Professional Documents

Culture Documents

26-00 Introduction PDF

26-00 Introduction PDF

Uploaded by

David BumbaloughOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

26-00 Introduction PDF

26-00 Introduction PDF

Uploaded by

David BumbaloughCopyright:

Available Formats

26 MACHINING HOLES

Objectives

The focus of the previous chapter (Fixed Cycles) had been on the concept of programming holes and hole opera-

tions in an efficient way. The purpose of fixed cycles is to simplify programming and make changes easier, if nec-

essary. The objective of projects presented in this section is to apply the fixed cycles in practical shop applications.

Applications

Machining holes is quite likely the most common operation in majority of machine shops. Unlike milling or

turning, where the toolpath is unique to a particular job, machining holes is a point-to-point (positioning) opera-

tion, where the action of a particular tool is always the same. What changes between operations or even between

jobs, are the hole and machining parameters.

The applications for machining holes are numerous. Typical operations will include spot drilling, center drilling,

drilling, boring, counterboring, countersinking, reaming, and tapping. Good knowledge of these tools is essential

for successful program development.

Overview

Fixed cycles provide the programming template, but the CNC programmer still has to do a lot of work. In addi-

tion to the general technological decisions, the main emphasis in programming holes is on calculating the R-level

and the Z-depth. As the R-level is only a clearance (albeit an important one), it usually presents no difficulties. On

the other hand, the Z-depth calculation depends on many factors, such as the drawing requirements, material thick-

ness, tool type, tool diameter and cutting angle, and many others. The most common formula for calculating the

drill point length P for 118° drill point angle is:

P=D´K

+ ... where D is the effective cutting diameter and K is the constant (see chart on page 196).

This is just one of many programming tools available. Calculating a spot drill depth or a center drill depth pres-

ents other challenges. Countersinking, for example, may require trigonometry, to calculate the Z-depth. Tapping

requires not only a proper tool selection but properly calculated feedrate. Some hole operations require care in

setup, for example, boring with a shift or back boring.

The following projects have been designed to address many important aspects of machining holes and provide a

starting point for gaining experience.

References

& CNC Programming Handbook - Chapter 25 Fixed Cycles

Chapter 26 Machining Holes

Chapter 27 Pattern of Holes

Peter Smid CNC Programming Handbook Chapter 26 [ 1 ]

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Black & Decker The Complete Guide To Outdoor CarpentryDocument591 pagesBlack & Decker The Complete Guide To Outdoor Carpentrymario70916100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tortort Manufacturing 80% Milled Receivers AK47Document6 pagesTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- HK94, MP5, Parts KitsDocument6 pagesHK94, MP5, Parts KitsDavid BumbaloughNo ratings yet

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocument17 pagesThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNo ratings yet

- Cipet Training ReportDocument34 pagesCipet Training ReportBABLU SHAIKH56% (9)

- Simba S7 D - TechspecificDocument4 pagesSimba S7 D - Techspecificsukhoi200900No ratings yet

- Barrels & Actions by Harold HoffmanDocument238 pagesBarrels & Actions by Harold HoffmanNorm71% (7)

- PATTA Self Drilling Screws Cat2018Document48 pagesPATTA Self Drilling Screws Cat2018Seth Madhusudan RathiNo ratings yet

- MCQ in Machine Design and Shop Practice Part 4 ME Board ExamDocument18 pagesMCQ in Machine Design and Shop Practice Part 4 ME Board ExamKenn Earl Bringino VillanuevaNo ratings yet

- Introduction To Drilling TechnologyDocument37 pagesIntroduction To Drilling Technologyguddisaha100% (4)

- DYWIDAG Drill Hollow Bar SystemDocument16 pagesDYWIDAG Drill Hollow Bar SystemrobertofortNo ratings yet

- Sam MalofDocument5 pagesSam MalofMarcos SalazarNo ratings yet

- Exercises After Abdominal SurgeryDocument5 pagesExercises After Abdominal SurgeryDavid BumbaloughNo ratings yet

- Scaling Function Q+A: # Answer 1Document2 pagesScaling Function Q+A: # Answer 1David BumbaloughNo ratings yet

- Feedrate Q+A: # Answer 1Document2 pagesFeedrate Q+A: # Answer 1David BumbaloughNo ratings yet

- Scaling Exercise: Use T01 Ø20 End MillDocument1 pageScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNo ratings yet

- 46-01 Horizontal MachiningDocument1 page46-01 Horizontal MachiningDavid BumbaloughNo ratings yet

- 49-01 Documenting Programs Q+A PDFDocument1 page49-01 Documenting Programs Q+A PDFDavid BumbaloughNo ratings yet

- CNC Machining Q+A: # Answer 1Document2 pagesCNC Machining Q+A: # Answer 1David BumbaloughNo ratings yet

- 44-01 Machining With TailstockDocument1 page44-01 Machining With TailstockDavid BumbaloughNo ratings yet

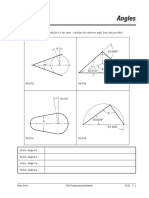

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocument1 pageAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNo ratings yet

- Verifying Programs Q+A: # Answer 1Document2 pagesVerifying Programs Q+A: # Answer 1David BumbaloughNo ratings yet

- 53-02 Locators PDFDocument1 page53-02 Locators PDFDavid BumbaloughNo ratings yet

- Machine Zero Return Q+A: # Answer 1Document2 pagesMachine Zero Return Q+A: # Answer 1David BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 53-03 Contour Points 1Document1 page53-03 Contour Points 1David BumbaloughNo ratings yet

- Unknown Radius: Chine Shop MagazineDocument1 pageUnknown Radius: Chine Shop MagazineDavid BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- 22 00 IntroductionDocument2 pages22 00 IntroductionDavid BumbaloughNo ratings yet

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocument1 pageTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNo ratings yet

- 22-01 Simple Linear Motion 1Document1 page22-01 Simple Linear Motion 1David BumbaloughNo ratings yet

- 25-01 Fixed Cycles Q+A PDFDocument2 pages25-01 Fixed Cycles Q+A PDFDavid BumbaloughNo ratings yet

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- 23-03 Skipped Holes With ObstaclesDocument1 page23-03 Skipped Holes With ObstaclesDavid BumbaloughNo ratings yet

- Tooling CatalogDocument34 pagesTooling CatalogzingalalaNo ratings yet

- HMT Pinjore HaryanaDocument12 pagesHMT Pinjore HaryanaAnurag KumarNo ratings yet

- 1 Esp Electrician b1 GlossaryDocument7 pages1 Esp Electrician b1 GlossaryIlonaNo ratings yet

- SELF FEED Rail DrillDocument20 pagesSELF FEED Rail DrillKarlos 6:No ratings yet

- Design of An Oyster Shell Grinding Machine Chapter 3 MethodologyDocument16 pagesDesign of An Oyster Shell Grinding Machine Chapter 3 MethodologyenadburatNo ratings yet

- L-1 PDFDocument5 pagesL-1 PDFDamas ChachaNo ratings yet

- KN238EGB A - OpsMan (Maxima II TM) - (#C3797 or Higher) PDFDocument212 pagesKN238EGB A - OpsMan (Maxima II TM) - (#C3797 or Higher) PDFurkkkkNo ratings yet

- JANUARY 2020 Surplus Record Machinery & Equipment DirectoryDocument717 pagesJANUARY 2020 Surplus Record Machinery & Equipment DirectorySurplus RecordNo ratings yet

- Jigs and FixturesDocument85 pagesJigs and FixturesNithin Mathew Eyyalil100% (2)

- Additional Manual For KLK1-with Marchin Room LiftDocument50 pagesAdditional Manual For KLK1-with Marchin Room LiftVictor RazoNo ratings yet

- Design and Fabrication Multi Spindle Drilling MachineDocument4 pagesDesign and Fabrication Multi Spindle Drilling MachineEditor IJTSRDNo ratings yet

- Specifications PDFDocument4 pagesSpecifications PDFrisal doNo ratings yet

- Tilt Up General NotesDocument20 pagesTilt Up General NoteswhsprzNo ratings yet

- Sumitomo Drill Catalog 10-11 PDFDocument120 pagesSumitomo Drill Catalog 10-11 PDFPablo Martínez BerenguerNo ratings yet

- Top Hammer Catalog Digital Version Eng q4 2022Document69 pagesTop Hammer Catalog Digital Version Eng q4 2022Eduardo Olivas MedinaNo ratings yet

- Bhel Summer Training (Industrial Training) ReportDocument35 pagesBhel Summer Training (Industrial Training) ReportAmelia WarnerNo ratings yet

- On The Evolution of Drill-Bit ShapesDocument37 pagesOn The Evolution of Drill-Bit ShapesJohn David Buenaventura EstacionNo ratings yet

- 20V Cordless Drill Set PABS 20-Li E6Document106 pages20V Cordless Drill Set PABS 20-Li E6m mNo ratings yet

- Fe Unit 1Document48 pagesFe Unit 1Duraid FalihNo ratings yet

- Makita General Catalogue 2011Document80 pagesMakita General Catalogue 2011Halcon1985No ratings yet

- Power Slips Spec SheetDocument2 pagesPower Slips Spec Sheetcacalot93No ratings yet