67% found this document useful (3 votes)

2K views11 pagesCondenser Design Calculation

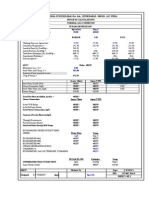

This document provides calculations to design a condenser according to HEI standards. It includes input data such as steam flow rate and temperatures. It then calculates the heat load, cooling water requirements, tube dimensions, heat transfer coefficient, required surface area, number of tubes needed, condenser diameter and pressure drop based on given parameters and HEI equations. The goal is to determine the design specifications for the condenser to meet the heating requirements.

Uploaded by

AlMakhieCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

67% found this document useful (3 votes)

2K views11 pagesCondenser Design Calculation

This document provides calculations to design a condenser according to HEI standards. It includes input data such as steam flow rate and temperatures. It then calculates the heat load, cooling water requirements, tube dimensions, heat transfer coefficient, required surface area, number of tubes needed, condenser diameter and pressure drop based on given parameters and HEI equations. The goal is to determine the design specifications for the condenser to meet the heating requirements.

Uploaded by

AlMakhieCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

- Condenser Design Calculation Introduction: Introduces key input data for condenser design including various inlet temperatures and pressures.

- Surface Area Requirements for Condenser: Covers the required surface area calculations necessary for the condenser, using derived heat transfer values.

- Heat Transfer Coefficient Calculations: Details the calculations to determine corrected and uncorrected heat transfer coefficient (U).

- Supplementary Data: Lists additional supplementary data aligned to HEI standards for condenser design.