Professional Documents

Culture Documents

Product Specification: Carbopol 980 NF Polymer

Uploaded by

tiroquim563Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Specification: Carbopol 980 NF Polymer

Uploaded by

tiroquim563Copyright:

Available Formats

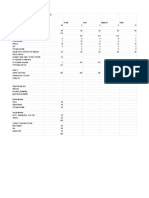

Product Specification

CARBOPOL* 980 NF POLYMER

Carbopol® 980 NF polymer meets the limits cited in the current edition of the following monographs:

• United States Pharmacopeia/National Formulary (USP/NF) monograph for Carbomer Homopolymer Type C

(Note: The previous USP/NF compendial name for this product was Carbomer 940.)

• European Pharmacopeia (Ph. Eur.) monograph for Carbomers

• India Pharmacopeia (IP) monograph for Carbomers

• China Pharmacopeia (ChP) monograph for Carbomers

General Product Characteristics

Appearance: White, fluffy powder

Odor: Slightly acetic

Lot Test

Test Specification Test Procedure2

Frequency1

Identification

Colorimetric test Pass 1:200 USP/NF

Gel formation test Pass 1:2003 USP/NF

Infrared spectrum Pass ---4 Lubrizol SA-102

Precipitate test Pass 1:200 USP/NF

Carboxylic Acid Content, Assay % 56.0 - 68.0 1:1 Lubrizol 1318-A

Viscosity, cP, 25°C

Brookfield RVT, 20 rpm, neutralized to pH 7.3 - 7.8

0.2 wt% mucilage, spindle #6 13,000 - 30,000 1:1 Lubrizol 430-I

0.5 wt% mucilage, spindle #7 40,000 - 60,000 1:1 Lubrizol 430-I

Clarity, % Transmission

0.5% Dispersion, neutralized, 420 nm 85 min 1:1 Lubrizol 485-D

Loss on Drying, % 2.0 max 1:1 USP/NF

Heavy Metals, ppm

Total heavy metals, as Pb 20 max 1:200 USP/NF

Specific metals: Hg, Pb, As, Sb 10 max 1:200 Lubrizol SA-012

Residual Solvent5

Ethyl acetate, % 0.30 max 1:1 Lubrizol SA-009

Cyclohexane, % 0.30 max 1:1 Lubrizol SA-009

Benzene6

Benzene, ppm 0.50 max 1:1 Lubrizol SA-064

Residual Monomer, ppm

Free acrylic acid 2,500 max 1:1 Lubrizol SA-005

Sulphated Ash, % (Residue on ignition) 2.5 max 1:200 USP/NF

1 Where lot test frequency is less than 1:1, Lubrizol Advanced Materials, Inc. certifies that each batch/lot meets requirements for the characteristics

based on historical process and product data. Because these characteristics are tested on a skip-lot test frequency, results are not reported on the

Certificate of Analysis.

2 Lubrizol test procedures have been cross-validated to specified compendial procedure(s) or validated if they are included in the monograph.

3 Gel formation is confirmed by the viscosity test procedure (Lubrizol 430-I) for each lot of polymer that is produced. Every 200 lots, the gel formation test

is conducted according to USP requirements.

4 Infrared reference spectra available upon request.

5 No other residual solvents as listed in USP/NF <467> (Class 1, 2, 3, Table 4 or any other solvents) or Ph. Eur. 2.4.24 are used in the manufacturing

process of this product.

6 Benzene is tested due to it being a potential impurity.

The information contained herein is believed to be reliable, but no representations, guarantees or warranties of any kind are made as to its accuracy, suitability for particular applications or the results to be obtained.

The information often is based on laboratory work with small-scale equipment and does not necessarily indicate end product performance or reproducibility. Formulations presented may not have been tested for

stability and should be used only as a suggested starting point. Because of the variations in methods, conditions and equipment used commercially in processing these materials, no warranties or guarantees are made

as to the suitability of the products for the applications disclosed. Full-scale testing and end product performance are the responsibility of the user. Lubrizol Advanced Materials, Inc. shall not be liable for and the

customer assumes all risk and liability for any use or handling of any material beyond Lubrizol Advanced Materials, Inc.’s direct control. The SELLER MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Nothing contained herein is to be considered as permission, recommendation nor as an inducement to

practice any patented invention without permission of the patent owner.

Rev. 20180801

Lubrizol Advanced Materials, Inc. / 9911 Brecksville Road, Cleveland, Ohio 44141-3247 / 216.447.5000

You might also like

- Txnelap Lab List PDFDocument41 pagesTxnelap Lab List PDFFrancisco OdinsonNo ratings yet

- Joncryl 1687: PropertiesDocument2 pagesJoncryl 1687: PropertiesHiba NaserNo ratings yet

- TDS-737 Carbopol 676 PolymerDocument2 pagesTDS-737 Carbopol 676 PolymerSimon Rodrigo Rizo Gonzalez100% (1)

- Deosen - F200-Xanthan GumDocument2 pagesDeosen - F200-Xanthan Gumkapil chopra100% (1)

- Stepan Formulation 1220Document2 pagesStepan Formulation 1220Devesh KumarNo ratings yet

- CL H0017 (La)Document1 pageCL H0017 (La)alfredooosNo ratings yet

- StepanFormulation335 PDFDocument2 pagesStepanFormulation335 PDFDiplomadoEnTecnicasCromatograficasNo ratings yet

- ChemicalDocument2 pagesChemicalSoheila FiroozNo ratings yet

- Dynasylan Product Range enDocument16 pagesDynasylan Product Range enbhisma.nugerahNo ratings yet

- Functional Products Inc.: Additives For Biobased ProductsDocument7 pagesFunctional Products Inc.: Additives For Biobased ProductsMenoddin shaikhNo ratings yet

- Poly Suga®Quat: Greener, Milder and SilkierDocument4 pagesPoly Suga®Quat: Greener, Milder and SilkierMellisa VezinaNo ratings yet

- Polartech AM 400Document2 pagesPolartech AM 400Liliana RodriguezNo ratings yet

- Optical Effect Products PDFDocument2 pagesOptical Effect Products PDFLogdi JamesNo ratings yet

- SC2042Document4 pagesSC2042A MahmoodNo ratings yet

- Formulation, Development and Evaluation of Delayed Release Capsules of Duloxetine Hydrochloride Made of Different Enteric PolymersDocument13 pagesFormulation, Development and Evaluation of Delayed Release Capsules of Duloxetine Hydrochloride Made of Different Enteric PolymersamanaeryNo ratings yet

- Cost of Production-2015Document14 pagesCost of Production-2015hemendra499No ratings yet

- DYNOL 607 - G - Surfactant 0717 EN OIDocument2 pagesDYNOL 607 - G - Surfactant 0717 EN OIJian WenNo ratings yet

- Shrink Sleeve PVC InksDocument1 pageShrink Sleeve PVC InksPRAVIN A.PANDHARKAMENo ratings yet

- Kathon Metalworking Fluid Biocides: Maintenance Biocides Used in 70% of Metalworking FluidsDocument11 pagesKathon Metalworking Fluid Biocides: Maintenance Biocides Used in 70% of Metalworking FluidsMohsin RazaNo ratings yet

- Tomadol 900Document2 pagesTomadol 900Ricardo BohorquezNo ratings yet

- Linkit - Aspx LinkIdentifier Id&ItemID 24382Document1 pageLinkit - Aspx LinkIdentifier Id&ItemID 24382pkh29No ratings yet

- Ez-Mud DPDocument1 pageEz-Mud DPAsif KhanzadaNo ratings yet

- Presentation of Rianlon V.2012 PDFDocument30 pagesPresentation of Rianlon V.2012 PDFDiego Armando RincónNo ratings yet

- ColaLube 3407Document2 pagesColaLube 3407mndmattNo ratings yet

- Stepan Formulation 1166Document2 pagesStepan Formulation 1166kus2002inNo ratings yet

- Pointer EpatintDocument6 pagesPointer Epatinttrường phạmNo ratings yet

- Inhibex 101 Ibc 1040l 1 000000000000828678 Rest of World (GHS) - EnglishDocument19 pagesInhibex 101 Ibc 1040l 1 000000000000828678 Rest of World (GHS) - EnglishPrototypeNo ratings yet

- ATBC Plasticizer for PVC and Medical ProductsDocument2 pagesATBC Plasticizer for PVC and Medical Productsmurteza semanNo ratings yet

- Uniquat 10-80 HQ MSDS March 2012Document9 pagesUniquat 10-80 HQ MSDS March 2012gregorypage2No ratings yet

- FCI PersonalCare HLBs TableDocument7 pagesFCI PersonalCare HLBs TablezodapesssNo ratings yet

- Eumulgin B-2 PDSDocument2 pagesEumulgin B-2 PDSYap Ming ZheNo ratings yet

- Byk 037Document9 pagesByk 037AmiNo ratings yet

- Aepd VOX 1000: Technical Data SheetDocument2 pagesAepd VOX 1000: Technical Data SheetCoco HüniNo ratings yet

- Alcomer 750 Types: Technical InformationDocument2 pagesAlcomer 750 Types: Technical InformationPrototypeNo ratings yet

- Nuosperse FA 196Document2 pagesNuosperse FA 196Sandra Rojas100% (1)

- Hostage LCLDocument2 pagesHostage LCLSampathNo ratings yet

- TDS-975 Carbopol Clear PDFDocument2 pagesTDS-975 Carbopol Clear PDFRafat Kitaneh100% (1)

- Oven Cleaner - 232Document1 pageOven Cleaner - 232mndmattNo ratings yet

- Max 5.2 Surfactant Brochure PDFDocument16 pagesMax 5.2 Surfactant Brochure PDFsanjay ukalkar100% (1)

- NeoCryl A-1049 acrylic emulsion product data sheetDocument1 pageNeoCryl A-1049 acrylic emulsion product data sheetLeandro EsvizaNo ratings yet

- CL F0003 (Eu)Document1 pageCL F0003 (Eu)Jelly AnneNo ratings yet

- Nourishing Face Mask with Firming & Anti-Aging BenefitsDocument2 pagesNourishing Face Mask with Firming & Anti-Aging BenefitsDr iram nadeemNo ratings yet

- Silicone Tire Shine and Protectant HI-700Document1 pageSilicone Tire Shine and Protectant HI-700francia.castilloNo ratings yet

- Dow Chelating AgentsDocument12 pagesDow Chelating Agentsfshirani7619No ratings yet

- Qingdao Icd Biochemistry Co.,Ltd.: Certificate of AnalysisDocument1 pageQingdao Icd Biochemistry Co.,Ltd.: Certificate of Analysiskarina dwi astutiNo ratings yet

- B100-047 Eye Serum With Eyeseryl Solution BDocument1 pageB100-047 Eye Serum With Eyeseryl Solution BMariano HaseNo ratings yet

- PQ Formulary PDFDocument16 pagesPQ Formulary PDFjcriveroNo ratings yet

- Navigating Safer Choice: Stepan'S Cleangredients Product & Formulation GuideDocument7 pagesNavigating Safer Choice: Stepan'S Cleangredients Product & Formulation GuideAnonymous 9lckaf9st6No ratings yet

- Raghucarbolinepresentations22122011 PDFDocument101 pagesRaghucarbolinepresentations22122011 PDFTanmay GorNo ratings yet

- TDS DC 56Document2 pagesTDS DC 56manox007No ratings yet

- Agricultural Spray AdjuvantsDocument5 pagesAgricultural Spray AdjuvantscarlosNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSfazeel mohammedNo ratings yet

- 1.8 Detergent FnRep28Nov06-f2Document133 pages1.8 Detergent FnRep28Nov06-f2Ioana MariaNo ratings yet

- Corial Ultrasoft NT TIDocument4 pagesCorial Ultrasoft NT TIEarl100% (1)

- ASTM D 1615 - 60 (Reapproved 1995) Glycerol, Ethylene Glycol, and Pentaerythritol in Alkyd ResinsDocument4 pagesASTM D 1615 - 60 (Reapproved 1995) Glycerol, Ethylene Glycol, and Pentaerythritol in Alkyd Resinsalin2005No ratings yet

- Kato Formulations of Dishwashing DetergentsDocument2 pagesKato Formulations of Dishwashing Detergentskato chivhungaNo ratings yet

- Product Specification: Carbopol 980 NF PolymerDocument1 pageProduct Specification: Carbopol 980 NF Polymeriosi23No ratings yet

- Carbopol934 NFDocument1 pageCarbopol934 NFirma rahmawatiNo ratings yet

- Product Specification: 940 NF PolymerDocument1 pageProduct Specification: 940 NF PolymerLuisAlbertoVazquezNo ratings yet

- Ficha Tecnica Acido SorbicoDocument1 pageFicha Tecnica Acido SorbicoCarlos SiuNo ratings yet

- Sulfathiazole Contains Not Less Than 99.0 Percent and Not More Than 100.5 Percent of C H N O S, Calculated On The Dried BasisDocument2 pagesSulfathiazole Contains Not Less Than 99.0 Percent and Not More Than 100.5 Percent of C H N O S, Calculated On The Dried Basistiroquim563No ratings yet

- Skin Bioactives Brochure ReducedDocument20 pagesSkin Bioactives Brochure Reducedtiroquim563No ratings yet

- Guia Exani-III 15a EdDocument1 pageGuia Exani-III 15a Edtiroquim563No ratings yet

- Carbopol974P NFDocument1 pageCarbopol974P NFtiroquim563No ratings yet

- Listado Alisadores Cabello AutorizadosDocument12 pagesListado Alisadores Cabello Autorizadostiroquim563No ratings yet

- Introduccion A La HPLC QuattrocchiDocument405 pagesIntroduccion A La HPLC QuattrocchiLucia CeNo ratings yet

- Cosm CareDocument40 pagesCosm Caretiroquim563No ratings yet

- Introduccion A La HPLC QuattrocchiDocument405 pagesIntroduccion A La HPLC QuattrocchiLucia CeNo ratings yet

- 1.3. Properties of Transition MetalsDocument2 pages1.3. Properties of Transition Metalsyash12312No ratings yet

- Iodimetric Titration of Vitamin C: ReagentsDocument2 pagesIodimetric Titration of Vitamin C: ReagentsEbenezer EffisahNo ratings yet

- Advance Phytochemical Screening of Active Phytocontents of Linum Usitatissimum and Guizotia Abyssinica Plant Seeds in Spectrometry A Study of Comparative PropertiesDocument6 pagesAdvance Phytochemical Screening of Active Phytocontents of Linum Usitatissimum and Guizotia Abyssinica Plant Seeds in Spectrometry A Study of Comparative PropertiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Astm D1654Document4 pagesAstm D1654Alejandro GutierrezNo ratings yet

- Carbonation Prediction Model for Coated ConcreteDocument7 pagesCarbonation Prediction Model for Coated ConcreteHaniel FcNo ratings yet

- Teraoka Adhesive Tapes For Industrial, Packing and Packaging Catalog 2017Document2 pagesTeraoka Adhesive Tapes For Industrial, Packing and Packaging Catalog 2017ion ionNo ratings yet

- Shimadzu AA-7800 Series BrochureDocument20 pagesShimadzu AA-7800 Series BrochureTNo ratings yet

- Astm d5543Document5 pagesAstm d5543CeciliagorraNo ratings yet

- IJOGST - Volume 3 - Issue 4 - Pages 67-77Document11 pagesIJOGST - Volume 3 - Issue 4 - Pages 67-77Hka IsmailNo ratings yet

- Ascorbyl Palmitate, Gamma Tocopherol and Edta Affect Lipid Oxidation N Fish Oil Enriched Salad Dressing DifferentlyDocument7 pagesAscorbyl Palmitate, Gamma Tocopherol and Edta Affect Lipid Oxidation N Fish Oil Enriched Salad Dressing Differentlyaisyah_asyrafNo ratings yet

- Science Mixtures WorksheetDocument8 pagesScience Mixtures WorksheetRaven AvoNo ratings yet

- Advanced FRP Panel Tank DesignDocument4 pagesAdvanced FRP Panel Tank DesignDyah Ayu widatiNo ratings yet

- General Chemistry 1 Activity Sheet Quarter 2 - MELC 4 Week 7Document14 pagesGeneral Chemistry 1 Activity Sheet Quarter 2 - MELC 4 Week 7LayNo ratings yet

- Cooling Tower Water Treatment TrainingDocument14 pagesCooling Tower Water Treatment TrainingZAHID HUSSAINNo ratings yet

- Description HOLEPLUGDocument4 pagesDescription HOLEPLUGMannar1No ratings yet

- Catalytic Hydrogenation in The Liquid PhaseDocument8 pagesCatalytic Hydrogenation in The Liquid PhasegiovanniNo ratings yet

- Clayfix II Plus SDSDocument9 pagesClayfix II Plus SDSdanalabNo ratings yet

- Granular Urea Certificate of AnalysisDocument2 pagesGranular Urea Certificate of AnalysisMuslim NasirNo ratings yet

- Gabion Wall Typical Design Sheet-Front-19-8-2008Document8 pagesGabion Wall Typical Design Sheet-Front-19-8-2008farrukhNo ratings yet

- Problems in Tablet ManufacturingDocument8 pagesProblems in Tablet ManufacturingParag MehtaNo ratings yet

- All Purpose Paint Remover - Dipping Grade: PRODUCT CODE: RRA 200-SeriesDocument2 pagesAll Purpose Paint Remover - Dipping Grade: PRODUCT CODE: RRA 200-SeriesPieter FourieNo ratings yet

- Chemical Changes and ReactionsDocument8 pagesChemical Changes and ReactionsHarshit KukrejaNo ratings yet

- 12B Model PapersDocument47 pages12B Model Papers11B 05 Ibrahim Mohammed IrfazNo ratings yet

- Rigid Pavement Design: 15.1.1 Modulus of Sub-Grade ReactionDocument11 pagesRigid Pavement Design: 15.1.1 Modulus of Sub-Grade ReactionVikash SinghNo ratings yet

- How to produce liquid sugar from brem dregs flourDocument10 pagesHow to produce liquid sugar from brem dregs flourNadia Gusti Ami PutriNo ratings yet

- BMEVEKFM210 - Green Reactions and Solvents ClassDocument21 pagesBMEVEKFM210 - Green Reactions and Solvents ClassjuansanninNo ratings yet

- Active IngredientsDocument7 pagesActive IngredientsJESRYL PAULITENo ratings yet

- HND Sector 2 Vol3-1Document530 pagesHND Sector 2 Vol3-1mbabit leslieNo ratings yet

- Process For The Extraction andDocument11 pagesProcess For The Extraction andabaNo ratings yet

- Pentadecafluorooctanoic Acid ESPECTRO IRDocument3 pagesPentadecafluorooctanoic Acid ESPECTRO IRSamVanyaNo ratings yet