Professional Documents

Culture Documents

Concrete specification and testing standards review

Uploaded by

Mudassar KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete specification and testing standards review

Uploaded by

Mudassar KhanCopyright:

Available Formats

STANDARDS

Concrete specification and testing –

is BS EN 206 fit for purpose?

review belongs to the same population as B.1 states that the probability of

A new edition of BS EN 206, the that verified as conforming via conformity conforming concrete being rejected is

Standard for concrete specification assessment by the producer’. A translation only 1%; no figure is given for the

and testing, was published in of this clause into plain UK English would probability of the customer having to

December 2013(1). Does it address be helpful – one assumes it means ‘testing to accept non-conforming concrete.

previous criticisms(2,3)? Is the establish whether concrete supplied to site Annex J states that more stringent

new edition now ‘fit for purpose’? complies with the specification’. criteria may be applied in Spain because

Alasdair N Beal of Thomasons According to Cl. B.2, the ‘volume of of its legal requirement that the risk to

concrete under review’ for ‘identity testing’ customers of defective concrete being

reports. may be anything from a single batch to accepted should not exceed 50%.

400m³ of concrete. Very little is said about Therefore presumably under the

sampling rates. According to Cl. B.3.1, if standard BS EN 206 rules the risk to the

S EN 206:2013 covers concrete from there is product control certification, one to customer of having to accept defective

B strength class C8/10 to C100/115

(characteristic cube strengths

10–115MPa).

six test results may be used for conformity

assessment:

• individual tests fci ≥ (fck – 4) MPa

•

concrete is more than 50%.

If one test per sample is acceptable for

producers, then it should also be

Cl. 3.1.5.4 defines concrete ‘characteristic • for a group of two to four tests fcm ≥ (fck acceptable for customers. Requiring

strength’ as the ‘value of strength below + 1) MPa, or group of five to six tests fcm customers to carry out twice as many

which 5% of the population of all possible ≥ (fck + 2) MPa). tests simply increases costs and

strength determinations of the volume of discourages testing.

concrete under consideration are expected Although concrete producers checking • On a small project with concrete from a

to fall’. This is a strangely abstract definition: concrete are permitted by Section 8 to only non-certified supplier, the requirement

instead of real strength measurements test one cube/cylinder from each concrete for a minimum of six tests regardless of

it is based on expected values of possible sample, if a customer wants to check the volume involved is simply absurd.

strength determinations. In addition, no concrete Annex B would require him to • The BS EN 206 compliance rules

lower limits are placed on the strength of the carry out twice as many tests – two cube/ appear to be based on analysis from

5% of tests that are allowed to fall below the cylinder tests from every concrete sample. ‘large number’ probability theory,

specified strength, so if a customer specifies No explanation is given as to why the where a small number of random

30MPa concrete and receives 20 batches requirement for customer tests is different samples is used to estimate the

with strengths of 30–45MPa and one batch from producer tests. characteristics of random variations in

of 20MPa, the supplier could claim that this Where the concrete has no product a quasi-infinite population. However,

complies with a specification. control certification, Cl. B.3.2 imposes concrete is delivered to construction

more stringent requirements for assessing sites in batches, so its strength

‘Volume of concrete under conformity: at least three test results are variations are ‘quantised’ and although

consideration’ and test criteria required and the strength requirements are: large variations are possible between

Most of the recommendations in BS EN 206 • individual tests fci ≥ (fck – 4) MPa batches, the variations within a batch

concern statistically based control criteria for • group of three to six tests fcm ≥ (fck + 4) of properly-mixed concrete are usually

concrete producers. According to Cl. 8.2.1.2, MPa. small. ‘Large number’ probability

concrete in continuous production by a theory does not apply in this situation

producer with product control certification Thus at least six cubes/cylinders must be unless the sampling rate is very low

shall be sampled at a rate of at least one per tested, even if only a single batch of concrete (1/10 or less)(5).

400m³, or per five production days or per is being considered. • The compliance rules ignore the effect

month (whichever is greatest). Test results of sampling rate on customer and

can be based on one test cube/cylinder per Analysis producer risk. If the entire concrete for

sample. The acceptance criteria are: The compliance rules in BS EN 206 have a project is assessed on the basis of a

• individual tests (fci ≥ (fck – 4) MPa) some odd features: single test result, or the combined

• tests are also assessed either in groups • As can be seen, the criteria for ‘identity results of a single group of test results,

of three (mean fcm ≥ fck + 4) MPa) or testing’ are more lenient than those for this creates a high risk for both the

groups of at least 15 (mean fcm ≥ fck + production control. They are also producer and the customer. However,

1.48σ) MPa, where σ is the standard lenient compared with past UK practice; these risks can be reduced by increasing

deviation). although the definition of the sampling rate. If every batch of

‘characteristic strength’ is similar to concrete is sampled and tested, so that

Annex B covers ‘identity testing’, in that in the old BS 5328(4), the allowable only good batches are accepted and bad

which clause B.1 states, ‘indicates whether limits on test results in BS EN 206 are batches rejected, the risk for both

the defined volume of concrete under generally 1MPa lower. The Note to Table producer and customer falls to 0%.

www.concrete.org.uk APRIL 2014 concrete 35

STANDARDS

Therefore with a high sampling rate, • When there is more than one test rules should be revised to take into account:

the risk for both producer and customer result, the rules mean that the entire • the difference between within-batch

is low. Reducing the sampling rate cuts concrete on a project may be rejected and between-batch strength variations

testing costs but for the producer it even if all the test results exceed the • the effect of different sampling rates on

increases the volume of concrete at risk specified strength (iii), (v), (viii), (x). risks to both customers and producers.

on a single decision and for the On the other hand, on another project

customer it increases the risk of concrete could be accepted even when The lower limit for individual test results

defective concrete being accepted. the results show that 10% or more was of 4MPa below characteristic strength is

• For the producer, a criterion based on below the specified characteristic too low, particularly for lower-strength

the mean of a group of test results strength (eg, iv, ix). concretes.

leads to a large volume of concrete • The rules for concrete from non- Assessment based on the average of

being put at risk on a single decision. certified suppliers give even stranger a group of test results puts an excessive

It can also lead to good batches of results: if there is only a single batch of volume of concrete at risk on a single

concrete with perfectly satisfactory test concrete, this would be rejected unless decision.

results being rejected because a bad the test results exceeded the specified Assessment based on the average of a

batch has been included in their strength by 4MPa (x). On a larger group of test results also creates a risk that

group. However, group criteria also project, concrete could be rejected good concrete may be rejected because a

mean that customers may be expected when the tests clearly show that all of low-strength batch has been included in

to accept bad batches of concrete if the concrete supplied exceeds the the group, or substandard concrete may be

they are assessed alongside other specified characteristic strength (xii). accepted because it has been assessed in a

better batches. On the other hand, on another project group that contains better batches. ●

concrete might be accepted even

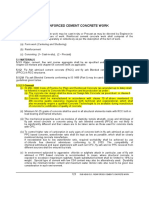

Table 1 shows the results from the BS though the tests show that more than

EN 206 ‘identity testing’ assessment rules 5% fell below the specified

in various situations. As can be seen, strict characteristic strength (xi).

application of the BS EN 206 rules would

lead to some very peculiar decisions. Concluding remarks

• Where there is only a single batch of The concrete strength rules in BS EN 206

concrete (i, vi), the results are bizarre: are unsatisfactory. References

if the producer is certified, individual The definition of ‘characteristic strength’

test results 4MPa below the specified is abstract and impractical. The assessment 1. BRITISH STANDARDS INSTITUTION, BS EN 206.

Concrete. Specification, performance, production

strength are accepted. Therefore, rules in later parts of the code are not and conformity, BSI, London, 2013.

although Cl.3.1.5.4 only permits 5% consistent with the definition and can lead 2. TOPLIS, P. Concrete compressive strength testing –

defective concrete, under the BS EN to concrete that complies with the definition is the industry getting it right? The Structural

206 assessment rules concrete may be being rejected and concrete that does not Engineer, Vol.86, No.23/24, 2 December 2008,

pp.43.

judged ‘acceptable’ even when 100% of comply being accepted. 3. BEAL, A.N. Viewpoint: Concrete strength testing –

it is below the specified strength. If the The risk to the customer of substandard are the code writers getting it right? The Structural

specified strength is 10MPa, the concrete being deemed ‘acceptable’ is too Engineer, Vol.87, No.10, 19 May 2009, pp.12–13.

strength of the concrete that is high. This is recognised in Annex J, which 4. BRITISH STANDARDS INSTITUTION, BS 5328.

Concrete. Guide to specifying concrete. BSI,

accepted might be only 60% of what permits more stringent acceptance rules to London, 1997, superseded.

was specified. be used in Spain. 5. BEAL, A.N. Concrete cube strengths – what use are

• Some 400m³ of concrete in a structure It is unreasonable to require customers to statistics? ICE Proceedings, Vol.71, Issue 4, 1

could be accepted on the basis of a test two cubes/cylinders from each sample December 1981, pp.1037–1048 and Vol.73, Issue

2, 1 June 1982, pp.515–532, Institution of Civil

single test result 4MPa lower than the when producers are allowed to use single Engineers, London.

specified strength (ii, vii). tests. The statistical analysis of acceptance

Table 1 – Results from BS EN 206 ‘identity testing’ assessment rules

Certified Non-certified Specified No. of No. of Results (MPa) Pass/fail?

production production strength batches tests

(MPa)

(i) / 10 1 1 6 Pass

(ii) / 50 1 6 Pass

(iii) / 2 2 11, 10 Fail

(iv) / 50 2 7, 15 Pass

(v) / 5 5 10, 13, 11, 12, 13 Fail

(vi) / 30 1 1 26 Pass

(vii) / 50 1 26 Pass

(viii) / 2 2 30, 31 Fail

(ix) / 50 2 26, 36 Pass

(x) / 5 5 30, 34, 31, 32, 33 Fail

(xi) / 30 1 3 33, 34, 34 Fail

(xii) / 50 3 26, 36, 40 Pass

(xiii) / 5 5 30, 34, 40, 32, 33 Fail

36 concrete APRIL 2014 Find concrete on : pinterest.com/concretemag/boards

You might also like

- RCC Design SheetsDocument40 pagesRCC Design Sheetsashuswara84% (25)

- Readymix Concrete BS EN 206-1Document66 pagesReadymix Concrete BS EN 206-1Ajit Singh Rathore100% (8)

- Astm C67Document12 pagesAstm C67ZEC LIMITED75% (12)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Nha Tamplate RatesDocument188 pagesNha Tamplate RatesMudassar Khan100% (1)

- ASTM-C 512 (Creep of Concrete Test)Document5 pagesASTM-C 512 (Creep of Concrete Test)Evgeny PankovNo ratings yet

- Astm C39 PDFDocument7 pagesAstm C39 PDFMadeleyn MoralesNo ratings yet

- Bar bending schedule wing wallsDocument10 pagesBar bending schedule wing wallsMudassar KhanNo ratings yet

- Concrete Specification and Testing - Is BS EN 206 Fit For Purpose?Document2 pagesConcrete Specification and Testing - Is BS EN 206 Fit For Purpose?escillaNo ratings yet

- En 206 2013 Is Fit For Purpose Concrete June 2014Document3 pagesEn 206 2013 Is Fit For Purpose Concrete June 2014Fernando Costa E SilvaNo ratings yet

- Concrete Strength Acceptance: by Bruce A. SuprenantDocument3 pagesConcrete Strength Acceptance: by Bruce A. SuprenantBruce SuprenantNo ratings yet

- What To Do When Cylinder Breaks Are LowDocument3 pagesWhat To Do When Cylinder Breaks Are LowRommel Villaroman EstevesNo ratings yet

- CI4508 Concrete QADocument2 pagesCI4508 Concrete QAEng.Ahmad AbuFaraNo ratings yet

- Acceptance of Concrete Cube Test ResultsDocument3 pagesAcceptance of Concrete Cube Test ResultsNino Celso AstilleroNo ratings yet

- Minimizing Durability Test RisksDocument6 pagesMinimizing Durability Test RiskscesaraleNo ratings yet

- Compressive Strength of Cylindrical Concrete Specimens': Standard Test Method ForDocument5 pagesCompressive Strength of Cylindrical Concrete Specimens': Standard Test Method ForAhmed AbidNo ratings yet

- RMC CHK Guideking On SiteDocument2 pagesRMC CHK Guideking On SiteSachin ShindeNo ratings yet

- Sub Head 5.0: Reinforced Cement Concrete WorkDocument16 pagesSub Head 5.0: Reinforced Cement Concrete WorkPritam DharNo ratings yet

- 04 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of DoubtDocument9 pages04 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of Doubtfadi talaNo ratings yet

- Speci FactionsDocument280 pagesSpeci FactionsNivetha VNo ratings yet

- How Good Is Your QC?: Part I of Concrete Quality Control SeriesDocument2 pagesHow Good Is Your QC?: Part I of Concrete Quality Control SeriesFarhanNo ratings yet

- Tieu Chuan EN 206-1 Cua Chau AuDocument9 pagesTieu Chuan EN 206-1 Cua Chau AuPhạm Thanh BìnhNo ratings yet

- 02 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of DoubtDocument3 pages02 BRMCA GUIDE BS EN 13791:2019, Clause 9: Assessment of Compressive Strength Class of Concrete in Case of DoubtRVNLPKG6B VBL-GTLMNo ratings yet

- Concrete Testing The Structural Engineer 87Document3 pagesConcrete Testing The Structural Engineer 87istructeNo ratings yet

- Airport Paving QualityDocument8 pagesAirport Paving QualityDjokovic AlarconNo ratings yet

- CIP35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerNo ratings yet

- PiP3Document4 pagesPiP3KarnalPreethNo ratings yet

- ASTM C39-C39M-10 - Compressive Strength of Cylindrical Concrete SpecimensDocument7 pagesASTM C39-C39M-10 - Compressive Strength of Cylindrical Concrete SpecimensMalaz Abdul Jalil100% (1)

- CIP 35 - Testing Compressive Strength of ConcreteDocument7 pagesCIP 35 - Testing Compressive Strength of ConcretesudhakarmnNo ratings yet

- Concrete Mix Design - (Part 1 & Part 2) PPT7Document39 pagesConcrete Mix Design - (Part 1 & Part 2) PPT7JuliaNo ratings yet

- RMC LetterDocument2 pagesRMC Letterbasum matNo ratings yet

- Concrete Mix DesignDocument49 pagesConcrete Mix Designankit100% (4)

- Concrete strength acceptance IS:456Document5 pagesConcrete strength acceptance IS:456rmdarisa100% (1)

- CIP 35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP 35 - Testing Compressive Strength of ConcreteAshutosh NautiyalNo ratings yet

- CIP 35 - Testing Concrete Compressive StrengthDocument2 pagesCIP 35 - Testing Concrete Compressive StrengthaaNo ratings yet

- CIP 35 - Testing Compressive Strength of ConcreteDocument2 pagesCIP 35 - Testing Compressive Strength of ConcreteAshutosh NautiyalNo ratings yet

- Concrete Testing MethodsDocument10 pagesConcrete Testing Methodsmr.xinbombayNo ratings yet

- Presentation On: 1: .Sampling of Concrete 2.acceptance Criteria of Concrete TestDocument12 pagesPresentation On: 1: .Sampling of Concrete 2.acceptance Criteria of Concrete TestSuson DhitalNo ratings yet

- FAAEB 34a PDFDocument5 pagesFAAEB 34a PDFFran GVNo ratings yet

- Qlassic Vs JKRDocument15 pagesQlassic Vs JKRFrederick TanNo ratings yet

- Compressive Strength of Cylindrical Concrete Specimens: Standard Test Method ForDocument5 pagesCompressive Strength of Cylindrical Concrete Specimens: Standard Test Method ForViet DinhHongNo ratings yet

- C917 PDFDocument9 pagesC917 PDFDIAZCORDOBANo ratings yet

- ASTM F1055-98 Standard Specification For Electrofusion Type Polyethylene Fittings For Outside Diameter Controlled Polyethylene Pipe and Tubing-2-4Document3 pagesASTM F1055-98 Standard Specification For Electrofusion Type Polyethylene Fittings For Outside Diameter Controlled Polyethylene Pipe and Tubing-2-4roy tambunanNo ratings yet

- Materials and Structures Volume 44 - TaerweDocument13 pagesMaterials and Structures Volume 44 - TaerweApollonNo ratings yet

- Compressive Strength of Cylindrical Concrete Specimens: Standard Test Method ForDocument7 pagesCompressive Strength of Cylindrical Concrete Specimens: Standard Test Method ForOsama TarekNo ratings yet

- Flexural Strength of ConcreteDocument2 pagesFlexural Strength of ConcreteVenkataLakshmiKorrapatiNo ratings yet

- Proper Procedures For Evaluating Low Strengths: CEMEX USA - Technical Bulletin 1.0Document3 pagesProper Procedures For Evaluating Low Strengths: CEMEX USA - Technical Bulletin 1.0abebechNo ratings yet

- NOV HRDTDocument21 pagesNOV HRDTWaelNo ratings yet

- Method Statement For Concrete Sampling and TestingDocument6 pagesMethod Statement For Concrete Sampling and Testingibrahim hegazyNo ratings yet

- Vitrified Clay Pipe: Standard Test Methods ForDocument4 pagesVitrified Clay Pipe: Standard Test Methods Fornisha_khanNo ratings yet

- Three Standards : Workshop 4 March 2010 Hong KongDocument5 pagesThree Standards : Workshop 4 March 2010 Hong Konginigo38No ratings yet

- Guidance On The Assessment of Strength in StructuresDocument5 pagesGuidance On The Assessment of Strength in StructuresPeter Jean-jacquesNo ratings yet

- Polymer SpecifcatiionDocument7 pagesPolymer SpecifcatiionSunny RohillaNo ratings yet

- Breaks Evaluation CIP09pDocument2 pagesBreaks Evaluation CIP09pgemotorresNo ratings yet

- BRMCA Webinar Presentation in Situ Strength Assessment v200327Document32 pagesBRMCA Webinar Presentation in Situ Strength Assessment v200327SebastianNo ratings yet

- Field Quality Plan of EHV Power CablesDocument10 pagesField Quality Plan of EHV Power CablesMohammed TauseefNo ratings yet

- Norma EsclerometroDocument4 pagesNorma EsclerometroManuel Aliaga TorresNo ratings yet

- Concrete Specifications ErrataDocument2 pagesConcrete Specifications ErrataFernandoNo ratings yet

- Tests and criteria for concrete strengthDocument9 pagesTests and criteria for concrete strengthArindam NandyNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- FHWA GEOTECHNICAL ENGINEERING CIRCULAR NO. 4 Ground Anchors and Anchored SystemsDocument304 pagesFHWA GEOTECHNICAL ENGINEERING CIRCULAR NO. 4 Ground Anchors and Anchored Systemsv100% (4)

- Bs En1537 2000 PDFDocument63 pagesBs En1537 2000 PDFalmirante_andreNo ratings yet

- Advt No 36 2019Document2 pagesAdvt No 36 2019Afrasayab QaiserNo ratings yet

- Full-Scale Tests of Ground Anchors in Alluvium Soils of EgyptDocument13 pagesFull-Scale Tests of Ground Anchors in Alluvium Soils of EgyptMudassar KhanNo ratings yet

- Technical AspectsDocument9 pagesTechnical AspectsMudassar KhanNo ratings yet

- Settlement Analysis: Stability During ConstructionDocument18 pagesSettlement Analysis: Stability During ConstructionKhairil ImranNo ratings yet

- Scheduling & Sequencing by Johnson'S Rule: Group MembersDocument18 pagesScheduling & Sequencing by Johnson'S Rule: Group MemberswawaNo ratings yet

- Plastic Hinge ConceptDocument1 pagePlastic Hinge ConceptNSunNo ratings yet

- Lecture11 PDFDocument16 pagesLecture11 PDFAswathy M NNo ratings yet

- Curriculum Vitae Expertise in Geotechnical EngineeringDocument13 pagesCurriculum Vitae Expertise in Geotechnical EngineeringMudassar KhanNo ratings yet

- Imp Tech Soil TestsDocument8 pagesImp Tech Soil TestsMudassar KhanNo ratings yet

- Guidelines For Site Inspection - by Blas R. Cadalso1Document18 pagesGuidelines For Site Inspection - by Blas R. Cadalso1abstickleNo ratings yet

- Dynamo BasicsDocument8 pagesDynamo Basicserrrr1No ratings yet

- Marsh FunnelDocument4 pagesMarsh FunnelMudassar KhanNo ratings yet

- Marsh FunnelDocument4 pagesMarsh FunnelMudassar KhanNo ratings yet

- Jigs and FixturesDocument85 pagesJigs and FixturesMudassar KhanNo ratings yet

- Lec 3Document10 pagesLec 3Bima WirawanNo ratings yet

- BS 4550 3.4 PDFDocument17 pagesBS 4550 3.4 PDFMatt IkhramNo ratings yet

- BBS For Barrier PDFDocument1 pageBBS For Barrier PDFMudassar KhanNo ratings yet

- Roadside Barrier Steel Calculation: Main BarsDocument1 pageRoadside Barrier Steel Calculation: Main BarsMudassar KhanNo ratings yet

- RY Khan-2-17Document164 pagesRY Khan-2-17Inaam Ullah MughalNo ratings yet

- Remediation of landslide in Murree through reinforced earth and drainage worksDocument1 pageRemediation of landslide in Murree through reinforced earth and drainage worksMudassar KhanNo ratings yet

- The Yield-Line Method For Concrete Slabs: Automated at LastDocument11 pagesThe Yield-Line Method For Concrete Slabs: Automated at LastMudassar KhanNo ratings yet

- Testing of Bored Pile InclinationDocument5 pagesTesting of Bored Pile InclinationMudassar KhanNo ratings yet

- RY Khan-2-17Document164 pagesRY Khan-2-17Inaam Ullah MughalNo ratings yet

- RY Khan-2-17Document164 pagesRY Khan-2-17Inaam Ullah MughalNo ratings yet