Professional Documents

Culture Documents

Api15651 PDF

Uploaded by

SAMARTHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Api15651 PDF

Uploaded by

SAMARTHCopyright:

Available Formats

P U M P S & S E A L S

Intermediate heavy-duty process pumps bridge

the gap between expensive API pumps and

less-sophisticated ANSI pumps in many

flammable and hazardous applications

By Gennaro A. D’Alterio

P

umping high-temperature process American Petroleum Institute (API) many years sign and construction materials. Most of these re-

liquids around the clock places ago set forth rigid standards for the design, con- quirements are stated in API Standard 610.

extraordinary demands on most struction and performance of process pumps used Over the years, however, a number of revi-

system components—particularly for these applications. The original API standards sions have been made to that standard as more ex-

the chemical pumps. In many ap- were issued some 40 years ago for refinery services. perience was gained through high-temperature

plications, catastrophic pump fail- According to the text of API Standard 610, process pump use. The changes also reflect the sig-

ure is seldom an option because it can lead to pro- “API standards are published as an aid to procure- nificant improvements made in pump design and

duction down-time, wasted effort, added mainte- ment of standardized equipment and materials. construction materials.

nance costs, ruined final product and personnel These standards are not intended to inhibit pur-

hazards. chasers or producers from purchasing or producing Rising costs spark alternatives

Because pump performance and reliability products made to other standards.” Some manufacturers of high-temperature

are critical issues whenever — and wherever — The intent was to minimize failure possibili- heavy-duty process pumps have refined their prod-

high-temperature liquids are being transferred, the ties from known causes with appropriate pump de- ucts often to meet subsequent revisions to the orig-

May 2003 www.chemicalprocessing.com

To bridge the gap between high-end by intermediate pumps for flammable and haz-

API-type pumps and lower-cost ANSI- ardous service without affecting performance,

type pumps, some manufacturers offer safety or reliability.

pumps that incorporate many of the design Like previous editions, the API-610 Ninth

and construction features required by the Edition also lists specific limits for process and util-

API standard at a substantially lower cost. ity services that allow the use of “pumps designed

They can do so by eliminating the exten- in compliance with other standards such as ISO

sive documentation and testing require- 5199 or ANSI/American Society of Mechanical

ments that might be deemed unnecessary Engineers [ASME] B73.1M.” In particular, the

for many applications. stated parameters mentioned are maximum dis-

charge pressure (275 pounds per square inch gauge

Revision eliminates [psig]), maximum suction pressure (75 psig), max-

restrictions imum pumping temperature (300°F), maximum

According to API sources involved rotating speed (3,600 rotations per minute [rpm]),

in the standard’s development, API maximum rated total head (400 feet [ft]) and max-

Standard 610, Ninth Edition was approved imum impeller diameter (13 inches [in.]).

in January of this year. This newest revi-

sion specifically allows users to employ Non-API pumps in service

non-API-style pumps in services defined Although the decision to use non-API pumps

by parameters addressed in “Section 1 — in flammable and hazardous service must be de-

Scope” of the standard. (Prior to this revi- termined on an individual basis, many organizations

sion, users could employ a non-API pump have been using alternative pumps for these appli-

in hazardous flammable operations, but cations on a routine basis.

Some manufacturers offer lower-cost pumps with the pump was not “approved” by API.) Although the “Basically, users who require the ‘ultimate’

many API- standard design and construction fea- API standard’s Eighth Edition (Paragraph 1.1.4) pump for high-temperature hot oil requirements —

tures by eliminating unnecessary documentation includes these same service limits, it also specifies the safest, heaviest possible pump — with cost as

and testing. that the allowable services be “nonflammable and no object ... would specify an API-610 pump,” em-

nonhazardous.” phasizes Will McKnight, a vice president with

inal standard. With each revision, the cost of API- The Ninth Edition eliminates this restriction, Process Equipment Co. in Fort Mills, S.C. He has

type pumps continued to rise above that of other permitting the use of non- API pumps in process and been involved with applications engineering for

heavy-duty process pumps not meeting the API utility services, provided the stated criteria on per- high-temperature pumps in the chemical and petro-

standard. Chemical pump users had little choice formance and construction are met. As a result, chemical industries for many years. “On the other

when selecting heavy-duty process pumps for many many new and existing users of API-610 pumps hand, if a user requires a pump for virtually the same

applications. now can take advantage of the lower costs offered service at a substantially less[er] cost, a non-API

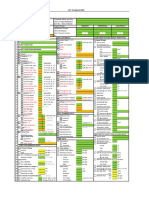

The American National Standards Institute

(ANSI) eventually issued its own standards for API-610 and ANSI/ASME B73.1 Pump Comparison

chemical pumps. Those standards are not nearly as

restrictive, nor as comprehensive, as API’S, partic-

Feature API-610 ANSI/ASME B73.1

ularly in the areas of testing, documentation and

traceability requirements. Consequently, ANSI- Service Petroleum, heavy-duty Chemical process

type pumps cost substantially less than API-type chemical and gas

pumps. Flanges Full faced or spot Back at 3 degrees

faced on back maximum on parallelism

API vs. ANSI Casing support Centerline of casing Foot under the casing

ANSI-type pumps do not incorporate many Bearing housing support Not allowed Yes

of the design and construction features specifi- Bearing housing material Steel for flammable Cast iron

cally mandated for the extreme service typically or hazardous liquids

encountered by API service pumps (see the table). Bearings Duplex, single row, Not specified

For example, centerline support structures in API- angular contact

type pumps are not required in ANSI-type pumps. Impeller mounting Keyed Keyed or threaded

Without centerline support, however, shaft align- Wearing rings Casing and impeller Not required

ment could lose concentricity under continuous Seals Per API 682 Not specified

high-temperature use. Premature bearing, cou- Seal chamber throat bushing Required Not specified

pling and/or seal failure could result. Other de- Gland throttle bushing Floating type required Not required

sign/construction differences include heavy-duty Auxiliary connections Sock weld, butt weld Threaded NPT

baseplates and steel bearing housings, all of which or flanged for flammable

are required in API-type pumps but not in ANSI or hazardous liquids

standard pumps. Auxiliary piping Minimum Schedule 160 Schedule 40

www.chemicalprocessing.com May 2003

P U M P S & S E A L S

pump such as described here is quite suitable. In our

experience, some engineers just have a ‘mindset’ on “The decision to use

the use of API pumps,” McKnight maintains.

Mitsubishi Polyester Film in Greer, S.C., has

been using non-API heavy- duty, high-temperature

non-API pumps in flammable

process pumps successfully for many years. The

pumps transfer Dowtherm glycol- water heat-trans-

and hazardous service must

fer fluid through heat exchangers to stabilization

systems for processing polyester-resin pellets. be determined on an

These pellets are sold to manufacturers that ex-

trude them to produce plastic sheets for packaging

applications.

individual basis.”

Tom Caudill, staff maintenance engineer at

Mitsubishi, says Dowtherm liquid is circulated For the most part, their lower costs are directly calls out specific performance standard require-

through the system at about 536°F. Mitsubishi has attributable to the elimination of testing, docu- ments, it includes two key statements that now per-

had 10 of these pumps in its stabilization unit for mentation, software and traceability requirements mit user discretion with regard to pump selection.

about six years, with five on-line simultaneously on the part of pump manufacturers. The new API- Specifically, “Section 1 — Scope” of the re-

and five reserved for backup, according to Caudill. 610 Ninth Edition fundamentally minimizes many vised API standard (“centrifugal pumps for petro-

of these previous requirements for those pump users leum, heavy-duty chemical and gas industry serv-

As good as API who do not actually need them. ices”) — is technically equivalent to International

Although the pumps at Mitsubishi are not true Standard Organization (ISO) 13709 and contains

API-style pumps, they have provided the company More choices the following statement:

with performance comparable to that of API-610 The original API standards were intended to “Process and utility services exist within most

pumps, at a substantially lower cost. Many factors establish a minimum set of mechanical criteria for facilities that do not require pumps of the robust-

are responsible for this successful track record, most refineries to enhance operating safety and reliabil- ness and intrinsic reliability of those covered in this

of them focused on pump design and construction ity through the design and construction of more standard. For such services that do not exceed ANY

features that are similar to those of API-610 pumps. rugged, reliable pumps. Although the Ninth Edition of the following limits, i.e., less rigorous services,

the user may want to consider pumps designed in

compliance with other standards such as ISO 5199

or ANSI/ASME B73.1M.”

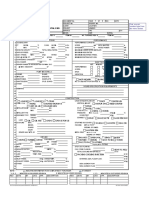

Designed for Performance Many other organizations also are applying

non-API pumps in flammable and hazardous serv-

ice successfully and have been doing so for years.

ecause substantial differences exist between

B

A word of caution: In the author’s opinion, when

API- and ANSI-style pumps, the pumps in use employing non-API pumps in traditional API serv-

at Mitsubishi’s Polyester Film plant in Greer, ices, users should not over-specify construction,

S.C., bridge the gap between these two standards

and offer advantages for use in applications gov- performance and software requirements in an at-

erned by the Ninth Edition. For example, these tempt to obtain a pump with API characteristics at

pumps are of a configuration similar to that of API- a lower, non-API cost.

610 pumps, with heavy-duty centerline-supported

casings in a variety of materials, including carbon Conclusion

steel and 316 stainless steel. The pumps are capa-

The API-610 Standard Ninth Edition — and

ble of flows as great as 6,000 gallons per minute

(gpm), heads to 800 ft, discharge pressures to 500 the availability of many suitable pumps to meet its

psig and temperatures to 500° F using ambient air requirements — gives chemical pump users the

cooling or 850°F with water cooling, actually ex- option to consider lower-cost alternatives. The in-

ceeding the capabilities defined by API-610. termediate heavy-duty process pumps also offer de-

Other standard construction features of these

sign, construction and performance advantages

pumps that permit their use for many API-610 ap-

plications include precision rabbetted casing and over ANSI-type pumps for many applications —

bearing housing joints, a confined casing gasket, a true back pull-out design, fully enclosed Francis vane without the added expense of a virtually compara-

impellers keyed to the pump shaft, ANSI Class 300# RF or RTJ flanges, casing wear rings and heavy- ble API-610 pump. CP

duty angular-contact thrust bearings.

A variety of mechanical seals can be employed, and cylindrical or tapered-bore stuffing boxes also

can be specified to meet process requirements.

D’Alterio works for the Dean Pump Div. of

To help extend seal and bearing life, the pumps are available with seal-chamber cooling jackets

and bearing-frame cooling coils to improve reliability and minimize downtime. Met-Pro Corp., Indianapolis. Contact him at

The pumps incorporate oversized shaft diameters to minimize shaft deflection, further enhanc- gdalterio@met-pro.com.

ing bearing and seal life, major causes of premature pump failures. Typical construction details include

standard pedestals for mounting on heavy-duty fabricated API-type baseplates; optional base mount-

ing includes a yoke-mounted centerline support that fits on an existing ANSI standard baseplate.

May 2003 www.chemicalprocessing.com

You might also like

- Summary of API 610, 12th EditionDocument4 pagesSummary of API 610, 12th EditionTyas Utami83% (6)

- How To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineDocument5 pagesHow To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineALP1981100% (2)

- Spec For Centrifugal Pumps - APIDocument12 pagesSpec For Centrifugal Pumps - APIjowar100% (1)

- Pump Standards ComparisonDocument4 pagesPump Standards ComparisonAnish Dani50% (2)

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- API 610 10th Edition (Iso 13709) Pump DatasheetDocument3 pagesAPI 610 10th Edition (Iso 13709) Pump DatasheetMuhammad Azka50% (4)

- Iso 5199 Technical Specification For Centrifugal Pump-Class II Data SheetDocument2 pagesIso 5199 Technical Specification For Centrifugal Pump-Class II Data SheetAndry Setiawan100% (2)

- 01SA0S02Document5 pages01SA0S02raobabar21No ratings yet

- Pump Engineer August 2015 Technical Article Flowserve PDFDocument4 pagesPump Engineer August 2015 Technical Article Flowserve PDFToan NguyenNo ratings yet

- Congreso Ccps 2013Document116 pagesCongreso Ccps 2013gustav agudeloNo ratings yet

- HSC Physics Paper 2 Target PDFDocument17 pagesHSC Physics Paper 2 Target PDFAnonymous QvdxO5XTR63% (8)

- API Vs ANSI PumpsDocument6 pagesAPI Vs ANSI PumpsRS100% (2)

- 013-Ansi Vs API PumpsDocument6 pages013-Ansi Vs API Pumpsrtorabi80No ratings yet

- Specification For Horizontal End Suction Centrifugal Pumps For Chemical ProcessDocument30 pagesSpecification For Horizontal End Suction Centrifugal Pumps For Chemical ProcessFrancisco Gonzalez100% (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- API 685 Vs API 610Document5 pagesAPI 685 Vs API 610sandeep100% (1)

- Calgary Presentation API 610 and 682Document90 pagesCalgary Presentation API 610 and 682dhanu_aqua100% (1)

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- API 682 4th Ed DatasheetDocument2 pagesAPI 682 4th Ed DatasheetMuhammad Ghufran KhanNo ratings yet

- Pump Baseplate Design and InstallationDocument4 pagesPump Baseplate Design and InstallationSeungmin Paek100% (1)

- What's New in API 610 11th EditionDocument4 pagesWhat's New in API 610 11th Editionshyam_anupNo ratings yet

- Api 617Document14 pagesApi 617ecsuperal100% (1)

- Centrifugal Pump - Horizontal End Suction - Asme B73.1Document3 pagesCentrifugal Pump - Horizontal End Suction - Asme B73.1wado11No ratings yet

- Technical Specification For Centrifugal PumpsDocument19 pagesTechnical Specification For Centrifugal Pumpsdheeraj1993100% (1)

- T13151-176 Api 614 PDFDocument26 pagesT13151-176 Api 614 PDFpietroNo ratings yet

- API 676 Datasheet PDFDocument6 pagesAPI 676 Datasheet PDFPierre Norris0% (1)

- 2858 021975Document4 pages2858 021975jskrippa100% (1)

- Pip Resp73h-97 (1991)Document31 pagesPip Resp73h-97 (1991)Darren KamNo ratings yet

- NPSH Pump OperatingDocument4 pagesNPSH Pump OperatingJanneth Herrera FloresNo ratings yet

- (0152) 4664-MSP-001 - API610 Centrifugal PumpsDocument6 pages(0152) 4664-MSP-001 - API610 Centrifugal PumpsSixto Gerardo Oña AnaguanoNo ratings yet

- HEI 2854-00 - Liquid Ring Vacuum Pump 2ndDocument25 pagesHEI 2854-00 - Liquid Ring Vacuum Pump 2ndSubrata Das100% (3)

- 3620 10th Lores 2Document8 pages3620 10th Lores 2Dinh Quang NhamNo ratings yet

- Preview of API 610 12th EditionDocument7 pagesPreview of API 610 12th EditionHatem ShawkiNo ratings yet

- Centrifugal Pump Selection and SizingDocument50 pagesCentrifugal Pump Selection and SizingmariasofiarossiNo ratings yet

- Api 671Document6 pagesApi 671ecsuperalNo ratings yet

- DHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageDocument61 pagesDHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageThanh Tin NguyenNo ratings yet

- Weir Roto JetDocument61 pagesWeir Roto Jetnana sylvanhaNo ratings yet

- A Guide To API Mechanical Seal and System Design-AessealsDocument30 pagesA Guide To API Mechanical Seal and System Design-AessealsboroumandNo ratings yet

- Pocket API 682 4th Edition Piping Plans - EN Burgmann PDFDocument131 pagesPocket API 682 4th Edition Piping Plans - EN Burgmann PDFPoncho RmzNo ratings yet

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Document14 pagesA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNo ratings yet

- Hermetic Pumpen Canned Motor Pumps Catalogue For Model CN - CNF - CNKDocument16 pagesHermetic Pumpen Canned Motor Pumps Catalogue For Model CN - CNF - CNKADITYA_PATHAKNo ratings yet

- API 610 11th Ed DatasheetDocument13 pagesAPI 610 11th Ed DatasheetHatem ShawkiNo ratings yet

- 27 Ways To Kill Your PD PumpDocument12 pages27 Ways To Kill Your PD PumpArsalan QadirNo ratings yet

- Asme b73.1 PDFDocument48 pagesAsme b73.1 PDFGerencia Rigar Colombia SAS100% (3)

- Pump Zone ArticleDocument13 pagesPump Zone Articlesameerc12No ratings yet

- Ansi Vs API PumpsDocument4 pagesAnsi Vs API PumpsarcanicrahulNo ratings yet

- A Pi Monogram For Tank StorageDocument22 pagesA Pi Monogram For Tank StoragepadalakirankumarNo ratings yet

- How The Quest For Better Pumps Came To (Almost) Nothing - Part 1 - Reliabilityweb - A Culture of ReliabilityDocument7 pagesHow The Quest For Better Pumps Came To (Almost) Nothing - Part 1 - Reliabilityweb - A Culture of Reliabilityatorresh090675No ratings yet

- Fire Pump Systems Design and SpecificationDocument5 pagesFire Pump Systems Design and Specificationasdج asdNo ratings yet

- 2nd Edition - Seal FAQsDocument9 pages2nd Edition - Seal FAQsphantuan080213No ratings yet

- Objasnjenje - NACE, TEMA, NORSK, ASME VIII, ....Document4 pagesObjasnjenje - NACE, TEMA, NORSK, ASME VIII, ....Nebojsa MirkovicNo ratings yet

- Aes Api682 01Document9 pagesAes Api682 01meghanahariNo ratings yet

- Pump Care ManualDocument3 pagesPump Care ManualGerencia Rigar Colombia SASNo ratings yet

- Comparación Entre Bombas API y ASMEDocument2 pagesComparación Entre Bombas API y ASMEFranklin Santiago Suclla Podesta100% (1)

- RESP003V Vert Centrifugal Pumps 4 WaterDocument36 pagesRESP003V Vert Centrifugal Pumps 4 WaterArmin MnNo ratings yet

- Resp73h 97Document31 pagesResp73h 97Jose HerreraNo ratings yet

- Liquid Ring CompressorDocument24 pagesLiquid Ring CompressorAnonymous zejWt17No ratings yet

- Canned Motor Pumps in Refinery PDFDocument2 pagesCanned Motor Pumps in Refinery PDFthawdarNo ratings yet

- Ansi Api?: Which Process Pump Is Right For Your Application?Document6 pagesAnsi Api?: Which Process Pump Is Right For Your Application?Anonymous u2FhhHVpmNo ratings yet

- Technical Paper - API 676 Compliance of Progressive Cavity Pumps - Delta P - Pumps & Systems BlogDocument5 pagesTechnical Paper - API 676 Compliance of Progressive Cavity Pumps - Delta P - Pumps & Systems BlognachiappanNo ratings yet

- What Is New in API 610 11th EdDocument6 pagesWhat Is New in API 610 11th EdAnonymous 1XHScfCINo ratings yet

- 006 API610 PumpsDocument110 pages006 API610 Pumpskaveh fadaeiNo ratings yet

- Advancements in Mechanical SealingDocument19 pagesAdvancements in Mechanical SealingZeeshan AnwarNo ratings yet

- 33KV GTP WbsebDocument13 pages33KV GTP Wbsebmaniking1No ratings yet

- New Microsoft Office Word DocumentDocument6 pagesNew Microsoft Office Word DocumentHosam ElgoharyNo ratings yet

- Analysis of Mechanical SystemDocument16 pagesAnalysis of Mechanical SystembigbangNo ratings yet

- VolvoDocument38 pagesVolvoMarculescu Nicolae CatalinNo ratings yet

- Short Wave DiathermyDocument2 pagesShort Wave DiathermyAkshat Singh100% (1)

- Ib Physics Ch11Document2 pagesIb Physics Ch11JoseManuelCuelloSantínNo ratings yet

- Apexi Installation Instruction Manual: S-AFC 2Document64 pagesApexi Installation Instruction Manual: S-AFC 2THMotorsports.netNo ratings yet

- Feyzin Oil Refinery DisasterDocument8 pagesFeyzin Oil Refinery DisasterDavid Alonso Cedano EchevarriaNo ratings yet

- Sir. Abdul-Kareem: Stereoisomerism - Geometric IsomerismDocument8 pagesSir. Abdul-Kareem: Stereoisomerism - Geometric IsomerismsaudNo ratings yet

- Ahu Transfer RoomDocument7 pagesAhu Transfer RoomCITACOM UTAMANo ratings yet

- Infineon ICE1PCS02 DS v01 02 enDocument18 pagesInfineon ICE1PCS02 DS v01 02 enZulfiqar AhmedNo ratings yet

- C-00 & Er 91april - May-2012Document39 pagesC-00 & Er 91april - May-2012John SandaNo ratings yet

- 2013 Tuli Kivi CatalogDocument34 pages2013 Tuli Kivi Catalogمحمدحنيدق محمد غنيمNo ratings yet

- Ship Shaft EarthingDocument12 pagesShip Shaft EarthingEdi LeeNo ratings yet

- CementDocument11 pagesCementHerdian NafiNo ratings yet

- Yonos 1Document20 pagesYonos 1Dim VatNo ratings yet

- Sales Training Slides - NetSure 501 AC0 (Actura Flex 48420)Document63 pagesSales Training Slides - NetSure 501 AC0 (Actura Flex 48420)chkimkimNo ratings yet

- Operation of Lime KlinDocument4 pagesOperation of Lime Klinhemendra499No ratings yet

- Test Procedure and Settings of RCCDocument5 pagesTest Procedure and Settings of RCCkundan kunalNo ratings yet

- Emergency Alternative Mode of Oxygen Generation: Confidential 1Document30 pagesEmergency Alternative Mode of Oxygen Generation: Confidential 1Mendoud SofianeNo ratings yet

- Your Guide To Hydraulic FracturingDocument1 pageYour Guide To Hydraulic FracturingMartin GriffinNo ratings yet

- Title - Study and Analysis of The Effects of Waves and Wind On Offshore Structures and Marine VesselsDocument5 pagesTitle - Study and Analysis of The Effects of Waves and Wind On Offshore Structures and Marine VesselsIszysax MediaNo ratings yet

- Hidraulika FESTO 2019 PDFDocument232 pagesHidraulika FESTO 2019 PDFKresimir Coric100% (1)

- Catalogo Unidad Condensadora YD360, 480, 600 AmericanaDocument19 pagesCatalogo Unidad Condensadora YD360, 480, 600 AmericanaCoordinador1 ServiciosNo ratings yet

- Baselec q1 QuestionsDocument5 pagesBaselec q1 QuestionsroiNo ratings yet

- Free Space OpticsDocument27 pagesFree Space Opticsapi-19937584No ratings yet

- LM 358 IC: Component DiscriptionDocument15 pagesLM 358 IC: Component DiscriptionLokesh RawatNo ratings yet