0% found this document useful (0 votes)

241 views12 pagesCase Study Worst Redo

The document provides troubleshooting steps for common issues with front load washers, including water leakage from various parts, door locking/unlocking problems, error codes, and detergent drawer issues. It also includes steps for dryer problems like lack of heating. The document contains detailed instructions on examining specific components and replacing parts if needed.

Uploaded by

dan themanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

0% found this document useful (0 votes)

241 views12 pagesCase Study Worst Redo

The document provides troubleshooting steps for common issues with front load washers, including water leakage from various parts, door locking/unlocking problems, error codes, and detergent drawer issues. It also includes steps for dryer problems like lack of heating. The document contains detailed instructions on examining specific components and replacing parts if needed.

Uploaded by

dan themanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

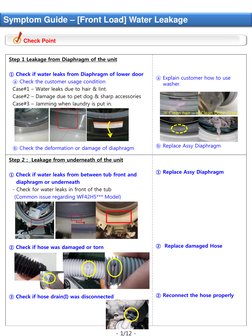

- Symptom Guide - Water Leakage: Provides steps to identify and fix water leakage issues in front-load units, covering areas like diaphragms and hoses.

- Symptom Guide - Door is not Locking/Unlocking: Explains how to address issues with doors not locking or unlocking by checking locks and electric connections.

- Symptom Guide - 1E (Pressure Sensor Error): Details procedures for troubleshooting the 1E error related to pressure sensors, including checking voltages and replacing sensors.

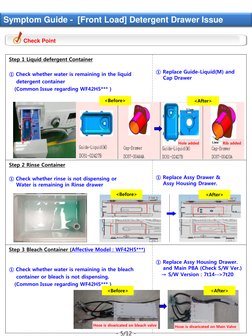

- Symptom Guide - Detergent Drawer Issue: Guides through resolving detergent drawer issues, focusing on checking and replacing specific parts.

- Symptom Guide - Mems Sensor Error (8E1/8E2): Describes steps to diagnose and fix Mems Sensor Errors 8E1 and 8E2, emphasizing wire harness checks.

- Symptom Guide - Unit is not Heating: Details the troubleshooting process for heating issues in dryers, including terminal and PBA checks.

- Symptom Guide - Unit is Weak Heating: Explains how to handle weak heating problems by verifying venting and drum temperature.

- Symptom Guide - Unit is not Spinning: Covers troubleshooting for spinning issues in dryers, including checking belts and motor thermals.

![- 7/12 -

Check Point

Symptom Guide - [Dryer] Unit is not Heating

Step 1 Check the Installation Condition

① Check the](https://screenshots.scribd.com/Scribd/252_100_85/336/398237755/7.jpeg)

![- 8/12 -

Check Point

Symptom Guide - [Dryer] Unit is not Heating

Step 2 Check the Main PBA

① Check the Main PBA

- Ch](https://screenshots.scribd.com/Scribd/252_100_85/336/398237755/8.jpeg)

![- 9/12 -

Check Point

Symptom Guide - [Dryer] Unit is not Heating

Step 3 Check the Assy Heater

① Check the Heater

-](https://screenshots.scribd.com/Scribd/252_100_85/336/398237755/9.jpeg)

![- 10/12 -

Check Point

Symptom Guide - [Dryer] Unit is weak heating

Step 1 Check the condition of dryer

※ Clogged drye](https://screenshots.scribd.com/Scribd/252_100_85/336/398237755/10.jpeg)