Professional Documents

Culture Documents

Loto Standard Operating Procedure Sop - Loto - : Lockout Points

Uploaded by

K3L ULP Tanjung Redeb0 ratings0% found this document useful (0 votes)

222 views2 pagesCara kerja LOTTO

Original Title

Zero Accident Campaign for k3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCara kerja LOTTO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

222 views2 pagesLoto Standard Operating Procedure Sop - Loto - : Lockout Points

Uploaded by

K3L ULP Tanjung RedebCara kerja LOTTO

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

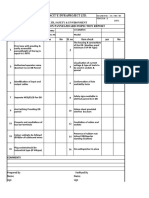

LOTO STANDARD OPERATING PROCEDURE

SOP - LOTO – 20012

LOTO Description: LOCATION (area): ORIGINAL? DATE: WRITTEN BY:

ML Return Pump 2D ML Pumps Area 35/36 m/d/yyyy 6/16/2015 Dick Eglinton

PURPOSE: To protect authorized employees against unexpected or unplanned activation REVISED? DATE: TITLE:

of equipment or energy while servicing equipment. m/d/yyyy Lead Mechanic

SCOPE: Utilize this procedure for all scheduled PM shutdowns, any maintenance task DEPARTMENT(S): SUPERVISOR:

That requires you to place your body in harm’s way of the equipment, or if you have to

leave the area while the equipment is in service. Operations Jan Guy

ENFORCEMENT: ✔ Maintenance SUPVSR APPROVAL & DATE:

LOCKOUT Failure to properly follow Jan Guy 6/22/2015

6 POINTS lockout-tagout procedure

may result in corrective action.

Laboratory

Administration

SAFETY APPROVAL & DATE

n/a

Lockout Application Process

1. Notify effected personnel. 2. Properly shut down machine. 3. Isolate all energy sources. 4. Apply lockout devices, locks, & tags.

5. Verify total de-energization of all sources.

E1 SCADA Control E2 HOA Switch E3 Key Switch

E4 Main Disconnect V1 Supply valve V2 Seal Water supply valve

orig: 5/15/2015 rev: 6/2/2015 SAFE 211

Energy Source Location of Energy Method of LOTO LOTO Device(s)

1.

E1 Other SCADA Control Place equipment in off Control command

2.

HOA Switch Place selector in off Properly filled out LOTO tag

E2 Electrical

3.

Key Switch Place key switch in off Properly filled out LOTO tag

E3 Electrical

4. Main breaker MCC22 Breaker ML

E4 Electrical Return pump 2D

Disconnect Power LOTO with padlock

5. Discharge valve # 36-V-04-MLR Chain with LOTO padlock and Tag

V1 Valve Close Valve

6.

Seal water supply line Close valve Properly filled out LOTO tag

V2 Valve

SHUTDOWN, LOCK, TAG, & TEST SEQUENCE

# STEP DESCRIPTION

1 Required PPE LOTO equipment, Site specific required PPE, Leather gloves

2 Notify Employees Notify West and East operators

Review Lockout

3 Review steps in Lockout Application Process

Procedure

Perform Machine

4 Operator to shut pump off in SCADA

Stop

5 Isolate Energy Shut off equipment per the Lockout Application Process. Operator to close valve

6 Lockout Energy Install all LOTO devices

7 Dissipate Energy Open drain line. Reference SOP 552

8 Attempt Restart Operator to attempt restart from SCADA

Lockout Removal Process

1. Ensure all tools and items have been removed. 2. Confirm that all employees are safely located. 3. Verify that controls are in

neutral. 4. Remove lockout devices and reenergize machine. 5. Notify affected employees that servicing is complete.

6. Verify total de-energization of all sources.

RESTORE TO SERVICE SEQUENCE

# STEP DESCRIPTION

1 Check Machine Verify guards in place

2 Check Area Remove tools and slip / trip hazards

3 Verify Machine Notify East and West Operator LOTO will be removed

4 Remove Lockout Remove LOTO in Reverse Order. Have operator open valves.

5 Notify Employees East or West Operator to assist with testing the machine. Operator to use SCADA to test, or other manual means

orig: 5/15/2015 rev: 6/2/2015 SAFE 211

You might also like

- SF6 Gas Material Safety Data SheetDocument8 pagesSF6 Gas Material Safety Data Sheetriesgoquimco drummondltdNo ratings yet

- Warning MemoDocument10 pagesWarning MemoZaki AziziNo ratings yet

- EHS October 2019 Calendar Safety Training AuditsDocument1 pageEHS October 2019 Calendar Safety Training AuditsSiddharth RanaNo ratings yet

- TBT Attendance PDFDocument1 pageTBT Attendance PDFDwitikrushna RoutNo ratings yet

- VE ST HE LM ET SH OE S GO GG LES: Violation DateDocument1 pageVE ST HE LM ET SH OE S GO GG LES: Violation DateSubzone ThreeNo ratings yet

- Sop OPOP - 050 - Breath Analyser, Alcohol and DrugsDocument5 pagesSop OPOP - 050 - Breath Analyser, Alcohol and Drugscontrax8100% (1)

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- Hazard Identification Prompt CDocument2 pagesHazard Identification Prompt CMohamed HamedNo ratings yet

- 09.00AM to11.00PM Clear: TCE EffwaDocument3 pages09.00AM to11.00PM Clear: TCE EffwaAjayNo ratings yet

- Emergency Contacts: Kafd Science Museum C-22Document1 pageEmergency Contacts: Kafd Science Museum C-22faisal nadeemNo ratings yet

- OHSE Project HIRA - Fencing Work - R 01Document8 pagesOHSE Project HIRA - Fencing Work - R 01Pankaj SinghNo ratings yet

- Observation Tracking SheetDocument8 pagesObservation Tracking Sheetirfan shafiqueNo ratings yet

- Manual Handling (Risk Assessment)Document3 pagesManual Handling (Risk Assessment)khurram shahzadNo ratings yet

- CAPA Register Safety IssuesDocument18 pagesCAPA Register Safety Issueshsesterling ikeaNo ratings yet

- Facility safety observations and risksDocument327 pagesFacility safety observations and risksSafetyNo ratings yet

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- Site Risk Register Summarizes Facility HazardsDocument4 pagesSite Risk Register Summarizes Facility HazardsvatasaNo ratings yet

- Motor Maintenance PDFDocument1 pageMotor Maintenance PDFAbdul HadiNo ratings yet

- Standard Work Clothing CatalogDocument3 pagesStandard Work Clothing CatalogdeweparumamenNo ratings yet

- SOP 4 - Coal Bed Leveling in PGPDocument18 pagesSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Lifting Tools & Tackle RegisterDocument1 pageLifting Tools & Tackle RegisterDth InfraNo ratings yet

- F-49 Full Body Harness Inspection ChecklistDocument1 pageF-49 Full Body Harness Inspection ChecklistSKH Culture100% (1)

- Working at Height Training ReportDocument4 pagesWorking at Height Training ReportMeshaNo ratings yet

- Risk Ass. - AD 417 - Installation of SocketDocument6 pagesRisk Ass. - AD 417 - Installation of SocketnsadnanNo ratings yet

- PAHANG CEMENT HAZARD ANALYSISDocument5 pagesPAHANG CEMENT HAZARD ANALYSISMahendren JayapalanNo ratings yet

- Safe Work PermitDocument1 pageSafe Work PermitagumsyahNo ratings yet

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 pagesChemical Manifest and Hazardous Chemical Substance List KathuVictorNo ratings yet

- Bharathi Cement HSD/LDO Unloading SOPDocument4 pagesBharathi Cement HSD/LDO Unloading SOPpothanNo ratings yet

- Acf-Mra-067 - UcDocument1 pageAcf-Mra-067 - UcFateh AliyaNo ratings yet

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabNo ratings yet

- Lockout Procedure: Image Found and DisplayedDocument2 pagesLockout Procedure: Image Found and DisplayedvanausabNo ratings yet

- List of Safety Committee MembersDocument1 pageList of Safety Committee MembersNisith SahooNo ratings yet

- Risk Register - 2022-23 SafetyDocument13 pagesRisk Register - 2022-23 SafetyR Sahadeo ReddyNo ratings yet

- WAH - Working On Roofs - 0Document13 pagesWAH - Working On Roofs - 0Rizki DarmawanNo ratings yet

- HIRADocument7 pagesHIRAAkhilesh DubeyNo ratings yet

- Daily TBT Attendance Record 4Document1 pageDaily TBT Attendance Record 4Mobin Thomas AbrahamNo ratings yet

- Appendix-AC, Guide For Working at HeightsDocument23 pagesAppendix-AC, Guide For Working at HeightsApm FoumilNo ratings yet

- Safety and Security Committe Meeting Presentation 12Document32 pagesSafety and Security Committe Meeting Presentation 12R Sahadeo Reddy100% (1)

- Vehicle Hoist Safe Work ProcedureDocument2 pagesVehicle Hoist Safe Work ProcedureWiwinIndahSariEffendiNo ratings yet

- 34.HIRA CompressorDocument2 pages34.HIRA CompressorMMRDACA07 SAFETYNo ratings yet

- Remarks: Organisation Structure Verified Through Safety Manual PG 7. Qualified Employee List Available and AttachedDocument23 pagesRemarks: Organisation Structure Verified Through Safety Manual PG 7. Qualified Employee List Available and AttachedjitsssNo ratings yet

- Daily Safety Report TemplateDocument1 pageDaily Safety Report TemplateMarkNo ratings yet

- JHA For Welding ShopDocument36 pagesJHA For Welding ShopSaboor KhanNo ratings yet

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- 007 - Safety Alert (Fatality +LTIs) PDFDocument2 pages007 - Safety Alert (Fatality +LTIs) PDFkumar kushNo ratings yet

- OHSE Project HIRA - Fencing Work - R 00Document3 pagesOHSE Project HIRA - Fencing Work - R 00Pankaj SinghNo ratings yet

- Jsa - New Hydro TestDocument2 pagesJsa - New Hydro TestDautsons InfratechNo ratings yet

- Boom Lift - Working FromDocument5 pagesBoom Lift - Working Fromwahyu nugrohoNo ratings yet

- 19 - Tata Power PPE Procedure - 01122021Document20 pages19 - Tata Power PPE Procedure - 01122021jacobpm2010No ratings yet

- HSE Observation Status Up To 12.04.2022Document26 pagesHSE Observation Status Up To 12.04.2022pabitra pandaNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Energypac Power Generation LTD.: Daily Safety ChecklistDocument1 pageEnergypac Power Generation LTD.: Daily Safety ChecklistMd. Ashraful IslamaNo ratings yet

- GEN-021 Fact FindingDocument3 pagesGEN-021 Fact Findingacanbasri1980No ratings yet

- OCP For Mock Drill of Onsite Emergency PlanDocument3 pagesOCP For Mock Drill of Onsite Emergency PlanTigor GurningNo ratings yet

- Form Accident ReportDocument4 pagesForm Accident ReportKarthik SNo ratings yet

- Over Head Guards-Are There Broken Welds, Missing: Bolts, or Damaged Areas?Document1 pageOver Head Guards-Are There Broken Welds, Missing: Bolts, or Damaged Areas?Mithlesh SinghNo ratings yet

- KAFD Programmed Abnormal Event Report FormDocument4 pagesKAFD Programmed Abnormal Event Report Formfaisal nadeemNo ratings yet

- Contractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020Document5 pagesContractor's EHSS Evaluation by PMT EHSS PK CLC Project FMO Jan 2020ManPower RecruitingNo ratings yet

- 013 UserGde Flatpack Rectifier Mod PDFDocument12 pages013 UserGde Flatpack Rectifier Mod PDFJairo Alirio Cultid InsuastyNo ratings yet

- Hempadur Mastic 45889: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument9 pagesHempadur Mastic 45889: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingEmre ÖzbilgiNo ratings yet

- Republic of The PhilippinesDocument3 pagesRepublic of The PhilippinesNovie Joy JulianoNo ratings yet

- Understanding Permit to Work SystemsDocument22 pagesUnderstanding Permit to Work SystemsAisha KhanNo ratings yet

- Model Code of Practice Confined SpacesDocument53 pagesModel Code of Practice Confined SpacesShaun MckayNo ratings yet

- Safe Erection, Use and Dismantling of FalseworkDocument4 pagesSafe Erection, Use and Dismantling of FalseworkRm1262No ratings yet

- Patrick Harel: Personal Safety DivisionDocument33 pagesPatrick Harel: Personal Safety DivisionWILFREDO SSOCONSULTORESNo ratings yet

- Environmental Risk Assessment: Abir Goldar Development Studies Discipline Khulna UniversityDocument27 pagesEnvironmental Risk Assessment: Abir Goldar Development Studies Discipline Khulna UniversityNina AzizNo ratings yet

- Ipc7a27 Anpr LPR Camera User ManualDocument123 pagesIpc7a27 Anpr LPR Camera User Manualrafael palmaNo ratings yet

- 3412 eDocument12 pages3412 eBruno Ventura100% (1)

- PED Training Course - 5Document8 pagesPED Training Course - 5RayNo ratings yet

- P3U en M G006 IEC Web PDFDocument426 pagesP3U en M G006 IEC Web PDFКонстантин ГригорьевNo ratings yet

- Grade 2 Health CGDocument10 pagesGrade 2 Health CGAriah TugadoNo ratings yet

- MSDS Silk Cream Conditioner 03.21.12Document4 pagesMSDS Silk Cream Conditioner 03.21.12Pure PawsNo ratings yet

- Belső Audit KérdéslistaDocument10 pagesBelső Audit KérdéslistaMózes BrassóiNo ratings yet

- United States - Detonating - Cord - All - Types - SDS - US - 110718 - FINAL - 1 PDFDocument7 pagesUnited States - Detonating - Cord - All - Types - SDS - US - 110718 - FINAL - 1 PDFAmgalanbaatarJargalsaikhanNo ratings yet

- Deif Parameter ListDocument132 pagesDeif Parameter Listfede_fab2009No ratings yet

- ASHRAE Guidelines and StandardsDocument52 pagesASHRAE Guidelines and StandardsMGPH67% (3)

- Maltose monohydrate MSDSDocument5 pagesMaltose monohydrate MSDSSatria Muliya PutraNo ratings yet

- OSHA Summary 1994 From UTMDocument40 pagesOSHA Summary 1994 From UTMmohdchemustafhaNo ratings yet

- Thesis Co 3-4Document3 pagesThesis Co 3-4Honey Mae LimNo ratings yet

- Tesco PIU Guidelines On The Audit Process For Sites Supplying TescoDocument7 pagesTesco PIU Guidelines On The Audit Process For Sites Supplying TescoGourav TailorNo ratings yet

- Army Corps of Engineers Notice Informing Court and Congress of Intent To Issue Easement For DAPLDocument21 pagesArmy Corps of Engineers Notice Informing Court and Congress of Intent To Issue Easement For DAPLMidwest Alliance for Infrastructure Now - MAINNo ratings yet

- MSDS Solar Panel 4Document9 pagesMSDS Solar Panel 4Basir Abu FaqihNo ratings yet

- Oil Rig Inspection ChecklistDocument17 pagesOil Rig Inspection ChecklistAhmedNo ratings yet

- DRM 512 - Industrial HygieneDocument52 pagesDRM 512 - Industrial HygieneReah CuetoNo ratings yet

- BRC Global Standard For Consumer Products PCH Issue 4Document89 pagesBRC Global Standard For Consumer Products PCH Issue 4DavidHernandez50% (2)

- Boiler Safety 2Document36 pagesBoiler Safety 2AkashNo ratings yet

- Hazard and RiskDocument13 pagesHazard and RiskMarites BalmasNo ratings yet

- TWM TW-BH95M4PHDocument30 pagesTWM TW-BH95M4PHغزوان عماد الدين الحسينيNo ratings yet

- Chemical Risk Assessment Screening Tool of A Globa PDFDocument33 pagesChemical Risk Assessment Screening Tool of A Globa PDFUlviyye ElesgerovaNo ratings yet