Professional Documents

Culture Documents

Uns S31803 F51 PDF

Uns S31803 F51 PDF

Uploaded by

furansu777Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uns S31803 F51 PDF

Uns S31803 F51 PDF

Uploaded by

furansu777Copyright:

Available Formats

Beeley Wood Works

Beeley Wood Lane

Sheffield S6 1ND

United Kingdom

T: +44 (0)114 231 2271

F: +44 (0)114 232 4983

E: info@abbeyfp.co.uk

UNS S31803 F51 – Duplex stainless Steel

Related Specifications

EN10088-3 X2CrNiMoN22-5-3

ASTM A182 F51

W.Nr. 1.4462

NORSOK D41 to D45

F51 is a duplex stainless steel with a 50:50 austenite, ferrite microstructure. The material combines good mechanical

strength and ductility with moderate to good corrosion resistance in a variety of environments.

This material is generally supplied in the annealed condition giving yield strengths in excess of 65 KSI (450Mpa), this

material cannot be hardened by heat treatment but stronger surface strengths can be achieved by cold working.

Typical applications include pumps, valves, pipework, flanges etc together with various applications in the oil and

gas, brewing, power generation and chemical engineering industries. In fact this alloy can be used successfully as an

alternative to 300 series austenitic stainless steels in almost all applications where higher mechanical strength/lower

weight is required.

Typical Chemical composition

PREn = Pitting Resistance Equivalent Carbon 0.03% Max

Silicon 1.00% Max

PREn= Cr% + 3.3Mo% + 16N%

Manganese 2.00% Max

Phosphorous 0.035% Max

Sulphur 0.015% Max

Chromium 21.0 – 23.0%

Nickel 4.5 – 6.5%

Molybdenum 2.5 – 3.5%

Nitrogen 0.10 – 0.20%

PREn >34

Mechanical Property Requirements - Annealed condition

Yield Tensile Strength Elongation Charpy Impact @ Rt Hardness

J

>450Mpa (65KSI) 650 – 800Mpa 25% 100 270HB Max

(94 – 128KSI)

Forging

Forging temperature for this material should be 1100 – 1250oC

Reheat as often as necessary and cool in still air.

Heat Treatment

Anneal – Heat to 1020 – 1120oC ensuring sufficient time is allowed for the centre to achieve furnace temperature and

hold for a time commensurate with the ruling section, followed by water quenching.

Machining

Material in the annealed condition is readily machinable by all conventional methods.

Welding

F51 is readily weldable using many of the standard electric arc welding processes but oxyacetylene welding is not

recommended because carbon pickup in the weld metal may occur.

Registered in England and Wales. Company Registration No: 1644542

You might also like

- Cast Iron Handbook PDFDocument144 pagesCast Iron Handbook PDFsachinguptachdNo ratings yet

- Piping Materials Selection TrainingDocument60 pagesPiping Materials Selection TrainingKagira Drawing Soltuion100% (3)

- Welding Duplex Stainless Steels - A Review of Currernt RecommendationsDocument12 pagesWelding Duplex Stainless Steels - A Review of Currernt RecommendationsTrushar Parmar100% (1)

- EJMA 10th Edition Changes and Engineering DataDocument8 pagesEJMA 10th Edition Changes and Engineering DatamasrooorNo ratings yet

- Bolts - ASTM F3125Document4 pagesBolts - ASTM F3125rahuljoagNo ratings yet

- NACE Seminar PowerPoint PDFDocument56 pagesNACE Seminar PowerPoint PDFravi00098No ratings yet

- Material CostDocument58 pagesMaterial CostLeon Peter100% (1)

- Monel® Alloy 400: C MN S Si Ni Cu FeDocument2 pagesMonel® Alloy 400: C MN S Si Ni Cu FeD_D_76No ratings yet

- Cast Iron HandbookDocument144 pagesCast Iron Handbooksachinguptachd100% (2)

- Key - 1Document237 pagesKey - 1Leon Peter100% (1)

- UTP Welding HandbookDocument431 pagesUTP Welding HandbookChee WeiNo ratings yet

- Astm A694 F65Document1 pageAstm A694 F65Anonymous oVRvsdWzfB100% (2)

- Selection of NodularizersDocument2 pagesSelection of Nodularizersarnaldorcr8646100% (2)

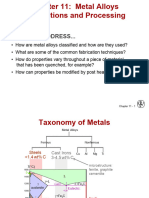

- Metal Alloys Application and ProcessingDocument57 pagesMetal Alloys Application and ProcessingtbmariNo ratings yet

- CMB 847Document107 pagesCMB 847ManuelNo ratings yet

- Lecture 2 - Submerged Arc Furnace-Part 2Document51 pagesLecture 2 - Submerged Arc Furnace-Part 2يوسف عادل حسانينNo ratings yet

- Applicable Codes and StandardsDocument48 pagesApplicable Codes and Standardskiki270977No ratings yet

- HIC Testing As Per NACE MR 0275Document3 pagesHIC Testing As Per NACE MR 0275g_sancheti100% (1)

- 02 CertificateDocument1 page02 CertificateLeon PeterNo ratings yet

- F316L Austenitic Stainless Steel: Related SpecificationsDocument2 pagesF316L Austenitic Stainless Steel: Related SpecificationsRAVIKIRAN BARDENo ratings yet

- Raw MaterialDocument14 pagesRaw MaterialAbhijeet AnkushNo ratings yet

- QA F316 Austenitic Stainless Steel PDFDocument2 pagesQA F316 Austenitic Stainless Steel PDFJAFFERNo ratings yet

- Uns N06625Document1 pageUns N06625robertNo ratings yet

- LM6 Casting Alloy PDFDocument2 pagesLM6 Casting Alloy PDFSankarNo ratings yet

- 817M40 PDFDocument2 pages817M40 PDFSamir ChaudharyNo ratings yet

- LM6 Aluminium Casting Alloyhb11Document4 pagesLM6 Aluminium Casting Alloyhb11Nader MohamedNo ratings yet

- Oaisdokas 123123Document5 pagesOaisdokas 123123Justine Lloyd BautistaNo ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- Lecture 10Document24 pagesLecture 10spsu2010No ratings yet

- LM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical CompositionDocument3 pagesLM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical Compositionsankar4582No ratings yet

- Theory of AlloysDocument19 pagesTheory of AlloysNeel PatelNo ratings yet

- Inconel 625Document1 pageInconel 625Juan PachecoNo ratings yet

- 2 HBI in EAF Fact Sheet Rev3 PDFDocument2 pages2 HBI in EAF Fact Sheet Rev3 PDFAaquil RaziNo ratings yet

- Aluminium Alloy 6063 NBDocument2 pagesAluminium Alloy 6063 NBBrijendra Mani PandeyNo ratings yet

- Aluminium Alloy 6063 NB PDFDocument2 pagesAluminium Alloy 6063 NB PDFBrijendra Mani PandeyNo ratings yet

- Thyssenkrupp Materials (UK) LTD Aluminium Alloy 6063: Material Data SheetDocument2 pagesThyssenkrupp Materials (UK) LTD Aluminium Alloy 6063: Material Data Sheetdinesh choudharyNo ratings yet

- Ferro TungstenDocument9 pagesFerro TungstenTarun ChakrabortyNo ratings yet

- 4140DE Data SheetDocument1 page4140DE Data SheetNabeel AmeerNo ratings yet

- Monel Nickel-Copper Alloy 400 (UNS N04400) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument5 pagesMonel Nickel-Copper Alloy 400 (UNS N04400) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webraja ENo ratings yet

- Material Data Sheet Thermally Broken Steel USADocument2 pagesMaterial Data Sheet Thermally Broken Steel USAYungfang HuangNo ratings yet

- D.A.Cooper Sons Product Datasheet AISI SAE 4140 1Document1 pageD.A.Cooper Sons Product Datasheet AISI SAE 4140 1Muhamad Wahyu BudiawanNo ratings yet

- Full CatalogDocument36 pagesFull Cataloglearsipi061No ratings yet

- Master Alloys - HPNbMasteralloysDocument8 pagesMaster Alloys - HPNbMasteralloysdei_sandeep7994No ratings yet

- A0176257 PDFDocument1 pageA0176257 PDFZac NastNo ratings yet

- Afrox Subarc 904L: Welding Consumables Stainless SteelDocument4 pagesAfrox Subarc 904L: Welding Consumables Stainless SteelBranko FerenčakNo ratings yet

- Data CIDocument1 pageData CIMajdi JerbiNo ratings yet

- Chapter 11Document52 pagesChapter 11TamiruNo ratings yet

- M.tech FinalDocument43 pagesM.tech FinalRaghav AcharyaNo ratings yet

- +44 (0) 1786 475 662 Sales@amsmetals - Co.ukDocument2 pages+44 (0) 1786 475 662 Sales@amsmetals - Co.ukidontlikeebooksNo ratings yet

- Thyssenkrupp Materials (UK) LTD Aluminium Alloy 6082: Material Data SheetDocument2 pagesThyssenkrupp Materials (UK) LTD Aluminium Alloy 6082: Material Data SheetSatendra ThakurNo ratings yet

- 1993 - Recycled LeadDocument9 pages1993 - Recycled LeadgutobegaNo ratings yet

- Blast Furnac E: S.Megha Metallurgy SemesterDocument18 pagesBlast Furnac E: S.Megha Metallurgy SemesterRahul PandeyNo ratings yet

- Wel 12 DDocument7 pagesWel 12 DWilly UioNo ratings yet

- Alloy 309Document3 pagesAlloy 309Branko FerenčakNo ratings yet

- Monel PropertiesDocument3 pagesMonel PropertiesSalman AzharNo ratings yet

- BM Full CatalogueDocument109 pagesBM Full CatalogueMiguelNo ratings yet

- Ultramet 2507: Stainless Steel Electrodes Product Data SheetDocument1 pageUltramet 2507: Stainless Steel Electrodes Product Data Sheetshaan1001gbNo ratings yet

- MSL Prod InfoDocument2 pagesMSL Prod InfoFlamarion BadaroNo ratings yet

- HC420LA: Micro-Alloyed Steel Grades With High Yield Strength For Cold FormingDocument1 pageHC420LA: Micro-Alloyed Steel Grades With High Yield Strength For Cold FormingowyeevengNo ratings yet

- Stainless-Steel-1.4301-304 - CopieDocument3 pagesStainless-Steel-1.4301-304 - CopieYoucef KherroubiNo ratings yet

- CHE-313-Lecture 18 19 and 20Document25 pagesCHE-313-Lecture 18 19 and 20Sakina KhawajaNo ratings yet

- Haltraco Company ProfileDocument8 pagesHaltraco Company Profileperkinstop2000No ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNo ratings yet

- Low Fuming Bronze: (Rbcuzn-C)Document1 pageLow Fuming Bronze: (Rbcuzn-C)Marcelino Navarrete EvaristoNo ratings yet

- EASA Module 6 - Detailed NotesDocument37 pagesEASA Module 6 - Detailed NotesSteven J. SelcukNo ratings yet

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4307 - 304LDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4307 - 304LpabloNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Nickel Strip For BatteriesDocument12 pagesNickel Strip For BatteriesSidNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- CP08 Supplement March 05Document80 pagesCP08 Supplement March 05Leon PeterNo ratings yet

- Annexure IvDocument1 pageAnnexure IvLeon PeterNo ratings yet

- Sabish Chirayil Sasi: ObjectiveDocument2 pagesSabish Chirayil Sasi: ObjectiveLeon PeterNo ratings yet

- OmniOMS Output GenerationDocument1 pageOmniOMS Output GenerationLeon PeterNo ratings yet

- Print Plan1 PDFDocument1 pagePrint Plan1 PDFLeon PeterNo ratings yet

- CP05 Inspection Manual March 05Document12 pagesCP05 Inspection Manual March 05Leon PeterNo ratings yet

- PdmsDocument1 pagePdmsLeon PeterNo ratings yet

- States Under The Jurisdiction of The Washington D.C. Office (East Coast)Document2 pagesStates Under The Jurisdiction of The Washington D.C. Office (East Coast)Leon PeterNo ratings yet

- ASTS - ProspectusDocument8 pagesASTS - ProspectusLeon PeterNo ratings yet

- DUBAI 2 Model PDFDocument1 pageDUBAI 2 Model PDFLeon PeterNo ratings yet

- Abuse Activist Activity Actor Actress Actual Actually Ad Adapt Add Addition Additional Address Adequate Adjust Adjustment AdministrationDocument165 pagesAbuse Activist Activity Actor Actress Actual Actually Ad Adapt Add Addition Additional Address Adequate Adjust Adjustment AdministrationLeon PeterNo ratings yet

- ATM Request LetterDocument1 pageATM Request LetterLeon PeterNo ratings yet

- Malayalamprayer PDFDocument3 pagesMalayalamprayer PDFLeon PeterNo ratings yet

- Bonafide CertificateDocument1 pageBonafide CertificateLeon Peter0% (1)

- For FillingDocument3 pagesFor FillingLeon PeterNo ratings yet

- Tik Tok PDFDocument2 pagesTik Tok PDFLeon PeterNo ratings yet

- Isometrics PDFDocument8 pagesIsometrics PDFLeon PeterNo ratings yet

- EMTL 250 Module 1 2018Document57 pagesEMTL 250 Module 1 2018Yeab MengistuNo ratings yet

- Kaczmar 2000Document10 pagesKaczmar 2000magalicantonNo ratings yet

- Non-Sparking Tools - Quick Tips #381 - Grainger Industrial SupplyDocument3 pagesNon-Sparking Tools - Quick Tips #381 - Grainger Industrial SupplyZulfiqar AliNo ratings yet

- Janaki Ram. CVDocument13 pagesJanaki Ram. CVdkannanapkNo ratings yet

- HQ Rawang - Meeting - Materialsdesign - ChangesDocument3 pagesHQ Rawang - Meeting - Materialsdesign - ChangesAmirul ShamNo ratings yet

- Study of Mechanical Properties and Change in Microstructure of Alloy Steel EN24 Under Various Heat Treatment ProcessDocument7 pagesStudy of Mechanical Properties and Change in Microstructure of Alloy Steel EN24 Under Various Heat Treatment ProcessAjeeth KumarNo ratings yet

- Upload MetallergyDocument2 pagesUpload MetallergyManoj MandavkarNo ratings yet

- AS 1290.7-1995 Linear Measuring Instruments Used in Construction Surveyors Measuring Bands and Readers PDFDocument7 pagesAS 1290.7-1995 Linear Measuring Instruments Used in Construction Surveyors Measuring Bands and Readers PDFSAI Global - APACNo ratings yet

- Materials List: Alloy FamilyDocument3 pagesMaterials List: Alloy FamilydiwakarNo ratings yet

- M05 ES AB Y9 5491 UE9.inddDocument2 pagesM05 ES AB Y9 5491 UE9.inddDina GhaddarNo ratings yet

- Dilthey WT2 - Welding MetallurgyDocument142 pagesDilthey WT2 - Welding MetallurgyMirnes HodzićNo ratings yet

- NMS Next 1.59 Refinery RecipesDocument11 pagesNMS Next 1.59 Refinery Recipesbweaver700No ratings yet

- Gold DrillsDocument28 pagesGold DrillsGrant CunninghamNo ratings yet

- Book - Nbsir83 2679 1 PDFDocument416 pagesBook - Nbsir83 2679 1 PDFarjun prajapatiNo ratings yet

- Development of C12 ADocument11 pagesDevelopment of C12 AVasu RajaNo ratings yet

- Behaviour of Aluminium Structures in Fire - A ReviDocument7 pagesBehaviour of Aluminium Structures in Fire - A RevitamaranmNo ratings yet

- Nickel Al Bronze For SeawaterDocument21 pagesNickel Al Bronze For Seawaterhinsome LeeNo ratings yet

- Lamina Tech - Catálogo 2017-2018 PDFDocument342 pagesLamina Tech - Catálogo 2017-2018 PDFGilberto Garcia100% (2)

- Delphi Global CatalogDocument404 pagesDelphi Global CatalogmathconsNo ratings yet

- SEA CURE Technical BrochureDocument12 pagesSEA CURE Technical BrochurekulilistrikNo ratings yet

- MCQDocument59 pagesMCQনুরুন নবী খোকনNo ratings yet

- Advanced Vessel Technologies ProgramDocument50 pagesAdvanced Vessel Technologies ProgramShrabani DebNo ratings yet