Professional Documents

Culture Documents

Sprue Bushing JIS B Type 635-636 PDF

Sprue Bushing JIS B Type 635-636 PDF

Uploaded by

NazriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sprue Bushing JIS B Type 635-636 PDF

Sprue Bushing JIS B Type 635-636 PDF

Uploaded by

NazriCopyright:

Available Formats

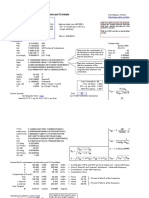

Electroforming Sprue Bushings

−JIS B type −

Details of electroforming sprue bushings P.608

−Straight type− ■Volume discount rate P.35

Catalog No.

Price Quantity 1∼4 5∼9 10∼14 15∼

Inside(approx. 0.5mm) 55∼60HRC Rate ー 5% 10% 15%

Body Nickel alloy

SBJN Outside 38∼42HRC

Head 1045 − D $ Unit price for 1∼4

SBJN SBJNT

L 10 12 13 16 20 25 10 12 13 16 20 25

3

0 ∼ 20.0 65.70 74.70 74.70 82.80 99.00 108.00 74.70 83.70 83.70 91.80 108.00 117.00

5 φ4×6

20.1∼ 40.0 71.10 81.90 81.90 90.90 103.50 115.20 80.10 90.90 90.90 99.90 112.50 124.20

R≦0.3 40.1∼ 60.0 80.10 92.70 92.70 101.70 115.20 131.40 89.10 101.70 101.70 110.70 124.20 140.40

A°±30′

1.6

60.1∼ 80.0 94.50 108.00 108.00 117.00 131.40 151.20 103.50 117.00 117.00 126.00 140.40 160.20

P ±0.1

80.1∼100.0 114.30 127.80 127.80 136.80 151.20 175.50 123.30 136.80 136.80 145.80 160.20 184.50

α(*1)

1.6

35 −0.1

100.1∼120.0 138.60 152.10 152.10 161.10 175.50 202.50 147.60 161.10 161.10 170.10 184.50 211.50

0

0.2

120.1∼140.0 165.60 179.10 179.10 188.10 202.50 229.50 174.60 188.10 188.10 197.10 211.50 238.50

SR 140.1∼160.0 201.60 234.00 261.00 210.60 243.00 270.00

160.1∼180.0 237.60 270.00 297.00 246.60 279.00 306.00

5 Dh6 180.1∼200.0 273.60 306.00 333.00 282.60 315.00 342.00

+0.1 − − − − − −

H ±0.1 L 0 0 200.1∼220.0 346.50 373.50 355.50 382.50

40 −0.1 220.1∼240.0 − −

391.50 418.50 400.50 427.50

240.1∼260.0 441.00 468.00 450.00 477.00

−Tapered type− Catalog No. Catalog

No. H L SR P A V G (AIW・AHW…etc.)

Alteration SBJNT

16 20 55.0 SR11 P3.5 A2 V11.0 G10 CTQ3

Inside(approx. 0.5mm) 55∼60HRC

Body Nickel alloy

SBJNT Outside 38∼42HRC

Head 1045 Alterations Code AIW AHW AXW ATW AJW AKW AEW ALW APW AUW ACW Spec.

Shape A ¡W dimension choices

3 (Trapezoid) 10゜ Spec. W t

φ4×6 R0.5 3 2.5

5

4 3

30′

$/1Code 10.00 10.00 18.00 20.00 20.00 20.00 20.00 15.00 15.00 15.00 15.00

W

5 3.5

−0

A°±30′

G°

6 4

P ±0.1

1.6 Combination with ZC not available.

AIW10 KC position 8 5.5

α(*1)

t Combination with RC not available.

35 −0.1

1.6

Dowel hole position(When KC code is used) For A 10 7

0

V−0.02

0.2 (T/J/K/E/L/P/U/C)W:(α−0.4) ≧W

0

Alterations Code BIR BHR BXR BTR BJR BKR BER BLR BPR BUR BCR Spec.

SR

R≦0.3 r

¡R dimension choices

Shape B

5 1

+0.1

0

D h6 (Semicircle) Spec. 1.25

H ±0.1 L 0 0 1.5

40 −0.1 1.75

R $/1Code 10.00 10.00 18.00 20.00 20.00 20.00 20.00 15.00 15.00 15.00 15.00 2

2.25

Combination with ZC not available. 2.5

BXR2 KC position 3

Combination with RC not available.

Dowel hole position(When KC code is used) For B 3.5

Catalog

No. L V G° (T/J/K/E/L/P/U/C)R:(α−0.4) ≧2×R 4

D h6 H SR P A°

Type D 0.1mm increments 0.1mm increments 1°increments Alterations Code CIQ CHQ CXQ CTQ CJQ CKQ CEQ CLQ CPQ CUQ CCQ Spec.

10 0 10 Shape C Q dimension choices

¡

−0.009 0 (Arc+Tangent) Spec. 2

5° 2.5

−Straight type− 10.5 2 3

12 12 0∼140.0

SBJN(Nickel alloy) 2.5 $/1Code 10.00 10.00 18.00 20.00 20.00 20.00 20.00 15.00 15.00 15.00 15.00 3.5

20 11 1 4

0 3 D>V≧α+2 1∼10 Combination with ZC not available.

13 −0.011 13 12 Q CTQ5 KC position 5

Combination with RC not available. 6

25 3.5 2 Available Available Dowel hole position(When KC code is used) For C(T/J/K/E/L/P/U/C)

Q:(α−0.4) ≧Q×1.09

13 for SBJNT for SBJNT 8

16 16 0∼200.0 4

−Tapered type− 3 only only

30 16

SBJNT(Nickel alloy) 4.5 Alterations Code Spec. $/1 Code Alterations Code Spec. $/1 Code

20 20 20 Changes the range of G tolerance.

0 5 G

−0.013 0∼260.0 21 Adds a key flat on 2.00 G 0 G 0

KC 0 the head. GKC −30 ’ −15 ’

18.00

25 25 17.5 −0.1 Available for tapered type whenR≦15 and(L−R)≧10

R Combination with ZC not available.

(*1)The value of α is set in accordance Working limits Conversion Chart of Trigonometric Functions P.1117 Changes full length tolerance

with L dimension. SBJN

¡ SBJNT

¡ Adds two parallel flats L+0.1 L 0

A A WKC 4.00 LKC 0 −0.02 6.00

D−α≧2(Calculation of α value)α=P+2{L+(U)+3}tan 2 V−α≧2 (Calculation of α value) α=P+2{L+(U)+H−3}tan 2 0

35 −0.1 on the head. L dimension can be designated at 0.01mm increments when LKC is used.

U:with ZC alteration U:with ZC alteration L

Combination with ZC not available.

D−V ※0.25 is a value that takes

L− ≧3(Calculation

r of value)

r r= The step radius R is processed in the tip bore to prevent the

2tan(G−0.25) G tolerance into account. R0.5

Undercut machining

S,T,U:0.1mm increments connection between the sprue and the runner from breaking when

R0.5 releasing from the mold.

Catalog

No. H L SR P A V G S≧α+2 The step radius R is cut with

Order α+2≦T≦D(V−2UtanG)10.00 Dimension selection of step radius R an inner R cutter.

ZC

T ±0.05

S ±0.05

Example 1 2

α

Surface roughness and position

SBJN

16 20 55.0 SR11 P3.5 A2 1.5≦U≦5 RC 8.00

Specification Lmax.≧L+U Step radius R Available for α≧5 precision are not provided.

SBJNT

16 20 55.0 SR11 P3.5 A2 V12.0 G5 L U±0.1 Straight type D−α−(2×RC)>2

ZC−S3.5−T4.0−U2.0

Tapered type V−α− (2×RC) >2

Production 8 Days Express B 6 Days $5.00/piece P.36 Combination with shapes A・B・C not available.

Combination with ZC not available.

Time

Express delivery charge for an order of three or more of an identical size will be a flat rate of $13.50.

635 Phone 1-800-681-7475 Fax 1-800-681-7402

636

(1-847-843-9105) www.misumiusa.com (1-847-843-9107)

You might also like

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Bav99 A7wDocument3 pagesBav99 A7wJosé Miguel Barbosa Hernández67% (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- NAD 3020 ServiceManualDocument6 pagesNAD 3020 ServiceManualmartin-d-johnsonNo ratings yet

- Verilog Styles For Synthesis of Digital SystemsDocument4 pagesVerilog Styles For Synthesis of Digital Systemscooljams670% (1)

- 2.describe Mould Parts and ConstructionDocument49 pages2.describe Mould Parts and ConstructionNazri100% (4)

- Shock Accelerometer Calibration K9525C Datasheet (DS 0053) 2Document2 pagesShock Accelerometer Calibration K9525C Datasheet (DS 0053) 2Phong Lê ĐìnhNo ratings yet

- Explain Basic Injection Molding Machine ProcessDocument9 pagesExplain Basic Injection Molding Machine ProcessNazriNo ratings yet

- Ck45 Mechanical PropertiesDocument3 pagesCk45 Mechanical PropertiesDaniel CringusNo ratings yet

- Gurucad Catia v5 Trainings deDocument61 pagesGurucad Catia v5 Trainings deGURUCAD GbR Catia V5 AerospaceNo ratings yet

- Sprue Bushing JIS A Type 625-626Document1 pageSprue Bushing JIS A Type 625-626NazriNo ratings yet

- Silicon PIN DiodeDocument16 pagesSilicon PIN DiodeHood CloudNo ratings yet

- Inductors Transformers Jyoti ElectronicsDocument12 pagesInductors Transformers Jyoti ElectronicsRajendra AgarwalNo ratings yet

- BL L502Document4 pagesBL L502Roberto GarzonNo ratings yet

- TorqueDocument2 pagesTorquerohiniNo ratings yet

- RG RM RGH DatasheetDocument3 pagesRG RM RGH DatasheetMomogi ForeverhappyNo ratings yet

- RG RM RGH Datasheet PDFDocument3 pagesRG RM RGH Datasheet PDFNNMSANo ratings yet

- C2 - Condensatoare CeramiceDocument8 pagesC2 - Condensatoare CeramiceSneezy DwarfNo ratings yet

- SSRDocument6 pagesSSRArvind NangareNo ratings yet

- 3685 FBDocument24 pages3685 FBPravin MevadaNo ratings yet

- 582126307901Document1 page582126307901vinu1175No ratings yet

- Si 4368 DyDocument9 pagesSi 4368 DyChristopher RiceNo ratings yet

- Features Descriptio: LT1097 Low Cost, Low Power Precision Op AmpDocument12 pagesFeatures Descriptio: LT1097 Low Cost, Low Power Precision Op Amphamid_violinNo ratings yet

- La 4278Document6 pagesLa 4278Carlos López Rivera0% (1)

- TAJ Series: Standard TantalumDocument7 pagesTAJ Series: Standard TantalumrmNo ratings yet

- Dual N-Channel, Notebook Power Supply MOSFET: June 1999Document9 pagesDual N-Channel, Notebook Power Supply MOSFET: June 1999dreyes3773No ratings yet

- TAJ Series: Standard TantalumDocument5 pagesTAJ Series: Standard TantalumPankaj MaithaniNo ratings yet

- Bourns SDR0302-471KLDocument2 pagesBourns SDR0302-471KLJoseph Abou El OulaNo ratings yet

- Irf7811Avpbf Irf7811Avpbf: Absolute Maximum RatingsDocument6 pagesIrf7811Avpbf Irf7811Avpbf: Absolute Maximum RatingsnewmailsNo ratings yet

- 2-Phase Stepper Motor Unipolar Driver Ics: Absolute Maximum RatingsDocument7 pages2-Phase Stepper Motor Unipolar Driver Ics: Absolute Maximum RatingsCalin LuchianNo ratings yet

- Wilkinson101 Rev1.3Document112 pagesWilkinson101 Rev1.3odyssey16No ratings yet

- R2 ProDocument36 pagesR2 ProduleNo ratings yet

- Type06 - D3-XI65-3W19-SSA - With SSA SupportDocument2 pagesType06 - D3-XI65-3W19-SSA - With SSA SupportDmitry059No ratings yet

- SDR0503 Series - SMD Power Inductors: Features ApplicationsDocument3 pagesSDR0503 Series - SMD Power Inductors: Features ApplicationsJoseph Abou El OulaNo ratings yet

- TSL257S DatasheetDocument9 pagesTSL257S DatasheetAndresPalaciosNo ratings yet

- Medium Power Transistor: L KQLT1G SeriesDocument4 pagesMedium Power Transistor: L KQLT1G SeriesStuxnetNo ratings yet

- 80 08211c LM and LSXDocument1 page80 08211c LM and LSXMarcio FreitasNo ratings yet

- Bzg01 Series 2Document8 pagesBzg01 Series 2drain rainNo ratings yet

- TAJ Series: Standard TantalumDocument5 pagesTAJ Series: Standard TantalumFaraz ElectronicNo ratings yet

- Si7336ADP: Vishay SiliconixDocument12 pagesSi7336ADP: Vishay SiliconixLiska DianaNo ratings yet

- 2N6027Document9 pages2N6027mariogizziNo ratings yet

- Taj 776811Document8 pagesTaj 776811balajiboss005No ratings yet

- Ferrites and AccessoriesDocument13 pagesFerrites and Accessoriessuresh parmarNo ratings yet

- Base Station Antenna: 1.5M 8-Port 2L2H Antenna With Integrated RCUDocument2 pagesBase Station Antenna: 1.5M 8-Port 2L2H Antenna With Integrated RCUСветланаNo ratings yet

- TDA7269ADocument7 pagesTDA7269ACojocar FlorinNo ratings yet

- Stps2045 CT CF CGDocument7 pagesStps2045 CT CF CGCah NgaloefNo ratings yet

- STR G 6653Document8 pagesSTR G 6653Saif RehmanNo ratings yet

- Onsms03751 1 PDFDocument4 pagesOnsms03751 1 PDFKevin DumbravaNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- 2450DP15D5400Document2 pages2450DP15D5400hadi545nNo ratings yet

- Product Data Sheet Ok Aristorod 12.50: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Ok Aristorod 12.50: G 'Gas-Shielded Metal-Arc Welding'João GuilhermeNo ratings yet

- Base Station AntennaDocument2 pagesBase Station AntennaNetwork EngineerNo ratings yet

- Performance EMI Filter: Single-Phase FiltersDocument4 pagesPerformance EMI Filter: Single-Phase FiltersbobmarllyNo ratings yet

- Silicon Schottky Diode: D2 D1 D1 D2 D1 D2 D3 D2 D1Document10 pagesSilicon Schottky Diode: D2 D1 D1 D2 D1 D2 D3 D2 D1amovchNo ratings yet

- Sprue Bushing JIS A Type 623-624Document1 pageSprue Bushing JIS A Type 623-624NazriNo ratings yet

- Philips Fa561 AudioDocument11 pagesPhilips Fa561 AudiovideosonNo ratings yet

- Rotel RB 1080 Service ManualDocument6 pagesRotel RB 1080 Service Manualsandy nNo ratings yet

- Diode Schootky Data SheetDocument14 pagesDiode Schootky Data Sheetanujchopra007No ratings yet

- T-Line ModelDocument5 pagesT-Line ModelJohn AnguloNo ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- How Solidworks WorksDocument7 pagesHow Solidworks WorksNazriNo ratings yet

- How To Use Hole WizardDocument4 pagesHow To Use Hole WizardNazriNo ratings yet

- Removable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingDocument14 pagesRemovable-Nozzle-Tips - 2019 - EN Mesin Injection MouldingNazriNo ratings yet

- Pengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaDocument18 pagesPengenalan Asas Solidworks® 2018: By: Nazri Bin MD Ali Institut Latihan Perindustrian Bukit Katil MelakaNazriNo ratings yet

- Correction Coment PRSDocument20 pagesCorrection Coment PRSNazriNo ratings yet

- Long-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFDocument5 pagesLong-Range Guided-Wave Ultrasonics A New Age in Pipeline Inspection - 2007 - Birch, Baker - Un PDFNazriNo ratings yet

- Nota Sem 3 Blue Print ReadDocument149 pagesNota Sem 3 Blue Print ReadNazri0% (1)

- Carry Out Two Plate Mould Drawing InterpretDocument4 pagesCarry Out Two Plate Mould Drawing InterpretNazri100% (1)

- Technical Specifications For Aerial BunchedDocument5 pagesTechnical Specifications For Aerial BunchedNazriNo ratings yet

- Real 3 Corrision PipeDocument8 pagesReal 3 Corrision PipeNazriNo ratings yet

- Scorpion Z4120C Z6020C Z8020C Installer ManualDocument23 pagesScorpion Z4120C Z6020C Z8020C Installer ManualNazriNo ratings yet

- LKM Standard Mould BaseDocument86 pagesLKM Standard Mould BaseNazriNo ratings yet

- Micron Scorpion Z4120C, Z6020C and Z8020C User ManualDocument18 pagesMicron Scorpion Z4120C, Z6020C and Z8020C User ManualNazri0% (1)

- Produk 2/2013: A Detail A Scale 4: 1 Unit: MMDocument1 pageProduk 2/2013: A Detail A Scale 4: 1 Unit: MMNazriNo ratings yet

- Discuss Basic Injection Moulding Machine SafetyDocument3 pagesDiscuss Basic Injection Moulding Machine SafetyNazriNo ratings yet

- Pme Mould & Die Standard Components PDFDocument84 pagesPme Mould & Die Standard Components PDFNazriNo ratings yet

- Monaco Guia 429 452Document24 pagesMonaco Guia 429 452Zeka ValladolidNo ratings yet

- Giddings & Lewis Sect06 Rotary TableDocument14 pagesGiddings & Lewis Sect06 Rotary TableAngel AdautaNo ratings yet

- Research MethodologyDocument7 pagesResearch Methodologysteven280893No ratings yet

- L060 Push Pull (2UP)Document10 pagesL060 Push Pull (2UP)srikanthkmsNo ratings yet

- Previous GATE Questions On Number SystemsDocument4 pagesPrevious GATE Questions On Number SystemshelithiNo ratings yet

- RBS 2111 Product DescriptionDocument17 pagesRBS 2111 Product DescriptionАлександр ЖебровскийNo ratings yet

- Dominique Bernales (Prospectus)Document3 pagesDominique Bernales (Prospectus)dominiqueNo ratings yet

- Chapter 1 Chapter 1 Introduction To Computers: Jim Michael Widi, S.KomDocument49 pagesChapter 1 Chapter 1 Introduction To Computers: Jim Michael Widi, S.KomYanalita LiemNo ratings yet

- SPM List of Physics ExperimentsDocument3 pagesSPM List of Physics ExperimentsAnythingAlsoCanLah57% (7)

- Expt 7 Compound CircuitsDocument10 pagesExpt 7 Compound CircuitsDamien ManceraNo ratings yet

- Activity Sheet 16 SEA 204 B1Document5 pagesActivity Sheet 16 SEA 204 B1Arch AstaNo ratings yet

- Jurnal Matra LautDocument32 pagesJurnal Matra LautFebrian DumaNo ratings yet

- 87-71408-1 REV B Snapdragon 8 Gen 3 Mobile Platform Product BriefDocument2 pages87-71408-1 REV B Snapdragon 8 Gen 3 Mobile Platform Product Briefjerinjohn2004No ratings yet

- NumPy Ufuncs - SummationsDocument1 pageNumPy Ufuncs - Summationsahmed salemNo ratings yet

- Cadworx Catalog Creation: Name: Type: Base Catalog: Description: Location: UnitsDocument4 pagesCadworx Catalog Creation: Name: Type: Base Catalog: Description: Location: UnitsElisa S Carrera100% (1)

- KONTRON 01023 0000 Datasheet 51775Document2 pagesKONTRON 01023 0000 Datasheet 51775Taufiq Adhi MNo ratings yet

- Topology Optimization: Homogenization Design Method (HMD)Document39 pagesTopology Optimization: Homogenization Design Method (HMD)cerdopuercoNo ratings yet

- A-Level Preparation - Right Angled Trigonometry - AnswersDocument3 pagesA-Level Preparation - Right Angled Trigonometry - AnswersmhacunaNo ratings yet

- Superfatting and The Lye DiscountDocument3 pagesSuperfatting and The Lye DiscountGleidiane SaloméNo ratings yet

- Excel VBA Programming FD 3E 1118490371Document4 pagesExcel VBA Programming FD 3E 1118490371DiegoNo ratings yet

- Research Paper Using GisDocument7 pagesResearch Paper Using Gistigvxstlg100% (1)

- Physics Investigatory ProjectDocument11 pagesPhysics Investigatory ProjectKishore Kumar Robinho50% (2)

- Section 9 - Compact SpacesDocument9 pagesSection 9 - Compact SpacesJaZz SFNo ratings yet

- Calendar Molt Code Cheatsheet PDFDocument2 pagesCalendar Molt Code Cheatsheet PDFTatchai TitichetrakunNo ratings yet

- S20A Parts List - 121019Document29 pagesS20A Parts List - 121019AstraluxNo ratings yet

- B 221m - 00 - Qjiymu0tmdaDocument14 pagesB 221m - 00 - Qjiymu0tmdaessai expertiseNo ratings yet

- Origin of The Solar SystemDocument12 pagesOrigin of The Solar SystemdhonaNo ratings yet