sales@pfmeng.com

E-mail: gd@spx.com

For more information about our worldwide locations, approvals, certifications, and local representatives, please visit www.spxpe.com.

SPX Corporation reserves the right to incorporate our latest design and material changes without notice or obligation. Design features, materials of construction and dimensional data, as

described in this bulletin, are provided for your information only and should not be relied upon unless confirmed in writing. Certified drawings are available upon request.

Issued: 01/2009 GD-1040 Copyright © 2009 SPX Corporation

You might also like

- AS568 O-Rings enDocument28 pagesAS568 O-Rings enJoão MatosNo ratings yet

- Pig Trap End Closure PDFDocument24 pagesPig Trap End Closure PDFashishNo ratings yet

- Pig Trap End Closure1 PDFDocument24 pagesPig Trap End Closure1 PDFashishNo ratings yet

- Pig Trap End Closure105671465 PDFDocument24 pagesPig Trap End Closure105671465 PDFashishNo ratings yet

- GD 1070 Providing Eng Pipeline Solns GD en A4Document24 pagesGD 1070 Providing Eng Pipeline Solns GD en A4Mubeen NavazNo ratings yet

- Zeds & Cees: Users GuideDocument40 pagesZeds & Cees: Users GuideTee Bun PinNo ratings yet

- Yoke Style Closure Double Single Bolt BrochureDocument14 pagesYoke Style Closure Double Single Bolt Brochureandreshuertascalderon02No ratings yet

- AS568 AS568 O-Rings O-Rings AS568 O-Rings AS568 AS568 O-Rings AS568Document17 pagesAS568 AS568 O-Rings O-Rings AS568 O-Rings AS568 AS568 O-Rings AS568Thiago Scarso ScarsoNo ratings yet

- Canalta DBB Product Manual - LOW RESDocument12 pagesCanalta DBB Product Manual - LOW RESFer VFNo ratings yet

- 4983Document16 pages4983Costin EneNo ratings yet

- Viega Profipress ManualDocument16 pagesViega Profipress Manualhasmit1No ratings yet

- Sop Magnesium Anode Installation - ThiessDocument10 pagesSop Magnesium Anode Installation - ThiessbonnicoNo ratings yet

- Datasheet Codeline OCTA 80S SeriesDocument4 pagesDatasheet Codeline OCTA 80S SeriesJulian Bocanegra ReyesNo ratings yet

- SBC (Safety Break-Away Couplings) v140630Document16 pagesSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Double Block and Bleed Valves - Instrumentation - Oliver ValvesDocument4 pagesDouble Block and Bleed Valves - Instrumentation - Oliver ValvesKehinde AdebayoNo ratings yet

- High quality casted sheaves for harsh conditionsDocument12 pagesHigh quality casted sheaves for harsh conditionsCao Long NhậtNo ratings yet

- CPS - Bridge PlugDocument8 pagesCPS - Bridge PlugJOGENDRA SINGHNo ratings yet

- Main Steel ConnectionsDocument40 pagesMain Steel ConnectionsIndrayadi AbdillahNo ratings yet

- PvMax Product Sheet PDFDocument3 pagesPvMax Product Sheet PDFCARLOS ANDRES SARMIENTO CUEVASNo ratings yet

- Oil Gas BrochureDocument12 pagesOil Gas BrochureAir-con MinatitlanNo ratings yet

- Rotex Pneumatic Cylinder CatalogueDocument4 pagesRotex Pneumatic Cylinder Cataloguekumar ambujNo ratings yet

- Solidrill Wellhead System PsDocument1 pageSolidrill Wellhead System Psبلال حسينيNo ratings yet

- Solidrill Wellhead System Ps PDFDocument1 pageSolidrill Wellhead System Ps PDFبلال حسيني100% (1)

- Valves - AWWA Valves PDFDocument28 pagesValves - AWWA Valves PDFnilnilen2009No ratings yet

- Reliable Innovative Solutions for Process PipingDocument38 pagesReliable Innovative Solutions for Process PipingEdinsonNo ratings yet

- Ringlock SystemDocument8 pagesRinglock Systemdox4useNo ratings yet

- Bursting Discs Breather Valves Signalling UnitsDocument16 pagesBursting Discs Breather Valves Signalling Unitssmab2162094No ratings yet

- DSI Threadbar PT System Uk PDFDocument4 pagesDSI Threadbar PT System Uk PDFkajewooNo ratings yet

- Quikcoup Catalogue 2011 6.01Document56 pagesQuikcoup Catalogue 2011 6.01desters1120No ratings yet

- VALVES: Euroguarco's Manual and Actuated Valve ManufacturingDocument8 pagesVALVES: Euroguarco's Manual and Actuated Valve ManufacturingrezajakakusumaNo ratings yet

- Needle Valves Series Bs03Document6 pagesNeedle Valves Series Bs03Uzair AnsariNo ratings yet

- Hydraulic Tube Fittings enDocument16 pagesHydraulic Tube Fittings enAlex PeñaNo ratings yet

- 02 Circular Duct SystemsDocument42 pages02 Circular Duct SystemsDiki PrayogoNo ratings yet

- Aw 2BPZDocument2 pagesAw 2BPZcoundoulNo ratings yet

- Renderoc Galvashield XP: Unit SketchDocument2 pagesRenderoc Galvashield XP: Unit SketchVenkata RaoNo ratings yet

- PV6USLPDocument1 pagePV6USLPLeidy RamirezNo ratings yet

- Destec G RangeBrochureDocument16 pagesDestec G RangeBrochureltrongluanvn100% (2)

- Single Spring SealsDocument128 pagesSingle Spring SealsicingrockNo ratings yet

- Halfen Coupler Mechanical Rebar SplicingDocument33 pagesHalfen Coupler Mechanical Rebar Splicingcarlosfilipegomes3994No ratings yet

- Connector Product Locations: GermanyDocument56 pagesConnector Product Locations: Germanywww.erwer9No ratings yet

- Sealing For Hydropower EquipmentDocument28 pagesSealing For Hydropower EquipmentJenny Cecilia Ureña ZuriNo ratings yet

- Cat-CMP Cable GlandDocument64 pagesCat-CMP Cable GlandSyahirul Alim100% (1)

- Product Overview: Valves Actuators Automation TechnologyDocument36 pagesProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaNo ratings yet

- SPO Webversion HighDocument6 pagesSPO Webversion HighchadNo ratings yet

- CA Bayonet PDFDocument56 pagesCA Bayonet PDFwww.erwer9No ratings yet

- d260barlockweldablecouplerDocument2 pagesd260barlockweldablecouplerGustavo Brea MalavéNo ratings yet

- ABB Padmounted Transformers GuideDocument12 pagesABB Padmounted Transformers GuideArturoMoreiraNo ratings yet

- Original RotaBoltDocument16 pagesOriginal RotaBoltsagar1503No ratings yet

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- ISC2 Series Broch A4Document6 pagesISC2 Series Broch A4isosicaNo ratings yet

- GV Products Catalog 2016Document12 pagesGV Products Catalog 2016Jitendra KadamNo ratings yet

- Model 2100bDocument4 pagesModel 2100bkeyur1109No ratings yet

- APARTARRAYOSDocument18 pagesAPARTARRAYOSJaime Hernandez HernandezNo ratings yet

- Conexpanduri Simpson Liebig Catalogue C SL 2009EDocument60 pagesConexpanduri Simpson Liebig Catalogue C SL 2009Emandela2013No ratings yet

- Aerospace Products Brochure PDFDocument15 pagesAerospace Products Brochure PDFArjun PanditNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- So Flange 30 Inch Ansi 150Document1 pageSo Flange 30 Inch Ansi 150agung wijayaNo ratings yet

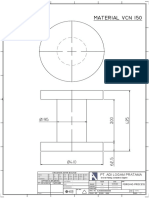

- Forging Process VCN150Document1 pageForging Process VCN150agung wijayaNo ratings yet

- RubberExpansionJoint SingleSphereBellowDocument2 pagesRubberExpansionJoint SingleSphereBellowagung wijayaNo ratings yet

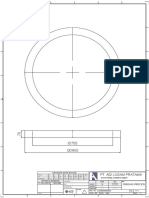

- OD900 ID755: Pt. Adi Logam PratamaDocument1 pageOD900 ID755: Pt. Adi Logam Pratamaagung wijayaNo ratings yet

- Denah LT 1Document1 pageDenah LT 1agung wijayaNo ratings yet

- Technical Datasheet Qoc With Jaws: Product InformationDocument1 pageTechnical Datasheet Qoc With Jaws: Product Informationagung wijaya100% (1)

- Ht2003 Tub Drag Types TB Jul2015Document3 pagesHt2003 Tub Drag Types TB Jul2015agung wijayaNo ratings yet

- Pig Launcher ReceiverDocument32 pagesPig Launcher ReceiverkarthickNo ratings yet

- Rite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Document8 pagesRite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Cristian PisitelloNo ratings yet

- Rotalock™: Quick Opening ClosureDocument2 pagesRotalock™: Quick Opening Closureagung wijayaNo ratings yet

- TK GWL GB 230616 Web PDFDocument125 pagesTK GWL GB 230616 Web PDFchechar10No ratings yet

- Cover MDR 33214 GI TanggeungDocument1 pageCover MDR 33214 GI TanggeungAgung PramuraharjoNo ratings yet

- Water Pipeline Test Report FormatDocument1 pageWater Pipeline Test Report FormatEzra AhumuzaNo ratings yet

- Metriccatalogue 1352086809Document324 pagesMetriccatalogue 1352086809agung wijayaNo ratings yet

- Insert MegaletDocument8 pagesInsert Megaletagung wijayaNo ratings yet

- TK GWL GB 230616 Web PDFDocument125 pagesTK GWL GB 230616 Web PDFchechar10No ratings yet

- Ham Let Wyle Report PDFDocument121 pagesHam Let Wyle Report PDFมินคุง เอโอซีNo ratings yet

- 525 Fritztown Road Sinking Spring, Pennsylvania 19608 (610) 670-3200Document1 page525 Fritztown Road Sinking Spring, Pennsylvania 19608 (610) 670-3200agung wijayaNo ratings yet

- High Tensile Steel 4340Document2 pagesHigh Tensile Steel 4340Arun KumarNo ratings yet

- Cast Steel and Stainless Steel Y StrainersDocument13 pagesCast Steel and Stainless Steel Y StrainersNinad SherawalaNo ratings yet

- CDI PRODUCT LINE CATALOG - 07 SEP 2017 - EmailDocument34 pagesCDI PRODUCT LINE CATALOG - 07 SEP 2017 - Emailagung wijayaNo ratings yet

- Kitz Gate Valve Price List 2019 from PT. Nugraha GlobalindoDocument1 pageKitz Gate Valve Price List 2019 from PT. Nugraha Globalindoagung wijayaNo ratings yet

- Hose, Tube & Connection Fittings Catalogue: JSG Industrial SystemsDocument20 pagesHose, Tube & Connection Fittings Catalogue: JSG Industrial Systemsagung wijayaNo ratings yet

- Rubber Expansion Joint, Single Sphere Bellow: 37 Readington Road Branchburg, New Jersey 08876Document2 pagesRubber Expansion Joint, Single Sphere Bellow: 37 Readington Road Branchburg, New Jersey 08876agung wijayaNo ratings yet

- Vol 2 Technical 20180703 181711 PDFDocument116 pagesVol 2 Technical 20180703 181711 PDFMEHDINo ratings yet

- Ht2003 Tub Drag Types TB Jul2015Document3 pagesHt2003 Tub Drag Types TB Jul2015agung wijayaNo ratings yet

- Water Pipeline Test Report FormatDocument1 pageWater Pipeline Test Report FormatEzra AhumuzaNo ratings yet

- Resilient Seated: CommercialDocument25 pagesResilient Seated: Commercialagung wijayaNo ratings yet

- PTS18 - QocDocument2 pagesPTS18 - Qocagung wijayaNo ratings yet

- CrsemihermeticcompressorDocument75 pagesCrsemihermeticcompressorworawan nuanpleanNo ratings yet

- EMKO ecoPID PID Temperature Controller Instruction ManualDocument2 pagesEMKO ecoPID PID Temperature Controller Instruction ManualWaldo herbas montaño100% (1)

- Terjemahan Itp ElektrikDocument4 pagesTerjemahan Itp ElektrikZakirNo ratings yet

- PT.Holcim Indonesia Tbk- Narogong Cement Process Instrumentation and Interlock list for ABC-inlet coolerDocument1 pagePT.Holcim Indonesia Tbk- Narogong Cement Process Instrumentation and Interlock list for ABC-inlet coolerSafrin SangiaNo ratings yet

- Cargo Gear Inspection and MaintenanceDocument47 pagesCargo Gear Inspection and MaintenanceSamar DasNo ratings yet

- SPARE PARTS CATALOG FOR REAR TANDEM AXLEDocument29 pagesSPARE PARTS CATALOG FOR REAR TANDEM AXLEjyapias_1No ratings yet

- Penn HT-100 Drag Washer DimensionsDocument2 pagesPenn HT-100 Drag Washer DimensionsduleNo ratings yet

- Stratovent-Tb Hood-Front View 08-22-13Document1 pageStratovent-Tb Hood-Front View 08-22-13apara_jitNo ratings yet

- FTTX Solutions: Mini Fiber Distribution Hub 3000Document5 pagesFTTX Solutions: Mini Fiber Distribution Hub 3000julianNo ratings yet

- Forklift ProceduresDocument1 pageForklift ProceduresimpathoenhleholdingNo ratings yet

- Power Track Socket Supplier CatalogDocument14 pagesPower Track Socket Supplier CatalogLe HieuNo ratings yet

- AUTOMATIC RIFLE 7.5", 11.5" / 14.5" / 20" : 5.56mm X 45mm Direct Impingement Gas-SystemDocument1 pageAUTOMATIC RIFLE 7.5", 11.5" / 14.5" / 20" : 5.56mm X 45mm Direct Impingement Gas-SystemCollin FarNo ratings yet

- Single Core Insulated and Sheathed PDFDocument1 pageSingle Core Insulated and Sheathed PDFalamNo ratings yet

- Catalogo de Peças Mastro SPB 28 Vector - Inglês (20989739) R-1Document109 pagesCatalogo de Peças Mastro SPB 28 Vector - Inglês (20989739) R-1dhmartiniNo ratings yet

- Assembly Instructions The Renard SS24 - Do It Yourself ChristmasDocument12 pagesAssembly Instructions The Renard SS24 - Do It Yourself ChristmasslothfaceNo ratings yet

- Philips hr7761 hr7762 Food-ProcessorDocument5 pagesPhilips hr7761 hr7762 Food-ProcessormotoxxNo ratings yet

- Railway Wagon Braking System: KSRM College of Engineering KadapaDocument19 pagesRailway Wagon Braking System: KSRM College of Engineering KadapaManjunathNo ratings yet

- Journeyman Answer KeyDocument5 pagesJourneyman Answer KeyMoises E. LegaspiNo ratings yet

- LaserAce1000 FAQs InglesDocument4 pagesLaserAce1000 FAQs InglesJuan CandoNo ratings yet

- Preventive Maintenance Checklist for Medical Imaging EquipmentDocument24 pagesPreventive Maintenance Checklist for Medical Imaging EquipmentfortroniNo ratings yet

- Track Master: Festoon SystemsDocument32 pagesTrack Master: Festoon SystemsRenwick69No ratings yet

- Mr366megane6 AcDocument134 pagesMr366megane6 AcAli ALiNo ratings yet

- Machined Parts for Corrugated MachineryDocument20 pagesMachined Parts for Corrugated MachinerySakahi SharmaNo ratings yet

- Samyo MPR 714Document79 pagesSamyo MPR 714Anonymous D8ay3BMJ5No ratings yet

- No Thread SetDocument2 pagesNo Thread SetpimpdaddywilkinsNo ratings yet

- Ps10ex Pressure Switch PresostatoDocument1 pagePs10ex Pressure Switch PresostatoJULIO AREVALONo ratings yet

- FS-C5100-C5200-C5300 PartsDocument47 pagesFS-C5100-C5200-C5300 PartsDennis LeeNo ratings yet

- NECP05 CommentsDocument263 pagesNECP05 Commentsjturner170No ratings yet

- Aircraft Lighting SystemDocument12 pagesAircraft Lighting SystemDavid DungNo ratings yet

- Cable specifications for South Africa divisionDocument12 pagesCable specifications for South Africa divisionDave CNo ratings yet