Professional Documents

Culture Documents

22 00 Introduction

Uploaded by

David BumbaloughOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

22 00 Introduction

Uploaded by

David BumbaloughCopyright:

Available Formats

22 LINEAR INTERPOLATION

Objectives

In this chapter, the main objective is to provide the opportunities to exercise linear interpolation in the most typi-

cal programming forms. In the exercises, the main emphasis is on learning the correct program syntax, correct us-

ing of the control modal features, and programming of a linear motion in both absolute and incremental modes.

Overview and Applications

Linear interpolation is defined as the shortest motion between two points, programmed at a specified feedrate. It

is programmed with the G01 command, in one, two, or three axes. The minimum and maximum programmable

feedrate for each axis is determined by the control manufacturer and cannot be changed. Linear interpolation is

used for cutting straight (linear) motions.

The programming format for linear interpolation is:

G01 X.. F.. for a single X axis motion

G01 Y.. F.. for a single Y axis motion

G01 Z.. F.. for a single Z axis motion

G01 X.. Y.. F.. for a two axis motion in X and Y

G01 X.. Z.. F.. for a two axis motion in X and Z

G01 Y.. Z.. F.. for a two axis motion in Y and Z

Typically, a linear interpolation is programmed after a rapid motion to the location where the straight cut is to

take place. It is also programmed when a contour cutting motion changes from a circular motion to a linear motion.

Both, the G01 command and the programmed feedrate command F are modal.

Linear interpolation can be canceled by any other motion command (G00, G02, G03), but the last active feedrate

will remain active, in memory. If the feedrate specification is missing in the program, the last active feedrate will

be used. If there were no previously active feedrate, the control system issues an alarm (error) and the program has

to be corrected at the control unit.

Two feedrate modes are normally used for linear interpolation - one for milling, the other for turning:

o Milling feedrate ... units per time mm/min or in/min

o Turning feedrate ... units per revolution mm/rev or in/rev

In a simultaneous linear motion in two or three axes, the control system automatically calculates actual feedrate

for each axis, in order to produce a straight motion.

A linear motion G01 can be programmed in absolute or incremental mode, using the G90 and G91 commands re-

spectively. The CNC operator can control the actual cutting feedrate at the machine, using the feedrate override

switch. This switch is located on the machine operation panel and can be used to increase or decrease the pro-

grammed feedrate, usually from 0% to 200%. When the program is optimized, the best feedrate should be re-

flected in the master program, which usually requires some minor changes to the program. To temporarily stop the

linear motion during a machining operation, the feedhold button is used.

The two simple examples on the next page show two versions of programs using linear interpolation. The firsts

example - Example 1 - shows the most rudimentary form, while the Example 2 is an actual program, albeit a simple

one. Note the format and the modal entries.

Peter Smid CNC Programming Handbook Chapter 22 [ 1 ]

ò Example - 1

The following four blocks use linear interpolation in incremental mode, to cut a square 50 x 50 mm, based on the

program zero at the lower left corner. Only critical motions are shown in this example:

G21

G91 G01 Y50.0 F100.0

X50.0

Y0

X0

ò Example - 2

The second example is a simple, yet complete program for one tool (Æ0.25 end mill). The groove is programmed

at 0.125 depth. In the program, note the use of linear interpolation along the Z axis for the plunge-in motion.

4.0

N1 G20

N2 G17 G40 G80

D C (IN BLOCK N3 MOVE TO LOCATION A ...>>)

2.375 N3 G90 G54 G00 X0.625 Y0.625 S2000 M03

N4 G43 Z0.1 H01 M08

N5 G01 Z-0.125 F3.0

N6 X3.375 F5.0 (LOCATION B)

3.0 N7 Y2.375 (LOCATION C)

N8 X0.625 (LOCATION D)

N9 Y0.625 (LOCATION A)

0.625 N10 G00 Z0.1 M09

A B N11 G28 Z0.1

N12 M30

%

0.625

3.375

In the example above, the tool moves first to location A (block N3), then cuts the groove in the direction B (N6),

C (N7), D (N8), and back to location A (N9). Specified cutting depth is listed in block N5 (Z-0.125).

The main application of linear interpolation is in contour based tool motions. Machining operations such as con-

touring, face milling, slot cutting and pocketing use this type of motion either exclusively, or combined with an-

other type of motions - such as circular interpolation and rapid motion.

Straight tool motions are also used internally by the system, within various fixed cycles for hole operations. The

fixed cycle does not use the linear interpolation command G01 directly, as it is built in the cycle internally.

In a true three dimensional applications (known as 3D), when machining a surface, a circular interpolation cannot

be used, and all motions consist of very small linear motions.

In summary, the linear interpolation mode G01 is used in a CNC program for the sole purpose of connecting any

two points with a straight line (the shortest distance between points).

References

& CNC Programming Handbook - Chapter 11 Absolute and Incremental Modes

Chapter 13 Feedrate Control

Chapter 13 Feedhold and Override

Chapter 22 Linear Interpolation

Peter Smid CNC Programming Handbook Chapter 22 [ 2 ]

You might also like

- CNC ProgDocument38 pagesCNC ProgPoornima JoshiNo ratings yet

- Special G Codes of CNC ProgrammingDocument14 pagesSpecial G Codes of CNC ProgrammingSimon Risteski100% (1)

- Slide01 Introduction CNCDocument149 pagesSlide01 Introduction CNCalexiskandarNo ratings yet

- Module 2 Part 1Document147 pagesModule 2 Part 1FRANCIS THOMASNo ratings yet

- Advanced Techniques and Technology of Computer-Aided Feedback ControlFrom EverandAdvanced Techniques and Technology of Computer-Aided Feedback ControlNo ratings yet

- Experiment 6 - CNC Programing-MillingDocument9 pagesExperiment 6 - CNC Programing-MillingG. Dancer GhNo ratings yet

- CNC Part ProgrammingDocument61 pagesCNC Part ProgrammingrajaNo ratings yet

- CNC Turning Programming Exellent ExplainationDocument29 pagesCNC Turning Programming Exellent ExplainationschrienerNo ratings yet

- Special G Codes of CNC ProgrammingDocument14 pagesSpecial G Codes of CNC ProgrammingAntónio OliveiraNo ratings yet

- Lesson Twelve TextDocument18 pagesLesson Twelve TextVignesh WaranNo ratings yet

- CNC Labsheet PMMDocument28 pagesCNC Labsheet PMMMax LuxNo ratings yet

- Chapter Two 2. Manual NC Part ProgrammingDocument33 pagesChapter Two 2. Manual NC Part ProgrammingMulugeta WoldeNo ratings yet

- How To Use Charly 4U Milling Mchine Using The GcodeDocument18 pagesHow To Use Charly 4U Milling Mchine Using The GcodeAnish KumarNo ratings yet

- CNC Book PDFDocument342 pagesCNC Book PDFDr V.Suresh Babu100% (2)

- Group 24 (Solar Mobile ChargingDocument22 pagesGroup 24 (Solar Mobile ChargingBanothu RameshNo ratings yet

- NC Part Programming: Manual Programming (G-Code)Document5 pagesNC Part Programming: Manual Programming (G-Code)AyasNo ratings yet

- CNC Programming3Document109 pagesCNC Programming3Akash SriNo ratings yet

- My CNCDocument5 pagesMy CNCzoranteicNo ratings yet

- GTCNC 150it IiDocument4 pagesGTCNC 150it Iilukman hakimNo ratings yet

- Mill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram ExampleDocument73 pagesMill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram Exampleسليمان مصريNo ratings yet

- Experiment No 1: CNC TURNING: MEP310 - Manufacturing Process Automation Lab ManualDocument10 pagesExperiment No 1: CNC TURNING: MEP310 - Manufacturing Process Automation Lab ManualBandam Nitish kumarNo ratings yet

- Hurco 5-Axis Post Notes - Cope 2013Document5 pagesHurco 5-Axis Post Notes - Cope 2013LaurențiuGabrielGăinăNo ratings yet

- Unit 4Document62 pagesUnit 4samnztNo ratings yet

- Turning: Chapter ObjectivesDocument78 pagesTurning: Chapter ObjectivesDany EscobarNo ratings yet

- Subject: Computer Aided Manufacturing Topic: CNC ProgrammingDocument12 pagesSubject: Computer Aided Manufacturing Topic: CNC ProgrammingAman RizviNo ratings yet

- Basic CNC Programming V2Document76 pagesBasic CNC Programming V2nuzul hamdaniNo ratings yet

- Chap5-Numerical ControlDocument32 pagesChap5-Numerical ControljojoNo ratings yet

- CNC Programming Tutorials Examples G and M Codes Programming Tutorial Example Code For Beginner To Advance Level CNC Machinist PDFDocument302 pagesCNC Programming Tutorials Examples G and M Codes Programming Tutorial Example Code For Beginner To Advance Level CNC Machinist PDFSanjai RohanNo ratings yet

- Chapter 3.Cnc Part ProgrammingDocument61 pagesChapter 3.Cnc Part Programminghari0118No ratings yet

- CNC Programming Tutorials Examples G M Codes G M Programming Tutorial ExampleDocument340 pagesCNC Programming Tutorials Examples G M Codes G M Programming Tutorial ExampleYassin Belkacem100% (2)

- 2.5 Programming Functions: (Mm/min or Inch/min) (Mm/rev or Inch/rev)Document59 pages2.5 Programming Functions: (Mm/min or Inch/min) (Mm/rev or Inch/rev)Srinivas YadavNo ratings yet

- Chapter 3.CNC Part ProgrammingDocument61 pagesChapter 3.CNC Part ProgrammingDr. Vivek SrivastavaNo ratings yet

- Phases of A CNC Program1Document5 pagesPhases of A CNC Program1jebishaNo ratings yet

- 6 Semester: Student ProfileDocument19 pages6 Semester: Student Profilealokkumar707977No ratings yet

- CNC Programming Tutorials Examples G and M Codes by Thanh TranDocument302 pagesCNC Programming Tutorials Examples G and M Codes by Thanh TranダンハイソンNo ratings yet

- Basic CNC ProgrammingDocument68 pagesBasic CNC ProgrammingAkash Kumar SinghNo ratings yet

- 5 - G-CodeDocument55 pages5 - G-CodefamilyumaNo ratings yet

- Tut1 ManualProgram FacemillDocument10 pagesTut1 ManualProgram FacemillPRABHU JNo ratings yet

- 00 EAGLE FANUC OiDocument60 pages00 EAGLE FANUC OiFranciscoDanielRamirezFloresNo ratings yet

- NC ProgrammingDocument54 pagesNC ProgrammingVed Vrat NuclearNo ratings yet

- Preparatory Functions (G-Codes)Document24 pagesPreparatory Functions (G-Codes)hasan alsarrafNo ratings yet

- NC Part ProgrammingDocument57 pagesNC Part ProgramminglijinthomasNo ratings yet

- Learning Rapid Tool Move & Linear Interpolation: ExperimentDocument1 pageLearning Rapid Tool Move & Linear Interpolation: ExperimentMuhammad AbdullahNo ratings yet

- FGDocument22 pagesFGRishabh PandeyNo ratings yet

- CNC-Lab Mechanical ManualDocument21 pagesCNC-Lab Mechanical ManualHaresh RaisinghaniNo ratings yet

- Cad Cam End Sem VDDocument90 pagesCad Cam End Sem VDDerik NelsonNo ratings yet

- Vikram 3Document29 pagesVikram 3Ayush JaiswalNo ratings yet

- CNC Programing ConceptDocument11 pagesCNC Programing ConceptGatot PrasetyoNo ratings yet

- Programming 1Document44 pagesProgramming 1shubhanshu kumarNo ratings yet

- CNC Programming Tutorials Examples G and M Codes by Thanh TranDocument151 pagesCNC Programming Tutorials Examples G and M Codes by Thanh TranBerkan KılıçNo ratings yet

- New Microsoft Word DocumentDocument19 pagesNew Microsoft Word DocumentŤhåýğųŢjNo ratings yet

- CADCAM CNC Unit-3.1Document54 pagesCADCAM CNC Unit-3.1kiranchennoju2004No ratings yet

- CNC Programming 1Document26 pagesCNC Programming 1mohamed alsalhyNo ratings yet

- CNC Programming "Milling": Module ObjectivesDocument37 pagesCNC Programming "Milling": Module Objectiveshasan alsarrafNo ratings yet

- LAB 5 - Coding LectureDocument16 pagesLAB 5 - Coding LectureHusnain AliNo ratings yet

- Me 473 - Unit 4 - 1Document70 pagesMe 473 - Unit 4 - 1Ama Serwaa YeboahNo ratings yet

- Exercises After Abdominal SurgeryDocument5 pagesExercises After Abdominal SurgeryDavid BumbaloughNo ratings yet

- HK94, MP5, Parts KitsDocument6 pagesHK94, MP5, Parts KitsDavid BumbaloughNo ratings yet

- Feedrate Q+A: # Answer 1Document2 pagesFeedrate Q+A: # Answer 1David BumbaloughNo ratings yet

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocument17 pagesThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNo ratings yet

- Tortort Manufacturing 80% Milled Receivers AK47Document6 pagesTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNo ratings yet

- Scaling Function Q+A: # Answer 1Document2 pagesScaling Function Q+A: # Answer 1David BumbaloughNo ratings yet

- 44-01 Machining With TailstockDocument1 page44-01 Machining With TailstockDavid BumbaloughNo ratings yet

- CNC Machining Q+A: # Answer 1Document2 pagesCNC Machining Q+A: # Answer 1David BumbaloughNo ratings yet

- Verifying Programs Q+A: # Answer 1Document2 pagesVerifying Programs Q+A: # Answer 1David BumbaloughNo ratings yet

- 46-01 Horizontal MachiningDocument1 page46-01 Horizontal MachiningDavid BumbaloughNo ratings yet

- Machine Zero Return Q+A: # Answer 1Document2 pagesMachine Zero Return Q+A: # Answer 1David BumbaloughNo ratings yet

- Scaling Exercise: Use T01 Ø20 End MillDocument1 pageScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNo ratings yet

- 49-01 Documenting Programs Q+A PDFDocument1 page49-01 Documenting Programs Q+A PDFDavid BumbaloughNo ratings yet

- 53-03 Contour Points 1Document1 page53-03 Contour Points 1David BumbaloughNo ratings yet

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocument1 pageAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNo ratings yet

- Unknown Radius: Chine Shop MagazineDocument1 pageUnknown Radius: Chine Shop MagazineDavid BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 53-02 Locators PDFDocument1 page53-02 Locators PDFDavid BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- 22-01 Simple Linear Motion 1Document1 page22-01 Simple Linear Motion 1David BumbaloughNo ratings yet

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocument1 pageTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNo ratings yet

- 25-01 Fixed Cycles Q+A PDFDocument2 pages25-01 Fixed Cycles Q+A PDFDavid BumbaloughNo ratings yet

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- 23-03 Skipped Holes With ObstaclesDocument1 page23-03 Skipped Holes With ObstaclesDavid BumbaloughNo ratings yet

- Internet of Things 2Document11 pagesInternet of Things 2Chithra NachiappanNo ratings yet

- 200ma, Automotive, Ultra-Low Quiescent Current, Linear RegulatorDocument15 pages200ma, Automotive, Ultra-Low Quiescent Current, Linear RegulatorAbdul KurniadiNo ratings yet

- Thermal Plasma Decomposition of Fluorinated Greenhouse GasesDocument12 pagesThermal Plasma Decomposition of Fluorinated Greenhouse GasesSai Santhosh ManepallyNo ratings yet

- 450 857 07 C44CL Memcom Otis REM6 Wiring Loom V02 MLDocument8 pages450 857 07 C44CL Memcom Otis REM6 Wiring Loom V02 MLsam11No ratings yet

- Oxygen Enters The Lungs and Then Is Passed On Into Blood. The Blood CarriesDocument9 pagesOxygen Enters The Lungs and Then Is Passed On Into Blood. The Blood CarriesPranita PotghanNo ratings yet

- Manual Survey Pro For RangerDocument337 pagesManual Survey Pro For RangerIni ChitozNo ratings yet

- Control System Applied Principles of ControlDocument23 pagesControl System Applied Principles of ControlAngelus Vincent GuilalasNo ratings yet

- Assignment 2dbmsDocument13 pagesAssignment 2dbmsTXACORPNo ratings yet

- ME302-Syllabus - ME-302 Mechanical Systems IIDocument2 pagesME302-Syllabus - ME-302 Mechanical Systems IIد.محمد كسابNo ratings yet

- Ec8071 Cognitive Radio: Diploma, Anna Univ UG & PG CoursesDocument2 pagesEc8071 Cognitive Radio: Diploma, Anna Univ UG & PG CoursesBALAKRISHNANNo ratings yet

- CCpilot XM and CrossCore XM - Programmers GuideDocument17 pagesCCpilot XM and CrossCore XM - Programmers GuideAndres Emilio Veloso RamirezNo ratings yet

- PHP BitsDocument24 pagesPHP BitskarunakarNo ratings yet

- Bridge Design Pattern: Presented By: Atif Saeed Misbah NiaziDocument22 pagesBridge Design Pattern: Presented By: Atif Saeed Misbah Niaziaaatif121No ratings yet

- Math Lecture 1Document37 pagesMath Lecture 1Mohamed A. TaherNo ratings yet

- Your World Made Simple.: Door Lock Interface InstructionsDocument8 pagesYour World Made Simple.: Door Lock Interface InstructionshungleteNo ratings yet

- Audit Program TempleteDocument3 pagesAudit Program TempleteKudakwashe ChiwunyaNo ratings yet

- Topic 7 Logic Gates: Learning OutcomesDocument5 pagesTopic 7 Logic Gates: Learning OutcomesEnitsuj Eam EugarbalNo ratings yet

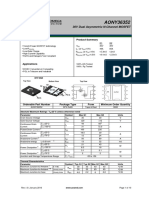

- AONY36352: 30V Dual Asymmetric N-Channel MOSFETDocument10 pagesAONY36352: 30V Dual Asymmetric N-Channel MOSFETrobertjavi1983No ratings yet

- Stem5 Pluto RRLDocument10 pagesStem5 Pluto RRLRosedel BarlongayNo ratings yet

- BU R&D Form 1 - Detailed R&D Program or Project ProposalDocument2 pagesBU R&D Form 1 - Detailed R&D Program or Project ProposalOween SamsonNo ratings yet

- Get The LUN ID at AIXDocument4 pagesGet The LUN ID at AIXMq SfsNo ratings yet

- 161-Gyro IXblue Quadrans User Manual 1-10-2014Document31 pages161-Gyro IXblue Quadrans User Manual 1-10-2014Jean-Guy PaulNo ratings yet

- V2X SurveyDocument37 pagesV2X SurveyAniket panditNo ratings yet

- SWC12Document11 pagesSWC12vikkasNo ratings yet

- Zero Defect Quality in The Automobile Industry: A SIX SIGMADocument3 pagesZero Defect Quality in The Automobile Industry: A SIX SIGMAshivi73No ratings yet

- Case RCBDocument76 pagesCase RCBSaurabh KatariaNo ratings yet

- Scanned & Edited By: Rajesh Kumar©Document36 pagesScanned & Edited By: Rajesh Kumar©SoumyaNo ratings yet

- Jay ValentineDocument9 pagesJay Valentinechrisdmello17No ratings yet

- What Are Application Security RisksDocument3 pagesWhat Are Application Security RisksSrinivasan KrishnanNo ratings yet

- Screenless DisplayDocument20 pagesScreenless DisplayjasonNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyFrom EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyRating: 1.5 out of 5 stars1.5/5 (2)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- DIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesFrom EverandDIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesRating: 3.5 out of 5 stars3.5/5 (3)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsFrom EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo ratings yet

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- AutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsFrom EverandAutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsNo ratings yet

- Medical and Healthcare Robotics: New Paradigms and Recent AdvancesFrom EverandMedical and Healthcare Robotics: New Paradigms and Recent AdvancesOlfa BoubakerNo ratings yet

- Practical E-Manufacturing and Supply Chain ManagementFrom EverandPractical E-Manufacturing and Supply Chain ManagementRating: 3.5 out of 5 stars3.5/5 (4)