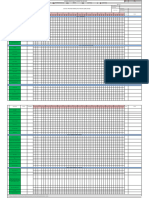

CONTROL CHART

Operation : Seaming Engineering Spec: 0.84 min Part Name:

Characteristic: Over lap Sample size/ Freq :

Time Indication of out of control limits

Date I. One point out of control limit

RE 1

AD 2

IN 3

II. Two point out of control limit

Sum

X bar

Range

III. Three point out of control limit

AVERAGE

0.27

0.24

###

0.21

0.18

0.15 USL

0.12

0.09

0.06 IV. Seven points run

0.03

1.20 X

0.03

0.06

0.09

0.12

0.15

0.18 LSL

0.21

0.24 V. High proportion of points near Limits

0.27

RANGE

0.35

0.3 ucl

0.25

0.2 USL lcl

0.15

0.1

0.05

0

VI. Trend ,either upwards or downwards

Refer action plan displayed on each machine for the actions on point out of control limits

Q3/d/Patil/control chart

� CONTROL CHART

Operation : Seaming Engineering Spec: 148~149 Part Name:

Characteristic: Compression bracket position

Sample size/ Freq :3/4Hrs FIAT PALIO

Time 7(I) 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 Indication of out of control limits

Date I. One point out of control limit

RE 1

AD 2

IN 3 II. Two point out of control limit

Sum

X bar

Range

III. Three point out of control limit

AVERAGE

1.20

0.16

###

0.14

0.12

1.10 USL

0.08

0.06

0.04 IV. Seven points run

0.02

1.00 X

0.02

0.04

0.06

0.08

0.90

0.12 LSL

0.14

0.16 V. High proportion of points near Limits

0.82

RANGE

0.35

0.3 ucl

0.25

0.2 USL lcl

0.15

0.1

0.05

0

VI. Trend ,either upwards or downwards

Refer action plan displayed on each machine for the actions on point out of control limits

1.If parameter is under conatinment,do not enter in the control chart & do 100 % checking (mention the same on control chart)

2.TS 16949 Non conformance during Nov'01 : All points out of control limits to have remarks of "reason" & "action taken"

Q3/d/Patil/control chart

� CONTROL CHART Zone - 6

Operation : Lower bracket

Engineering Spec: 291.15~292.15 Part Name: YH Rake Jacket asm

welding

Characteristic: Lower bracket

Sample size/ Freq :3/4Hrs

distance

Time 7(I) 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 Indication of out of control limits

Date I. One point out of control limit

RE 1

AD 2

IN 3 II. Two point out of control limit

Sum

X bar

Range

III. Three point out of control limit

AVERAGE

292.04

0.24

###

0.21

0.18

0.15 USL

291.89

0.09

0.06 IV. Seven points run

0.03

291.77 X

0.03

0.06

0.09

291.65

0.15

0.18 LSL

0.21

0.24 V. High proportion of points near Limits

291.50

RANGE

0.7

0.6 ucl

0.5

0.4 USL lcl

0.3

0.2

0.1

0

VI. Trend ,either upwards or downwards

Refer action plan displayed on each machine for the actions on point out of control limits

1.If parameter is under conatinment,do not enter in the control chart & do 100 % checking (mention the same on control chart)

Q3/d/Patil/control chart

�2.TS 16949 Non conformance during Nov'01 : All points out of control limits to have remarks of "reason" & "action taken"

Q3/d/Patil/control chart

� CONTROL CHART Zone - 6

Operation : Lower bracket weldingEngineering Spec: 56.45 / 56.95 Part Name: YH STD Jacket asm

Characteristic: LB Distance Sample size/ Freq :3/4Hrs YH7 STD Column

Time 7(I) 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 Indication of out of control limits

Date I. One point out of control limit

RE 1

AD 2

IN 3 II. Two point out of control limit

Sum

X bar

Range

III. Three point out of control limit

AVERAGE

278.20

0.24

###

0.21

0.18

278.08 USL

0.12

0.09

0.06 IV. Seven points run

0.03

277.93 X

0.03

0.06

0.09

0.12

277.78

0.18 LSL

0.21

0.24 V. High proportion of points near Limits

277.66

RANGE

0.7

0.6 ucl

0.5 USL

0.4

lcl

0.3

0.2

0.1

0

VI. Trend ,either upwards or downwards

Refer action plan displayed on each machine for the actions on point out of control limits

1.If parameter is under conatinment,do not enter in the control chart & do 100 % checking (mention the same on control chart)

2.TS 16949 Non conformance during Nov'01 : All points out of control limits to have remarks of "reason" & "action taken"

Q3/d/Patil/control chart

� CONTROL CHART Zone - 6

Operation: IP bracket welding Engineering Spec: 171.5~172.5 Part Name: Upper jacket asm

Characteristic: Groove Distance Sample size/ Freq :3/4Hrs YH7 STD Column

Time 7(I) 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 3.00 7.00 11.00 Indication of out of control limits

Date I. One point out of control limit

RE 1

AD 2

IN 3 II. Two point out of control limit

Sum

X bar

Range

III. Three point out of control limit

AVERAGE

172.27

0.24

###

0.21

0.18

172.15 USL

0.12

0.09

0.06 IV. Seven points run

0.03

172.00 X

0.03

0.06

0.09

0.12

171.75

0.18 LSL

0.21

0.24 V. High proportion of points near Limits

171.73

RANGE

0.7

0.6 USL ucl

0.5

0.4

lcl

0.3

0.2

0.1

0

VI. Trend ,either upwards or downwards

Refer action plan displayed on each machine for the actions on point out of control limits

1.If parameter is under conatinment,do not enter in the control chart & do 100 % checking (mention the same on control chart)

2.TS 16949 Non conformance during Nov'01 : All points out of control limits to have remarks of "reason" & "action taken"

Q3/d/Patil/control chart