Professional Documents

Culture Documents

Solidrill Wellhead System Ps

Uploaded by

بلال حسيني0 ratings0% found this document useful (0 votes)

104 views1 pageOriginal Title

solidrill-wellhead-system-ps

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

104 views1 pageSolidrill Wellhead System Ps

Uploaded by

بلال حسينيCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

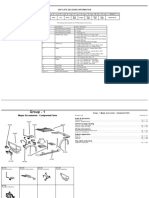

SOLIDrill

Modular compact wellhead system

FEATURES Correctly installing the wellhead is crucial to

■■ Debris tolerance design through drilling- and workover-operation success. But

proprietary profiles and features. most conventional installations involve landing

■■ Alignment: utilizes a self-aligning hanger tubing hangers on top of the casing hanger

and centralizing features to provide the packoff’s flat area where debris can accumulate.

most reliable installation experience. This condition causes the wellhead to be

■■ Versatility: has the ability to accommodate misaligned, preventing its proper installation

different casing programs from a single and resulting in nonproductive time. For

system as well as minimal tooling, and a operators conducting drilling and workovers

wide range of tubing programs including involving complex land or deepwater wells,

single, dual and completions with ESP these challenges are accentuated.

cable penetrator.

Now such conditions can be mitigated with

■■ Hanger retention: optional temporary

the SOLIDrill* modular compact wellhead

lockdown when landing casing hangers to

system. The wellhead is designed to endure

facilitate the cementing process.

extreme operating conditions, pressures up to

■■ Position indication to ensure correct land 10,000 psi and severe kickoff well angles up

off for worry-free installations. to 60° kickoff at 80 m, while increasing safety

■■ Time savings: incorporates our quick and efficiency. Its proprietary design reduces

connectors and diverter connections and the possibility of hanger tilt and secures

reduced BOP connections resulting in reliable hanger alignment, while reducing

typical rig time savings as much as 50%. wellhead debris. The SOLIDrill wellhead

■■ Safety: reduces exposure to potential open system has a compact, unitized housing and

hole and lost time accidents by reducing provides operational flexibility in a single

the number of BOP connections, wellhead system. The system is available in either two-

penetrations (no lockscrews) and through- or three-stage arrangements with 11-in and

BOP/diverter operations. 135/8-in nominal sizes.

■■ Sealing capabilities: utilizes Cameron

state of the art sealing technology Each of these unique attributes helps reduce

including Dovetail and metal-to-metal wellhead installation time, so operators can

seals, with optional Metal End Cap (MEC) maximize drilling uptime to get to first oil quicker. RP-003517

seals for the packoff for critical services.

■■ Feedback capability (optional) on

housing misalignment.

■■ Low maintenance: the reliability,

standardization, lack of plastic packing

or lockscrews and the availability

of continuous control lines reduce

maintenance costs.

* Mark of Schlumberger

Other company, product, and service names

are the properties of their respective owners.

Copyright © 2016 Schlumberger. All rights reserved. SUR-1033 slb.com/SOLIDrill

You might also like

- Administration and Supervisory Uses of Test and Measurement - Coronado, Juliet N.Document23 pagesAdministration and Supervisory Uses of Test and Measurement - Coronado, Juliet N.Juliet N. Coronado89% (9)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Consumer Behaviour of Titan WatchesDocument57 pagesConsumer Behaviour of Titan Watchesmanu100% (1)

- WellDocument12 pagesWellmuklis anggaraNo ratings yet

- Layher Allround Scaffolding - Technical BrochureDocument48 pagesLayher Allround Scaffolding - Technical BrochureEmaVanni100% (5)

- CCA159 PowerFlex 70 Maintenance and Troubleshooting PDFDocument2 pagesCCA159 PowerFlex 70 Maintenance and Troubleshooting PDFبلال حسيني0% (1)

- Solidrill Wellhead System Ps PDFDocument1 pageSolidrill Wellhead System Ps PDFبلال حسيني100% (1)

- Weir Oil Gas BrochureDocument33 pagesWeir Oil Gas BrochureRatnakar Patil100% (1)

- CaseStudy EagleBurgmann SeccoLip-for-roller-dryers EN 23-05Document2 pagesCaseStudy EagleBurgmann SeccoLip-for-roller-dryers EN 23-05edavidNo ratings yet

- Turret MooringsDocument3 pagesTurret Mooringsjo0% (1)

- Rotalock™: Quick Opening ClosureDocument2 pagesRotalock™: Quick Opening Closureagung wijayaNo ratings yet

- Datasheet Codeline OCTA 80S Series PDFDocument4 pagesDatasheet Codeline OCTA 80S Series PDFlordsethdarknessNo ratings yet

- Metal and Cased Hole Liner System - TSSDocument2 pagesMetal and Cased Hole Liner System - TSSDavid LuhetoNo ratings yet

- Inflatable Packers enDocument51 pagesInflatable Packers enDavid LuhetoNo ratings yet

- H09626 IsolizerCentralizerDocument2 pagesH09626 IsolizerCentralizerAQUILES CARRERANo ratings yet

- Expandable SolutionsDocument2 pagesExpandable SolutionsHunterNo ratings yet

- Steel Purlins ManualDocument48 pagesSteel Purlins ManualKenshin HimuraNo ratings yet

- SLB Xcelis PsDocument2 pagesSLB Xcelis Pseduardo navarroNo ratings yet

- Technical Specification SheetDocument2 pagesTechnical Specification Sheetfauzan kartiyasaNo ratings yet

- EN - Allround Technical BrochureDocument48 pagesEN - Allround Technical BrochuresivanaNo ratings yet

- 04 Swell TechnologyDocument18 pages04 Swell TechnologyMEUBRONo ratings yet

- Su-90Document16 pagesSu-90pooNo ratings yet

- Quick Release Hooks Readymoor: Product Application BriefingDocument6 pagesQuick Release Hooks Readymoor: Product Application BriefingcarloosNo ratings yet

- Quick Release Hooks Readymoor: Product Application BriefingDocument6 pagesQuick Release Hooks Readymoor: Product Application BriefingRanjith SriNo ratings yet

- BMCT-V TRUSS LESS ROOF STRUCTURESDocument25 pagesBMCT-V TRUSS LESS ROOF STRUCTURESDevine MerakiNo ratings yet

- Substation Structures: An engineering insight into low-profile cost savingsDocument111 pagesSubstation Structures: An engineering insight into low-profile cost savingsdavidfc26No ratings yet

- Bateria Seca - CatalogoDocument2 pagesBateria Seca - CatalogoDan QspNo ratings yet

- Baterias SecasDocument2 pagesBaterias SecasLEONARDO BALTAZAR ACARAPINo ratings yet

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocument10 pagesGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationbdikicNo ratings yet

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocument10 pagesGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationNur FajarNo ratings yet

- Gas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationDocument10 pagesGas-Insulated Switchgear For Substations: Common Characteristic Features of Switchgear InstallationNur FajarNo ratings yet

- Dynamic sealing eliminates leaks and reduces costsDocument1 pageDynamic sealing eliminates leaks and reduces costsAlejandro MorenoNo ratings yet

- 04 Swell TechnologyDocument16 pages04 Swell TechnologyPedro Tiago Batista CoelhoNo ratings yet

- Harness Leading Technology To Improve Process Performance.: AEV™ C-Ball ValvesDocument8 pagesHarness Leading Technology To Improve Process Performance.: AEV™ C-Ball ValvesJORGE ALBERTO PEREZ RAMIREZNo ratings yet

- Modular Cable Protector PsDocument1 pageModular Cable Protector Pslepro brunelNo ratings yet

- CC Awwa c561 en r3Document17 pagesCC Awwa c561 en r3SoeiroMarinaNo ratings yet

- Brochure Bettis CBB Series Scotch Yoke Pneumatic Actuators Us en 84486 PDFDocument6 pagesBrochure Bettis CBB Series Scotch Yoke Pneumatic Actuators Us en 84486 PDFIsidro RODRIGUEZ VILLEGASNo ratings yet

- PPG Sigmashield 880: Single Coat System For Maintenance of Floating Tank RoofsDocument2 pagesPPG Sigmashield 880: Single Coat System For Maintenance of Floating Tank RoofsSantiago Cuichán VelascoNo ratings yet

- 1 EN - Solutions For The Metal Industry - Machined SealsDocument20 pages1 EN - Solutions For The Metal Industry - Machined Sealswilliams vasquezNo ratings yet

- Pentair Codeline BrochureDocument6 pagesPentair Codeline BrochurekeilyNo ratings yet

- Kal Zip PDFDocument16 pagesKal Zip PDFMiky CastenNo ratings yet

- Hybrid Substation PDFDocument20 pagesHybrid Substation PDFJayadevDamodaran75% (4)

- The SSMC Wellhead System Is - CedipDocument8 pagesThe SSMC Wellhead System Is - CedipAaron Vazquez Martinez100% (1)

- Man Rigiseal EngDocument4 pagesMan Rigiseal EngvictorsoroNo ratings yet

- Cost Effective For Soil Nail Wall Designs - Fast Installation and Immediate Loading - Predictable Capacity - Limited Access Areas - Pre-Engineered SystemDocument4 pagesCost Effective For Soil Nail Wall Designs - Fast Installation and Immediate Loading - Predictable Capacity - Limited Access Areas - Pre-Engineered SystemVerenice CentenoNo ratings yet

- REI Pneumatic ValvesDocument2 pagesREI Pneumatic ValveskyongngNo ratings yet

- Wellbore Integrity Restoration Services Brochure PDFDocument8 pagesWellbore Integrity Restoration Services Brochure PDFDavid LuhetoNo ratings yet

- CP Eg Saundersidvsml Bu en A2!06!2013 12 Sml1Document20 pagesCP Eg Saundersidvsml Bu en A2!06!2013 12 Sml1Matt TremoglieNo ratings yet

- Strength Through Adversity: The Global First ChoiceDocument2 pagesStrength Through Adversity: The Global First ChoiceAnil Kumar JhaNo ratings yet

- Copperhead Brochure 09 2Document1 pageCopperhead Brochure 09 2tonyNo ratings yet

- Sky DeckDocument44 pagesSky DeckEyob YimerNo ratings yet

- Legendary Performance With Next-Level ComfortDocument8 pagesLegendary Performance With Next-Level ComfortSaraNo ratings yet

- Valve Solutions For Onshore Production BRDocument8 pagesValve Solutions For Onshore Production BRshamekhalmaamariNo ratings yet

- Sonardyne ModularDocument2 pagesSonardyne ModularMuhamad AlfaniNo ratings yet

- Zeds & Cees: Users GuideDocument40 pagesZeds & Cees: Users GuideTee Bun PinNo ratings yet

- How It Works Gate ValvesDocument1 pageHow It Works Gate ValvesWael FaragNo ratings yet

- System Summary - Cardium Hanger OnlyDocument9 pagesSystem Summary - Cardium Hanger OnlyRahima RahoumaNo ratings yet

- Sealing For Hydropower EquipmentDocument28 pagesSealing For Hydropower EquipmentJenny Cecilia Ureña ZuriNo ratings yet

- Brochure Valves For Chemical and Petrochemical ProcessesDocument32 pagesBrochure Valves For Chemical and Petrochemical ProcessesBastian DwiNo ratings yet

- HMT - Aluminator 1000 - BrochureDocument2 pagesHMT - Aluminator 1000 - BrochureJorge ZumaranNo ratings yet

- BHMN 35002 Camflex BR 19377B 0620 EnglishDocument12 pagesBHMN 35002 Camflex BR 19377B 0620 EnglishMario LopezNo ratings yet

- Kal ZipDocument16 pagesKal ZipNgaiLamNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Greetings in English - 210414 - 152650Document2 pagesGreetings in English - 210414 - 152650بلال حسينيNo ratings yet

- The Bottom Hole PressureDocument2 pagesThe Bottom Hole Pressureبلال حسينيNo ratings yet

- 913 2013Document2 pages913 2013بلال حسينيNo ratings yet

- Formation Fracture GradientDocument16 pagesFormation Fracture GradientDoni KurniawanNo ratings yet

- KBMG Series Side Pocket MandrelsDocument2 pagesKBMG Series Side Pocket Mandrelsبلال حسينيNo ratings yet

- Kirksey - Squeeze CementingDocument37 pagesKirksey - Squeeze CementingAquiles CarreraNo ratings yet

- Formation Fracture GradientDocument16 pagesFormation Fracture GradientDoni KurniawanNo ratings yet

- 365 14Document3 pages365 14بلال حسينيNo ratings yet

- Multistage Restriction Orifice DeltafluidDocument3 pagesMultistage Restriction Orifice Deltafluidsaka dewaNo ratings yet

- Norsok Standard - Process Design (P-001r3)Document29 pagesNorsok Standard - Process Design (P-001r3)Thitikorn WassanarpheernphongNo ratings yet

- The Bottom Hole PressureDocument2 pagesThe Bottom Hole Pressureبلال حسينيNo ratings yet

- Land Transportation Safety Recommended Practice Guidance Note 16Document3 pagesLand Transportation Safety Recommended Practice Guidance Note 16bumbac robertNo ratings yet

- Instrument Loop DiagramDocument121 pagesInstrument Loop Diagramroutine1976No ratings yet

- Pro 11Document3 pagesPro 11silverpenNo ratings yet

- Harrys Error UncertaintyDocument50 pagesHarrys Error Uncertaintyبلال حسينيNo ratings yet

- 913 2013Document2 pages913 2013بلال حسينيNo ratings yet

- Pro 11Document3 pagesPro 11silverpenNo ratings yet

- CCN144 Studio 5000 Logix Designer Level 4 Kinetix 6500 (CIP) ProgrammingDocument2 pagesCCN144 Studio 5000 Logix Designer Level 4 Kinetix 6500 (CIP) Programmingبلال حسينيNo ratings yet

- FFFFFDocument8 pagesFFFFFبلال حسينيNo ratings yet

- 2.3 List of Components - NomenclatureDocument4 pages2.3 List of Components - Nomenclatureبلال حسينيNo ratings yet

- BN-MR Metal Ruler - V.2 PDFDocument1 pageBN-MR Metal Ruler - V.2 PDFبلال حسينيNo ratings yet

- Nozzles Crude Oil Storage Tanks C4 Center Zarzaitine FieldDocument1 pageNozzles Crude Oil Storage Tanks C4 Center Zarzaitine Fieldبلال حسينيNo ratings yet

- Ame Veco Ps 672 Rev 1Document682 pagesAme Veco Ps 672 Rev 1بلال حسينيNo ratings yet

- BN-MR Metal Ruler - V.2 PDFDocument1 pageBN-MR Metal Ruler - V.2 PDFبلال حسينيNo ratings yet

- Nature and Purpose of CommunicationDocument17 pagesNature and Purpose of CommunicationEdmond Dantès100% (4)

- Dreamers Chords by Jungkook (정국) tabs at Ultimate Guitar ArchiveDocument4 pagesDreamers Chords by Jungkook (정국) tabs at Ultimate Guitar ArchiveLauraNo ratings yet

- Marine Ecotourism BenefitsDocument10 pagesMarine Ecotourism Benefitsimanuel wabangNo ratings yet

- CotomDocument8 pagesCotommuangawaNo ratings yet

- Training Report PRASADDocument32 pagesTraining Report PRASADshekharazad_suman85% (13)

- A Grammar of Awa Pit (Cuaiquer) : An Indigenous Language of South-Western ColombiaDocument422 pagesA Grammar of Awa Pit (Cuaiquer) : An Indigenous Language of South-Western ColombiaJuan Felipe Hoyos García100% (1)

- 2010 - Caliber JEEP BOITE T355Document484 pages2010 - Caliber JEEP BOITE T355thierry.fifieldoutlook.comNo ratings yet

- Raoult's law and colligative propertiesDocument27 pagesRaoult's law and colligative propertiesGøbindNo ratings yet

- Contract of Lease 2Document4 pagesContract of Lease 2Allen Solomon TamNo ratings yet

- Vsphere Storage PDFDocument367 pagesVsphere Storage PDFNgo Van TruongNo ratings yet

- (Leon 2021) Pengaruh Financial Distress, Laverage Terhadap Konservatisme Akuntansi Pada Perusahaan Manfaktur Sektor Konsumsi 2016-2019Document24 pages(Leon 2021) Pengaruh Financial Distress, Laverage Terhadap Konservatisme Akuntansi Pada Perusahaan Manfaktur Sektor Konsumsi 2016-2019PUTRI AYU HASTUTINo ratings yet

- BOM RMCC Parking-Shed Rev2Document15 pagesBOM RMCC Parking-Shed Rev2Ephrem Marx AparicioNo ratings yet

- Beef & Dairy 2016Document36 pagesBeef & Dairy 2016The Standard NewspaperNo ratings yet

- MBA Regular Part-I (Sem I)Document17 pagesMBA Regular Part-I (Sem I)Jasdeep SinghNo ratings yet

- Enzyme KineticsDocument13 pagesEnzyme KineticsMohib100% (1)

- The Three Pillars of The ASEANDocument13 pagesThe Three Pillars of The ASEANLouwell Abejo RiñoNo ratings yet

- Green Tree PythonDocument1 pageGreen Tree Pythonapi-379174072No ratings yet

- Workbook. Unit 3. Exercises 5 To 9. RESPUESTASDocument3 pagesWorkbook. Unit 3. Exercises 5 To 9. RESPUESTASRosani GeraldoNo ratings yet

- Viennot - 1979 - Spontaneous Reasoning in Elementary DynamicsDocument18 pagesViennot - 1979 - Spontaneous Reasoning in Elementary Dynamicsjumonteiro2000No ratings yet

- MS Excel Word Powerpoint MCQsDocument64 pagesMS Excel Word Powerpoint MCQsNASAR IQBALNo ratings yet

- Bahasa Inggris RanggaDocument3 pagesBahasa Inggris RanggaArdiyantoNo ratings yet

- Gen - Biology 2 Module 2Document12 pagesGen - Biology 2 Module 2Camille Castrence CaranayNo ratings yet

- Eliminator ® Liquid Line Fi Lter Driers: DML and DCLDocument12 pagesEliminator ® Liquid Line Fi Lter Driers: DML and DCLbracaNSNo ratings yet

- Ndeb Bned Reference Texts 2019 PDFDocument11 pagesNdeb Bned Reference Texts 2019 PDFnavroop bajwaNo ratings yet

- Rguhs Dissertation PharmacyDocument6 pagesRguhs Dissertation PharmacyWhatAreTheBestPaperWritingServicesSingapore100% (1)

- ......... NCP CaseDocument34 pages......... NCP Casevipnikally80295% (19)

- PILE LOAD TEST PROCEDURE GUIDEDocument2 pagesPILE LOAD TEST PROCEDURE GUIDEJEFFY JACOBNo ratings yet