Professional Documents

Culture Documents

Section 2 Hot Tap Checklist Form A To Be Completed by The Job Coordinator Prior To Welding

Section 2 Hot Tap Checklist Form A To Be Completed by The Job Coordinator Prior To Welding

Uploaded by

estudiemosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 2 Hot Tap Checklist Form A To Be Completed by The Job Coordinator Prior To Welding

Section 2 Hot Tap Checklist Form A To Be Completed by The Job Coordinator Prior To Welding

Uploaded by

estudiemosCopyright:

Available Formats

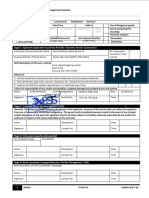

SECTION 2 (Owner Approval) Hot Tap Checklist Form A

To be completed by the Job Coordinator Prior to Welding

( ) Y ( ) N ( ) n/a Has a JSA been completed and attached to this form?

( ) Y ( ) N ( ) n/a Does the JSA address the risks associated with losing a coupon or introducing metal

shavings?

( ) Y ( ) N ( ) n/a Does the JSA denote measures taken to reduce the risk of burn through, and provide

a contingency plan in the event of burn through?

( ) Y ( ) N ( ) n/a Will radio communication with the Control Room be available during the execution of

this work?

( ) Y ( ) N ( ) n/a Has a complete Hot Tap/Stopple Document Package been provided to the Operations

Manager or designee?

( ) Y ( ) N ( ) n/a If a stopple is going to be used, does the JSA address measures to be taken if the

stopple fails?

To ensure compliance with OSHA's Lockout/Tag-out Standard under 1910.147, the hot tap must be

justified. The OSHA standard, as proposed, stipulated that hot tap operations would be exempt from the

requirements of the standard if the employer could demonstrate that: (1) Continuity of service is essential;

(2) shutdown of the system is impractical; and (3) documented procedures and special equipment are

utilized which will provide effective protection for employees.

Details of Requirement for continuity of service and/or impracticality of system shutdown:

NOTE: Operation Signatures signify that the Hop Tap location and size are correctly identified, that the risks

of performing a hot tap and the alternatives to a hot tap have been reviewed, and that performing a hot tap is

necessary.

Signatures

Operations Manager or Designee

Print Name:

Signature: Date:

Job Coordinator

Print Name:

Signature: Date:

A hot work permit CANNOT be issued if Sections 1 & 2 are not signed and/or there are any “No” answers.

CONTROLLED DOCUMENT- 24 HRS

8:37 am 12/29/2018

-- UNCONTROLLED THEREAFTER --

You might also like

- Method Statement: Assembly & Disassembly of Terex Demag CC8800-1 Crawler CraneDocument37 pagesMethod Statement: Assembly & Disassembly of Terex Demag CC8800-1 Crawler Craneccollado7100% (1)

- Safety Bulletin 2007-1 - Rev 8 Sept 30 2014Document3 pagesSafety Bulletin 2007-1 - Rev 8 Sept 30 2014Mohammed Jahanzeb ChoudaryNo ratings yet

- AC7102 Rev H Heat TreatDocument72 pagesAC7102 Rev H Heat TreatDimitris Grimanelis100% (3)

- P-007 Electrical Isolation PermitDocument1 pageP-007 Electrical Isolation PermitSatheesh Kumar PNo ratings yet

- Permit To Work ProcedureDocument8 pagesPermit To Work Proceduretnsv22No ratings yet

- VT4 PTW TemplateDocument26 pagesVT4 PTW TemplateHữu Nguyên100% (1)

- SMM 12 Hot Work PermitDocument4 pagesSMM 12 Hot Work PermitPavan mylapalliNo ratings yet

- 742 Method Statement 2011Document20 pages742 Method Statement 2011kikokiko KarimNo ratings yet

- 5) SWP-05 Hot WorksDocument4 pages5) SWP-05 Hot WorksRachel NoraNo ratings yet

- Permit Hot WorkDocument1 pagePermit Hot Worksrinu degalaNo ratings yet

- CP 01-2 Hot Work Permit STTGDCDocument2 pagesCP 01-2 Hot Work Permit STTGDCsttkolkataNo ratings yet

- 149 Handover Inspection ChecklistDocument10 pages149 Handover Inspection Checklistsudeepjm100% (1)

- Smith Brothers - MS 310018Document5 pagesSmith Brothers - MS 310018Daniel MoorhouseNo ratings yet

- Pages From Safety Bulletin 2007-1 - Rev 8 Sept 30 2014Document2 pagesPages From Safety Bulletin 2007-1 - Rev 8 Sept 30 2014Mohammed Jahanzeb ChoudaryNo ratings yet

- Method Statement (DKi 2024)Document2 pagesMethod Statement (DKi 2024)Noman AliNo ratings yet

- Work Permit Form (Compulsory)Document1 pageWork Permit Form (Compulsory)AdibCheAzizNo ratings yet

- Signatures Shift Supervisor: Print Name: Signature: DateDocument1 pageSignatures Shift Supervisor: Print Name: Signature: DateestudiemosNo ratings yet

- MOP Proforma (000169f02)Document5 pagesMOP Proforma (000169f02)junglonNo ratings yet

- Form Izin Kerja - Hot WorkDocument2 pagesForm Izin Kerja - Hot Worksafetyofficer752No ratings yet

- Maintenance Work Instruction: Page. 1 of 2Document2 pagesMaintenance Work Instruction: Page. 1 of 2hobam3297No ratings yet

- Paintng Works U#3 Boiler Turbine Area: DuplicateDocument1 pagePaintng Works U#3 Boiler Turbine Area: DuplicatevenkateshbitraNo ratings yet

- Agreement by Permit Holder: I Understand and Agree That No Work Is Permitted Accept That Shown On The Permit. IDocument1 pageAgreement by Permit Holder: I Understand and Agree That No Work Is Permitted Accept That Shown On The Permit. ISameer YadavNo ratings yet

- Dhi-Ehs-Hsm-031 Permit To Work Rev0Document21 pagesDhi-Ehs-Hsm-031 Permit To Work Rev0khoahuyen_89No ratings yet

- Checklist For Working in Substations or Vicinity of Energized Panels-1Document1 pageChecklist For Working in Substations or Vicinity of Energized Panels-1Madhu Electricals & Engineering100% (1)

- ICT Permit To Work Application - Rev 2021Document2 pagesICT Permit To Work Application - Rev 2021Fatma AlSuwaidiNo ratings yet

- Hot Work Permit Format (HSE-CTN-HPP-FMT-009)Document2 pagesHot Work Permit Format (HSE-CTN-HPP-FMT-009)Radha BuildtechNo ratings yet

- Hot Works Permit: HSE Manual Ref. No.: HSEM GF04039 Location: Site ID: Sub Contractor Details (If Any) : DateDocument2 pagesHot Works Permit: HSE Manual Ref. No.: HSEM GF04039 Location: Site ID: Sub Contractor Details (If Any) : DateTonmay MajumderNo ratings yet

- General Work PermitDocument2 pagesGeneral Work PermitJareem PeesNo ratings yet

- HSE FormsDocument36 pagesHSE FormsEdidiong100% (1)

- DB6X - Method Statement TemplateDocument13 pagesDB6X - Method Statement TemplateRakan PierwszyNo ratings yet

- Confined Space Entry Risk AssessmentDocument9 pagesConfined Space Entry Risk Assessmentkoketso0% (1)

- Overhauling Report Unit#2 2020 FinalDocument52 pagesOverhauling Report Unit#2 2020 FinalJhajjar100% (1)

- AC7102 - Rev - K - For - Use - On - Audits - On - or - After - 15-Aug-2021 (Main Induction Furnace) AUDIT SHEET 42CRMO4Document111 pagesAC7102 - Rev - K - For - Use - On - Audits - On - or - After - 15-Aug-2021 (Main Induction Furnace) AUDIT SHEET 42CRMO4amit gajbhiyeNo ratings yet

- D7390 Incr 011Document1 pageD7390 Incr 011DSNo ratings yet

- PTW-02 Hot Work PermitDocument4 pagesPTW-02 Hot Work PermitjayNo ratings yet

- Hot Work Permit Revision 3Document2 pagesHot Work Permit Revision 3Phelelani NkabindeNo ratings yet

- Dham Hse F 26 Hse Work Permit - v0Document2 pagesDham Hse F 26 Hse Work Permit - v0Design Xess EventsNo ratings yet

- EM - EHS - PTW - General UpdatedDocument1 pageEM - EHS - PTW - General UpdatedMushfiqur ChowdhuryNo ratings yet

- Hot Works PermitDocument1 pageHot Works Permitabhilash sureshNo ratings yet

- 0418MC 04.17.19 Form 25 CPM Flagging Checklist 28th STDocument3 pages0418MC 04.17.19 Form 25 CPM Flagging Checklist 28th STMohammed Jahanzeb ChoudaryNo ratings yet

- Hotwork Permit Rev 3Document1 pageHotwork Permit Rev 3Mohd AzwadiNo ratings yet

- Oe MS Ar 3082 - Rev1Document51 pagesOe MS Ar 3082 - Rev1Alvin BadzNo ratings yet

- EHS-00030 R6 Equipment Decommissioning and Removal ProcedureDocument6 pagesEHS-00030 R6 Equipment Decommissioning and Removal Procedurexjaf010% (1)

- Beat The Heat Audit FormDocument1 pageBeat The Heat Audit Formiftikhar ahmadNo ratings yet

- Passivation Criteria For NadCAPDocument49 pagesPassivation Criteria For NadCAPSounak BanerjeeNo ratings yet

- Method StatementDocument16 pagesMethod StatementMark FashNo ratings yet

- Permit HWDocument1 pagePermit HWsurya adi wijayaNo ratings yet

- Stop Work Authority Reporting FormDocument2 pagesStop Work Authority Reporting Formengineering IndopileNo ratings yet

- Isolation and Release of EquipmentDocument34 pagesIsolation and Release of Equipmenthazopman100% (1)

- Hot Works PermitDocument1 pageHot Works PermitRana Muhammad NaeemNo ratings yet

- Arc Flash Presentation IEEE CED FinalDocument68 pagesArc Flash Presentation IEEE CED FinalzomglolzscribdNo ratings yet

- ATT 3 Hot Works PermitDocument2 pagesATT 3 Hot Works PermitSamsu Usup SudiarsonoNo ratings yet

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- 16052-TGC-MTH-ARC-00021 - Engineer's Comments - Rev.02Document1 page16052-TGC-MTH-ARC-00021 - Engineer's Comments - Rev.02Mohammad MohammadNo ratings yet

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pages011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- Simptww PSV C208Document4 pagesSimptww PSV C208Vijay RajaindranNo ratings yet

- Method Statement For Heat Exchanger Revise1Document19 pagesMethod Statement For Heat Exchanger Revise1DanielLeeNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Appendix H Sample Calculations For Branch ReinforcementDocument2 pagesAppendix H Sample Calculations For Branch ReinforcementestudiemosNo ratings yet

- AutoCAD NET Basics 8Document1 pageAutoCAD NET Basics 8estudiemosNo ratings yet

- AutoCAD NET Basics 7Document1 pageAutoCAD NET Basics 7estudiemosNo ratings yet

- METERRUN Technical Guide Danieenior Orifice Fitting en 44048 3Document1 pageMETERRUN Technical Guide Danieenior Orifice Fitting en 44048 3estudiemosNo ratings yet

- Acmgd - DLL Exposes All The Editor Functionality (Selectionsets, Commands and KeywordsDocument1 pageAcmgd - DLL Exposes All The Editor Functionality (Selectionsets, Commands and KeywordsestudiemosNo ratings yet

- Create An Isometric Directory: ISOGEN I-Configure WebinarDocument1 pageCreate An Isometric Directory: ISOGEN I-Configure WebinarestudiemosNo ratings yet

- I Configure 9Document1 pageI Configure 9estudiemosNo ratings yet

- ISOGEN Control Files: DO NOTDocument1 pageISOGEN Control Files: DO NOTestudiemosNo ratings yet

- The Drawing Setup Wizard: Object Enabler ErrorDocument1 pageThe Drawing Setup Wizard: Object Enabler ErrorestudiemosNo ratings yet

- I-Configure 1 PDFDocument1 pageI-Configure 1 PDFestudiemosNo ratings yet

- I-Configure Installation: Compatibility For Cadworx and CaesarDocument1 pageI-Configure Installation: Compatibility For Cadworx and CaesarestudiemosNo ratings yet

- Hot Tap Machine Dimension & Calculation Sheet: 12/29/2018 Controlled Document-24 Hrs - Uncontrolled ThereafterDocument1 pageHot Tap Machine Dimension & Calculation Sheet: 12/29/2018 Controlled Document-24 Hrs - Uncontrolled ThereafterestudiemosNo ratings yet

- Hot Tap Machine: 12/29/2018 Controlled Document-24 Hrs - Uncontrolled ThereafterDocument1 pageHot Tap Machine: 12/29/2018 Controlled Document-24 Hrs - Uncontrolled ThereafterestudiemosNo ratings yet