100% found this document useful (1 vote)

303 views6 pagesPlate Load Report

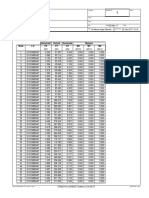

Geosol Engineering Co. LLC conducted plate bearing tests at the site of a proposed multi-storey car park in Al Bahja Mall, Oman. Three plate bearing tests were performed using 300mm diameter plates to determine the allowable bearing capacity. The maximum test pressure of 1800kN/m2 was three times the anticipated stress and no bearing failure occurred. The report concludes the allowable bearing capacity at the test location is 600kN/m2 based on achieving a safety factor of 3 against shear failure.

Uploaded by

Anonymous V6up3d0QGCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

303 views6 pagesPlate Load Report

Geosol Engineering Co. LLC conducted plate bearing tests at the site of a proposed multi-storey car park in Al Bahja Mall, Oman. Three plate bearing tests were performed using 300mm diameter plates to determine the allowable bearing capacity. The maximum test pressure of 1800kN/m2 was three times the anticipated stress and no bearing failure occurred. The report concludes the allowable bearing capacity at the test location is 600kN/m2 based on achieving a safety factor of 3 against shear failure.

Uploaded by

Anonymous V6up3d0QGCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd