Professional Documents

Culture Documents

Utility System PDF

Utility System PDF

Uploaded by

NAMIT GADGEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Utility System PDF

Utility System PDF

Uploaded by

NAMIT GADGECopyright:

Available Formats

Utilities Systems: Selection, Sizing and Design

Introduction

If one were to take a dispassionate and of course, a rather deglamourized

view of the basic functions of a chemical engineer, it would be obvious that

they boil down to two sets:

to either bringing intimately together certain chemicals under pre -

specified

environmental conditions of temperature, pressure for a certain period of time

Given a mixture of chemicals, to separate them from each other into

their relatively purer form with the least am ount of equipment and

expenditure of energy.

For defining these two function sets, with the first one covering the

synthesis of chemical molecules while the second covering purification of

synthesized molecules, most of the core chemical engineering skill s we learn

such as chemical kinetics (both what environmental conditions and for how

long), thermodynamics (what environmental conditions) with heat / mass

transfer and fluid flow thrown in for good measure (mixing and energy / material

transfer, for example) are called upon.

While the weighty questions of what process environmental conditions and for

how long etc. are undoubtedly important, having once decided these

parameters, it then becomes equally important to decide on how theses

environmental conditions are to be created in actual practice.

Th us for e xample, one may want to carry ou t ozo niz ation of an

un sa turated compound at -30 ° - -40 ° C whereas, the steam cracking of

naphtha might require temperatures as high as 850 ° – 900 ° C and while a

host of other reactions take place under conditions which are in between

these two widely spaced extremes. A ch e mi cal e n gin e e r i s cal le d u p o n n o t

m e r e l y t o in d ic at e wh at p r o ce ss e n v i r o n m e n t a l c o n d i t i o n s a r e

r e q u i r e d b u t a l s o t o s p e c i f y h o w t h e s e environments are to be created.

It is easy enough to guess that the creation of the process environmental

conditions would involve transferring energy either in or out of a system or

equipment. Thus for an exothermic reaction, the challenge would be to take

the heat of reaction out just as soon as it is released thus maintaining the

Compiled By Prof. Prasad Parulekar

temperature at the desired level, wh ile in the case of an end othe rmic

r ea ct ion , the de sign obje ct ive would be providing the requisite quantity of

heat rapidly enough so the reaction reaches the desired degree of completion

within a reasonable time.

The creation of the desired process environmental conditions for carrying out

the chemical transformations and physical separations is what Utility

Engineering is all about. In addition to the basic function of providing means of

energy transport, the smooth running of the plant also requires other sub-

systems such as cool, clean, dry compressed air to operate the pneumatically

operated controls, the motive energy :

electrical energy, Nitrogen for blanketing inflammable liquids, clean, treated

soft or de-mineralized water, specialized systems such as sterile air etc.

Given that the "Plant Utility" has now been made an elective subject as opposed

to a mandatory one makes the discussion of the utility sys tems, their

selection and sizing all the more important since many of the students taking

up this subject are thoroughly unaware of how the process conditions they

need to bring about the intended chemical transformations are to be actually

achieved in practice.

Scope of Plant Utilities

While the range of auxiliary subsystems needed to successfully run a plant

have been touched upon in passing, it is appropriate to broadly list these at

the very beginning :

1. Heating Utilities

Required, for example to make a reaction to occur at commercially viable

rate, or to make a material melt / volatilize. Whilst steam is the tbiquitous utility

in chemical plants, there are a fair amount of other heating utilities available

depending upon the temperature range of interest and these are discussed in

detailed further on.

2. Cooling Utility

This would be required when for example maintaining the temperature of a

reactor in which an exothermic reaction is taking place at a predetermined

desirable level or for ensuring condensation of a vapour in a condenser or

for inducing crystallization from a supersaturated solution. Here again, while a re-

circulating cooling tower type of system is present practically in every

Compiled By Prof. Prasad Parulekar

chemical plant, a number of other cooling utility subsystems are available

depending upon the temperature range desired.

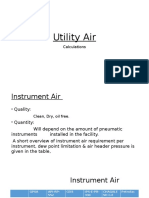

3. Compressed Air

This could be of several different types depending upon end use : for

cleaning, flushing, for running diaphragm pumps, instrument air, in air curtains

etc. depending upon the end use, the air pressure would be different, as also

the degree of treatment (filtration, drying, sterilization etc.)

4. Nitrogen

This is not a commonly used utility but is always present in plants using

inflammable liquids / gases. Normally produced through PSA rou te, the end

uses would normally involve flushing, inerting and evacuation amongst others.

In certain rare instances, this may also be used for inerted pneumatic

transport, inert heating (e.g., drying of an oxidizable / inflammable material in a

spray dryer)

5. Vacuum:Vacuum is another almost ubiquitous utility encountered in

chemical plants especially those in which vacuum distillations etc. are

routinely carried out. Vacuum is used for several purposes including

reducing pressure in an enclosed vessel for reducing the boiling point of

substances (as in a vacuum distillation apparatus), evacuation before

inerting, transfer of liquid from one equipment to another etc.

6. Electricity:For motive power, fan / lighting / air-conditioning, instrument cabling

7. Water: For use as water for process, washing & cleaning, special purpose

(boiler feed, softened, de-mineralized, sterilized etc).

We will now look at some of the utilities in greater details to determine

criteria and heuristics which govern their selection.

Heating Utility

As mentioned above, the need to heat material is a *perpetual

requirement in chemical plants. The way to heat material depends upon the

temperature range to wh ich the he atin g is t o be done . The acco mpanyin g

t able provide s a list of commonly used heat transfer fluids for temperature range

indicated against them.

In designing / sizing / selecting a heating utility, the following designer

chosen variables values are used :

Phase change heat transfer modes always yield much better heat

transfer rates as compared to convection type.

Compiled By Prof. Prasad Parulekar

AT between the material to be heated and the heating fluid between 200 -

400 subject to the maximum tolerable skin temperature to which the

material to be heated exposed.

Improving heat transfer through high turbulence from the heating liquid

side (see hook-ups)

Ensuring clean, hydrophilic (for condensing organic vapours –

Dowtherm Vapours) / hydrophobic (for condensing steam applications)

surfaces to ensure drop-wise condensation as opposed to film condensation

Steam Systems

Steam is the most widely used heat transport fluid being a non -toxic

substance whose only hazards are its basic limitations :

Low critical point : it has no latent heat above 372° C

• Re lat ive ly h igh vap o u r p re ssu re re qu irin g eq u ip me nt capab le

b e arin g progressively higher pressure for phase change type heat

transfer as the temperature of heat transmission rises

For the temperature range 100° - 270° C, steam is the ideal working fluid.

Further, in many instances, direct injection of steam is a viable o ption as

the systems to be heated are aqueous and thus steam condensate tolerant.

Installation of a condensate collection and recycle system enable at least a

partial utilization of the condensate sensible heat and reduce considerably

the quantity of boiler feed water which needs to be treated. In fact for

thermal power stations this is routinely done.

Pressurized Hot Water systems

This is a favourable system which allows the use of higher density (vis -a-vis

steam) and higher heat capacity but requires system pressures of 17.5 bar g

to maintain wat e r in liq u id st at e . Ame ri c an n u cle ar r e a ct o rs are b a se d

o n p r e s su riz e d superheated water systems for extracting heat from the nuclear

reaction.

Thermal Fluid systems

Thermal fluids used for heating and cooling co nsist of liquids and vapours

or a combination. These include tempered hot water (as opposed to

superheated pressurized water) for moderate heating and controlled skin

temperature, various organic liquids such as Diphenyl – Diphenyl Oxide Eutectic

(Dowtherm A), Treated o-Dichlorobenzene (Dowtherm E), Sodium – Potassium

alloy (NaK alloy), Mercury, Molten Salt Mixtures, Mineral Oils, Aryl – Aryloxy

Compiled By Prof. Prasad Parulekar

Silanes (Hydrotherm 750 – 200), Tetra Aryl Silicate (Hydrotherm 700-160), and

Chlorinated Biphenyls (Therminols).

• Dowtherm A

Dowtherm A is a eutectic mixture containing 73.5% Diphenyl Oxide

and 26.5% Diphenyl, wt / wt. At its freezing point of 12.2° C, Dowtherm

contracts slightly thereby reducing the possibility of damage to process

equipment when shut down under cold conditions.

Dowtherm A is non-toxic to humans and does not attack commonly

employed heat transport systems MOC (Steel). Dowtherm A is stable up

to about 340° C with no decomposition. Above 400° C, 2 molecules of

Diphenyl may react to yield p-Diphenyl benzene and benzene. Of

these the former dissolves in Dowtherm A while the latter escapes

as a vapour through vent. Diphenyl oxide may also undergo similar type

of decomposition.

In case of extreme overheating, Dowtherm may decompose into carbon

and hydrogen. This may occur for example under circumstances of poor

circulation / flame impingement etc. The deposited carbon increases

resistance to heat transfer aiding further thermal degradation. In such an

instance, in a matter of a few hours, the entire material may be carbonized.

To prevent overheating, Dowtherm vapourizers are of liquid tube / fire

tube with natural convection type or liquid tube with forced circulation design.

Dowtherm E

Dowtherm E is specially processed o-Dichlorobenzene which boils at about

177° C and freezes below -15° C. Dowtherm E is normally used in the range

177° to about 260° C. Although when working within the recommended

range of temperature, Dowtherm E does not show signs of decomposition,

there is some evidence that Aluminium te nds to catalyze the

decomposition of Dowtherm E with generation of HCI which then

attacks metallic surfaces. Aluminium is therefore to be avoided when using

Dowtherm E.

• Inorganic Salt Mixtures

Mixtures of inorganic salts, one of which consists of 40% Na NO 2 , 7% NaNO3

and 53% KNO 3 are widely used in salt baths and petroleum refining where

high temperatures are maintained and where the system is in

continuous operation.

Compiled By Prof. Prasad Parulekar

The MP of the mixture indicated above is about 142° C which precludes any

low temperature use and requires that the circulating fluid be kept hot

and molten throughout its flow path. The salt mixture need not be

pressurized higher than to cover the system AP.

Inorganic salt mixtures are non-toxic and stable up to about 450° C in

the absence of contaminants. Between 450° C to 900° C, a slow

decomposition reaction sets in converting the nitrite into a mixture of

alkali metal oxide, nitrate and nitrogen. This reaction is evidenced by a

slow generation of nitrogen and is also accompanied by a gradual increase

in the freezing point of the salt mixture.

The nitrite is also subject to slow oxidation by atmospheric oxygen

above about 450° C with the formation of NaNO 3 . By blanketing the salt

mixture with nitrogen this reaction can be eliminated. Other reactions which

also affect the composition of the salt baths is slow absorption of C O 2

and water vapour from atmosphere to give rise to carbonates which may

settle out of the melt and formation of alkali hydroxides.

While these two transformations do not interfere with the process

application, if allowed to continue over a long tem, will give adversely

affect the utility of the system. Again, by use of nitrogen blanketing, both

these deterioration modes can be held in check.

For the system, ordinary carbon steel is an acceptable MOC up to about

450 ° C. Beyond this temperature, more resistant alloys are recommended.

Copper is found satisfactory for moderate temperatures (up to about

340– 350 C). Cast iron, however is unsuitable on account of reaction

between the molten salts and iron which leads to embrittlement and / or fissuring.

5

Mineral Oils

Conventional mineral oils are of low cost and readily available for process

use and are valuable as heating fluids in the range 0° through about 315° C.

The paraffinic type cylinder oils are used in open systems till about 230° C

while a closed system is required for higher temperatures up to about 315° C.

Beyond this temperature, the mineral oils are susceptible to thermal cracking

type reactions commonly encountered in producing gasoline from heavy stock.

Although the actual attack may not be as severe as what happens during

petroleum refining, such reactions give rise to volatiles which increase the

flash point and AIT on the one hand and heavy stock on the other w hich

flows less easily leading to carbon deposition after long periods of operation.

Compiled By Prof. Prasad Parulekar

Mobiltherm 600 and Mobiltherm Light are aromatic mineral oils of

lower viscosity than conventional mineral oils and can operate between 0°

C and 315° C for the former and between -25° C and 210° C for the latter.

These oils will not decompose if used within the recommended temperature

range. If subjected to excessive temperature, the aromatic mineral oils also

tend to decompose through thermal cracking. However, due to the

superior solvent action of the aromatic mineral oils, sludge formation and

coke deposition does not readily occur.

The aromatic mineral oils can be used in an open system as they undergo

rapid oxidative degradation. All systems involving aromatic mineral o ils must

include a "cold oil" expansion tank with temperature not exceeding 55° C to

prevent the hot oil coming in contact with atmospheric oxygen. Copper and

copper bearing alloys are to be avoided in contact with aromatic mineral oils

as they catalyze oxidation and sludging. Iron and carbon are the preferred

materials of construction for such systems.

Other oils such as lubricating oils etc. should not be allowed to come in

contact with these oils as they tend to reduce solvent power of these oils

and may lead to harmful sludge deposition on the heating surfaces in the

system.

Silicon Compounds

Three types of silicon compounds are used as heating fluids : substituted

silanes, silicones and silicates. The most commonly used heating fluids of this

type are silicates, i.e., organic esters of silicic acid.

Hydrotherm 750 – 200 is an aryl – Aryloxy (mixed) silane used in the

temperature range of 60° C to about 380° C. It is a transparent amber

coloured liquid, with a faint phenolic odour. There appears to be no chronic

effect from exposure to vapours. Skin tests show results similar to those of

phenol. It is lethal if ingested or injected.

Hydrotherm 700 - 160 heat transfer fluid can be used in the temperature

range -45° C to 345° C, neither reheating not steam tracing is required.These

thermal fluid are con-corrosive to steel, Cu and alloys even at highertemperatures.

Therminols

Therminols are heat transfer fluids based on chlorinated biphenyls. Whenusing these

fluids, provision must me made for an expansion vessel alongwith a desiccator trapped

air vent for escape of HCI if formed and also for tapping moisture from any aspirated air.

Compiled By Prof. Prasad Parulekar

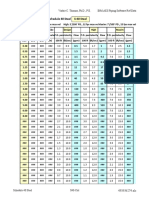

The accompanying Table I lists the various thermal fluids types commonly encountered

in chemical industry and their useful temperature range.Table ll liststhe branded fluids,

their chemical nature and their useful temperature range of application.

Ratings of boilers is done by their evaporating capacity while the heating systems using

thermal; fluids are based on their "Heat Delivering Capacity",typically, Kcal. / hr.

Table - I

Heating Fluids Their Recommended Operating

Temperature and Pressure Ranges

Temperature Range,

o

C Pressure Range,

Fluid

bar g

Water 50-600 0-16

Steam 150-200 6-16

Dowtherm A 220-400 0-10

Dowtherm E 150-260 0-5

Mineral Oil 0-310 0

Molten Salt Baths 145-600 0

Silicon Compounds

35-370 0

(Silicones, silanes and

silicates)

Chlorinated Diphenyl

-15-315 0

NaK Alloy

35-760 0

Mercury

300-530 0-12.5

Compiled By Prof. Prasad Parulekar

Flue Gases or Hot Air 0-1100 0-7

Table - II

Commercially Available Heating Fluids, Their Chemical

Characteristics, and their Useful Operating

Temperature Ranges

Fluid Name Chemical Nature Maximum ° C

Temperature,

Diphenyl / Diphenyl Oxide

Dowtherm A 400

Eutectic

Chevron Heat Transfer Oil Paraffinic 340

Diphyl DT Dimethyl Diphenyl Oxide 330

Di - and Tri-aryl

Dowtherm G 370

Compounds

Mixture of Isomeric

Dowtherm J 370

Alkylated Aromatics

Gilotherm Ad X 10 Alkyl Benzenes 250-280

Mixture of Dibenzyl

Marlotherm S 350

Toluenes

Mobiltherm 600 Paraffinic 315

Shell Thermic Oil C Mineral Oil 287

--------

Transcal LT 260

Syltherm 800 Siloxane Polymer 400

Santotherm /

Hydrogenated Terphenyls 345

Therminol 66

Compiled By Prof. Prasad Parulekar

Cooling Utility

As important heating is in chemical synthesis and separation, cooling systems play an

equally important role. In choosing a particular heat transfer fluid for cooling duty, the

considerations are always the freezing temperature of the fluid, chemical aggressiveness

vis--vis the common MOC's, flammability, toxicity, viscosity in the operating

temperature range and finally, the cost.

In choosing cooling utility, especially for reactors in which exothermic reactions are

carried out, it is important to avoid cold shock / dead volume around the coolant

entrance area. The temperature of cooling utility thus should be calibrated such as not

to "extinguish" a reaction. A typical AT of 10 – 15° should be chosen consistent with the

least acceptable "low" skin temperature. In certain extreme cases, much smaller design

AT are chosen in order to ensure good heat transfer without the fluid to be cooled does

not freeze due to too low a temperature of the coolant. When this happens, it leads to

solidified fluid to be cooled introducing additional thermal resistance and hindering

cooling of the fluid in bulk.

Typical cooling utilities include cooling tower water, chilled water, "brines" of various

compositions and special low melting chlorinated hydrocarbons systems for low

temperature use, direct refrigerant cooling. The cooling utility subsystems are rated by

their heat removal capacity measured in "Tons Refrigeration" or "TR", with each TR

representing approximately 3025 Kcal / hr. heat removal duty.

Cooling Tower Water

The most commonly used cooling utility is of course cooling tower water with typical

operating range of between 5 – 10° C AT range (i.e., between incoming hot water and

outgoing cold water temperatures) with the lowest temperature limited by the local

atmospheric conditions of ambient temperature and humidity.

With careful cleaning up, periodic blow-down, timely dosing of anti-algal compounds,

cooling towers give excellent service over long periods. The various types of cooling

towers and their construction / limitations are outside the scope of the present

discussion.

Chilled Water

Providing that the temperature does not fall below 4° C, chilled water is an excellent

cooling medium. The actual chilled water loop typically involves a twin water reservoir

consisting of a "cold well" and a "hot well". A separate circuit takes the "hot" water

returning from the "process" from the hot well, cools it in a heat exchanger by the

primary refrigerant (ammonia / Freon / Other refrigerant) from the heat pump circuit

before returning it to the "cold" well. A separate chilled water circuit pump would

extract the "cold" chilled water from the cold well and circulate it throughout the

process and finally return the "hot" chilled water to the hot well.

Compiled By Prof. Prasad Parulekar

Chilled Brine Systems

The original observation that adding salt to water decreased its freezing point

led to the concept of using a salt solution as a cooling medium for sub -zero

temperature cooling and hence the word "brines". Sodium or Calcium Chloride

as the ingredient to reduce freezing point of water has several drawbacks,

the most objectionable amongst them being the strong corroding action of

salt / CaCl2 on the commonly used MOC's for these systems.

In past, the corrosive action was kept somewhat in check by using a

strong oxidizing atmosphere by using dichromate. The toxic and potentially

carcinogenic nature of hexavalent chromium has made this approach unviable

and for most parts, common salt / CaC12 brines are seldom used.

An alternative to this was use of Calcium Nitrate brines which are good

up to - 24° C. Calcium Nitrate brines do not need the use of dichromate and the

attendant toxic hexavalent chromium pollution question is eliminated.

The most widely used brines for low temperature are aqueous solutions of

mono, di-and polyethylene glycols which depress the freezing point of water

substantially. Given below are the temperatures and the compositions of these glycol

"brines" :

Min. Explosive?

Constituents

Sr. Practical

in Aqueous. Toxic? Corrosive?

No. Temperature,

Solutions

0C

Salts

1 CaCl2 -40 No No Yes

2 NaCI -10 No No Yes

3 CaNO3 -25 No No No

Glycols

4 Propylene -10 No No Some

Ethylene

5 -15 Yes No some

(MEG)

Alcohols

6 Methanol -35 Yes Yes Some

Compiled By Prof. Prasad Parulekar

7 Ethanol -30 No Yes some

Constituents Min.

Sr. Practical

Toxic? Explosive? Corrosive?

No. Temperature,

0C

Other Low

Temp.

"Brines"

Methylene No, but

8 -85 No No

Chloride incompat.

With Al, Zn

Trichloro-

9 -75 No No and most

ethylene

elastomers

Trichloro-

10 -100 No No No

fluoromethane

11 Acetone -100 No Yes No

Hook-Ups

Transfer of heat is a relatively inexpensive operation as long as the source of

heat is at a higher temperature than the ambient temperature. Refrigeration

involves "heat pumping" from a source at a lower than ambient temperature

to atmosphere which is at ambient temperature. The difference between the

temperature at which heat is to be extracted and for the temperature at

which it is to be rejected can be looked upon as the "thermal head" for the

heat pump that a cooling utility is. As one requires lower and lower

temperatures (e.g. for condensing out the last traces of vo latile organ ic

vap ours in a vent cond enser), the the rmal "he ad " ke eps on increasing,

thus requiring more and more energy expenditure for the pumping action.

Further, the larger the difference between the desired low tem perature

and the ambient temperature, larger is the "leak back" of heat from the

surroundings into the refrigerated space / system. This explains why the

rating of the same Freon / ammonia compressor gets progressively lower

as the target temperature of th e secondary coolant ("brine") dips. This also

explains why one TR duty at say - 30° C is considerably more expensive as

compared to one TR duty at say - 10° C.

Compiled By Prof. Prasad Parulekar

To avoid large scale use of this expensive utility, many times cooling is

done in stages staring with the cheapest cooling utility viz. cooling tower water

finally ending up with the really cold brine utility. While this increases the

equipment cost as multiple heat exchangers / condensers are required,

given that the bulk of heat pumping duty has been carried out by the

inexpensive utility, the size of the final condenser and the significantly

lower TR duty required from the expensive brine utility reduces the recurring

cost significantly. The trade-off, as always, is between the one time equipment cost

and its amortization v s. the recurring cost of the more expensive utility.

Other considerations as regards the design AT to avoid extinguishing/ thermally

shocking the process requires special hook- up to ensure proper maintenance of the

desired temperature with concurrent adequate heat removal. Schematic

representations of a cascade of heat exchangers in series and a hook up for ensuring a

correct temperature on the process side are depicted below:

Compiled By Prof. Prasad Parulekar

Sizing of Cooling Utility

In majority of detailed engineering exercises, the sizing of utilities requires

estimating t h e t o t a l h e a t l o a d f r o m a l l s o u r c e s , r e a c t o r s , c o n d e n s e r s ,

s i d e - a r m h e a t exchangers, product coolers, heat losses / ingress to / from the

atmosphere and arrive at the total heat pumping (in or out) required. This can

then be suitably increased to take into account future developments /

additional reserve capacity required for design errors etc. before arriving at the

size of the cooling utility.

For smaller capacity cooling towers to which several heat sources are

connected, it is always a good practice to oversize the tower and provide an

independent circuit similar to a chilled water / brine system ensuring that the

full capacity of the tower is always on tap. A pump taking cooling tower water

to process and returning to the top of the tower has the inherent potential

of the total water flow being reduced with the attendant reduction in the TR

capacity of the tower. In extreme cases, the TR capacity can be further

degraded due to inadeq uate wetting of the tower p ackin g. An o th e r

a lt e r nat ive in su ch case s is to sp lit t he to t al coo lin g lo ad strategically

and layout-wise over several cooling towers, each tower catering to the cooling

need of a particular section / plant in a complex thus all owing partial shut-

down without affecting the working of other plants. While such a solution

may increase the capital outlay, many times, the flexibility and safety

provided by such an arrangement far outweigh the increased cost.

Compressed Gases : Air, Nitrogen

Compressed Instrument Air

In most plants for operating the final control devices, compressed air

("instrument air") is commonly used. Air used for actuating pneumatic

instruments must be free from particulate impurities including dust, oil

particles etc as well as moisture. In majority of case, such air is generally

compressed in non-lubricated ("oil free") type of compressors which have a

appropriately sized pressure vessel type reservoir and an attached adsorption

type air drying unit (the PSA drying units) with twin desiccant packed towers

alternating in "dry" and "regenerate" modes. Typical pressures 6 – 7 bar and

post dehydration, the dew point of air is - 40° C or lower. Here again, the

total quantum of the "instrument" air required will have to be calculated

based on the no. of pneumatically actuated devices and the manufacturer's

recommended air requirements plus adequate spare capacity to tide over

such emergencies as leakage.

Compiled By Prof. Prasad Parulekar

Other type of special purpose air utility such as air used as a c urtain, aseptic

air for packing areas of pharmaceutical industries are somewhat more

specialized and are outside the scope of the present discussion.

Compressed Nitrogen

Compressed Nitrogen is another commonly encountered utility in chemical

plants especially where flammable easily polymerizable substances are

handled. The compressed nitrogen is used for blanketing tanks / vessels,

flushing out contents of a vessel under oxygen-free atmosphere, packing of foodstuffs

/ other perishable items

u n d e r o x yg e n - f r e e a t mo sp h e re as a h e a t t ran sf e r f lu id f o r d ryin g

t h e r m al ly degradable / oxidizable products in equipment such as spray dryers,

fluid bed dryers etc.

Like instrument air, nitrogen used in plants is generated using pressure

swing adsorption technique with the oxygen from compressed, dried air being

adsorbed out on special carbon molecular sieves. These pSA units are similar in

construction to the air drying units described in instrument air above. For large scale

use, it may be preferable to have an air liquefaction and fractionation unit which would

generate a “purer” nitrogen. Indeed, steel making units invariably have both the oxygen

and nitrogen separating units for different requirements.

Sizing of nitrogen and even the method of generating it would depe nd

upon the sum total of the specific, individual needs in a plant, the %

recovery from air as specified by the PSA / Adsorbent supplier, and the purity of

nitrogen desired.

Vacuum

Vacuum is available as utility in many plants to suck spillage, transfer to liquids etc.

Vacuum connected with specific unit operations such as distillation normally is a

dedicated system as opposed to a general utility. In case that a number of units are

carrying similar operations, they may be all connected to a single vacuum system but

this is best avoided to eliminate the sudden change in vacuum in other systems and

corresponding deleterious effects due to accidental venting periodic drain-out of surge

tanks etc.

Compiled By Prof. Prasad Parulekar

You might also like

- Conservation of FurnitureDocument2 pagesConservation of FurnitureSalander21No ratings yet

- Engineering Calculation ProcessDocument3 pagesEngineering Calculation ProcessMafe SalazarNo ratings yet

- Capcost 2012Document17 pagesCapcost 2012abdaziz_salamNo ratings yet

- List of Ashrae Books & Reference MaterialDocument1 pageList of Ashrae Books & Reference Materialwado11No ratings yet

- 8-12 How Do You Calculate GPMDocument2 pages8-12 How Do You Calculate GPMlutfi awnNo ratings yet

- Pharmaceutical Facility DesignDocument27 pagesPharmaceutical Facility Designmdalt9180No ratings yet

- Sample Dew Point CalculationDocument3 pagesSample Dew Point Calculationapi-3709413100% (1)

- 11 - Pipe Sizing Data.75102626Document50 pages11 - Pipe Sizing Data.75102626Zelalem MengistuNo ratings yet

- Diesel Fuel Storage Tank Vent Sizing CalculationDocument2 pagesDiesel Fuel Storage Tank Vent Sizing CalculationKrishnamoorthyNo ratings yet

- Chiller Heat Load & Water FlowDocument3 pagesChiller Heat Load & Water FlowDan NugrahaNo ratings yet

- Asme V Si UnitsDocument3 pagesAsme V Si UnitsvidhisukhadiyaNo ratings yet

- Heating Load Calculation ExampleDocument1 pageHeating Load Calculation Examplemuhd.qasimNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- Hot Water System Sizing CalculationDocument1 pageHot Water System Sizing CalculationPhyu Mar Thein KyawNo ratings yet

- Consultant Queries - Chilled Water PumpDocument6 pagesConsultant Queries - Chilled Water PumpMohammad Abdul KhadeerNo ratings yet

- Fgas Refrigerant CalculatorDocument10 pagesFgas Refrigerant CalculatorKumar sssssNo ratings yet

- Rules of Thumb ACDocument25 pagesRules of Thumb ACAmank D Harve100% (1)

- Psychrometric ProcessesDocument9 pagesPsychrometric ProcessesArt JamesNo ratings yet

- Equipment StandardsDocument30 pagesEquipment StandardsMadan YadavNo ratings yet

- Evolving Design Chiller PlantDocument7 pagesEvolving Design Chiller PlantMohsin KhanNo ratings yet

- Instrument AirDocument9 pagesInstrument AirRaja Ahsan Azan JanjuaNo ratings yet

- Volume IIA Technical SpecificationDocument83 pagesVolume IIA Technical SpecificationSanjeev Kumar DasNo ratings yet

- Aeration Solutions Comparison Chart - VlightDocument2 pagesAeration Solutions Comparison Chart - VlightprannoyNo ratings yet

- Use of Nitrogen Purge in Flare and Vent SystemsDocument2 pagesUse of Nitrogen Purge in Flare and Vent Systemsandistwn99No ratings yet

- Instrucalc ViDocument25 pagesInstrucalc ViNorberto Soto100% (1)

- Clean Coal Technology Demonstration ProjectDocument817 pagesClean Coal Technology Demonstration ProjectMallinatha PNNo ratings yet

- Pipe Size Guide To GPMDocument2 pagesPipe Size Guide To GPMengomar76100% (1)

- Rules and Rules of Thumb For Duct SystemsDocument1 pageRules and Rules of Thumb For Duct SystemssauroNo ratings yet

- Basic Temperature Control SystemDocument26 pagesBasic Temperature Control SystemRajeev ValunjkarNo ratings yet

- Water Balance ChecklistDocument5 pagesWater Balance ChecklistmohamednavaviNo ratings yet

- Aspen Hysys Dynamics Modelling of Differential Pressure (DP) Transmitter For Flow ControlDocument3 pagesAspen Hysys Dynamics Modelling of Differential Pressure (DP) Transmitter For Flow ControlMayurShindeNo ratings yet

- Design, Construction and Maintenance of A Biogas GeneratorDocument23 pagesDesign, Construction and Maintenance of A Biogas GeneratorOxfamNo ratings yet

- Hvac Oil GasDocument8 pagesHvac Oil GasManuelNo ratings yet

- 5-Thermodynamics For CryogenicsDocument52 pages5-Thermodynamics For CryogenicsBhuvanaNo ratings yet

- Air DryerDocument4 pagesAir Dryerrashm006ranjanNo ratings yet

- Air LeakageDocument2 pagesAir LeakageanurudhNo ratings yet

- Ac Sizing - Duct SizingDocument9 pagesAc Sizing - Duct SizingHarpreet SinghNo ratings yet

- Vessel Volume CalculationDocument2 pagesVessel Volume CalculationDhia Slama100% (1)

- Water Heating and Data CollectionDocument41 pagesWater Heating and Data CollectionDGGNo ratings yet

- Variable Refrigerant FlowDocument6 pagesVariable Refrigerant FlowRahul PrajapatiNo ratings yet

- Natural Gas - Pipe SizingDocument6 pagesNatural Gas - Pipe SizinglekakasNo ratings yet

- Underwater Optical Wireless CommunicationDocument30 pagesUnderwater Optical Wireless CommunicationPhuc HoangNo ratings yet

- LNG Cold Energy Utilization UpdatedDocument13 pagesLNG Cold Energy Utilization UpdateddishankmpatelNo ratings yet

- 1-BLDG 471 Intro HVAC System DesignDocument15 pages1-BLDG 471 Intro HVAC System DesignSara HayekNo ratings yet

- TEWI AnalysisDocument63 pagesTEWI Analysismirali74No ratings yet

- Technical Specification For Auxiliary Cooling Tower 2 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 2 PDFAnonymous vwbLPTpjNo ratings yet

- Natural Gas Process InstrumentationDocument4 pagesNatural Gas Process InstrumentationaaashfNo ratings yet

- Average Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Document7 pagesAverage Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Alexandre HugenNo ratings yet

- Air Separation Unit QRADocument109 pagesAir Separation Unit QRALi QiNo ratings yet

- HVACPow Den InstructionsDocument5 pagesHVACPow Den InstructionsadamyzcNo ratings yet

- Types of GasifierDocument13 pagesTypes of GasifierMehul ZareNo ratings yet

- Chvac Software Tutorial PDFDocument55 pagesChvac Software Tutorial PDFPhelan Roque100% (1)

- Comparison of Different Gas Turbine Inlet Air Cooling MethodsDocument6 pagesComparison of Different Gas Turbine Inlet Air Cooling MethodsOmair FarooqNo ratings yet

- P&ID Drawing of Underground Solvent TanksDocument1 pageP&ID Drawing of Underground Solvent Tankshps sgNo ratings yet

- Innovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987From EverandInnovation for Energy Efficiency: Proceedings of the European Conference, Newcastle upon Tyne, UK, 15–17 September 1987D A ReayNo ratings yet

- Plant Engineering and Design The Ultimate Step-By-Step GuideFrom EverandPlant Engineering and Design The Ultimate Step-By-Step GuideNo ratings yet

- Energy Management and Efficiency for the Process IndustriesFrom EverandEnergy Management and Efficiency for the Process IndustriesNo ratings yet

- Facilities Energy Management A Complete Guide - 2020 EditionFrom EverandFacilities Energy Management A Complete Guide - 2020 EditionNo ratings yet

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28From EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28No ratings yet

- Reliability of Instrumentation Systems for Safeguarding & Control: Proceedings of the IFAC Workshop, Hague, Netherlands, 12-14 May 1986From EverandReliability of Instrumentation Systems for Safeguarding & Control: Proceedings of the IFAC Workshop, Hague, Netherlands, 12-14 May 1986No ratings yet

- Cost Accounting-3Document9 pagesCost Accounting-3prasadparulekarNo ratings yet

- Cost Estimation-3Document9 pagesCost Estimation-3prasadparulekarNo ratings yet

- Cost Estimation-2Document8 pagesCost Estimation-2prasadparulekarNo ratings yet

- Cost Estimation-1Document12 pagesCost Estimation-1prasadparulekar100% (1)

- Sizing Costing TablesDocument7 pagesSizing Costing TablesBhavik JainNo ratings yet

- Flowsheet SynthesisDocument27 pagesFlowsheet SynthesisPrasad Jayavant ParulekarNo ratings yet

- Basics of Economics - Part-3Document8 pagesBasics of Economics - Part-3prasadparulekar100% (1)

- Basics of Economics - Part-3Document8 pagesBasics of Economics - Part-3prasadparulekar100% (1)

- PE - IntroductionDocument6 pagesPE - IntroductionprasadparulekarNo ratings yet

- Preliminary Process SelectionDocument3 pagesPreliminary Process SelectionPrasad Jayavant ParulekarNo ratings yet

- Common Core Math Standards 1516Document2 pagesCommon Core Math Standards 1516api-191125030No ratings yet

- BN-EG-UE109 Guide For Vessel SizingDocument29 pagesBN-EG-UE109 Guide For Vessel SizingSachin ChavanNo ratings yet

- MCFCDocument4 pagesMCFCagam YuliantoNo ratings yet

- Fyp Final Report Template (Guideline)Document14 pagesFyp Final Report Template (Guideline)Arif ZukriNo ratings yet

- Deep Freezers - Razor Blade Treatment ChamberDocument2 pagesDeep Freezers - Razor Blade Treatment ChamberEnvisys TechnologiesNo ratings yet

- [Download pdf] Experimental Hydraulics Methods Instrumentation Data Processing And Management Volume Ii Instrumentation And Measurement Techniques 1St Edition Jochen Aberle Editor online ebook all chapter pdfDocument43 pages[Download pdf] Experimental Hydraulics Methods Instrumentation Data Processing And Management Volume Ii Instrumentation And Measurement Techniques 1St Edition Jochen Aberle Editor online ebook all chapter pdfjonah.hunsaker604100% (9)

- Departure FunctionDocument6 pagesDeparture FunctionzidinhoNo ratings yet

- 2.5 Equivalent Matrices. Hazen A. MoleDocument18 pages2.5 Equivalent Matrices. Hazen A. MoleNad DeYn100% (1)

- 2018 00 Pro 03 PropulsionmodelsDocument9 pages2018 00 Pro 03 PropulsionmodelsAndreu GimenezNo ratings yet

- Hoja de DatosDocument37 pagesHoja de Datoscastillo_leoNo ratings yet

- Method of Image ChargesDocument5 pagesMethod of Image ChargesSrikar VaradarajNo ratings yet

- The LengthDocument1 pageThe LengthRAIZZ67% (3)

- Galaxy NDT ProfileDocument34 pagesGalaxy NDT Profileambrish kumarNo ratings yet

- Dynamic Simulation - Steam SystemDocument11 pagesDynamic Simulation - Steam SystemDicky Wahyu PerdianNo ratings yet

- Design and Fabrication of Centrifugal Air Blower Test RigDocument8 pagesDesign and Fabrication of Centrifugal Air Blower Test RigIAEME PublicationNo ratings yet

- GenChem Reviewer Quiz 4Document2 pagesGenChem Reviewer Quiz 4Raian PaderesuNo ratings yet

- Converting Sinusoidal Voltage To Square WaveDocument2 pagesConverting Sinusoidal Voltage To Square WaveSerdar7tepeNo ratings yet

- Rohini 58430691489Document2 pagesRohini 58430691489GurunathanNo ratings yet

- Shape Memory AlloyDocument20 pagesShape Memory AlloyChandra Sekhar CNo ratings yet

- GMAT Quantitative - Diagnostic Test 1Document13 pagesGMAT Quantitative - Diagnostic Test 1GMATrixNo ratings yet

- CE8351-Surveying QBDocument15 pagesCE8351-Surveying QBSandhiya SandhiyaNo ratings yet

- Metatron: The Fall of Atlantis Revisited: The Crystalline Field of 10-10-10Document14 pagesMetatron: The Fall of Atlantis Revisited: The Crystalline Field of 10-10-10Robert Cody MacomberNo ratings yet

- 2-Planck's Constant-FORMAT 1Document5 pages2-Planck's Constant-FORMAT 1VAIBHAV KUMARNo ratings yet

- Canopy ArchitectureDocument8 pagesCanopy ArchitectureRahul JerryNo ratings yet

- Review Paper On Study of Black Cotton Soil To Enhancing The Properties of Sub Grade and Base Layer of PavementDocument4 pagesReview Paper On Study of Black Cotton Soil To Enhancing The Properties of Sub Grade and Base Layer of PavementEditor IJTSRDNo ratings yet

- Dillon - Serie Ed Manual de ServicioDocument44 pagesDillon - Serie Ed Manual de ServicioViruSaxNo ratings yet

- Question Bank EMDocument2 pagesQuestion Bank EMJaishree ChauhanNo ratings yet

- Dynamics of Virtual ParticlesDocument4 pagesDynamics of Virtual ParticlesJose Antonio Freyre ZavalaNo ratings yet

- Methods of ReliabilityDocument26 pagesMethods of ReliabilityNISHANT ROYNo ratings yet

![[Download pdf] Experimental Hydraulics Methods Instrumentation Data Processing And Management Volume Ii Instrumentation And Measurement Techniques 1St Edition Jochen Aberle Editor online ebook all chapter pdf](https://imgv2-1-f.scribdassets.com/img/document/733062608/149x198/0011576c45/1719157233?v=1)