Professional Documents

Culture Documents

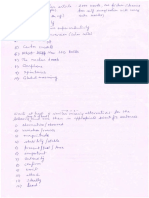

Ph.D.topics Dec.2018 Final PDF

Uploaded by

manojpatel24100 ratings0% found this document useful (0 votes)

40 views15 pagesOriginal Title

Ph.D.topics Dec.2018 final.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views15 pagesPh.D.topics Dec.2018 Final PDF

Uploaded by

manojpatel2410Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

Ph.

D Topics December 2018

Sr. Topic Eligibility Category No. of

No position

available/A

dvisor

1 Direct laser lithography for energy BTech/MTech/MSc TA

harvesting applications

Description: Strategic patterning of material is

reported to lead enhanced performance in

photodevices. In this project, various simple

and complex structures will be conceived and

fabricated for specific applications in solar

cells.

2 Plasmonic metamaterials for sensing BTech/MTech/MSc TA

applications

Description: (Metamaterials is an upcoming

research field with many exciting

applications. Arranging micro and 1

nanostructures in predefined manner may (Shobha

alter the interaction of electromagnetic field Shukla)

with the materials. Here, we will make these

plasmonic nanostructures, characterize and

use for sensing applications.

3 Water purification using graphene BTech/MTech/MSc TA

composite materials

Description: Nanoporous graphene has

emerged as wonder materials for water

purification. Synthesis of graphene based

composite materials will be followed by

extensive characterization. Finally, water

treatment will be performed using this

material system.

4 All oxide superconducting devices M. Sc. In Physics, TA

M.Tech in Materials

Superconductor (S) / Half Metal (HM) films Science

(where both S and HM are oxides) in various

multilayered stacked forms will be fabricated

into either planar junctions or pillar type

trilayer

junctions in order to study the S/HM

proximity effect. The possibility of

developing an all oxide

spin valves will also be investigated.

5 Novel routes towards Graphene M. Sc. In Physics, TA

Spintronics M.Tech in Materials

Science or Electrical

The traditional approach to Graphene engineering.

spintronics has been by spin injection through 1

ferromagnetic contacts. However, last year (Avradee

exfoliable 2D ferromagnets have been p Pal)

discovered,

and Graphene devices coupled to

ferromagnetic insulators have not been

studied in detail.

Detailed hall bar characterizations of

Graphene either stacked with a 2D

ferromagnet or with

ferromagnetic insulators grown over them

will be studied to ascertain the possibility of

spintronics in graphene through these routes.

6 Preparation of vertically aligned carbon BE/Btech/M.Tech in TA

nanostructures for energy and sensor Metallurgy, materials

applications science and

nanotechnology.

Description: Using atmospheric plasma

M.Sc/M.Tech. in

growth method, vertically aligned carbon

nanostructures will be prepared on large area physics/applied

flexible substrates for energy and coating physics/electronics.

applications. The study involves preparation

of devices for the energy applications

(supercapacitors, J. Electroanal. Chem.

Volume 803, 2017, Pages 30-39) and

miniature sensors for the detection of the

impurities (RSC Adv., 2016, 6, 100383).

Device preparation for supercapacitors and

sensors will be based on methods already

established in the lab.

7 Corrosion sensor based on the interdigital BE/Btech/M.Tech in TA 1

Metallurgy, materials (Smrutir

patterns

science and anjan

Description: Objective is to design a nanotechnology. Parida)

corrosion sensor using interdigital electrode M.Sc/M.Tech. in

(IDE) system. The wrok is require to use the physics/applied

thin film processing such as PVD and CVD. physics/electronics

A new electrochemical patterning will also be

used for the the sensor design. After the

preparation of the IDE, electrochemical

testing of sensor will be done to measure the

paraterer of the merits such as potential,

impedance and capacitance.

8 Electrochemical additive manufacturing BE/Btech/M.Tech in TA

Metallurgy, materials

Description: Objective is to design a system

science and

for the electrochemical additive

manufacturing system. Electrochemical nanotechnology.

additive manufacturing will be a miniature M.Sc/M.Tech. in

mobile electrochemical cell with drive control physics/applied

position and height. The understanding of the physics/electronics/chem

established mechanisms of the istry.

electrochemical processes

(deposition/dissolution) at the micro- and

millimeter electrode will be used to create

varios 3D form and patterns on the surface.

The forms will be used for various

applications such as sensors and

supercapacitors.

9 Pressure sensitive patterns from the nano- BE/BTech/M.Tech in TA

carbon and conductive polymers Materials science,

polymer science and

Description: The project aims to prepare engineering, chemical

smart pressure responsive patterns using engineering, polymer

carbon nanomaterials and conductive engineering and

polymers. The patterns will be created using nanotechnology

hydrogels and hollow spheres prepared using (polymer specialization).

carbon nanomaterials and conductive M.Sc/M.Tech. in

polymers. The responsiveness of these Chemistry/applied

surfaces to the pressure will be tested using a chemistry/polymer/rubb

dynamic pressure system. er and plastic

engineering.

10 Layered hybrid materials for B.Tech./ BE or M.Tech. TA

supercapacitors and membranes in any relevant

Engineering discipline,

Three-dimensional (3D) hybrid carbon or M.Sc. in Chemistry or

nanomaterials are of considerable interest due Physics. Candidate

to their potential of combining merits of both should have good

one-dimensional (1D) and two-dimensional analytical and

(2D) nanostructures. 3D hierarchical quantitative skills

structures comprised of graphene and carbon

nanotubes provide a large accessible surface

area, which can enable high energy storage

and better catalytic activity making them ideal

for high-performance supercapacitors and

membranes. The organization of constituent

graphene and carbon nanotubes in hybrid

materials depends on the interplay of various

molecular level interactions, and determines

the properties and performance of hybrid

materials. This project will involve the use of

self-assembly based methods for fabrication

of hybrid nanostructures and molecular-level

computer simulations for predicting

interactions in hybrids.

11 Design and analysis of bio-inspired B.Tech./ BE or M.Tech. TA 1 (Ajay

membranes for ultra-pure separations in any relevant Panwar)

Engineering discipline,

There exist several examples in biology of

or M.Sc. in Chemistry or

ultra-fine pores in membranes which can

Physics. Candidate

purify or separate analytes with extreme

precision. Synthetic membranes composed of should have good

nanomaterials such as carbon nanotubes or analytical and

graphene, and functional polymers can be quantitative skills.

fabricated which mimic the essential

properties of biological membranes to achieve

analyte separation for industrial and

technological applications. This project will

involve the use of molecular-level computer

simulations to design and simulate analyte

separation through ultra-fine pore structures.

Simulation and analysis would help in

estimating transport coefficients and

optimizing device design for ultra-fast and

ultra-pure separations.

12 Polymer Nanocomposites for Piezoelectric M.Tech/M.Sc with TA

Applications Polymer Science &

Engineering/Chemical

It is observed that few polymeric materials,

Engineering/ Mechanical

viz. polyvinylydene fluoride (PVDF),

polyvinyl alcohol (PVA) exhibit piezoelectric Engineering/Physics/Ch

behaviour. This is due to the development of a emistry background is

specific crystal structure associated with desirable.

piezoelectric behaviour. Moreover, various

nano-fillers (carbon nano tubes, graphene

oxide) also induce that specific crystal

structure, which shows piezoelectric

behaviour. Further, orientation during

processing also leads to the metastable beta

phase for PVDF, which is responsible for the

piezoelectric behaviour. The scope of the

research project is to develop PVDF and PVA

based nanocomposites, which show enhanced

piezoelectric properties. In this context,

processing-structure-property relationship

studies will be investigated

13 Films and Fibers of Graphene and Carbon M.Tech/M.Sc with TA 1 (Arup

nanotubes incorporated Polymer Polymer Science & Bhattach

Nanocomposites Engineering/Chemical arya)

Engineering/ Mechanical

It is known that orientation during processing Engineering/Physics/Ch

leads to the alignment of the nano-materials emistry background is

along with polymer chains. Moreover, a desirable

higher extent of orientation can be achieved if

the interfacial interaction between the

polymer phase and the nano-material can be

judiciously tailored. The scope of the project

is to develop hybrid nano-filler based polymer

composite fiber or film for various industrial

applications. In this context, processing-

dispersion-interfacial interaction-

crystallization behaviour-property

relationship studies will be investigated.

14 Localized thermomechanical properties in Candidate with M.Sc./ TA

confined polymer nanocomposites: M.Tech with Physics/

Chemical Engineering/

Understanding of mechano-rheological

Chemistry/ Polymer

properties of polymer nanocomposite is

Science & Engineering/

expected to advance designing of

Materials Science &

mechanically improved polymer

Engineering/ Mechanical

nanocomposites (PNC) with optimum particle

Engineering background

loading and desired functionalities. On the

is suitable.

question of confinement and glass transitions,

PNC is comparable to a polymer thin film,

where the interparticle distance in the

nanocomposite could be comparable to the

film thickness dictating the extent of

confinement and reportedly shown variation

in glass transition temperature (Tg). Beyond

this simplistic picture it has been found that

confinement (from film thickness) in polymer

thin film enhances nanoparticle dispersion in

polymer matrix. The enhanced dispersion

takes place without altering the polymer–

particle interactions, whereas, nanoparticles in

a bulk polymer matrix are known to alter the

entanglement and stress relaxation in

polymers. How and why the viscous/

viscoelastic properties in PNC films distinct 1

compare to polymer film are is an interesting (Mithun

area to explore and signify further questions Chowdh

in PNC films should be addressed in a way ury)

that exploits nanoparticle-polymer interaction

in a localized and controllable manner. In the

proposed work by spatially incorporating

polymers, nanoparticles and PNC films in a

multilayer geometry, viscous flow at the

suitable polymer-nanoparticle or polymer-

PNC interface will be probed. In-situ hot-

stage optical and atomic force microscopy

will be employed to primarily probe

topographical features and their relaxation in

PNC films, whereas, at the advanced stage X-

ray reflectivity and/ or dielectric spectroscopy

could be used. For X-Ray studies appropriate

Synchrotron sources (around the world) will

be used upon requirement and advancement

of the project.

15 Fundamental studies on controlling Candidate with M.Sc./ TA

orientation and crystallinity in semi- M.Tech with Physics/

crystalline functional polymers: Chemical Engineering/

Chemistry/ Polymer

The central idea to enhance the performance

Science & Engineering

of organic electronic devices is to tune the

background is suitable.

way excitons and electrons (holes) travel

within the active conjugated material by

controlling its morphology, crystallinity,

aggregation, and domain purity. Many studies

aimed to enhance the long-range ordering

(crystallinity) in semi-crystalline conjugated

polymers, whereas, role of short-range

ordering primarily by pi-stacking induced

aggregation also remain beneficial for exciton

diffusion and carrier mobility. Especially the

interlamellar region and their role on

structure-property relationship is yet to be

fully understood. The proposed research

project will particularly probe mostly-

amorphous (less-crystalline) yet high

performance conjugated polymeric materials

and exploit its ability to reorganize into

relatively ordered domains via controlled

inclusion of its small-molecule (or short

chain) analogues utilizing controlled blending

and annealing. The process will be extended

with acceptor molecules and small molecules

having complexation abilities by charge

transfer. Beyond conjugated polymers, at the

advanced level the project will also

investigate controlling orientation and

crystallinity in ferroelectric/ piezoelectric

polymers, such as PVDF. Upon satisfactory

progress and understanding of structural

properties, experiments could be extended

towards characterizing optoelectronic and

transport properties, if needed, seeking

appropriate collaborations within the institute.

Microscopic (optical and atomic force),

Spectroscopic (UV-VIS and Fluorescence)

and X-ray diffraction studies will be primarily

used. Processing of semi-crystalline polymers

will be performed through precision hot-stage

and custom-built solvent annealing stage. For

X-Ray studies appropriate Synchrotron

sources (around the world) will be used upon

requirement and advancement of the project.

16 Physico-chemical phenomena during Metallurgical TA/RA 1 (N N

induration of single hematite pellet engineering or chemical Viswanat

engineering. Should han)

Proportion of pellets in lieu of iron ore have interest in

sinter is being is thermodynamics,

increasing in iron making processes as more chemical reaction

spherical uniform size kinetics and transport

pellets gives better permeability. On the phenomena

other hand, with decreasing grade of iron ore,

liberation and benefeciation

calls for finer size, which again favour

pelletization process. Though

there are numerous studies to understand

induration of hematite pellets mixed with

carbon, these studies

primary empirical in nature without seriously

going in the processes

occuring with in the pellets. Recently such

work has been carried out for magnetite

pellets using optical dilatometer. Along the

same

lines, this project proposes to look at the

physico-chemical phenomena,

which includes, reaction of carbon particles in

the hematite pellet,

sintering hematite mixed with fluxes and

associated heat and mass transfer. The work

will be a combination of experiments and

modeling.

17 Analysing the role of defects and dopants MSc/ MTech TA 1

in modulating the magnetic and electronic (Amrita

properties of Heusler compounds Bhattach

arya)

18 Encapsulants for Photovoltaic modules M.Tech or M.Sc. TA/RA

Background in polymers

The aim of the project is to evaluate the and Hands on experience

various types of encapsulants and back sheets in chemical synthesis/

use for protecting the solar cells in a PV characterization is

module. The evaluation will require detailed desired.

mechanical, optical and chemical

characterization of the polymeric

encapsulants and back sheets.

1

(Sudhans

hu

Mallick)

19 Perovskite based solar cells :M.Tech or M.Sc. TA/RA

Hands on experience in

The aim of the project is to develop large area chemical synthesis/

perovskite based solar cells and detailed characterization is

characterization to improve the cell lifetime desired

and efficiency.

20 Thermo-physical properties of molten Metallurgical engg. / TA

oxides and halides - modelling at the nano Ceramics / Chemistry

and sub-nano scale (M.Sc.) - preferably with

specialisation in physical

Understanding the high temperature or inorganic chemistry /

properties (like viscosity and interfacial Chemical engg.. (in

tension) of oxide and halide melts, in terms of

decreasing order of

ordering and ionic arrangements. Suitable

preference)

modelling approach would have to be

developed to simulate the physical properties,

followed by validation with experimentally

measured values. 1

(Somnat

h Basu)

21 Fusion and flow characteristics of FeO-rich Metallurgical / Ceramics TA

oxide melts / Chemical /

Mechanical engineering.

This project would focus primarily on

incipient melts encountered during metal Applicants with M.Sc.

oxide reduction, typical examples being iron Chemistry background

oxide reduction in a BF or COREX. The work are also welcome,

would involve estimation of intermediate provided they have done

compositions, experimental determination of M.Tech. in

liquidus and viscosity measurement of the ME&MS/equivalent,

incipient oxide melts over relevant

preferably with

temperature range(s). The results would then

specialisation in Process

be used to develop a mathematical model to

predict the sequence of melt formation, the Metallurgy (in

local compositions (as opposed to the gross decreasing order of

reported composition) and the flow preference):

characteristics of the different liquid streams.

It is expected that this would eventually

provide an insight into the effect of these

liquid steams on the kinetics of the gas-solid

reactions that occur during pyrometallurgical

extraction of several metals.

22 Role of thermal vibrations on phase BTech/MTech/MSc TA 1 (T R S

stability/transitions Prasanna

)

Predicting the stability of any material is an

area of current research in materials science.

This topic involves the first principles (ab

initio)calculations of the free energy of

different phases at different temperatures and

pressures to determine the phase stability. In

particular, the role of thermal vibrations on

phase stability will be carefully studied. This

is expected to lead to better understanding of

phase stability and phase transitions. The

phase transition temperatures and pressures

will be compared with experimental data.

23 Fabrication of flexible and stretchable TA

electronic devices

1 (Dipti

Gupta)

24 Fabrication of flexible pressure and strain TA

sensors for biomedical

applications

TAP

1 Mopping oil with graphene based BTech/MTech/MSc TAP

composite sponge

RD/0118

Description: Superhydrophobic graphene-

-

framework is expected to be an excellent 1 (Shobha

DST0000 Shukla)

candidate for oil adsorbent. Oxidized

-010

graphene frame-work is hydrophilic in

nature and can be used directly for

removing organic contaminants from

water. Here we plan to reduce and convert

the framework from hydrophilic to

superhydrophobic for applications in

organic materials removal. The ultimate

aim of this project will be to focus on

development of processes and devices that

can be implemented in coastal areas after

extensive characterization and studies.

2 Silver Pastes for solar PV and other M.Tech. Materials TAP

industrial applications science or

Nanotechnology, M.Sc.

The fellowship will be 1.5 times the regular chemistry (organic). 1 (Parag

TA but there is lack of clarity on whether Candidates with Bhargava)

tuition fee would have to be paid by the background/experience

student or not. The candidate will be in materials

required to do three courses in Tata Centre characterization and

in addition to prescribed regular courses. interested in industrial

research or product

development would be

preferred.

3 Superconducting proximity effect studies M.Tech Materials TAP

with ferromagnetic insulators. Science, M. Sc. In (seed

Physics, some grant)

The project involves ultra-high vacuum 1

experience in vacuum

(UHV) sputter growth of thin films of (Avradeep

systems preferable.

superconducting Nb, Al and NbN and Pal)

ferromagnetic insulating GdN, and

subsequently multi-layers of these

materials in various combinations

depending on the physics to be probed.

Standard thin films characterization

techniques like AFM, Low Angle XRD,

TEM will be employed to study quality of

films and multilayers. Low temperature

(4K) Current in plane measurements will

be then used to study the proximity effect.

The initial part of the project will involve

participation in setting up an UHV sputter

deposition system.

4 Development of Passive daytime BE/BTech/M.Tech in TAP

radiative cooling (PDRC) coatings Materials science,

polymer science and

Description: The project aims to prepare engineering, chemical 1

smart responsive nanomaterials using engineering, polymer (Smrutira

emulsion polymerization methods already engineering and njan

Parida)

established in the lab (Polymer 118, 2017, nanotechnology

116-126). These materials and method will (polymer specialization).

be used to create Passive daytime radiative M.Sc/M.Tech. in

cooling (PDRC) coatings. The Chemistry/applied

responsiveness of these smart materials in chemistry/polymer/rubb

the coating to temperature will be tested. er and plastic

The temperature sensitivity will be tested engineering

by exposing the coating to the sun and

measuring solar reflectance index (SRI)

using the instrument available in the lab.

5 Development of high performance M Tech/B.Tech/MSc in TAP

hybrid supercapacitors based on Materials

The

nanostructure carbon and core/shell Si Science/Engineering project is

nanowires (and associated areas) sponsored

and/or physics/chemistry by the

Description: The project will focus on

Departme 1

development of the nanostructure carbon

nt of (Smrutira

and core/shell Si nanowires (NW) by CVD

Science njan

method, which involve optimization of the and Parida)

process parameters to tune the structure Technolog

(length, thickness of core/shell) of the y (DST),

nanowires. The surface of the NWs will be Govt. of

modified by conformal deposition of metal India, and

oxide and conducting polymer coatings, to the

prepare hybrid device. These electrodes scholarshi

will be used to assemble supercapacitors of p will be

various symmetric and asymmetric as per the

regular

configurations (RSC Adv., 2016, 6,

SRF or

100467). After studying the individual

JRF DST

devices, the supercapattery stacks will be norms (as

designed based on the output voltage and applicable

power requirements. . ). The

IITB

project

code is:

RD/0117-

DST0000-

029.

6 Identifying materials with improved MSc/ MTech TAP

properties by combining advance

(Seed

machine learning approaches with first

1 (Amrita

principles based methods grant) Bhattacha

rya)

7 Role of processing conditions of Candidate with M.Sc./ TAP

polymers on the mechano-rheological M.Tech with Physics/ (Seed

properties of confined glassy thin films: Chemical Engineering/ Grant)

Chemistry/ Polymer 1 (Mithun

In a simple picture, compared to bulk Chowdhu

Science & Engineering/

polymers, sufficiently thin polymer films ry)

Materials Science &

are expected to have a lower-density due to

Engineering/ Mechanical

poor packing, since chains do not

Engineering background

significantly interpenetrate each other due

is suitable.

to high entropy losses. This may

correspond to a reduction of the glass

transition temperature (Tg) of the polymer

film, which in turn, can be related to the

lower density of a polymer film deposited

on solid substrate. On the other hand,

extent of adsorption of polymer chains at

the substrate interface during annealing

above the Tg of polymer dictates the Tg

deviation of thin polymer films, where a

poorly packed, high free volume, less dense

adsorbed layer of restricted mobility is

expected at the substrate. At this point it is

not clear how the Tg of entire film

including the surface is perturbed by the

interfacial adsorbed layer, and how the

extent of non-equilibrium properties of

polymer chains is contributing to the

material properties (density, modulus) of

the entire film. Primarily, using techniques

like atomic force microscopy, optical

microscopy, ellipsometry and/or X-ray

reflectivity the adsorbed layer of

polystyrene will be characterized. To probe

the non-equilibrium properties related to

viscoelasticity and density in the entire

film, hole growth and adsorption approach

will be applied, those will be further

characterized by atomic force and optical

microscopy. At the advanced stage of the

project relaxation dynamics can be

followed using dielectric spectroscopy.

8 Flux-assisted inclusion engineering Metallurgical / TAP 1

Mechanical / (Somnath

DST Basu)

This project would focus on the influence Chemical engineering(i (approve

of welding flux composition on the n decreasing order of d)

chemistry and morphology of inclusions preference):

generated in the melt pool during high heat

input (and deep pool) welding process (e.g.

SAW of thick plates). It would further

investigate the effect the inclusions on the

morphology and orientation of the grains

formed in the weld metal during cooling,

and explore if specific inclusions can be

used to "engineer" the microstructure of the

welded joint.

The work would be part of a BRICS STI

framework project, proposed in

collaboration with Northeastern University

(China) and University of Pretoria (South

Africa), which has just been approved by

DST. One JRF position would be supported

for a period of three years. Portions of the

work would be carried out at the partner

universities and DST would support the

travel expenses of the research scholar

(within the terms of the grant). The prime

focus of the work at IITB will be to

investigate the flow behaviour and

interfacial properties of molten fluxes, and

their interaction(s) with inclusions as well

as the molten steel. The experimental

results (from all three partner institutions)

would then be collated and used for

developing a model to explain the

formation and growth of the inclusions, as

well as it influence on evolution of the

weld metal microstructure.

9. Omni-Directional Micro-TIG Cladding Metallurgical / TAP 1 (K

for Hybrid Layered Manufacturing Mechanical Engineering Narasimh

(16DSTI an)

(HLM)

MP001

(MHRD

Metal Inert Gas (MIG) and Tungsten

IMPRIN

Inert Gas (TIG) are the two types of arc

T project

cladding processes. Omni-directionality

on

refers to the invariance of the geometry and

quality of the bead with the path of the Multi-

cladding torch. This is an essential Station

requirement in HLM. Both energy and Multi-

mass flow from the same source in MIG Axis

whereas they are from two different

sources in TIG. Therefore, MIG inherently HLM)

has omni-directionality but suffers poor

bead quality due to the lack of independent

control of these flows and vice-versa in

TIG. As the quality of bead is better in

TIG, we wish to develop a special

mechanismfor varyingthe orientation of

wire feeding to achieve omni-

directionality.

Traditional arc cladding

usefillersstarting from 1.2mm and hence

produce very large beads and involve

extensive heat. Therefore, we propose to

develop a micro-TIG which will use wires

as thin as 0.2mm.

After the development of omni-

directional micro-TIG cladding system, a

systematic set of experiments will be

carried out to study the effect of various

parameters on the bead quality,

microstructure and mechanical properties,

which in turn will be used to arrive at

optimum process parameters. Finally, a few

case studies of complex geometries and

exotic materials will be carried out using

the developed omni-directional micro-TIG

HLM system.

10 Development of Low Corrosion Rate B.Tech metallurgy / TAP 1

Completion Fluid Formulation for High corrosion engg / (Smrutira

Pressure High Temperature Oil and Gas chemical engg. MTech njan

Parida)

Wells in metallurgy / corrosion

engg / chemical engg /

*Description:* The project will focus on

Materials Science /

development of a low corrosion completion

Materials engg. M.Sc in

fluid for the high pressure and high

chemistry / chemical

temperature gal well. Drilling is carried out

technology / applied

using drilling fluids or drilling muds to

chemistry

remove the rock cuttings and keep the hole

stabilized. Once target depth is attained, the

well completion process starts to get oil

and gas production from the well.

Completion fluids are specially designed to

aid in completion operations. The most

commonly used completion fluids are clear

brines. These brines can be composed of

one type of dissolved salt (single salt), or

mixture of two more inorganic/organic

salts that are compatible with one another

and do not contain any suspended solid

mass. Oil wells have temperature beyond

150°C and may reach as high as 250°C. In

this condition corrosion happens in the

brine used. So the objective is to design a

non-corrosive, clear and environmental

friendly aqueous completion fluid and test

its corrosiveness and stability in high

temperature and pressure.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Braun MR30 Hand BlenderDocument2 pagesBraun MR30 Hand BlenderHana Bernard100% (1)

- DD 3600 3500 3000 Parts CatalogDocument46 pagesDD 3600 3500 3000 Parts CatalogAndres Fdo Mora D100% (2)

- TEFL Entrance ExamDocument3 pagesTEFL Entrance ExammerekNo ratings yet

- MM658 HandoutDocument1 pageMM658 Handoutmanojpatel2410No ratings yet

- Advtg SG 2019 2020 PDFDocument6 pagesAdvtg SG 2019 2020 PDFmanojpatel2410No ratings yet

- MM655 Spring 2019: Homework 1: A B C DDocument2 pagesMM655 Spring 2019: Homework 1: A B C Dmanojpatel2410No ratings yet

- Ph.D.topics Dec.2018 Final PDFDocument15 pagesPh.D.topics Dec.2018 Final PDFmanojpatel2410No ratings yet

- General Tips For Filling Application FormDocument3 pagesGeneral Tips For Filling Application Formmanojpatel2410No ratings yet

- S G India: Central Recruitment & Promotion Department Corporate Centre: - D-Block, Near CGO COMPLEX, New DelhiDocument6 pagesS G India: Central Recruitment & Promotion Department Corporate Centre: - D-Block, Near CGO COMPLEX, New Delhimanojpatel2410No ratings yet

- S G India: Central Recruitment & Promotion Departmentapplication Format For Recruitment (One Form For One Post Only)Document3 pagesS G India: Central Recruitment & Promotion Departmentapplication Format For Recruitment (One Form For One Post Only)manojpatel2410No ratings yet

- Massabo-Richiami FratturaDocument53 pagesMassabo-Richiami FratturaTan ChingNo ratings yet

- Plot 40Document17 pagesPlot 40manojpatel2410No ratings yet

- Nickel-Based SuperalloysDocument32 pagesNickel-Based Superalloysmanojpatel2410No ratings yet

- Application For Guest Accommodation in Hostel: Co-Ordinating Warden To, The WardenDocument1 pageApplication For Guest Accommodation in Hostel: Co-Ordinating Warden To, The Wardenmanojpatel2410No ratings yet

- Wester Ga ArdsDocument1 pageWester Ga Ardsmanojpatel2410No ratings yet

- Ph.D.topics Dec.2018 Final PDFDocument15 pagesPh.D.topics Dec.2018 Final PDFmanojpatel2410No ratings yet

- Lec6 PDFDocument17 pagesLec6 PDFAbhishek AroraNo ratings yet

- Lec 1Document17 pagesLec 1Abhishek AroraNo ratings yet

- Fluid Theory PDFDocument31 pagesFluid Theory PDFmanojpatel2410No ratings yet

- Tut22 GuideDocument11 pagesTut22 Guidemanojpatel2410No ratings yet

- Tut22 PDFDocument34 pagesTut22 PDFrudra042No ratings yet

- 06 AIST Trans FlowDefects Pp127-143 July06 LowRes PostDocument16 pages06 AIST Trans FlowDefects Pp127-143 July06 LowRes Postmanojpatel2410No ratings yet

- Brochure PHD 201809 MarchDocument53 pagesBrochure PHD 201809 Marchmanojpatel2410No ratings yet

- State Bank of India Iit Pay TransactionDocument1 pageState Bank of India Iit Pay Transactionmanojpatel2410No ratings yet

- Project Proposal DraftDocument1 pageProject Proposal DraftCarl Axel M. FajardoNo ratings yet

- Geography Paper 1Document7 pagesGeography Paper 1Sudhir TewatiaNo ratings yet

- Glossary of Terms 2nd PartDocument2 pagesGlossary of Terms 2nd Part2DJoyce D.N CapacieteNo ratings yet

- Memo ALS Literacy MappingDocument4 pagesMemo ALS Literacy MappingJEPH BACULINANo ratings yet

- FO - Course Transition Info - Acknowledgement - SIT50422 - Dip Hospitality Management - V1Document2 pagesFO - Course Transition Info - Acknowledgement - SIT50422 - Dip Hospitality Management - V1nitesh.kc06No ratings yet

- Test Cases: Project Name: Virtual ClassroomDocument5 pagesTest Cases: Project Name: Virtual ClassroomTina HernandezNo ratings yet

- QLD Plan Draft Review Raw DataDocument242 pagesQLD Plan Draft Review Raw DataRohit Jain100% (1)

- Preliminary Voters ListDocument86 pagesPreliminary Voters Listمحمد منيب عبادNo ratings yet

- 2 Beats Per Measure 3 Beats Per Measure 4 Beats Per MeasureDocument24 pages2 Beats Per Measure 3 Beats Per Measure 4 Beats Per MeasureArockiya StephenrajNo ratings yet

- Van Daley - Leadership ResumeDocument1 pageVan Daley - Leadership Resumeapi-352146181No ratings yet

- MELASMA (Ardy, Kintan, Fransisca)Document20 pagesMELASMA (Ardy, Kintan, Fransisca)Andi Firman MubarakNo ratings yet

- Lecture 08Document32 pagesLecture 08SusovanNo ratings yet

- Advancement of SGDocument2 pagesAdvancement of SGkailasasundaramNo ratings yet

- AC AMMETER / Moving Iron: Model AECDocument33 pagesAC AMMETER / Moving Iron: Model AECRoonar Aponte NoaNo ratings yet

- Unit 4 Transistor Frequency ResponseDocument6 pagesUnit 4 Transistor Frequency ResponseShaina MabborangNo ratings yet

- 7273X 47 ITOW Mozart PDFDocument3 pages7273X 47 ITOW Mozart PDFAdrian KranjcevicNo ratings yet

- UV-Visible Systems - Operational Qualification - Col23 PDFDocument10 pagesUV-Visible Systems - Operational Qualification - Col23 PDFIsabelle PlourdeNo ratings yet

- Combat Storm - Shipping ContainerDocument6 pagesCombat Storm - Shipping ContainermoiNo ratings yet

- Hotel Voucher: Itinerary ID Hotel Santika Taman Mini Indonesia IndahDocument2 pagesHotel Voucher: Itinerary ID Hotel Santika Taman Mini Indonesia IndahSyukron PribadiNo ratings yet

- Components of Vectors Prepared By: Victor Rea OribeDocument17 pagesComponents of Vectors Prepared By: Victor Rea OribeGerone Tolentino AtienzaNo ratings yet

- Intermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageDocument11 pagesIntermediate Programming (Java) 1: Course Title: Getting Started With Java LanguageRickCy Perucho PccbsitNo ratings yet

- U04 Fxs of Humeral ShaftDocument88 pagesU04 Fxs of Humeral Shaftadrian_mogosNo ratings yet

- VRF Mv6R: Heat Recovery Outdoor UnitsDocument10 pagesVRF Mv6R: Heat Recovery Outdoor UnitsTony NguyenNo ratings yet

- C305 - QTO Workshop PDFDocument90 pagesC305 - QTO Workshop PDFJason SecretNo ratings yet

- Accounting For A Service CompanyDocument9 pagesAccounting For A Service CompanyAnnie RapanutNo ratings yet

- SM-G900F Esquematico Completo Anibal Garcia IrepairDocument2 pagesSM-G900F Esquematico Completo Anibal Garcia Irepairfix marketNo ratings yet