Professional Documents

Culture Documents

THM Gas Turbines PDF

THM Gas Turbines PDF

Uploaded by

Aminovic MostafaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

THM Gas Turbines PDF

THM Gas Turbines PDF

Uploaded by

Aminovic MostafaCopyright:

Available Formats

THM Gas Turbines

THM Gas Turbines

Heavy duty gas turbines for industrial applications

Combined advantages A major design objective is the ability of bustors allow easy access, mainte-

The THM 1304 heavy duty gas turbine continuous retrofitting. Regular uprat- nance and can be modified for use of

family consists of two members with ing and upgrading measures at MAN other gaseous or liquid fuels such as:

ISO power outputs of 10,500 kW and Diesel & Turbo make new technologies Diesel, Kerosene or Methanol.

12,500 kW. These machines are all self- available for all customers. The modular

contained, completely integrated in- design philosophy allows for the easy Individual arrangement

dustrial prime movers of a compact, integration of these technologies into With more than 20 million operating

axial-flow design. Due to their twin- existing engines. hours in different environmental condi-

shaft construction the gas generator tions, the THM gas turbine family offers

and power turbine are mechanically Meeting emission regulations various layouts to meet your individual

independent of each other, which is In addition to the standard diffusion requirements, either as mechanical or

crucial in respect of rapid installation type combustor, a lean premix com- generator drive.

and maintenance. bustor is available for the THM Gas

Turbine family to meet stringent emis-

The design of the THM family combines sion regulations.

the advantages of heavy duty machines

with the convenience of low mainte- The system limits and controls the

nance from today’s aeorderivative tur- maximum flame temperature by means

bines: The engines are of modular de- of a patented air bypass system over

sign and are easy to disassemble for a wide power range. The combustor

service and handling. The aerodynamics, thus reduces the formation of nitrogen

cooling technologies and materials are oxides (NOx) and carbon monoxide

based upon recent aero engine know- (CO) significantly. The external com-

how. Another prime characteristic of

the THM family is their ability to operate

at gas temperatures and stress levels

which provides maximum assurance

of long life of the major rotating and

stationary components. The result is a

combination of outstanding performance

characteristics together with competi-

tive operation and optimal service best

suited for industrial use.

2 THM Gas Turbines

Features Benefits Modular THM concept for genera

Twin shaft heavy duty Easy and rapid installation.

modular design High reliability and availability.

Easy and rapid maintenance of modules.

On-site maintenance.

Long life resulting from a low turbine

inlet temperature.

DLE Combustion System Low NO x and CO exhaust emissions levels

over a wide load range.

Fuel flexibility Gaseous fuels with wide range of

calorific values.

Various types of liquid fuel including

Diesel, Kerosene, Methanol and

light distillates.

Applications

Compressor drives for pipeline and process applications

Pump drives for oil pipelines and water injection

Power Generation

Combined heat and power generation (cogeneration)

THM Gas Turbines 3

ator drive and mechanical drive applications

THM Gas Turbines 4

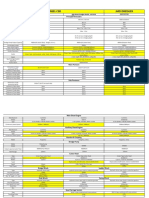

Technical Data

1304-10N 1304-12N

Mechanical drive

(at coupling)

Power output kW 10,500 12,500

Efficiency % 30.4 31.8

Heat rate kJ/kWh 11,840 11,320

Power turbine speed rpm 9,000 9,000

Generator drive

(at generator terminals)

Power output kWe 10,080 12,000

Efficiency % 29.2 30.5

Heat rate kJ/kWh 12,380 11,790

Exhaust gas data

Exhaust gas °C 490 515

temperature

Exhaust gas flow kg/s 46.5 49.1

Above specifications valid under the following conditions:

15°C (59°F), sea level, no inlet/outlet losses, RH = 60%, natural gas, = 97,5%, = 98,5%

gen. Gear

THM Gas Turbines 5

All data provided in this document is non-binding. This data serves informational

purposes only and is especially not guaranteed in any way. Depending on the

subsequent specific individual projects, the relevant data may be subject to

changes and will be assessed and determined individually for each project. This

will depend on the particular characteristics of each individual project, especially

specific site and operational conditions · Copyright © MAN Diesel & Turbo ·

D02082016EN Printed in Germany GMC-OBH01012XX

MAN Diesel & Turbo

Steinbrinkstr.1

46145 Oberhausen, Germany

Phone +49 208 692-01

Fax +49 208 669-021

www.mandieselturbo.com

MAN Diesel & Turbo – a member of the MAN Group

You might also like

- SGT600Document2 pagesSGT600fabyanoNo ratings yet

- TSL Fr5001 1st Stage BucketsDocument1 pageTSL Fr5001 1st Stage BucketsthanarajtnbNo ratings yet

- An Investigation of Air-Swirl Design Criteria For Gas Turbine Combustors Through A Multi-Objective CFD OptimizationDocument16 pagesAn Investigation of Air-Swirl Design Criteria For Gas Turbine Combustors Through A Multi-Objective CFD Optimizationperules100% (2)

- Solutions To Assignment 4 PDFDocument11 pagesSolutions To Assignment 4 PDFVirajitha MaddumabandaraNo ratings yet

- SiemensDocument9 pagesSiemensGhassen Khalil100% (2)

- SST600 en InteractiveDocument6 pagesSST600 en InteractiveMani SunNo ratings yet

- Elcometer 456 Coating Thickness GaugeDocument1 pageElcometer 456 Coating Thickness GaugeRino SutrisnoNo ratings yet

- SVS.435 Steam Turbine Control UpgradesDocument4 pagesSVS.435 Steam Turbine Control UpgradesMachineryengNo ratings yet

- Ansaldo Thomassen - Spare Parts (2014)Document4 pagesAnsaldo Thomassen - Spare Parts (2014)guerrezNo ratings yet

- Erosion in TurbomachinaryDocument11 pagesErosion in TurbomachinaryJulio Herrera Venegas100% (2)

- Siemens Technical Paper Gas Turbine ModernizationDocument14 pagesSiemens Technical Paper Gas Turbine ModernizationAldiarso UtomoNo ratings yet

- Hot Gas ExpanderDocument2 pagesHot Gas ExpanderMary GomezNo ratings yet

- Ansaldo Thomassen - CMU (2014)Document4 pagesAnsaldo Thomassen - CMU (2014)guerrezNo ratings yet

- MHPS Large Frame F Series Gas Turbine PDFDocument8 pagesMHPS Large Frame F Series Gas Turbine PDFI Wayan Arimbawa100% (1)

- Fatigue in NozzleDocument28 pagesFatigue in NozzlebookppNo ratings yet

- 07 Development of Turbo-Expander Based Liquid Nitrogen Plant - Ranjit Kumar SahooDocument95 pages07 Development of Turbo-Expander Based Liquid Nitrogen Plant - Ranjit Kumar Sahoomohamadsadegh kamali100% (1)

- Structural Design of Modern Steam Turbine Blades Using ADINADocument9 pagesStructural Design of Modern Steam Turbine Blades Using ADINANico Scheggia100% (1)

- 06 Advanced Technology OfferingsDocument27 pages06 Advanced Technology Offeringsatfrost4638No ratings yet

- 7FA Upgrade Combustion HardwareDocument2 pages7FA Upgrade Combustion Hardwaresauerbach1No ratings yet

- York Centrifugal M PamphletDocument8 pagesYork Centrifugal M Pamphletgustavofx21No ratings yet

- Cold Spray Application Deptt of Dense UseDocument34 pagesCold Spray Application Deptt of Dense UseNabeel BhattiNo ratings yet

- Introduction of Gas Turbine Air Intake Cooling SystemDocument12 pagesIntroduction of Gas Turbine Air Intake Cooling SystemAndry Kurnia100% (1)

- Effect of The Thickness of Cold Sprayed Aluminium Alloy Coating On The Adhesive Bond StrengthDocument7 pagesEffect of The Thickness of Cold Sprayed Aluminium Alloy Coating On The Adhesive Bond StrengthRudolf Krause RiffoNo ratings yet

- A Review of Advances in Cold Spray Additive ManufacturingDocument46 pagesA Review of Advances in Cold Spray Additive ManufacturingRodolpho VazNo ratings yet

- Cold Spray SpairDocument12 pagesCold Spray SpairAnasNo ratings yet

- A600438 - Cold Spray Al MIL 83488Document46 pagesA600438 - Cold Spray Al MIL 83488Kewell LimNo ratings yet

- Meraj Engineering - CatalogueDocument29 pagesMeraj Engineering - CatalogueMohammad Iqbal KhanNo ratings yet

- The Modernization of A 1965, MS New Life For An Old 5001, Gas Turbine: UnitDocument8 pagesThe Modernization of A 1965, MS New Life For An Old 5001, Gas Turbine: UnitRozy AlriadiNo ratings yet

- Es2001 PDFDocument2 pagesEs2001 PDFfrdnNo ratings yet

- Inplant TrainingDocument19 pagesInplant TrainingArun KumarNo ratings yet

- By: Satyendra Nath Dwivedi: Triune Energy Services, New DelhiDocument46 pagesBy: Satyendra Nath Dwivedi: Triune Energy Services, New Delhinabeelengg100% (1)

- EEI 7FA Supplement r1 2octDocument42 pagesEEI 7FA Supplement r1 2octAnonymous ieWpd823LgNo ratings yet

- Coatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbineDocument1 pageCoatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine Turbinefrdn100% (1)

- Arcraft Plasma Equipments (I) Pvt. LTD.: Plasma Transferred Arc - PtaDocument4 pagesArcraft Plasma Equipments (I) Pvt. LTD.: Plasma Transferred Arc - Ptapavi32No ratings yet

- TurboTalk Vol11Document12 pagesTurboTalk Vol11Prastowo PriyatmokoNo ratings yet

- Gas Turbines Technical PerformanceDocument2 pagesGas Turbines Technical PerformanceRoozbeh P100% (1)

- Actuador Limitorque MX y QXDocument6 pagesActuador Limitorque MX y QXManuel FernizaNo ratings yet

- General Power Present 1 PDFDocument29 pagesGeneral Power Present 1 PDFSudin Pala100% (1)

- A Plant Supplier and Market Overview SIEMENSDocument33 pagesA Plant Supplier and Market Overview SIEMENSKenneth Castelo GilerNo ratings yet

- B600 PDFDocument4 pagesB600 PDFzsmithNo ratings yet

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDocument13 pagesI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad Afif100% (1)

- Technical Training For Siemens SB5-17-0039-GT-EN-02cDocument5 pagesTechnical Training For Siemens SB5-17-0039-GT-EN-02cbabunidoniNo ratings yet

- Liburdi SuperalloyDocument25 pagesLiburdi SuperalloyCarlosAlbertoRibeiroRuyNo ratings yet

- SIEMENS The H Class To Korea BrochureDocument8 pagesSIEMENS The H Class To Korea Brochurelink2u_007No ratings yet

- Thermal Peaking PDFDocument26 pagesThermal Peaking PDFkhozaqiNo ratings yet

- On The Fabrication of Metallic Single Crystal Turbine Blades With A Commentary On Repair Via Additive ManufacturingDocument28 pagesOn The Fabrication of Metallic Single Crystal Turbine Blades With A Commentary On Repair Via Additive Manufacturingmrkshitij.sNo ratings yet

- Gas Turbine CombustionDocument38 pagesGas Turbine CombustionSiva Subramaniyan100% (1)

- Hot Borescoping ProjectDocument12 pagesHot Borescoping ProjectThanapaet Rittirut100% (1)

- Steam Turbine PDFDocument2 pagesSteam Turbine PDFeselcosacNo ratings yet

- Study of Manufacturing of Gas TurbineDocument33 pagesStudy of Manufacturing of Gas TurbineSalman MohammedNo ratings yet

- Mak214e hmw1Document3 pagesMak214e hmw1çağla AydınNo ratings yet

- Frame6BHighwheelspacetemperaturerev 2Document17 pagesFrame6BHighwheelspacetemperaturerev 2partha6789100% (1)

- Welding Cheat SheetDocument1 pageWelding Cheat SheetDude100% (1)

- Secure Energy For Europe Chapter 7Document18 pagesSecure Energy For Europe Chapter 7Krishna KusumaNo ratings yet

- Ansaldo Thomassen - Gas Turbine Remanufacturing (2014)Document4 pagesAnsaldo Thomassen - Gas Turbine Remanufacturing (2014)guerrez100% (1)

- A471Document5 pagesA471rohit kumarNo ratings yet

- GT2019 90177Document11 pagesGT2019 90177Hiwa Khaledi100% (1)

- Mil HDBK 506Document15 pagesMil HDBK 506Jais JohnNo ratings yet

- Flashback Mechanisms in Lean Premixed Gas Turbine CombustionFrom EverandFlashback Mechanisms in Lean Premixed Gas Turbine CombustionNo ratings yet

- From Pinch Methodology to Pinch-Exergy Integration of Flexible SystemsFrom EverandFrom Pinch Methodology to Pinch-Exergy Integration of Flexible SystemsNo ratings yet

- MANDocument6 pagesMANMadhana GopalNo ratings yet

- IIT Madras - Smart City - Frame Work Energy and Electric VehicleDocument13 pagesIIT Madras - Smart City - Frame Work Energy and Electric VehicleMukundMikkilineniChowdaryNo ratings yet

- VFD Domestic Water Booster Standard Sequence of Operation PDFDocument13 pagesVFD Domestic Water Booster Standard Sequence of Operation PDFCristianDumitruNo ratings yet

- BiobriquetteDocument7 pagesBiobriquetteputri wahyuniNo ratings yet

- NTC Type FP07: AmphenolDocument2 pagesNTC Type FP07: AmphenolMARCELA RODRIGUEZ CEDIELNo ratings yet

- JMD Dredger Hansel CSD: Principle ParticularsDocument3 pagesJMD Dredger Hansel CSD: Principle Particularshassan hamdyNo ratings yet

- MAN - Electrical Noise ProcedureDocument25 pagesMAN - Electrical Noise ProcedureDimitrisNo ratings yet

- Chery QQ Maintenance Manual 465 Engine Mechanical SystemDocument53 pagesChery QQ Maintenance Manual 465 Engine Mechanical SystemAngel Pulido UrreaNo ratings yet

- Darmatt Brochure-08Document2 pagesDarmatt Brochure-08Jairo ContrerasNo ratings yet

- CODIGO PQS REFRIGERADOR HaierDocument2 pagesCODIGO PQS REFRIGERADOR HaierSebastian HernandezNo ratings yet

- Hyd & N2 Calculations PDFDocument8 pagesHyd & N2 Calculations PDFRicardo NapitupuluNo ratings yet

- EAT227-Lecture 2.3 - Continuous CastingDocument25 pagesEAT227-Lecture 2.3 - Continuous CastingSurya Da Rasta100% (1)

- Section 11 - Instrumentation & Process ControlDocument59 pagesSection 11 - Instrumentation & Process Controlaanouar77No ratings yet

- Chapter 7 Fluidization and Entrainment 2Document33 pagesChapter 7 Fluidization and Entrainment 2Sharmimi RazakNo ratings yet

- GK 2 Tieng Anh 9 (7N) 20 21Document6 pagesGK 2 Tieng Anh 9 (7N) 20 21SelenaNo ratings yet

- Tristack IOMManualDocument32 pagesTristack IOMManualApril MitchellNo ratings yet

- Air Cooler With Checking DoorDocument2 pagesAir Cooler With Checking DoorSuraj KumarNo ratings yet

- Understanding Power MOSFET Avalanche OperationDocument12 pagesUnderstanding Power MOSFET Avalanche OperationJorge Alberto Romero CoronaNo ratings yet

- Solar Powered Battery Charging System: Catherine ConaghanDocument71 pagesSolar Powered Battery Charging System: Catherine ConaghanVasantaraj Fbi CriminalNo ratings yet

- PDS en-MY 20220811Document2 pagesPDS en-MY 20220811MUHAMMAD AMIR BIN RASIDNo ratings yet

- Active Fire Protection Philosophy PDFDocument37 pagesActive Fire Protection Philosophy PDFOmar Tocmo100% (1)

- Exp 3 - Rolling Disc and AxleDocument7 pagesExp 3 - Rolling Disc and AxleCoco YapNo ratings yet

- lectut-MTN-304-pdf-Sintering All Slides - 1st April PDFDocument107 pageslectut-MTN-304-pdf-Sintering All Slides - 1st April PDFDevashish MeenaNo ratings yet

- Assignment - 1Document3 pagesAssignment - 1Abdul WadoodNo ratings yet

- Piping Installation Diagrams For Compact Steam Trapping StationsDocument2 pagesPiping Installation Diagrams For Compact Steam Trapping StationsRabindranath Hendy TagoreNo ratings yet

- Sudarshan GujarDocument5 pagesSudarshan GujarNitin GhotekarNo ratings yet

- (PRL) Pakistan Refinery LimitedDocument16 pages(PRL) Pakistan Refinery LimitedHammad Naeem0% (1)

- 5.5 KW 4p-Ds - EilDocument9 pages5.5 KW 4p-Ds - EilVaibhav PatilNo ratings yet

- Whitening The CloudsDocument3 pagesWhitening The CloudsMartin Wac HandNo ratings yet

- Proteus XR F Generator Service Manual SM 5764770-1EN 4Document540 pagesProteus XR F Generator Service Manual SM 5764770-1EN 4fortroniNo ratings yet